provides tin bronzes that meet international standards.

About us

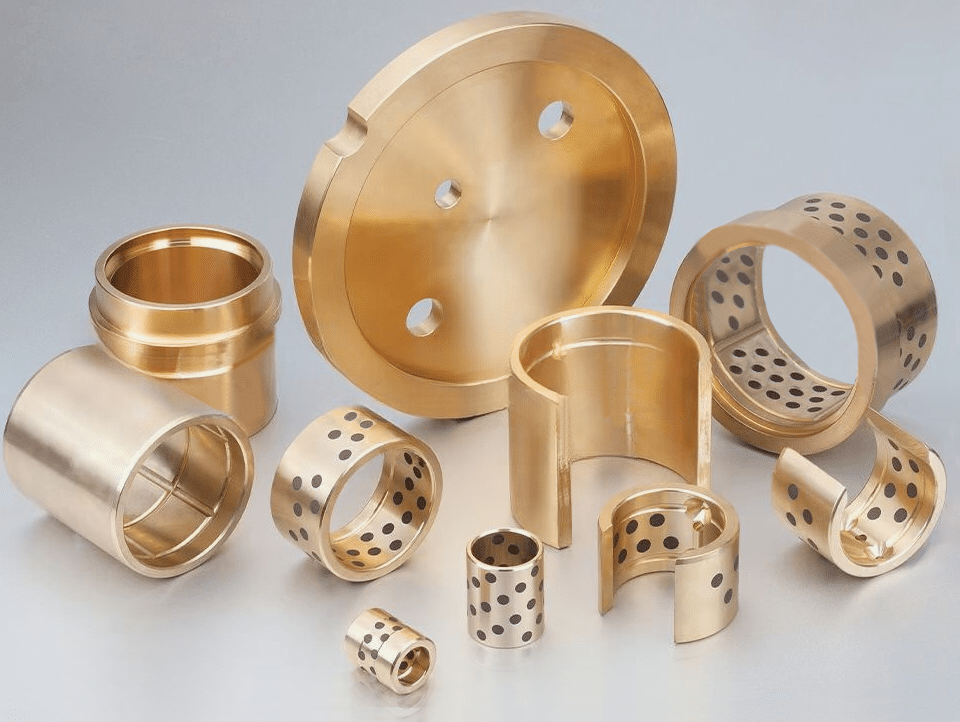

Custom-Made Tin Bronzes Bearings and Bushes

Tin bronzes, also called red bronzes or leaded gunmetal, are highly sought for their hardness, machinability, and resistance. Engineered for Excellence!

Boost your machinery’s efficiency with our high-strength tin bronze bearings. Ideal for demanding environments. Shop now for superior wear resistance!

C93200 graphite plugged bronze bushings represent a reliable solution for the hydro industry, combining excellent mechanical properties with self-lubricating features. Their ability to perform under high loads and harsh conditions makes them indispensable for ensuring the efficiency and longevity of hydropower systems. As the demand for renewable energy sources continues to grow, the role of high-quality components like C93200 bushings will remain essential in optimizing hydropower operations.

Tin Bronze Bearings

C93200 Graphite Plugged Bronze Bushings in the Hydro Industry. C93200 bronze bushings, specifically those that are graphite plugged, are highly valued in the hydroelectric industry for their durability and self-lubricating properties. These bushings are designed to withstand the demanding conditions typical of hydropower applications, such as high loads and constant exposure to water.

premium Tin Bronze Bearings Available!

C93200 bronze bushings, specifically those that are graphite plugged, are highly valued in the hydroelectric industry for their durability and self-lubricating properties. These bushings are designed to withstand the demanding conditions typical of hydropower applications, such as high loads and constant exposure to water.

Bronze Alloys

Design Custom Bearings, Custom Parts Manufacturing. Download Our Plain Bearing Brochure

Tin bronze is a copper alloy that contains tin and is highly popular in industrial applications due to its excellent hardness, machinability, and wear resistance. These properties make tin bronze an ideal material for manufacturing bearing parts and bushings that play a critical role in mechanical systems.

Need durable bearings? Our tin bronze options offer superior hardness and machinability. Click here to explore products that meet international standards.

