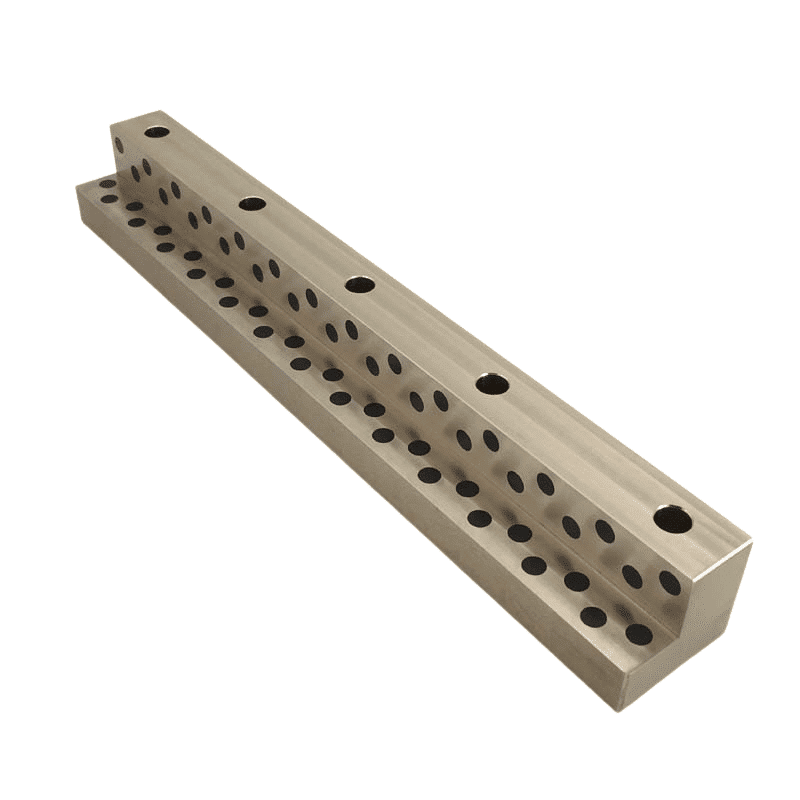

Solar Power Bushing

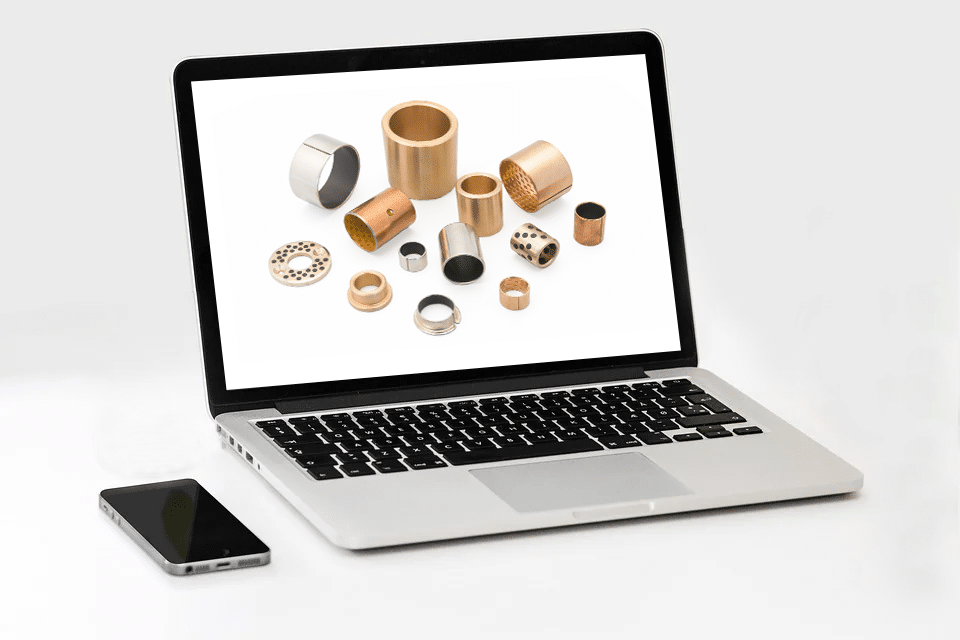

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Solar Power Bushing

BronzeLube’s Premium Bronze Bushings: Powering the Future of Industries

In today’s industrial landscape, machinery’s efficiency and durability are paramount, especially in power generation plants where the tiniest glitch can result in monumental disruptions. Enter BronzeLube’s premium Bronze Bushings – not just any bushing, but a solution molded from years of expertise and top-tier manufacturing processes. Wind & Solar Projects – Plain Bearing Projects, Maintenance-Free Bearings, Special custom solutions, Solar Power Bushing, Extremely flexible.

Metal Bushing Increase Service Life And Reduce Costs By 40%.

Precision Bearings For Solar Energy,Engineer Live.

BronzeLube’s Premium Bronze Bushings: Powering the Future of Industries

In today’s industrial landscape, machinery’s efficiency and durability are paramount, especially in power generation plants where the tiniest glitch can result in monumental disruptions. Enter BronzeLube’s premium Bronze Bushings – not just any bushing, but a solution molded from years of expertise and top-tier manufacturing processes.

Why Choose BronzeLube’s Bronze Bushings?

1. Made in China – A Guarantee of Quality

While some might be wary of products made in China, BronzeLube stands as a testament to the nation’s ever-evolving manufacturing prowess. Our bronze bushings are not just ‘Made in China’ – they represent the pinnacle of QualityMade Manufacturing, ensuring that you get only the best for your industry needs.

2. Customized Solutions for Diverse Needs

No two power generation plants or industrial setups are the same. Understanding this, BronzeLube offers custom bushings tailored to just about any size. Whether you need a specific diameter, thickness, or even a unique design, we’ve got you covered.

3. Quick Quotes and Short Lead Times

Time is of the essence in the industrial world. With BronzeLube, you won’t have to wait endlessly. Our quick quote system ensures you get an estimate in no time, and our manufacturing process guarantees short lead times, ensuring your operations remain uninterrupted.

