The Essential Role of Bronze Wear Plates in Automotive Metal Stamping Dies

Experience the Strength of Self-lubricating Bearings

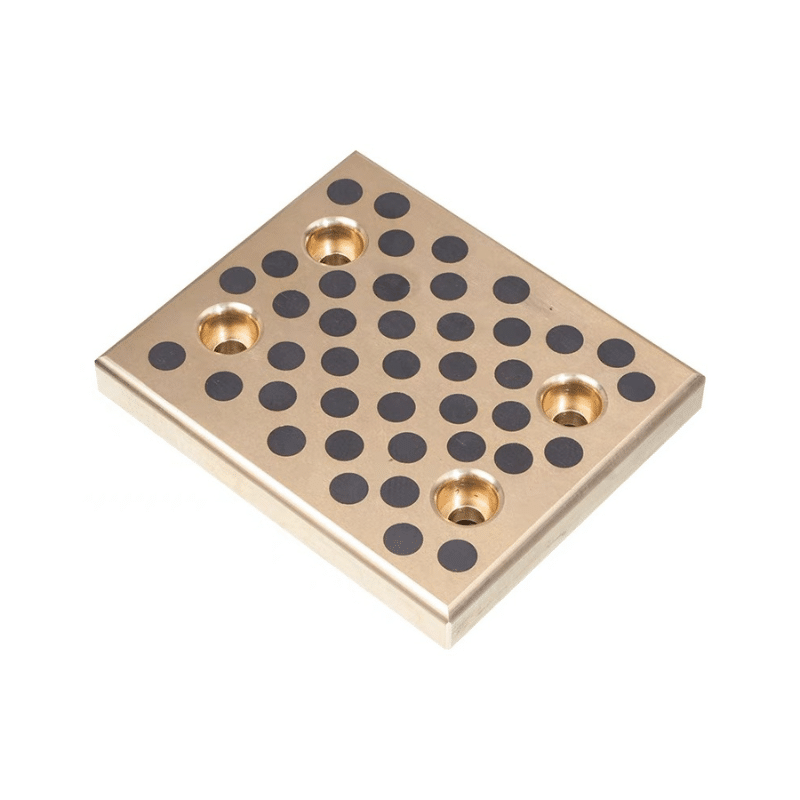

Wear Plates, Wear Plate – Brass Bearing with Embedded Solid

In the high-stress, high-performance realm of automotive manufacturing, ensuring the longevity and efficiency of metal stamping dies is crucial. One of the key components in achieving this is the integration of bronze wear plates. These plates play a pivotal role in reducing downtime, enhancing precision, and extending the life span of stamping tools. Let’s explore why bronze wear plates are indispensable in automotive metal stamping dies and how they contribute to the industry’s demanding needs.

