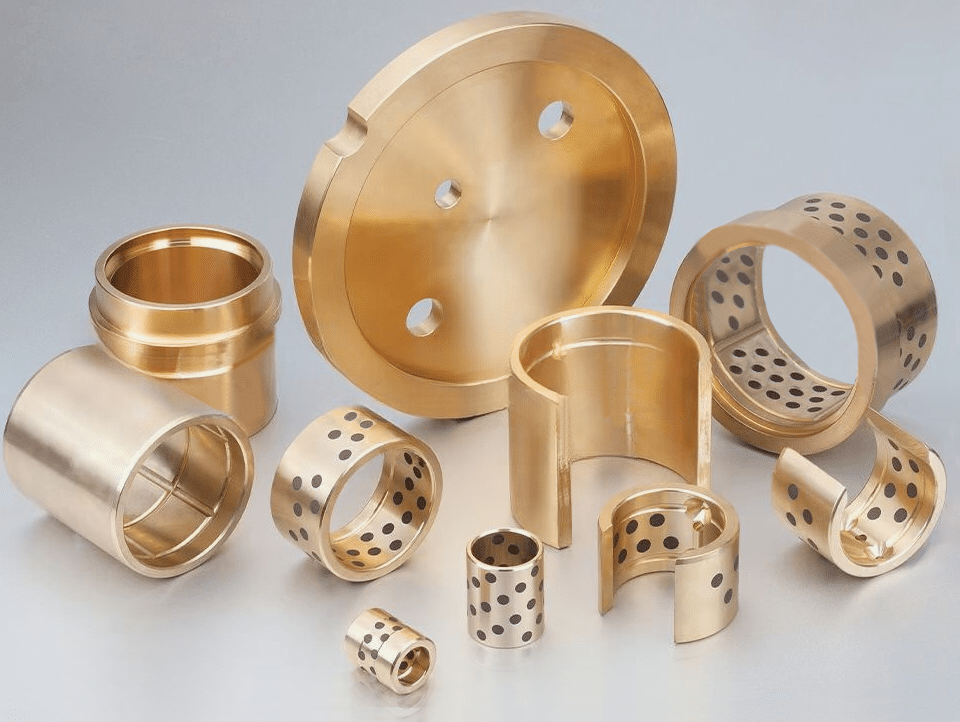

Specialized Bronze Alloys, High-Performance Bronze Bearings

About us

Custom-Made Specialized Bronze Alloys, Customized Bronze Alloys for Moulds & Valves

We provide a selection of specially formulated bronzes, ideal for use in applications including molds for glass or embossing, marine bearing bushings, and components for valves and terminals. Upgrade to High-Performance Bronze Bearings, Discover durability with our specialized bronze alloys. Perfect for heavy-load applications! Enhance machinery efficiency with custom bronze bearings. Get a quote now!

Type Of Bearing

Special bronze alloys for moulds, and valve components.

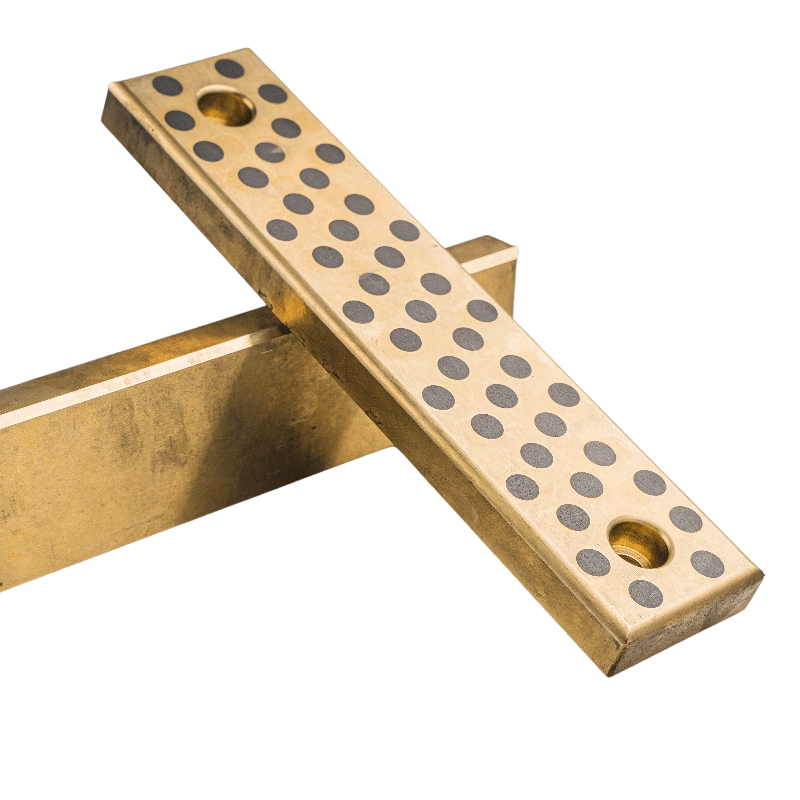

Bronze Alloys for Valve Components, Specialist in machined bronze and self-lubricating bronze based on clients’ drawings. Specialized Bronze Plates,Advanced Bronze Plates for Industrial Use. Need superior strength & corrosion resistance? Check out our bronze plates! Tailored solutions for your industrial needs. Contact us for custom bronze plates today!