4. More than Just Bushings – A Comprehensive Catalog

Beyond our celebrated bronze bushings, we manufacture Bronze Bushing Idler Sprockets, Pulleys, and more. Dive into our online catalog to explore a world of top-quality products that cater to a broad spectrum of industrial needs.

5. Graphite Bushings & Bearings – The Next-Gen Solution

If you’ve faced bushing problems, our graphite bushings and bearings might just be the solution you’re looking for. Offering superior performance, they can replace ball bearings in hundreds of applications, ensuring smoother operations and longevity.

6. Comprehensive Services: From Design to Support

At BronzeLube, we don’t just sell products; we offer solutions. Our services range from custom design to engineering support, ensuring that you not only get the best products but also the knowledge and assistance to use them effectively.

Ideal for a Multitude of Industries

Our self-lubricating bronze bearings are perfect for various industrial areas, including:

- Power Generation & Distribution

- Oil & Gas

- Locomotive Parts

- Water Potabilization and Distribution

… and many more!

Conclusion

When it comes to ensuring the smooth and efficient operation of machinery, especially in critical sectors like power generation, settling for anything less than the best isn’t an option. With BronzeLube’s premium bronze bushings, you get quality, durability, and a partner committed to your industry’s success.

Explore our range, request a quote, and let us empower your industrial operations with unmatched excellence.

For more information or to view our extensive product catalog, visit BronzeLube’s official website. Together, let’s usher in a new era of industrial efficiency.

A Maintenance-Free Revolution in Solar Power with BronzeLube Bearings

The future is solar, and as industries pivot towards cleaner energy solutions, the demand for efficient and long-lasting equipment has never been higher. Solar power plants, though a beacon of sustainable energy, are not immune to the challenges posed by nature. Enter BronzeLube’s self-lubricating bearings – the game-changer in solar technology.

