PTFE-Lined Stainless Steel Bushings – Self-Lubricating & Durable

Experience the Strength of Self-lubricating Bearings

PTFE composite plain bush, Metal/polymer composite plain bush, maintenance-free, ISO 3547, with Stainless Steel backing

Stainless steel bushes, particularly those with PTFE (polytetrafluoroethylene) composite and steel backing, are engineered components used in various industrial applications due to their unique properties. Stainless steel bushes with PTFE (polytetrafluoroethylene) composite and steel backing are precisely engineered for a range of industrial applications due to their exceptional characteristics. Upgrade your equipment with high-performance stainless steel PTFE-lined bushings. Superior durability, corrosion resistance, and self-lubricating properties ensure seamless operation.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

Plain bearing stainless steel bushes / composite material

Material: Filler Added PTFE Layer, Sintered Bronze Layer. Steel-backed Metal Layer Tin Plating!

PTFE composite plain bearings are indeed an excellent choice for applications that demand a combination of strength, low friction, and self-lubrication.

Maintenance-Free: PTFE composite bearings require minimal or no maintenance, which is a significant advantage in environments where regular maintenance is difficult or costly.

Frictional Properties: The low friction coefficient of PTFE makes these bearings ideal for reducing energy consumption and wear, which can lead to longer service life and improved efficiency.

High Load Capacity: The steel backing ensures that these bearings can handle heavy loads, making them suitable for a wide range of industrial applications.

Temperature Resistance: The ability to operate in temperatures up to 250 degrees Celsius makes PTFE composite bearings suitable for high-temperature applications where other materials might degrade or fail.

Self-Lubricating stainless steel Bushings:

Composite product consisting of three layers: steel-backed metal layer, sintered bronze layer and filler added PTFE layer.

Self-Lubricating: The PTFE-based layer provides self-lubrication, which is crucial in applications where traditional lubricants cannot be used or where the environment is hostile to lubrication.

Corrosion Protection: Tin-plating the steel backing adds an extra layer of protection against corrosion, which is important for the longevity and reliability of the bearings in harsh environments.

Heavy Load Applications: The combination of high load capacity and self-lubrication makes these bearings particularly well-suited for heavy load/medium speed applications where traditional bearings might fail prematurely.

Environmentally Friendly: The use of a lead-free sliding layer is important for meeting environmental regulations and avoiding the use of toxic materials.

Dry Sliding Bearings: PTFE composite bearings are designed to operate effectively even in the absence of a lubricating fluid, which can be an advantage in applications where lubrication is not feasible or where the presence of a lubricant could be problematic.

Self-Lubricating PTFE Bushings – Stainless Steel Backed

Optimize machinery with composite stainless steel PTFE-lined bushings. Plain, durable, and maintenance-free for smooth, reliable operation in corrosive or high-temp conditions.

Stainless Steel Bushes: These cylindrical bearings or bushings are crafted from stainless steel for its corrosion resistance, strength, and ability to endure challenging operating conditions.

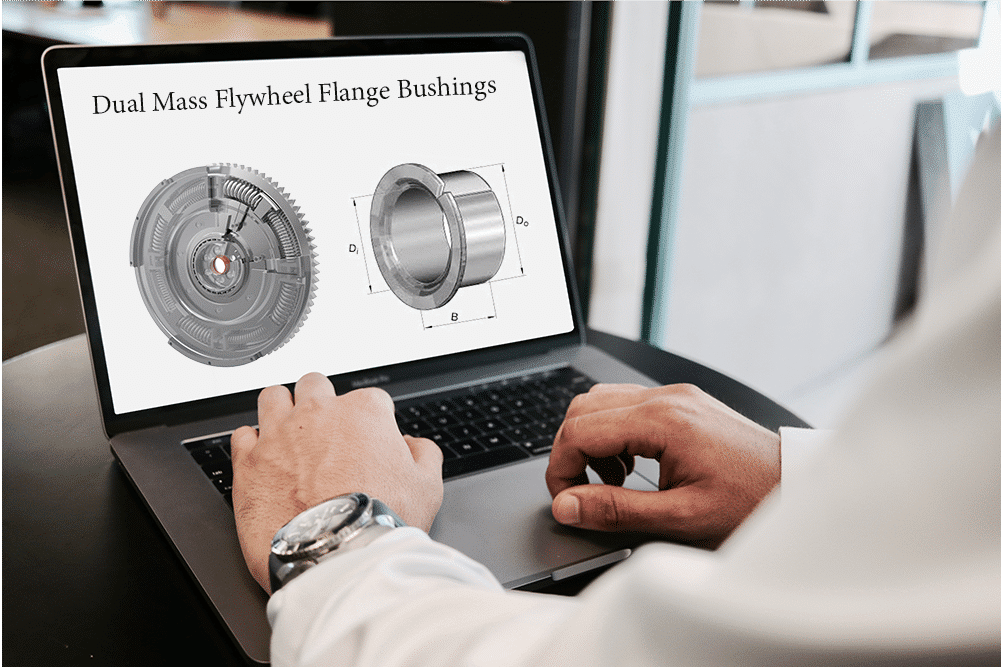

Plain Bushes: Simple, solid cylindrical bearings without internal features like grooves or flanges. They reduce friction between moving parts and offer a straightforward, low-friction solution.

PTFE Composite: PTFE is a low-friction, chemically resistant plastic. It’s self-lubricating and can function in environments where lubrication is limited or unavailable. PTFE composites often blend PTFE with bronze or carbon fibers for enhanced mechanical performance.

Steel Backing: Steel backing reinforces the PTFE composite, providing extra strength and allowing the bushing to handle high loads while maintaining shape under pressure, ideal for heavy-duty applications.

Valve Sleeve Bearing: In valve systems, these bearings ensure smooth valve stem movement within the valve body, facilitating efficient operation and minimizing wear.

Precision in manufacturing is crucial for optimal fit and performance. The combination of stainless steel with PTFE composite and steel backing makes these bushes ideal for corrosive or high-temperature environments, as well as low-maintenance, long-lasting applications.

If you have questions about selecting or using these components in your specific setup, I’m here to help!

Explore Other Plain Beairng

Suggested Searches: Straight, Flange, Steel, Bronze