Bronze bearing alloys are primarily composed of copper (Cu) and tin (Sn), with additional elements such as lead (Pb), zinc (Zn), nickel (Ni), or iron (Fe) sometimes added to enhance specific properties. These alloys are widely used in the manufacture of sliding bearings due to their excellent wear resistance, friction reduction, high fatigue strength, and good thermal conductivity.

Self Lubricating Custom parts, Customized Bronze Standards

We produce copper-based alloys in accordance with any international standard. Feel free to contact us.

Standards Include: ASTM, BS, EN1982, DIN, JIS, AS, ISO

Our bronzes and high tensile brasses are manufactured to meet stringent international standards and are available in both inch size and metric size. Explore some of our most popular bronzes and high tensile brasses as frequently requested by our clients.

Premium Bronze Plates: Premium Quality Bronze Plates Available: Experience the best in class with our high-tensile bronze plates. Ideal for challenging environments! From seawater to high temperatures, our plates withstand it all. Get your quote now! Custom Bronze Alloy Solutions, Custom Bronze Alloys for Bearings & Plates. Customize your bronze alloy mix to suit your specific industrial applications. Get the perfect balance of strength and durability. Request a consultation today!

Custom Plain Bearing, Optimize with ASTM, Alloys according to EN 1982 Standard

ASTM B505 is a standard established by ASTM International, detailing the requirements for continuous castings of copper-based alloys. These castings are commonly used in the manufacture of various bearings and mechanical components. Alloy C95400, an aluminum bronze, is one of the alloys that meets the ASTM B505 standard and is favored for its high strength, wear resistance, and excellent mechanical properties.

EN 1982 is a European standard that encompasses cast ingots and castings of copper and copper alloys. This standard specifies the composition, mechanical properties, and other relevant characteristics of copper and copper alloys, along with the sampling procedures and testing methods used to verify these characteristics.

bronze alloys under ASTM B505 standard: C95400 Aluminum Bronze: This is a high-strength, highly wear-resistant aluminum bronze alloy frequently used in the manufacturing of bearings, bushings, and gears. It conforms to the ASTM B505/B505M-2018 standard.

Bronze scope under the EN 1982 European standard: EN 1982:2017: This standard encompasses the requirements for cast ingots and castings of copper and copper alloys, including composition, mechanical properties, and related characteristics. It applies to copper alloy ingots intended for remelting and processing (such as for castings) and to copper and copper alloy castings that are ready for use without further processing.

Custom Parts Services and Prototyping!

Special Bronze Alloys And Aluminium Bronze Bearing, Search Our Material Alloy

We manufacture copper-based alloys that meet any international standard, including ASTM-compliant bronzes and special bronze alloys according to the EN 1982 standard.

We manufacture a comprehensive selection of continuous and centrifugal cast bronzes, adhering to the European standard EN 1982. Durable Bronze Bearings for Machinery, Optimize your heavy machinery with our strong & resilient bronze bearings. Increase load capacity and reduce maintenance. Learn more about our alloys! Get the perfect alloy mix for your specific application requirements. Exceptional strength and corrosion resistance. Contact us to discuss your needs!

ASTM B505 continuous casting

-

C83600: This is a leaded tin bronze alloy, equivalent to Bronze Alloy CC491K (CuSn5ZnPb5-C), known for its good casting properties and resistance to deformation under load.

-

C84400: Another leaded tin bronze, equivalent to Bronze Alloy CC490K (CuSn3Zn8Pb5-C), which offers good strength and wear resistance.

-

C86200: This is a high tensile brass, equivalent to Bronze Alloy CC764S (CuZn34Mn3Al2Fe1-C), designed for applications requiring high strength and resistance to wear.

-

C86300: Another high tensile brass, equivalent to Bronze Alloy CC762S (CuZn25Al5Mn4Fe3-C), which is known for its excellent mechanical properties and resistance to wear.

-

C90300: This is a tin bronze alloy, but the table does not provide a specific Bronze Alloy equivalent.

-

C90700: Equivalent to Bronze Alloy CC483K (CuSn12-C), this is a high-tin bronze with good corrosion resistance and mechanical properties.

-

C92200: This category is listed as tin bronzes, but no specific alloy or equivalent is provided.

-

C92700: Equivalent to Bronze Alloy CC480K (CuSn10-C), this is a tin bronze with good casting properties and strength.

