Types of Centrifugal Casting for Large-Size Bronze Bearings

Experience the Strength of Self-lubricating Bearings

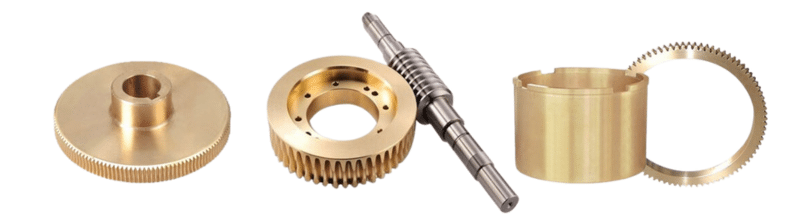

types of centrifugal casting, specialize in the production of various grades of bronze castings, aluminium bronze Bushing centrifugal castings

In the world of high-strength, durable components, bronze bearings stand out for their unparalleled wear resistance and load-carrying capacity. Centrifugal casting—a process that uses rotational force to create these bearings—has become indispensable for producing high-quality, large-size bronze bearings.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

Grades of Bronze in Centrifugal Casting, aluminium bronze centrifugal castings

The centrifugal casting process can handle various grades of bronze alloys, each offering unique properties to suit different applications:

Aluminum Bronze: Known for its high strength, corrosion resistance, and wear resistance.

Phosphor Bronze: Offers excellent fatigue resistance and is commonly used in high-stress environments.

Lead Bronze: Features superior machinability, making it suitable for bearings that require frequent replacements.

Bronze Standards: Bronze Alloys: We provide high-quality tin, lead, and aluminum bronzes, along with high-tensile brasses, delivering maximum performance in even the most demanding sectors. These materials are engineered to meet stringent industry standards and specifications, ensuring durability, corrosion resistance, and optimal mechanical properties. Whether used in marine, oil and gas, or other challenging environments, these bronzes and brasses are crafted to deliver superior quality and reliability. Would you like more details on the properties, applications, or specific standards of these materials?

Centrifugal casting, aluminium bronze Bearing centrifugal castings

Centrifugal casting, in its different forms, has paved the way for producing large-size bronze bearings with exceptional quality. By leveraging the appropriate method for the task, manufacturers can deliver consistent, defect-free bronze components that meet the rigorous demands of today’s industries. Whether it’s horizontal, vertical, or centrifuge casting, each type has its specific strengths, making it essential to choose the right method to achieve optimal results.

Types of Centrifugal Casting

- Horizontal Centrifugal Casting

This method involves rotating the mold horizontally. Molten metal is poured into one end while it spins at high speed. The centrifugal force distributes the metal evenly, forming a cylindrical shape ideal for making pipes, bushings, and large-size bronze bearings.- Advantages:

- Consistent and uniform wall thickness

- Minimal shrinkage and porosity

- Cost-effective for medium to large batches

- Applications:

- Bronze bearings in large industrial machinery

- Bushings for heavy-duty equipment

- Advantages:

- Vertical Centrifugal Casting

Here, the mold is positioned vertically, with the molten metal poured into the center. Gravity and rotational force work together to distribute the material.- Advantages:

- Allows for a broader range of shapes

- Suitable for thicker-walled castings

- Less equipment footprint compared to horizontal casting

- Applications:

- Bearings with varying wall thicknesses

- Complex-shaped bronze components

- Advantages:

- Centrifuge Casting

Unlike the other methods, centrifuge casting uses a rotating mechanism that spins multiple molds simultaneously around a central axis. This setup is beneficial when producing many smaller castings concurrently.- Advantages:

- High production speed

- Uniform quality across batches

- Reduced waste due to multiple molds

- Applications:

- High-volume production of smaller bronze bearings

- Standard-sized bronze components for various industries

- Advantages:

Centrifugal casting is a manufacturing process where molten metal is poured into a mold that is then rotated at high speed. This rotation creates a centrifugal force that helps to distribute the molten metal evenly within the mold, resulting in a denser and more uniform casting. The process is particularly useful for creating cylindrical or hollow shapes with a high degree of precision and surface finish.

