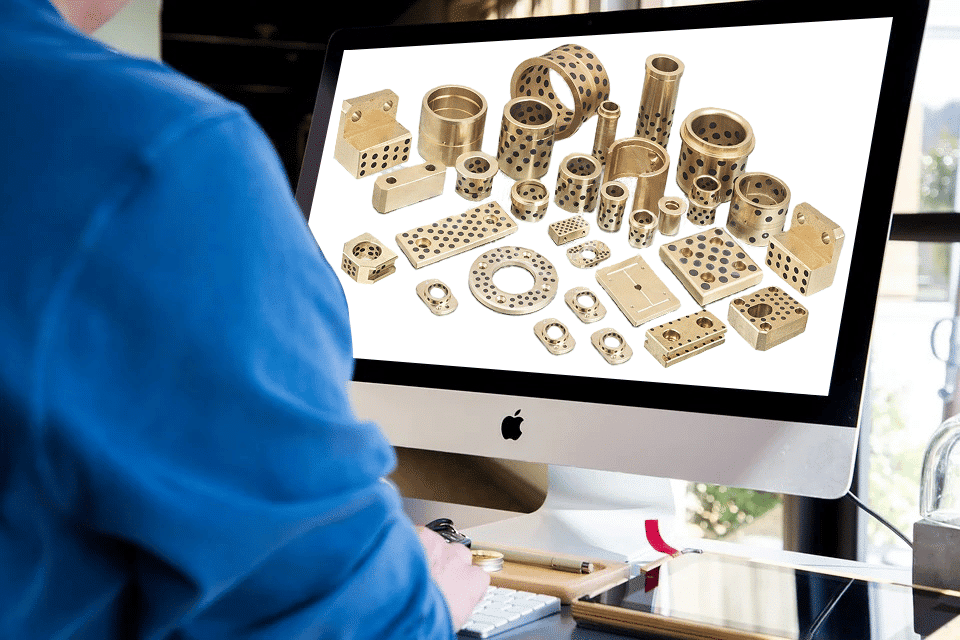

Almost all the self-lubricating bushings & bearings are available.

One-stop sliding bearing solutions provider

Sliding bearings are the counterpart to the widely known and widely used bearings. Movement applications using bearings can be found in every industry: slow and fast applications, light and heavy applications, abrasive and clean applications. Every industry has its own preference for a bearing type and every application in turn has its preference for specific variants, for example sleeve bearings or sliding bearings, such as composite sliding bearings or bronze sliding bearings.

about the company

Design engineering of Slide bushing

Design and engineering of bushing applications to support new concepts of machines and/or upgrade machines. Learn more! Inquire now . Distribution and production of machined bushings, plain bearing components and engineered bearing bushings. A wide range of self-lubricating plain bearing materials for our products gives you more options! For the full range of industry high quality sliding bearings and bushings solutions that cater to your needs.

Product Quality Index

Energy Generation

Quality Sliding Bushing Supplier & Manufacture in China, Contact Now!

Online customized sliding bushings. Are you seeking to find a sliding bushing solutions? Contact us, to learn how we can support you. High Quality Sliding Bushings with Competitive Price. Plain bearings are a reliable, cost-efficient solution for applications with multi-directional. Sliding bearings: a complete range for all your needs! Custom-Made Bearings – Sliding Bearings & Bushings! Bushes Manufacturer – Tech Standard & Special Parts, Technical Metal Bushing Parts. Standards & special bearing slide bushing parts for var applications. We Manufacture Our Products Using Quality And Environment Standards. View Catalogues.

Sliding Bushing & Bearings, Factory Price Online sales

We have a large selection of plain and flanged bearings for various applications. With more than 2,000 dimensions in our warehouse and with the co-operation of skilled subcontractors, we are one of the most reliable suppliers available. With us you can order your sliding bearings products according to your own drawings and specifications or you can choose from our large and wide standard selection. In addition, our short lead times and good logistics makes us an efficient and reliable partner. Will Exceed Your Expectations Of A Supplier, Hence Our Customers See Bronzelube.com More As A Partner.

Proven accredited Quality to trust

“Bushing Services: Find your sliding material and bushing type selection guides.”

We manufacturing sliding bearing bushing tailored to your individual needs.

