Experience self lubricating bushing

Self-lubricating Bearing Bushings: The Oil-Free Effect

“Self-lube bushings” is a term used in mechanical engineering and refers to a type of bushing or bearing that incorporates a lubricating material within the structure of the bushing itself. This means that the bushing does not require additional lubrication during operation and can self-lubricate, reducing maintenance requirements and extending the life of the bushing.

self lubricating bearing The Oil-free Effect

Traditionally, self-lubricated bushings operate on this principle and include several maintenance-free bearings composed of specialized sliding plain bearing layers.

Contact Us:

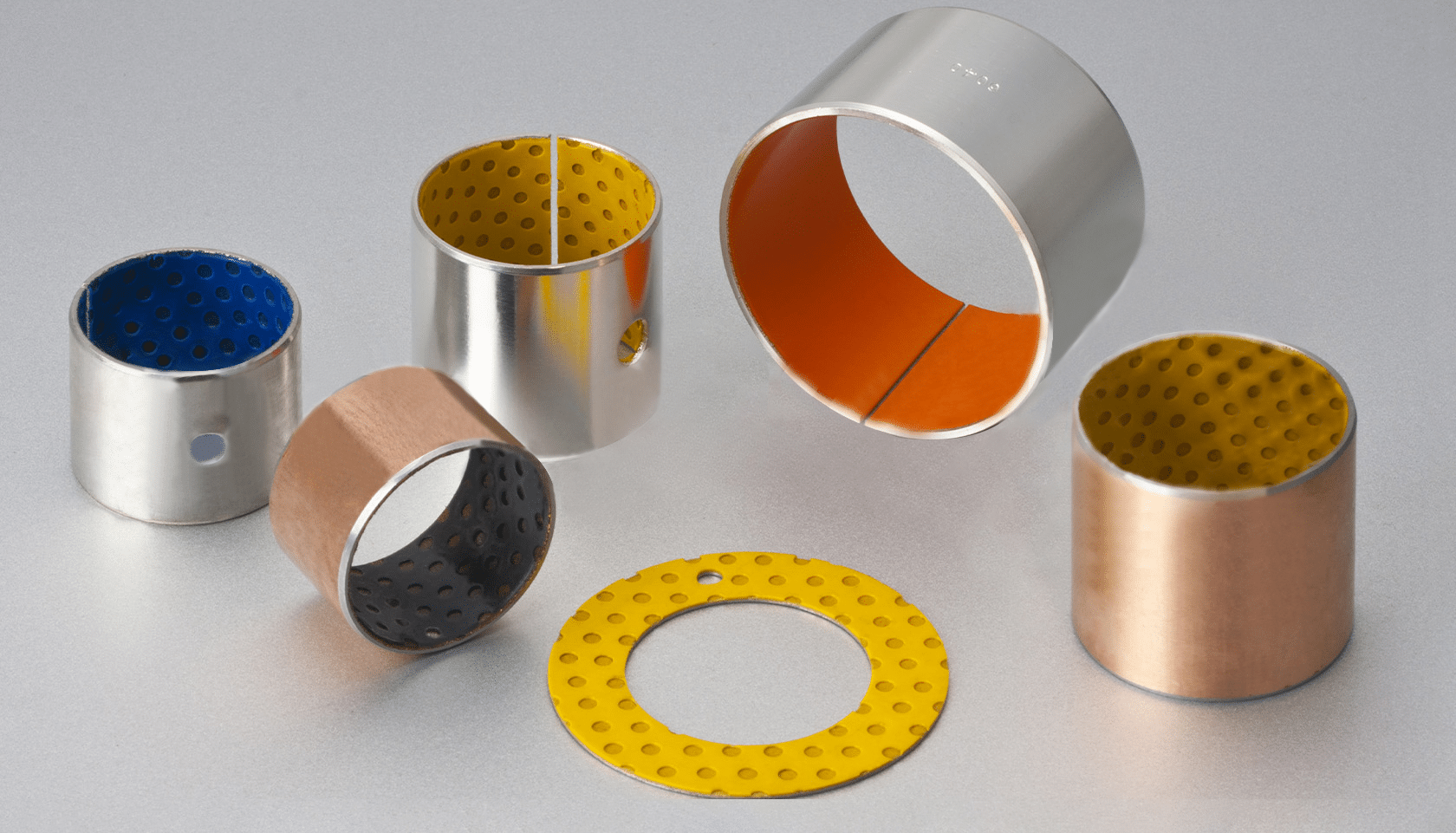

Metallic Self-Lubricating Bushings Bearings

Improve your machines - engineered self-lubricating bearings and plain bushings, Learn more about self-lubricating bushings and bearings: Try the plain bearing material, Switching from ball bearing to metallic plain bushings provides predictable performance and frees the user from from grease and maintenance cycles. Take a tour of our bushing material, see our online catalog, and experience the wide breadth of applications in this page!

Premium Self-Lubricating Bearing Solutions for Global Industries