Why Choose BronzeLube’s Self-Lubricating Bearings for Solar Power Plants?

1. Designed for Extreme Conditions

Solar power plants are not only exposed to intense ultraviolet rays but also have to endure the harshness of high temperatures, sand wear, dust, and the corrosive effects of some environments. Our bearings, meticulously designed, can withstand these challenges, ensuring uninterrupted power generation.

2. Precision at Its Best

With the efficiency of solar power plants being paramount, our plain bearing technology guarantees high-precision operation. This ensures that solar power plants around the world achieve their peak efficiency, harnessing the sun’s power to its fullest potential.

3. The Magic of the Solar Tracker

The efficiency of a photovoltaic power station heavily relies on solar cells, which need to continuously align with the sun. The heart of this alignment system, the solar tracker, is crucial. BronzeLube recognizes this importance and has designed a self-lubricating bearing assembly that always remains in optimal condition. This not only saves on maintenance time but also prevents costly malfunctions and downtime.

4. A Leap in Tribological Technology

By harnessing the principles of tribology, we’ve enhanced the structural design of our oil-free plain bearing products. The result? A bearing system crafted from self-lubricating composite material designed explicitly for solar trackers, ensuring unparalleled system performance.

BronzeLube – Redefining Solar Equipment Efficiency

-

Extremely Long Service Life: Our bearings are not just designed for the present but the future. Their longevity ensures that solar power plants can operate with minimal interruptions.

-

Lightweight and Maintenance-Free: Say goodbye to regular maintenance checks. Our bearings, while being lightweight, are designed to be completely maintenance-free, reducing operational hassles.

-

Quiet, Vibration-Free Operation: Solar power plants need to operate smoothly, and our bearings guarantee just that with their quiet and vibration-free operation.

Conclusion

BronzeLube isn’t just a product provider; we’re a partner in the journey towards a cleaner, more sustainable future. As the complete tribological service provider, we promise not just products but solutions that stand the test of time and nature.

Harness the power of the sun with BronzeLube’s self-lubricating bearings – the future of efficient solar power.

For more insights or to explore our range of products tailored for the solar industry, visit BronzeLube’s official website. Let’s illuminate the world together, sustainably.

Self-lubricating and maintenance-free bearings used in solar technology

Solar is one of the cleanest forms of energy production in the world. In addition to saving your wallet, you can help save the environment!

The material properties of the self-lubricating bearing system are superior, resisting ultraviolet radiation while also withstanding wear caused by dust and sand grains, without the need for any other external lubricant or regular maintenance. In addition, self-lubricating bearing products comply with the strict RoHS specifications.

Low friction, high wear resistance bushing

Because of the low friction coefficient, so no lubrication, at the same time smooth operation, reduce wear, prolong service life.

Free maintenance bushing

Suitable for applications that require long service life and do not require regular maintenance, or for lightly lubricated, non-lubricated operating conditions.

Lower system cost plain bearing

Self-lubricating bearings do not need to harden and process lubricating oil paths, thus reducing overall system costs. Plain bearings bushing uses a compact integrated structure to reduce the space and weight of the system and simplify the assembly process.

Environmental protection

Plain bearings require no lubricating oil, contain no lead, and comply with increasingly stringent environmental regulations, such as the RoHS directive, which restricts the use of hazardous substances in certain types of electrical and electronic equipment.

We are your tribological partner, committed to developing tribological solutions that drive industrial progress, not limited to any shape or material. For more information about sliding bearings, please contact us for an in-depth understanding.

Solar Power

High radiation power and no pollution

Photovoltaic power generation

Reliable and durable materials can better ensure the service life of components, reduce the amount of waste caused by early failure of components, and have environmental friendliness

Composition of the photovoltaic system

In general, photovoltaic systems and components include solar tracking systems and their tracker bearing assemblies.These tracking systems are able to follow the sun throughout the day to generate maximum power.The key component that makes these systems move is the solar tracker bearing.These applications require materials with low friction and the ability to maintain toughness and other characteristics over a long period of time in all weather conditions.