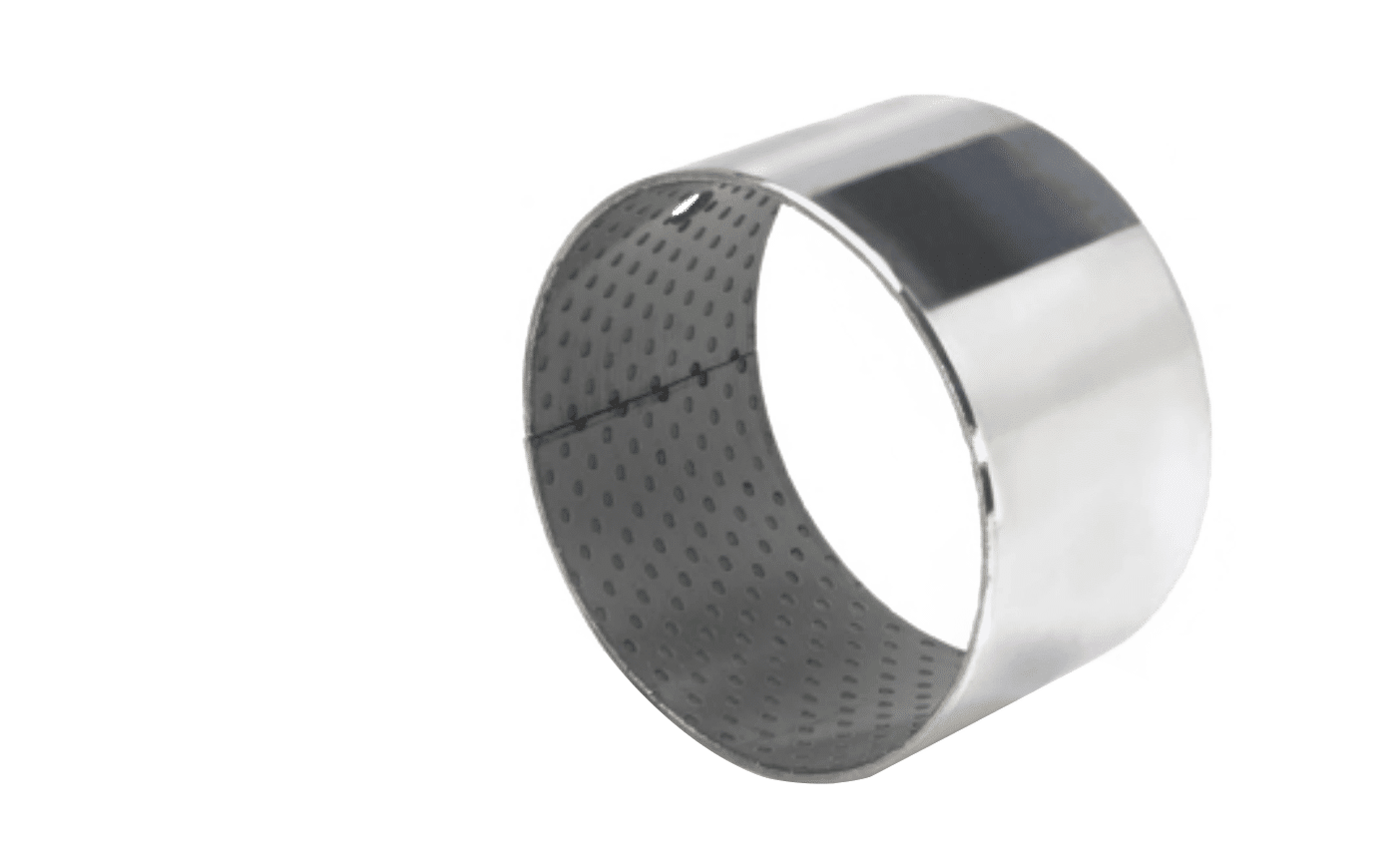

Self-lubricating shaft sleeve

self-lubricating shaft sleeves are a type of shaft sleeve that have become increasingly popular in recent years due to their unique properties and advantages. Unlike traditional shaft sleeves, which require external lubrication, self-lubricating sleeves have built-in lubrication that eliminates the need for additional lubrication during operation.

Self-lubricating shaft sleeves are typically made of a composite material that incorporates lubricants, such as graphite or PTFE, into the sleeve. The lubricants are evenly distributed throughout the material, ensuring a continuous supply of lubrication to the shaft during operation. This results in reduced friction and wear between the shaft and the sleeve, recognized to longer lifespan and improved efficiency of the system.

One of the most significant advantages of self-lubricating shaft sleeves is their ability to operate in environments where traditional lubrication methods are not practical. For example, in applications where the shaft is exposed to corrosive or abrasive fluids, such as seawater or chemicals, external lubrication can quickly break down or become contaminated. Self-lubricating shaft sleeves eliminate this problem by providing a constant supply of lubrication from within the sleeve itself, ensuring smooth operation and reducing the risk of damage.

