Welcome to bronzelube.com

Self-Lubricating Bearings Manufacturer in China

manufacturer of self-lubricating sleeve bushings and sliding bearing bushings in China. We offer a wide range of materials and sizes for various applications. Our state-of-the-art manufacturing process ensures that all raw materials are subjected to rigorous quality control before production. The production process begins with the forming of metal strips if metallic components are used.

Finding the most efficient manufacturing method and the ideal high-performance lubricating bushing material to meet your specific requirements. We offer free CAD downloads, prompt lead times, competitive pricing, and small minimum order quantities to meet the needs of diverse customers. Choose Self-lubricating Bearings for your sliding bearing bushing and sleeve bushing needs, and benefit from their expertise, high-quality products, and excellent customer service. When selecting a sliding bushing manufacturer, consider factors like material options, size range, application-specific requirements, and regional availability. Also, consider customer reviews and support to ensure the best performance and reliability for your specific needs. provider of high-quality bearings, including sliding bushings, for aerospace, industrial, and defense applications.

We manufacturing self-lubricating sliding bearings tailored to your individual needs.

Manufacturer of high-performance sliding bushings, offering a wide range of materials and sizes for various applications.

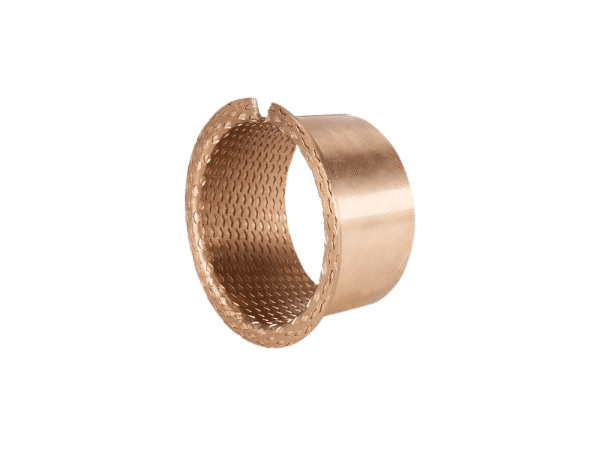

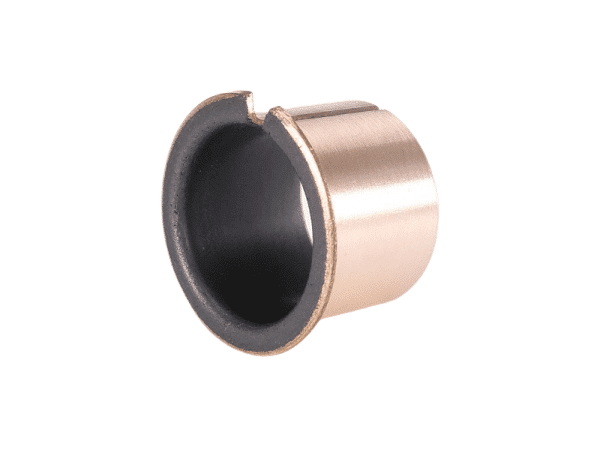

Sliding bushing, also known as plain bearing or sleeve bearing, is a type of bearing that provides a low-friction, wear-resistant surface for rotating or sliding parts. Sliding bushings are typically made of materials like bronze, steel, or plastic, and can be found in various applications, such as automotive, aerospace, and industrial machinery.

A custom sliding bearing bushing is a specialized type of bearing designed to provide a low-friction, smooth sliding surface for an application. These bushings are commonly used in a wide range of mechanical systems to reduce wear and tear, increase efficiency, and minimize the need for maintenance.

Custom sliding bearing bushings are tailored to meet specific requirements of a particular application or machinery. They can be made from various materials such as bronze, brass, steel, plastic, or composite materials depending on the desired properties, such as load capacity, temperature resistance, and corrosion resistance.

To design a custom sliding bearing bushing, consider the following factors:

Application: Understand the specific requirements of the application or machinery where the bushing will be used. This includes load capacity, speed, operating temperature, and environmental conditions.

Material selection: Choose the most suitable material based on the application requirements. Each material has its own advantages and disadvantages in terms of friction, wear resistance, and load capacity.

Dimensions: Determine the appropriate dimensions for the custom sliding bearing bushing, including the inner diameter, outer diameter, and length. These dimensions will depend on the shaft size and the available space within the machinery.

Lubrication: Sliding bearing bushings can be either self-lubricating or require external lubrication. Self-lubricating bushings have lubricant embedded within the material, reducing the need for maintenance. For bushings that require external lubrication, a proper lubrication system must be designed.

Tolerances and surface finish: Specify the required tolerances and surface finish for the custom sliding bearing bushing to ensure proper fit and function within the machinery.