Benefits:

- UV-resistant, self-lubricating and maintenance-free

- Quiet operation without any torque fluctuations

- Extremely low coefficients of friction due to tribo-optimized plastics

- Suitable for confined installation spaces and where there isn’t much room for movement

- Dirt and dust resistant

- Long service life

- Low cost

- More than ten years of experience in the solar power bushings

Application of bearings in photovoltaic energy

We are well aware of the material requirements for photovoltaic systems and components, and contribute bearings and solutions with low friction, low wear, maintenance free, weather resistance and other characteristics to photovoltaic systems, contributing to sustainable development.

The MN527 high-performance polymer bearing is developed and produced using a special material optimized for UV performance for photovoltaic applications. This material is ideal for PV tracker bearing applications due to its UV resistance, excellent impact strength, UV resistance linearity and thermal stability.

And MN527 has a specific low wear, low friction properties, conducive to the smooth operation of the bearing, do not need to grease or maintenance as often as metal bearings.It also has better endurance than metal bearings, which gives the tracker better calibration in the field of application.

- High strength and rigidity

- Low wear

- Low friction ductility and toughness

- Extremely low moisture absorption

- Dimensional stability

Photovoltaic (solar) power generation system is often applied in a more direct natural environment, need to better adapt to various environmental (weather) conditions, so the reasonable use and maintenance of bearings is very important. Engineered plastic bearings developed and produced by Viiplus can adapt to the harshest outdoor environments under high loads. They do not require lubrication, helping the system to extend its service life. Viiplus has always been committed to providing a variety of self-lubricating bearings and their solutions for all industries.

- No grease or maintenance is required

- The tracer has better endurance and correction

- It is suitable for bearing applications with high strength

- Low friction and smooth operation

Flexible Delivery, Self-lubricating plain bearings made of metal used in the solar industry!

Targeted energy insights that sharpen your solar power bushing strategy.

Specialized in researching and developing, manufacturing, selling solar power bushing products. Withstand all weather conditions: plain bearings defy dirt and extreme temperatures. Self-lubricating and wear-resistant. In the hot summer, intense uv rays are not only a nightmare for outdoor workers, but also pose a severe challenge to facilities that are exposed to extreme outdoor conditions for a long time. The operation cost of many industries is high, and the requirements for the component materials of self-lubricating bearings are extremely high. Even in the face of harsh environment, the perfect operation of the equipment must be ensured. In the solar power industry, for example, the components inside the equipment are exposed to the sun almost all the time, and any failure during that time can cause incalculable losses. How to extend the service life of the product while maintaining high stability? How to reduce the negative effects of ultraviolet light on components? For harsh working conditions, we export self-lubricating composite bearing solutions, which can accurately strike various problems and easily meet challenges.

www.bronzelube.com

Plain Bearing solutions across energy sectors, all in one place. Cost-effective special solution.

We supply plain bushing for power plant, transmission, gas, and renewables projects. and self-lubricating bushing solutions. Find new opportunities. Save your cost. Metal sleeve bushing products particularly suitable in the solar industry! Change your bearings now to plain bushing! Reduce maintenance by 100%, weight by 80%,Cost by 40% while increasing the service life! Extremely low coefficients of friction thanks to self-lubricating bearing material.

Customized: Sliding bearing & plate made of composite bushing material

Tested and with guarantee: Self-lubricating bearing

Solar Power Bushing Solution

We are committed to offering quality solar power bushings solution. Multiple bearing types of Products, including ground solar racking system, roof solar racking, carport solar mount, floating solar system, etc. Featured with strong structure strength, good stalbility and high corrosion resistance, solar power bushings have good performance in quality.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.