Another advantage of self-lubricating shaft sleeves is their ability to reduce maintenance and downtime. Traditional shaft sleeves require regular lubrication and inspection to ensure proper operation, which can be time-consuming and costly. Self-lubricating sleeves, on the other hand, require little to no maintenance once installed, reducing the overall cost of operation and increasing the uptime of the system.

When selecting a self-lubricating shaft sleeve, it is essential to consider the specific requirements of the application. Different types of lubricants and composite materials are available, each with its own unique properties and advantages. For example, graphite-based sleeves are excellent for high-temperature applications, while PTFE-based sleeves offer superior chemical resistance.

Self-lubricating shaft sleeves offer several advantages over traditional shaft sleeves, including reduced maintenance, improved efficiency, and the ability to operate in harsh environments. With the right selection of materials and proper installation, self-lubricating sleeves can provide long-lasting protection and reliable operation for a wide range of mechanical systems.

Types of bearing bushings

Bushings, also known as bearings, are mechanical components that are designed to provide low-friction support and guidance for rotating or sliding shafts. There are many different types of bushings available, each designed to meet specific performance requirements for a variety of applications. In this article, we will discuss the most common types of bushings, their applications, and the key factors to consider when choosing the right type of bushing for your needs.

Plain Bearings: Plain bearings are the most basic type of bushing and are commonly used in applications where low-friction support and guidance are required. These bearings consist of a simple sleeve or journal that is placed around the shaft and provides support by reducing friction and wear.

Ball Bearings: Ball bearings are used in high-speed applications where low-friction support and guidance are required. These bearings consist of a series of balls that are placed between the shaft and the bushing, providing support and guidance while reducing friction and wear.

Roller Bearings: Roller bearings are used in applications where high loads and high speeds are present. These bearings consist of a series of rollers that are placed between the shaft and the bushing, providing support and guidance while reducing friction and wear.

Tapered Roller Bearings: Tapered roller bearings are used in applications where high axial and radial loads are present. These bearings consist of a series of tapered rollers that are placed between the shaft and the bushing, providing support and guidance while reducing friction and wear.

Spherical Roller Bearings: Spherical roller bearings are used in applications where high radial loads and misalignment are present. These bearings consist of a series of spherical rollers that are placed between the shaft and the bushing, providing support and guidance while reducing friction and wear.

Needle Roller Bearings: Needle roller bearings are used in applications where high radial loads and limited space are present. These bearings consist of a series of needle rollers that are placed between the shaft and the bushing, providing support and guidance while reducing friction and wear.

When choosing a type of bushing, it is important to consider several key factors, including the type of application, the loads that the bushing will be exposed to, the speed at which the shaft will be rotating, and the space available for the bushing. By considering these factors, you can ensure that you choose the right type of bushing for your needs, ensuring that your mechanical system performs as expected and lasts for years to come.

In conclusion, bushings are critical components in many mechanical systems and are used to provide low-friction support and guidance for rotating or sliding shafts. There are many different types of bushings available, each designed to meet specific performance requirements for a variety of applications. Consider the type of application, the loads that the bushing will be exposed to, the speed at which the shaft will be rotating, and the space available for the bushing when choosing the right type of bushing for your needs.

Sliding bearing bushing supplier

Sliding bearing bushings, also known as plain bearings, are mechanical components that provide low-friction support and guidance for rotating or sliding shafts. They are commonly used in applications where low-friction and wear resistance are critical requirements. In this article, we will discuss the basic principles of sliding bearing bushings, their applications, and the key factors to consider when choosing the right sliding bearing bushing for your needs.

Sliding bearing bushings are typically made from a range of materials, including bronze, plastic, and composite materials, and they work by reducing friction and wear between the shaft and the bushing. The shaft and the bushing are separated by a thin film of lubricant, which helps to reduce friction and wear. In some applications, self-lubricating materials, such as PTFE, can be used to reduce maintenance and improve reliability.

Sliding bearing bushings are used in a wide range of applications, including machinery, automotive, and aerospace. They are particularly useful in high-speed applications where low-friction support and guidance are critical, and in applications where high radial and axial loads are present.

When choosing a sliding bearing bushing, it is important to consider several key factors, including the type of application, the loads that the bushing will be exposed to, the speed at which the shaft will be rotating, and the space available for the bushing. Additionally, it is important to consider the environmental conditions that the bushing will be exposed to, such as temperature, moisture, and contamination, as these can affect the performance of the bushing over time.