Manufacturing process: Choose an appropriate manufacturing process, such as casting, machining, or injection molding, based on the selected material and design requirements.

Quality control: Implement quality control measures to ensure the custom sliding bearing bushings meet the required specifications and perform as expected.

By considering these factors, you can design a custom sliding bearing bushing that optimally suits your specific application, improving the performance and efficiency of your machinery.

Sliding Bearings Supplier

supplier of bearings, bushes, lubrication bushing, and services. We offer a comprehensive range of sliding bushings for multiple industries.

A bearing is a crucial component of a machine, used to support a shaft. The shaft is placed within the bearing. When the relative sliding friction between the journal and the bearing is referred to as a sliding bearing, the friction during bearing operation is called a rolling bearing.

In operation, the journal produces relative rolling friction. Sliding bearings can be classified into two categories according to the friction state during operation: liquid friction bearings and non-liquid friction bearings.

Liquid friction bearings:

In these bearings, the journal and the bearing’s working surface are entirely separated by a lubricant film, eliminating friction and wear between the metal surfaces. Bearings operating under these conditions are called liquid friction bearings. The working resistance of this type of bearing is also reduced.

Liquid friction bearings can be further divided into two types based on the method of oil film formation:

Dynamic pressure bearing:

Under full oil supply conditions, the lubricating oil is introduced between the friction surfaces due to the relative sliding speed of the journal and bearing.

Static pressure bearing:

A pressure oil pump is used to input pressurized oil between the bearing and journal’s working surfaces, forming an oil film bearing. This type of bearing ensures liquid friction even at low speeds.

Non-liquid friction bearings:

When the relative sliding speed between the journal and the bearing’s working surfaces is too low, oil supply is insufficient, or a thick enough film cannot be formed for other reasons, sliding bearings cannot achieve liquid friction lubrication. However, metal surface molecules and lubricating oil molecules have a mutual attraction that allows a very thin lubricating oil film to be adsorbed on the metal surface, forming a boundary lubricant film. Bearings operating under these conditions are called non-liquid friction bearings. This boundary lubricant film is generally less than 1um and cannot completely separate uneven metal surfaces. When in operation, the surface’s convex peaks make contact, resulting in increased wear. The friction coefficient of this type of bearing ranges from 0.01 to 0.1.

Compared to rolling bearings, sliding bushings offer several advantages, including being maintenance-free and providing high performance. Sliding bearings can also be classified based on the load direction they can withstand: radial bearings, thrust bearings, and radial-thrust bearings.

Characteristics and performance of sliding bearings:

Sliding bearings have several advantages over rolling bearings:

Long life and suitability for high speeds.

Impact resistance, vibration absorption, and large bearing capacity.

High rotational accuracy, smooth operation, and noise-free.

Simple structure, easy installation and disassembly, and low cost.

However, sliding bearings also have some disadvantages, such as high friction losses and severe wear in non-liquid friction bearings. Liquid friction bearings have lower friction losses than rolling bearings, but it can be challenging to maintain liquid friction during startup, stopping, or frequent changes in speed and load. Additionally, the design, manufacturing, lubrication, and maintenance requirements for sliding bearings are higher.

Structure type of sliding bearings & plain bearing

Manufacturer of polymer-based sliding bushings, offering low-friction and maintenance-free solutions for various applications.

Sliding bearings and plain bearings are used to support and reduce friction between a rotating shaft and its surrounding components. There are several types of sliding bearings and plain bearings, including:

Integral radial plain bearings: These bearings can be with or without bushings and are simple in construction, convenient to manufacture, and cost-effective. They are mainly used in low-speed, light-load, or intermittent work machinery.

Open radial plain bearings: These bearings consist of a bearing housing, bearing cover, split shaft tile, and bolt, and are easy to install. The thickness of the shim can be adjusted to account for wear of the shaft tile.

Spherical radial plain bearings: These bearings provide a spherical fit between the shaft and bearing body, allowing the shaft tile to rotate in any direction to adapt to the deflection of the journal, preventing load concentration and severe wear.

Clearance radial plain bearings: These bearings are used to adjust the radial clearance due to wear of the journal and shingle surface. They have columnar mating surfaces and tapered outer surfaces that can be adjusted by loosening and tightening a nut.