Characteristics of tin bronzes: Discover Tin Bronze Bearings

Enhance Mechanical Performance!

Our Tin Bronzes Bearings Are Designed For High Load And High Wear Applications. Perfect For Automotive And Aerospace. Order Today For Reliable Solutions!

- Hardness: Tin bronze is harder than pure copper, allowing it to withstand greater mechanical loads.

- Machinability: It can be easily shaped through casting, forging, and machining, making it suitable for manufacturing various shaped components.

- Wear resistance: The wear resistance of tin bronze makes it an ideal choice for producing sliding bearings and other components that require friction reduction.

- Corrosion resistance: Tin bronze has good resistance to many chemicals, maintaining performance even in harsh environments.

- Thermal conductivity: The good thermal conductivity of copper is also present in tin bronze, aiding in the thermal stability of components.

Long-Lasting Tin Bronze Bearings

Improve Your Equipment’s Lifespan, Tin Bronzes Applications

Choose Our Corrosion-Resistant Tin Bronze Bearings For Marine And Industrial Use. Exceptional Quality, Ready To Ship. Click For Details!

- Mechanical engineering: Used to manufacture bearings, gears, and liners.

- Marine engineering: Often used in ship and marine platform components due to its corrosion resistance.

- Aerospace: In the aerospace industry, tin bronze is used to manufacture parts that require high strength and wear resistance.

- Automotive industry: Used in manufacturing components for car engines and transmissions.

Design Custom Tin Bronzes Parts & International Standards: Search Our Material Alloy

Tin Bronzes, Oversized Bronze Bearings- Alloy Selection

Tin Bronze Alloys are known for their excellent resistance to corrosion and exceptional wear ability. The bronze alloys CuSn5Zn5Pb5, CuSn6, CuSn7Pb6Zn4, CuSn8, CuSn10, and CuSn12 are widely utilized in bearing applications due to their exceptional mechanical properties and resistance to wear and corrosion. These bronze alloys are chosen based on their specific mechanical properties tailored to the demands of various industrial applications. Their combination of strength, corrosion resistance, and wear characteristics make them suitable for critical components in machinery across multiple sectors.

CuSn5Zn5Pb5 (RG5) Bronze Bearing

Composition: Contains approximately 83-87% copper, 4-6% tin, 4-6% lead, and up to 6% zinc.

Key Features:

High load-carrying capacity.

Good corrosion resistance.

Applications: Commonly used in machinery components where durability and performance are critical, such as in automotive and industrial machinery.

CuSn6 Bronze Bearing

Composition: Comprises about 94% copper and 6% tin.

Key Features:

Good electrical conductivity and wear resistance.

High corrosion resistance, particularly in marine environments.

Excellent cold deformation capabilities.

Applications: Utilized in electrical and mechanical industries for parts like connectors, pins, springs, and components requiring high mechanical strength.

CuSn7Pb6Zn4 Bronze Bearing

Composition: Contains around 90% copper, 7% tin, 6% lead, and 4% zinc.

Key Features:

Half-hard bronze known for good workability.

Suitable for applications with moderate speeds and pressures.

Applications: Frequently used in friction parts such as bearings, gears, and bushings in automotive and shipbuilding industries.

CuSn8 Bronze Bearing

Composition: Approximately 92% copper with about 8% tin.

Key Features:

High load capacity due to its hardness.

Excellent wear resistance and low friction properties.

Applications: Ideal for high-load applications including bushings and bearings in industrial machinery where durability is essential.

CuSn10 Bronze Bearing

Composition: Composed of around 88-90% copper and 10-12% tin.

Key Features:

High strength and hardness due to elevated tin content.

Superior wear resistance and self-lubricating properties.

Applications: Used extensively in bearings, bushings, pumps, valves, and gears that operate under high friction conditions.

Design Custom Tin bronzes Parts & International standards:

Choose Our Corrosion-Resistant Tin Bronze Bearings For Marine And Industrial Use. Exceptional Quality, Ready To Ship. Click For Details! Manufacturing tin bronze parts often follows international standards to ensure product quality and performance, which may include:

- ISO (International Organization for Standardization)

- ASTM (American Society for Testing and Materials)

- DIN (German Institute for Standardization)

- JIS (Japanese Industrial Standards)