In conclusion, sliding bearing bushings are an essential component in many mechanical systems and are used to provide low-friction support and guidance for rotating or sliding shafts. They are commonly used in applications where low-friction and wear resistance are critical requirements, and they are available in a range of materials and designs to meet specific performance requirements. Consider the type of application, the loads that the bushing will be exposed to, the speed at which the shaft will be rotating, and the space available for the bushing when choosing the right sliding bearing bushing for your needs.

Sliding bearings bushing manufacturer

Sliding bearings, also known as plain bearings, are mechanical components that provide low-friction support and guidance for rotating or sliding shafts. They play a critical role in many industrial and consumer products, from automobiles and aircraft to machinery and consumer electronics. In this article, we will discuss the importance of choosing a high-quality sliding bearing manufacturer, the factors to consider when selecting a manufacturer, and the benefits of working with a reputable manufacturer.

The quality of sliding bearings can have a significant impact on the performance and reliability of the products in which they are used. High-quality sliding bearings are essential for ensuring low-friction and wear-resistant support, reducing maintenance costs, and extending the life of the products in which they are used. Choosing a reputable and experienced sliding bearing manufacturer can help ensure that you receive high-quality products that meet your specific requirements.

When selecting a sliding bearing manufacturer, it is important to consider several key factors, including the manufacturer’s experience, product quality, and reputation. You should also consider the manufacturer’s ability to produce sliding bearings to your specific requirements, the availability of custom designs and materials, and the manufacturer’s technical support and after-sales service. Additionally, it is important to consider the manufacturer’s production capacity and lead times, as well as the cost of the products.

Working with a reputable and experienced sliding bearing manufacturer can provide many benefits, including access to high-quality products, custom designs and materials, and technical support. A reputable manufacturer will also have the experience and expertise to help you choose the right sliding bearing for your specific requirements and will provide the necessary support to help ensure that the products are installed and used correctly.

In conclusion, sliding bearings play a critical role in many industrial and consumer products, and choosing a high-quality manufacturer is essential for ensuring low-friction and wear-resistant support and extending the life of the products in which they are used. Consider the manufacturer’s experience, product quality, and reputation, as well as their ability to produce sliding bearings to your specific requirements and provide technical support when selecting a sliding bearing manufacturer. Working with a reputable and experienced manufacturer can provide many benefits, including access to high-quality products, custom designs, and technical support.

Sliding shaft bushing

A sliding shaft bushing is a type of mechanical component that is used to support and guide a rotating or sliding shaft. It is typically made of a low-friction material, such as bronze or brass, and is designed to be a close fit around the shaft.

One of the primary functions of a sliding shaft bushing is to reduce friction between the shaft and the housing, improving the efficiency and lifespan of the system. By providing a low-friction surface for the shaft to slide against, the bushing helps to reduce wear and heat generated by friction, which can cause premature failure of the system.

Another function of a sliding shaft bushing is to provide a smooth, accurate guiding surface for the shaft. This is particularly important in applications where precise movement is required, such as in machine tools or robotics. By maintaining a tight fit around the shaft, the bushing helps to prevent any lateral movement or play, ensuring accurate and smooth operation.

Sliding shaft bushings are available in a variety of sizes and materials to suit different applications. Bronze and brass bushings are commonly used in low-load applications where moderate wear resistance is required. For higher loads and increased wear resistance, materials such as graphite or PTFE (polytetrafluoroethylene) can be used. These materials have excellent self-lubricating properties, which reduce the need for external lubrication and maintenance.

When selecting a sliding shaft bushing, it is important to consider the specific requirements of the application, including load, speed, and environmental conditions. Proper installation and maintenance are also essential to ensure the optimal performance and lifespan of the bushing.

Sliding shaft bushings are a critical component in many mechanical systems, providing support, guidance, and reduced friction between rotating or sliding shafts and their housing. With the right selection of materials and proper installation and maintenance, sliding shaft bushings can provide long-lasting protection and reliable operation for a wide range of applications.

We offer a large selection of graphite copper sleeve and flange bushing.

MAINTENANCE Self-lubricating flange bushing, highly durable, and reliable bushing supplier with or without graphite plugged. Learn more!

CUSTOM-MADE STANDARD PRODUCTS

Learn More

Your Partner for sliding bearing technology

Sliding bearings are placed between shafts and housing to reduce friction, wear and to facilitate rotary and/or translation motions. Sliding bearings are made with high properties materials (bronze, lead, graphite, iron, PTFE, …) and can be used dry or with grease. Drives for every application!