Here are some common types of centrifugal casting and the specialized products that can be produced using this technique:

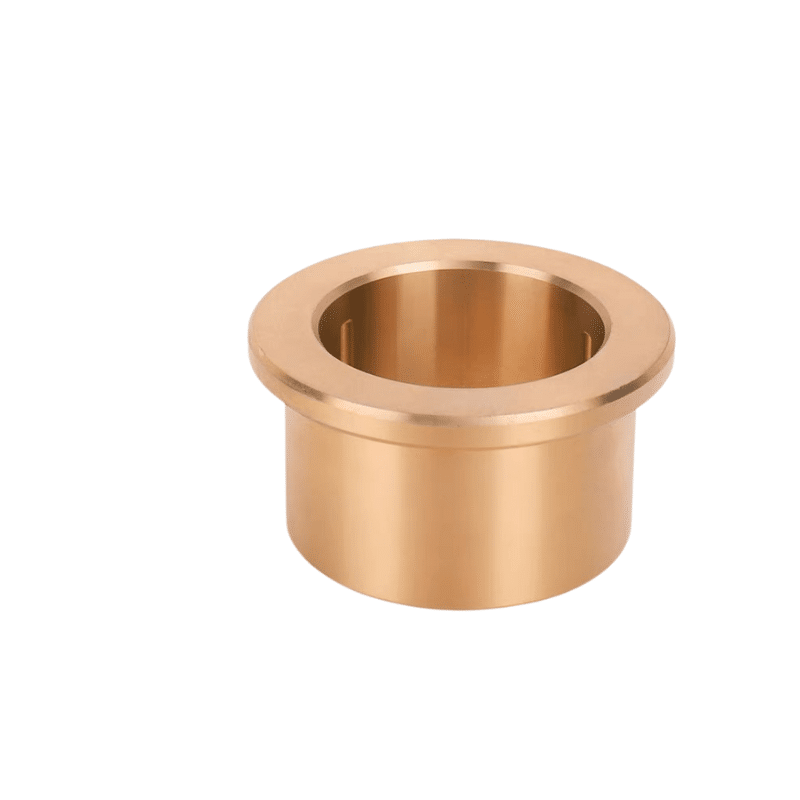

- Copper Sets: These are sets of components made from copper, which is often used for its excellent thermal and electrical conductivity. Copper sets might include items like bushings, bearings, or electrical contacts.

- Bearing Slide: Bearings are essential components in machinery that reduce friction between moving parts. A bearing slide could refer to a part of a bearing assembly that allows for smooth, linear motion.

- Gasket: Gaskets are used to seal joints between two parts to prevent leakage of fluids or gases. Centrifugal casting can produce gaskets with precise tolerances and a smooth finish.

- Side Flange: A flange is a flat, rim-like projection used to strengthen or connect components. A side flange is a specific type of flange that is positioned on the side of a cylindrical object.

- Product Display Strip: This could refer to a cast component used in retail settings to display products, such as a strip for hanging items or a stand for showcasing goods.

- Partial Flange: Similar to a side flange but may not encompass the entire circumference of the object it is attached to.

- Ordinary Slider: This might be a simple sliding component used in mechanical assemblies, where it allows for linear motion along a fixed path.

- Featured Products: This category could include any of the above or other products that are highlighted for their quality or uniqueness.

- Turbine Worm: A worm is a type of gear used in a worm gear system, which is often found in applications like turbines where high torque is required.

- Middle Flange: This is a flange located in the middle of a structure, often used to connect or strengthen sections.

- Bush: A bush is a plain bearing, which is a simple bearing that uses friction to allow movement. Bushings are often made from materials like bronze or copper, which can be cast using centrifugal casting.