Your Trusted Manufacturer of Custom Self-Lubricating Bearings

We specialize in designing and manufacturing high-performance self-lubricating bearings and bushings tailored to meet the unique demands of your applications. With competitive factory pricing, assured payment security, and seamless global shipping from China, we deliver cost-effective, reliable solutions for industries worldwide.

How Do Self-Lubricating Bearings Work?

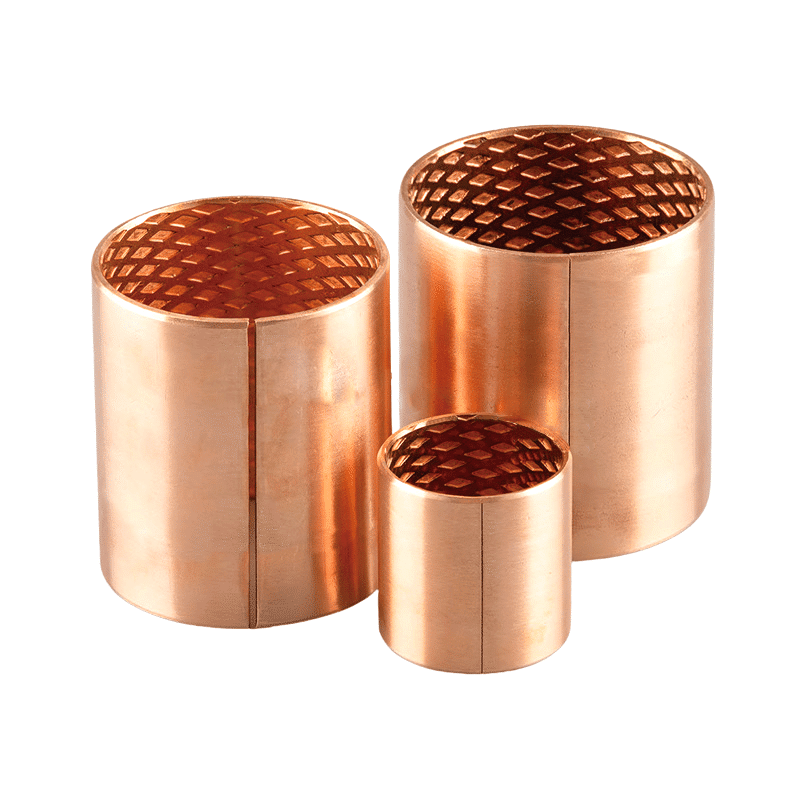

Self-lubricating bearings combine a durable metal substrate (typically copper) with embedded solid lubricants like graphite. During operation:

-

The metal substrate bears the primary load, ensuring structural integrity.

-

Friction triggers the release of lubricant from embedded pores, forming a smooth, protective transfer film on the bearing surface.

-

This film minimizes wear, reduces friction coefficients, and eliminates the need for external lubrication.

-

Continuous lubricant replenishment ensures consistent performance and extended service life, even in harsh environments.

Ideal for applications where traditional lubrication is impractical, our bearings prevent seizing, reduce downtime, and enhance operational efficiency.