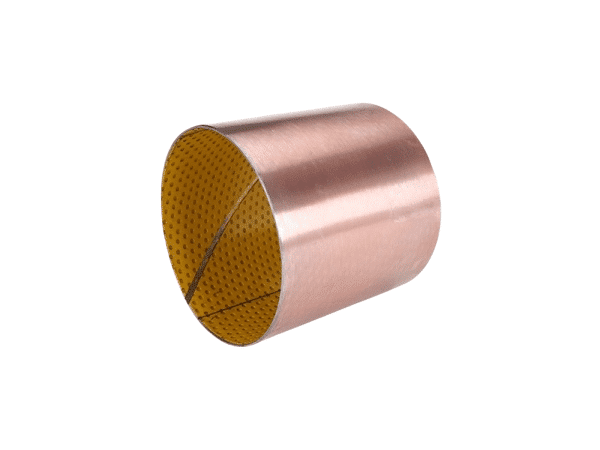

Manufacturer of polymer-based sliding bushings:

Polymer-based sliding bushings are made of high-performance, low-friction materials that offer maintenance-free solutions for various applications. These bearings are lightweight, resistant to corrosion, and can operate without lubrication, making them suitable for use in industries such as automotive, aerospace, construction, and more.

One example of a manufacturer specializing in polymer-based sliding bushings is the company viiplus. They offer a wide range of polymer bushings, including their well-known viiplus bearing and bushing product lines. These products are designed for applications where low friction, wear resistance, and maintenance-free operation are crucial.

Radial plain bearings can be categorized into several types, including integral, open, spherical, and clearance types.

Integral radial plain bearing:

This type of bearing can be with or without bushings. The integral radial plain bearing with bushings has a simple structure, is convenient to manufacture, and is cost-effective. However, the shaft must be installed from the bearing end, making assembly less convenient, and the overall bearing wear radial gap cannot be adjusted. It is mainly used in low-speed, light-load, or intermittent work machinery, such as manual machinery and agricultural machinery.

Open radial plain bearings:

These bearings typically consist of a bearing housing, bearing cover, split shaft tile, and bolt. According to the different load direction, this type of bearing is divided into positive sliding bearing and tilting open sliding bearing. The bearing cover has a threaded hole for mounting the oil cup. This type of bearing is easy to install, and the thickness of the shim can be adjusted to account for wear of the shaft tile. The inner hole of the shaft tile should be repaired after adjustment.

Spherical radial plain bearing:

When there is installation error or significant shaft bending deformation, the bearing ends may produce edge contact, causing load concentration, heat, and wear. To avoid this issue, spherical bearings are used, which provide a spherical fit between the shaft and bearing body. The shaft tile can rotate in any direction to adapt to the deflection of the journal, preventing load concentration and severe wear.

Clearance radial plain bearings:

Due to the inevitable wear of the journal and shingle surface, the radial clearance will gradually increase, affecting the normal operation and running accuracy of the machinery. To adjust the clearance, adjustable clearance radial plain bearings can be used. The mating surfaces of the journal and the shaft tile are columnar, while the outer surface of the shaft tile and the bearing body are tapered. By loosening and tightening the nut, the shaft is moved, and the shank will be deformed by the pressure, changing the size of the bore and adjusting the radial clearance.

Types of thrust plain bearings:

There are two types of thrust plain bearings: vertical and horizontal. Vertical plane thrust bearings consist of a cast iron or cast steel bearing seat, a bronze or other material-made thrust shaft tile, and a pin to prevent the thrust shaft tile from rotating. The upper surface of the thrust shaft has a radiating oil groove for distributing lubricating oil. The lower surface matches the spherical surface of the bearing seat to ensure even distribution of friction surface pressure. Horizontal multi-ring thrust bearings with radial load have multiple thrust rings on the shaft and can withstand large bi-directional axial loads.

01

Engineering Bushing

Engineering Bushing is a company that specializes in providing oilless bushings, which are bearings designed to operate without the need for lubrication. These bushings offer a cost-effective and low-maintenance solution for various industries, such as automotive, aerospace, heavy machinery, and more. As your supplier for oilless bushings, Engineering Bushing focuses on delivering high-quality products and exceptional customer service to ensure a seamless and efficient experience for their clients.

02

Custom Bushings

Custom bushings are a specialty of many bearing manufacturers. In addition to providing standard sliding bushings, these companies also produce custom bearings tailored to the specific needs of their clients. This means that customers can request bushings with unique dimensions, materials, or other requirements, ensuring a perfect fit for their particular application. By offering custom bushing solutions, manufacturers can cater to a wide range of industries and applications, providing an enhanced level of flexibility and performance for their clients.

03

Performance upgrade

Custom bearings made from high-strength metal are designed to meet the unique requirements of various applications and industries. These bearings are tailored to provide superior performance, durability, and reliability in challenging environments or demanding conditions. By utilizing high-strength metals, manufacturers can create custom bearings that offer enhanced load-carrying capacity, wear resistance, and extended service life. This level of customization allows clients to receive bearings that are precisely suited for their specific needs, ensuring optimal performance and efficiency in their operations.