Centrifugal casting is a versatile process that can produce a wide range of products with complex geometries and high levels of precision. The items listed above are just a few examples of the types of castings that can be made using this method.

Understanding the Types of Centrifugal Cast Bronze

The categorization of bronze based on casting methods plays a crucial role in metallurgy and manufacturing. Let’s delve deeper into the specific types of centrifugal cast bronze:

Continuous Cast Bronze:

In this method, molten bronze is poured into a continuous casting machine, which solidifies the molten metal into a continuous billet or slab. This method is renowned for its efficiency, producing long material lengths with consistent cross-sections and a high production rate.

Centrifugal Cast Bronze:

This process can be classified into two main categories based on the mold material:

1. Sand-Centrifugal Cast Bronze:

This method utilizes a sand mold crafted to the desired shape. The mold spins rapidly in a centrifuge, which uses centrifugal force to compact the sand and shape the molten bronze according to the mold’s design. This technique is ideal for casting complex shapes that might otherwise be challenging to achieve through traditional methods.

2. Metal-Centrifugal Cast Bronze:

In this technique, molten bronze is poured into a high-speed spinning metal mold. The metal mold ensures a smoother finish and more precise dimensions compared to sand molds, making it suitable for high-volume production of intricately detailed parts.

Advantages of Centrifugal Casting:

Both sand-cast and metal-cast centrifugal casting leverage the power of centrifugal force to enhance casting quality:

- Improved Density & Reduced Porosity:

The force compacts the molten bronze, minimizing porosity and enhancing density. - Uniform Metal Distribution:

Centrifugal force ensures the molten bronze is evenly spread throughout the mold. - Fewer Defects:

The spinning motion helps eliminate impurities and gases, reducing defects in the final product.

Why Bronze Suits Centrifugal Casting:

Bronze’s excellent fluidity while molten allows it to fill intricate mold details effectively. Its relatively low melting point compared to other metals means it can be cast using less energy, which reduces costs and environmental impact. Furthermore, centrifugal casting takes advantage of bronze’s fluid characteristics to achieve high-quality, precisely detailed products.

Understanding the nuances of these casting methods helps manufacturers choose the right process for their specific needs, ensuring efficiency, quality, and cost-effectiveness in bronze production.

Here’s a more detailed description of cast bronze bearing materials, including their standards and technical data:

- CuAl10Fe2: An aluminum bronze alloy containing 10% aluminum and 2% iron. It is known for its high strength, corrosion resistance, and wear resistance, making it ideal for bearings and other high-load applications.

- CuSn11P: A phosphor bronze alloy containing 11% tin and phosphorus. It’s known for excellent corrosion resistance, strength, and machinability, making it ideal for precision bearings.

- CuSn7Zn4Pb7: A leaded bronze alloy with 7% tin, 4% zinc, and 7% lead. Its self-lubricating properties, machinability, and resistance to wear make it useful for bearings and bushings.

- CuZn33Pb: A leaded brass alloy with 33% zinc and lead. It has good machinability, moderate corrosion resistance, and high ductility, suitable for bearings and other applications.

- CuAl10Fe: An aluminum bronze with 10% aluminum and iron for increased strength and corrosion resistance. It’s used in heavy-duty applications like bearings and gears.

- UE12: A European bronze alloy standard with specific properties for use in high-load bearings and applications.

- CuAl10Ni3Fe2: An aluminum bronze containing 10% aluminum, 3% nickel, and 2% iron. This composition enhances its mechanical properties and corrosion resistance, especially in seawater applications.

- CuSn11Pb2: A tin bronze alloy with 11% tin and 2% lead. It’s known for excellent wear resistance and is used in heavy-duty bearing applications.

- CuSn10Pb10: A leaded tin bronze alloy with 10% tin and 10% lead, providing excellent machinability, corrosion resistance, and self-lubricating properties.

- CuZn37Pb: A brass alloy with 37% zinc and lead content for good machinability and moderate corrosion resistance.