Industries We Serve

Our bearings are engineered for excellence across diverse sectors, including:

-

Aerospace & Automotive

-

Industrial Machinery & Construction

-

Agriculture & Energy (Oil/Gas, Solar)

-

Fluid Power Systems & Heavy Metals

-

Packaging & Entertainment Equipment

Why Choose Our Self-Lubricating Bearings?

-

Maintenance-Free Operation: Eliminate frequent relubrication.

-

Exceptional Durability: Engineered for high loads and corrosive environments.

-

Reduced Friction & Noise: Smooth performance for precision applications.

-

Custom Designs: Tailored to fit your exact specifications.

-

Cost Efficiency: Lower operational costs with long-lasting reliability.

Commitment to Quality

Every bearing undergoes rigorous testing to ensure unmatched performance and safety. From material selection to final inspection, we prioritize precision and reliability.

Global Reach, Local Support

Partner with a leading supplier that combines cutting-edge technology with responsive service. Explore our range of self-lubricating bronze bushings and polymer-based solutions at Bronzelube.com.

Contact Us Today to optimize your machinery with high-quality, maintenance-free bearing solutions—and start saving on operational costs!

Smart Design | Perfect Fit | Long Life | Trusted Worldwide

Self Lube Bushings - What are the options

Self-lubricating bushings, also known as self-lube bushings, are a type of bearing that operates without the need for external lubrication. There are several options available for self-lube bushings, including:

- Solid metal bushings: These are made from materials like bronze, brass, or steel and have a built-in lubricant that is evenly distributed throughout the material. They are typically used in high load and low-speed applications.

- Composite bushings: These are made from a combination of materials such as PTFE (polytetrafluoroethylene) or nylon and are designed for high-speed and low-load applications. They have a low coefficient of friction and are resistant to wear.

- Metal and bimetal bushings: These are made from metals that are compressed and sintered together to form a solid piece. They are typically used in high-load and low-speed applications.

- Composite bushings: These are made from materials such as acetal or PTFE and are designed for low-load and high-speed applications. They have a low coefficient of friction and are resistant to wear and corrosion.

- Graphite bushings: These are made from graphite impregnated materials and are designed for high-temperature applications. They have a low coefficient of friction and can withstand extreme temperatures without losing their lubricating properties.

The choice of self-lubricating bushing will depend on the specific application requirements, such as load, speed, temperature, and environment. It is important to choose the right self-lubricating bushing to ensure reliable and efficient operation

What are self-lubricating bearings? Self-lubricating bearings and self-lubricating materials

With the continuous progress of science and technology today, mechanical technology is moving towards advanced, sophisticated, diversified trends. Especially aerospace technology, atomic energy industry, military industry and other research fields plain bearing technology is facing many new issues, for example, self-lubricating bearing in vacuum conditions, high-temperature conditions and low-temperature conditions and other extreme environmental problems, its solution mainly relies on self-lubricating bearings of special lubrication properties. Self-lubricating bearing is the rolling body, inner and outer ring raceway or cage after special material treatment, no need to add oil or grease lubricants can work properly bearings. Self-lubricating bearings from the lubrication mechanism can be divided into self-lubricating material itself to produce self-lubricating characteristics of bearings and sintered microporous material due to the nature of the self-lubricating characteristics of bearings.

Self-lubricating bearings is the rolling body, inner and outer ring raceway or cage after special material treatment, do not need to add oil or grease lubricants can work properly bearings. Self-lubricating plain bearings from the lubrication mechanism can be divided into self-lubricating material itself to produce self-lubricating characteristics of plain bearings and sintered microporous materials due to the nature of the self-lubricating characteristics of bearings.

Self-lubricating bearings, self-lubricating bearing characteristics

Lubrication is divided into fluid lubrication, mixed lubrication, boundary lubrication, and solid lubrication. In the field of solid lubrication, the bearing material itself shows good friction characteristics, wear resistance of the bearing is called self-lubricating bearings. Because self-lubricating bearings are used in parts where lubricant cannot be used or in parts where the lubricant is poor and used in boundary lubrication, mixed lubrication and other stable parts, this self-lubricating bearing is also called "self-lubricating bearing", "dry bearing" and so on.