-

C93200: Equivalent to Bronze Alloy CC493K (CuSn7Zn4Pb7-C), this is a leaded tin bronze with good mechanical properties and corrosion resistance.

-

C93600: No specific alloy or equivalent is provided in the table.

-

C93700: Equivalent to Bronze Alloy CC495K (CuSn10Pb10-C), this is a leaded tin bronze known for its good self-lubricating properties and machinability.

-

C93800: Equivalent to Bronze Alloy CC496K (CuSn7Pb15-C), this is a lead bronze with excellent machinability and good self-lubricating properties.

-

C93900: Listed as a lead bronze, but no specific alloy or equivalent is provided.

-

C94100: Equivalent to BronzeAlloy CC497K (CuSn5Pb20-C), this is a leaded bronze with high lead content for improved self-lubrication.

-

C95200: Equivalent to Bronze Alloy CC331G (CuAl10Fe2-C), this is an aluminum bronze with good resistance to corrosion and high-temperature strength.

-

C95400: Listed as an aluminum bronze, but no specific alloy or equivalent is provided.

-

C95500: Equivalent to Bronze Alloy CC333G (CuAl10Fe5Ni5-C), this is a high-strength aluminum bronze with additional nickel for improved properties.

-

C95520: No specific alloy or equivalent is provided in the table.

-

C95800: Listed as an aluminum bronze, but no specific alloy or equivalent is provided.

-

C95900: No specific alloy or equivalent is provided in the table.

These alloys are used in a variety of applications, including bearings, bushings, gears, valves, and other components where high strength, wear resistance, and corrosion resistance are required. The specific alloy chosen will depend on the particular needs of the application, such as the operating environment, load requirements, and desired performance characteristics.

ASTM B271 centrifugal casting standards, STM B271 designations along with the closest Bronze Alloy equivalents and a brief description of the type of alloy.

-

C83600: Leaded tin bronze alloy.

-

C84400: Equivalent to bronzeAlloy CC490K (CuSn3Zn8Pb5-C), this is a tin bronze alloy known for its good mechanical properties and corrosion resistance.

-

C86200: Equivalent to bronze Alloy CC764S (CuZn34Mn3Al2Fe1-C), this is a high tensile brass alloy with enhanced strength and wear resistance.

-

C90300: No specific alloy or equivalent is provided in the table.

-

C93200: Equivalent to bronze Alloy CC493K (CuSn7ZnPb7), this is a leaded tin bronze with good mechanical properties and self-lubricating characteristics.

-

C93600: Listed as a lead bronze, but no specific alloy or equivalent is provided.

-

C93700: Equivalent to Bronze Alloy CC495K (CuSn10Pb10-C), this is a leaded tin bronze alloy known for its excellent machinability and self-lubricating properties.

-

C93800: Equivalent to Bronze Alloy CC496K (CuSn7Pb15-C), this is a lead bronze with a high lead content for improved self-lubrication and wear resistance.

-

C95200: Equivalent to Bronze Alloy CC331G (CuAl10Fe2-C), this is an aluminum bronze with good resistance to corrosion and high-temperature strength.

-

C95400: No specific alloy or equivalent is provided in the table.

-

C95500: Equivalent to Bronze Alloy CC333G (CuAl10Fe5Ni5-C), this is a high-strength aluminum bronze with added nickel for improved properties.

-

C95800: No specific alloy or equivalent is provided in the table.

-

C95900: No specific alloy or equivalent is provided in the table.

The alloys listed under ASTM B271 are typically used in the manufacture of sand-cast bearings and other components that require good wear resistance, mechanical strength, and in some cases, self-lubricating properties. The choice of alloy will depend on the specific requirements of the application, such as the operating conditions, load-bearing requirements, and desired performance characteristics.

Bronze Alloys according to ASTM B22

-

C86300: This is categorized as a high tensile brass. High tensile brasses are known for their excellent mechanical properties, making them suitable for applications where high strength and durability are required. However, the table does not provide a specific closest alloy equivalent.

-

C90500: This is listed under the type of alloy as Aluminium Bronzes. Aluminium bronzes are valued for their high strength, good corrosion resistance, and resistance to dezincification. They are often used in marine and industrial applications. Again, no specific alloy equivalent is provided.

-

C91100: This is categorized as Tin Bronzes. Tin bronzes, which are alloys of copper and tin, are known for their high corrosion resistance and good casting properties. They are often used in marine hardware, bells, and artistic castings. The table does not specify a closest alloy.

-

C93700: This is categorized as Lead Bronzes. Lead bronzes are alloys that include lead for improved machinability and lubricity. They are often used in bearings and other applications where a self-lubricating surface is beneficial. The table does not provide a specific alloy equivalent for this designation.

We produce a wide array of continuous and centrifugal cast bronzes in compliance with the European standard EN 1982.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services