- CuAl10Ni: An aluminum bronze alloy containing 10% aluminum and nickel, known for strength and corrosion resistance in harsh environments.

- B555: A standard for bronze alloys, providing guidelines for specific mechanical and chemical properties.

- CuAl10Fe5Ni5: A high-strength nickel-aluminum bronze alloy with 10% aluminum, 5% iron, and 5% nickel. It excels in wear resistance and corrosion resistance.

- CuSn12: A tin bronze with 12% tin, providing high strength, corrosion resistance, and good wear resistance.

- CuZn25Al5Mn4Fe3: A manganese-aluminum brass alloy with zinc, providing high strength and wear resistance for bearings.

- CuZn25Al5: An aluminum brass alloy with zinc for enhanced corrosion resistance and moderate strength.

- CuAl11Ni: An aluminum bronze alloy with 11% aluminum and nickel, offering high corrosion resistance and mechanical properties.

- RG7: A leaded tin bronze alloy known for excellent sliding properties and machinability, suitable for bearings and bushings.

- CuAl11Fe6Ni6: An aluminum bronze alloy with 11% aluminum, 6% iron, and 6% nickel, ideal for high-stress bearing applications due to its wear resistance.

- CuSn12Ni2: A tin bronze alloy with 12% tin and 2% nickel, providing high strength, corrosion resistance, and good machinability.

- CuZn34Mn3Al2Fe1: A high-strength brass alloy containing manganese, aluminum, and iron for improved mechanical properties.

- CuZn34Al2: An aluminum brass alloy containing zinc and aluminum, offering moderate corrosion resistance and machinability.

- CuSn5ZnPb: A tin-zinc-lead bronze alloy providing excellent sliding and machinability properties.

- B1010: A standard alloy specification guiding the production and testing of specific bronze bearings.

- CuSn10: A tin bronze alloy containing 10% tin for high corrosion resistance and good wear properties.

- CuSn5Zn5Pb5: A leaded tin-zinc bronze alloy, with excellent machinability and wear resistance.

- CuZn32Al2Mn2F31: A manganese-aluminum brass with high strength and resistance to wear.

- CuZn35Al1: An aluminum brass alloy with zinc and aluminum, providing good corrosion resistance and moderate strength.

- CuSn7ZnPb: A tin-zinc-lead bronze alloy for bearings and bushings.

- C95800: An aluminum bronze alloy with excellent resistance to cavitation and corrosion, particularly in marine environments.

- B101: A standard specification defining properties for bronze bearing materials.

- BS1400 AB2: A British Standard for aluminum bronze alloys, specifying requirements for corrosion resistance and mechanical properties.

- C52400: A phosphor bronze alloy with good machinability, strength, and corrosion resistance.

- C91700: A high-strength bronze alloy with good machinability and corrosion resistance.

- C83600: A leaded red brass, widely used in various industrial applications for its machinability and corrosion resistance.

- C93200: A leaded tin bronze alloy with good strength, wear resistance, and machinability.

- C90500: A tin bronze alloy with high strength and corrosion resistance, often used in marine environments.

- C86300: A manganese bronze alloy known for excellent strength and resistance to wear.

- C86200: A high-strength manganese bronze alloy, suitable for high-stress bearing applications.

- CC495K: A European standard for leaded bronze alloys, offering guidelines for specific bearing applications.

- CC762S: A European standard for phosphor bronze alloys, providing specific mechanical and chemical properties.

- CC480K: A leaded brass standard offering high machinability and good wear resistance.

- CC333G: An aluminum bronze standard providing guidelines for high-strength applications.

- CC332G: A phosphor bronze standard with excellent wear resistance and corrosion properties.

- CC764S: A leaded tin bronze standard ensuring good machinability and strength for bearings.

- CC493K: A leaded bronze standard offering high wear resistance and machinability.

- CC483K: A leaded bronze standard for specific bearing applications.

- CC481K: A European standard for phosphor bronze, guiding the production of precision bearing components.