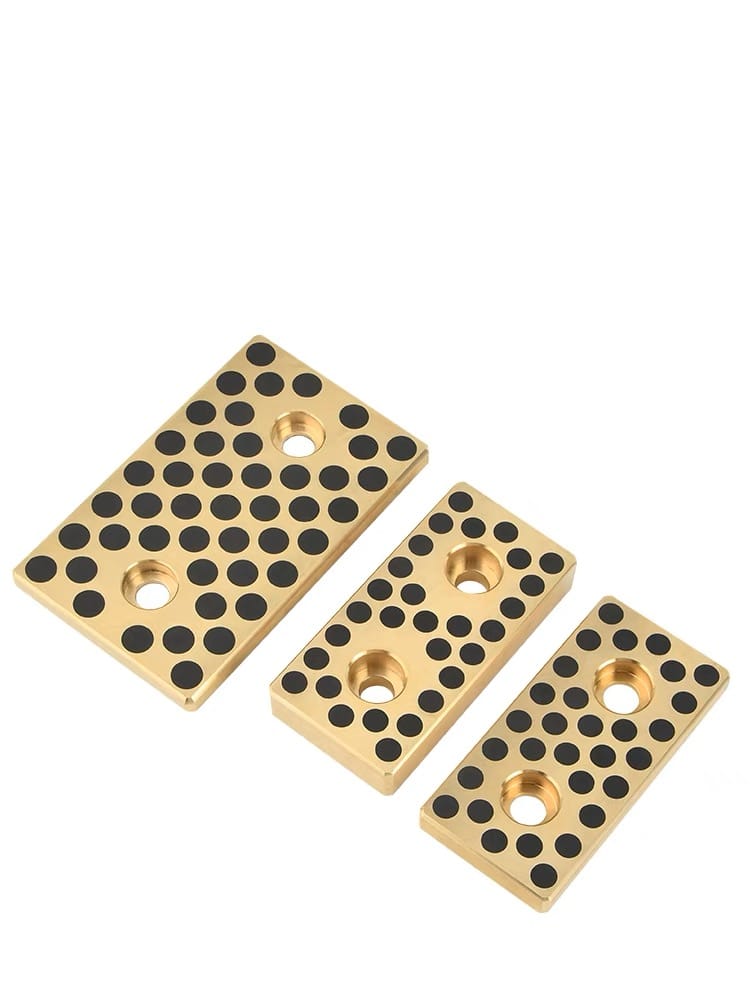

Available in Solid Aluminum Bronze and Brass, these come in a range of standard thicknesses, widths, and lengths. Options include with or without mounting holes, and with graphite plugs, grease grooves, or plain.

Bronze wear plates are a cornerstone in the construction and maintenance of automotive metal stamping dies. Their ability to withstand wear, reduce friction, bear significant loads, and function efficiently without constant lubrication makes them an invaluable asset in the automotive industry. As we look towards a future of more demanding manufacturing processes, the role of bronze wear plates will undoubtedly become even more critical, reinforcing their status as essential components in industrial applications.

Understanding Bronze Wear Plates, Oilless Wear Plate – Graphite Filled Bronze

Bronze Wear Strips with Graphite: These components are crafted from solid aluminum bronze and feature embedded self-lubricating graphite. Available in standard sizes.

Bronze wear plates are crafted from high-strength bronze alloys, renowned for their exceptional wear resistance and durability. These alloys typically include materials such as phosphor bronze or aluminum bronze, which are chosen for their ability to withstand the harsh environments of metal stamping processes. The primary function of these wear plates is to provide a robust, wear-resistant surface that can endure the sliding motion inherent in stamping operations without deteriorating.

In automotive metal stamping, precision and reliability are paramount. Bronze wear plates are used in various parts of stamping dies, including guide and slide components, where their properties help maintain the alignment and accuracy of the stamping process. This precision is essential for producing consistent, high-quality automotive parts that meet strict industry standards.

Wear Strips – Inch Aluminum Bronze, Steel; with Graphite, Grease Grooves or plain! Wear Plates Size Range:

- Thickness: 0.250 – 0.625 inches

- Width: 1.0 – 8.0 inches

- Length: 2.0 – 36 inches

Bronze wear plates are crucial for industrial applications, valued for their excellent wear resistance, low friction, and high load-bearing capacity. These plates are crafted from robust bronze alloys, often enhanced with graphite to provide self-lubrication. For special features or custom hole patterns, please place your order using your job and detail number, and provide a print or CAD model.

Here’s a concise overview:

Types of Bronze Wear Plates:

- Standard Bronze Wear Plates: Made from high-quality bronze alloys for durability and resistance.

- Graphite Impregnated Bronze Plates: These incorporate graphite for improved self-lubrication.

- Aluminum Bronze Wear Plates: Known for their low friction and high wear resistance, typically made from alloys like C95400.

- Brass-Based Wear Plates: Utilize brass alloys, offering the strength of steel with better machinability and less maintenance.

Composition and Properties:

- Aluminum bronze: About 83% copper, with aluminum, iron, and nickel.

- Tin bronze alloys: Renowned for corrosion resistance and low friction.

- Brass alloys: Blend of copper and zinc, known for corrosion resistance and malleability.

- Graphite additions enhance the self-lubricating qualities, crucial for reducing wear in moving parts.

Applications:

Bronze wear plates are employed in diverse sectors such as heavy machinery, automotive manufacturing, industrial equipment, marine industry, aerospace, and more. They are particularly effective in areas requiring high durability and minimal maintenance, aligning well with the needs in automotive metal stamping dies, where precision and tool longevity are paramount.

Advantages:

- Exceptional wear resistance and durability.

- Low friction and self-lubricating in graphite-impregnated variants.

- Excellent corrosion resistance.

- Can handle high loads and temperatures, reducing maintenance needs.

- Versatile in customization of size and shape.

Standard Sizes and Customization:

- Available in various thicknesses and diameters up to 120 inches.

- Customizable in alloy composition, graphite distribution, and specific shapes for tailored applications.

Bronze wear plates combine strength and innovative design to significantly enhance machinery performance and reduce maintenance costs across numerous industries. Their adaptability and robust characteristics make them a top choice for demanding applications, including those in automotive metal stamping, where your expertise could particularly appreciate the nuanced benefits they offer.