“Your sliding bearing expert – Graphite plugged bronze bushings ”

Feel Free To Contact Us For Further Informations And Broze Graphite Bushings Drawings. Wide Range Of High Quality Bronze Bushings Entirely Supplied By China Sliding Bearings Factories. Our company has a sound engineering know-how, mainly serving the marine and offshore, mining and energy sectors, as well as many other industries such as injection molding, steel mills, agriculture, construction, etc. We offer different types of plain bearings and bushing materials, and we are able to provide you with a one-stop solution to your bearing problems.

WE DELIVER SLIDING BUSHING BEARINGS WORLDWIDE

Type of self-lubricated Bushing, Made in china

Offers an extensive range of Standard Sliding Bushings Bearings to fulfill your needs!

Slide bearing, Maintenance, Customizing the sliding bushings material. Our Products Made Of Engineering Self-lubricating Bearing, Metals And Oilless Bronze Parts. Slide bearings are especially suitable for large loads and sliding speeds.Thanks to their geometrical shape and lubricant film, they withstand impact-type force, suppress vibration and are quiet. The bearings come in any shape and size to facilitate installation and maintenance. With the correct lubrication, slide bearings almost non-wearing.

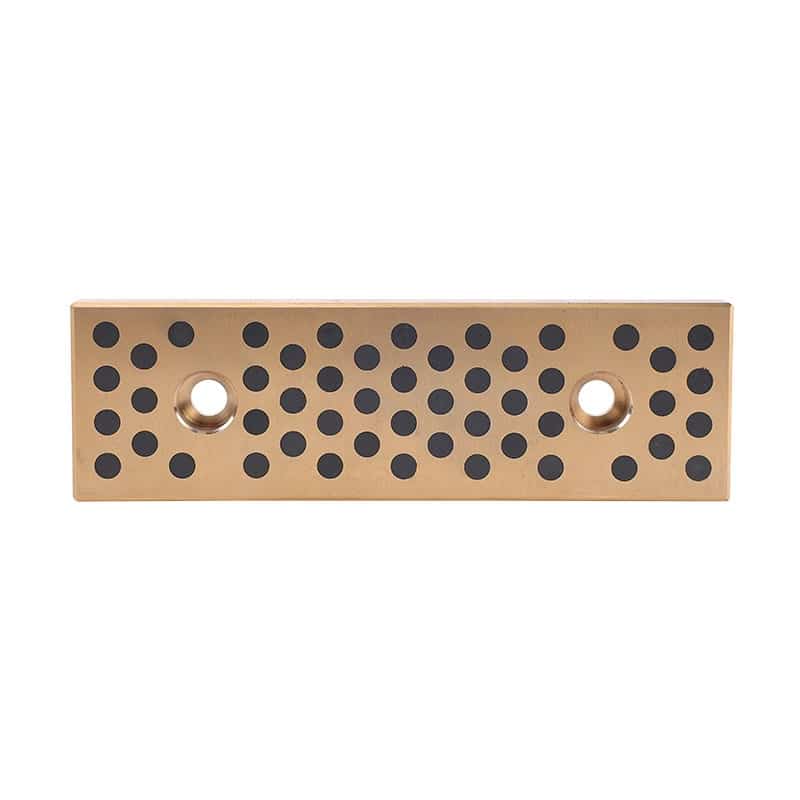

- Bronze bearings with lubrication pockets.

- Self lubricating plain bearings with PTFE sliding layer

- Bronze bearings with lubrication holes.

- Multi layer bearings with acetal sliding layer.

- Stainless self lubricating plain bearings.

- Graphite plugged bronze bushings

“High performance sliding bearings for multiple applications.”

Every application is unique, and every manufacturer has different challenges to overcome.

Plain bearings are used for sliding, rotating, oscillating or reciprocating motion. We can also tailor the material structure of the sliding bearings. Whether a customer is looking for a change in load or sizing capability, tolerance compensation or torque, we can design a bearing that delivers.

Benefit from our industry expertise

Worldwide Shipping Every Order, Slide bearings facilitate precise linear motion and accommodate structural expansion. We offer a portfolio of quality slide bearings designed to improve the reliability and efficiency of industrial equipment and machinery that keep industry in motion.

Self-lubricating Sliding Bushing Experience

Sliding Bushings & Bearings, *Shop all your Plain & Self-Lubricating Bearings and Sliding Bushings & Thrust Washers needs. Self-lubricating bearings have been our passion for many years. As a partner with profound professional expertise, we stand at your side with 100% commitment whatever the challenge.

Sliding Bushing, Self-lubricating Bearings Manufacturer

Breathtaking design for home living.

Stepping forward together with our customers, Technologies for top performance! Sliding bearings for ordinary long life time, Sliding bushings solution!

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.