Self-lubricating plain bushes bearings have the following characteristics.

1) self-lubricating bearing low friction: in the use of solid lubricants, direct friction between solids is a small coefficient of friction.

2) self-lubricating bearing heat resistance: solid lubrication and fluid lubrication compared to the coefficient of friction are small, and therefore can withstand the friction (direct friction between solids) generated by the high heat.

3) self-lubricating bearing sinter resistance: not easy to sinter.

4) self-lubricating bearing wear resistance: not easy to wear.

(5) self-lubricating bearing environmental adaptability (corrosion resistance): can withstand the air, gas, and working oil on its chemical corrosion effect.

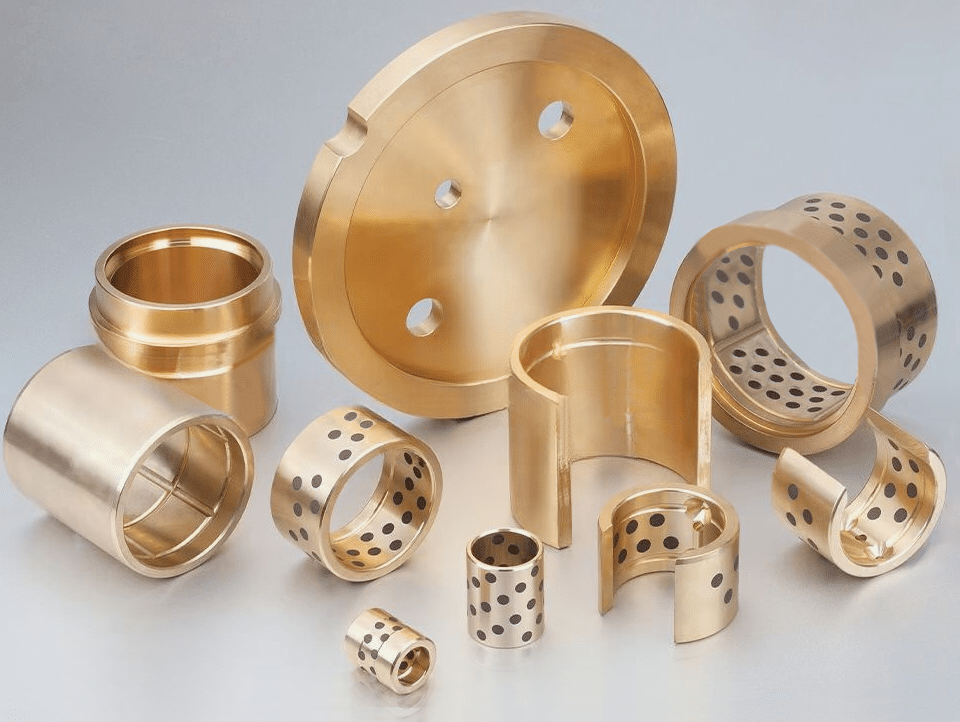

Self-lubricating plain bearings materials, which type of bearing metal is self-lubricated

Self-lubricating bushes are a type of bearing that are designed to operate without the need for external lubrication. They are commonly used in applications where traditional lubricants cannot be used or where frequent lubrication is not practical.

Self-lubricating bushes are made from a variety of materials, including:

- Bronze: Bronze self-lubricating bushes are commonly used in high-load, low-speed applications. They are known for their high wear resistance and ability to withstand harsh environments.

- Graphite: Graphite self-lubricating bushes are commonly used in high-temperature applications. They have a low coefficient of friction and can withstand extreme temperatures without losing their lubricating properties.

- PTFE: PTFE self-lubricating bushes are commonly used in high-speed, low-load applications. They have a low coefficient of friction and are resistant to chemicals and corrosion.

- POM: POM self-lubricating bushes are commonly used in low-load, high-speed applications. They have a low coefficient of friction and are resistant to wear and abrasion.

Self-lubricating bushes are an excellent choice for applications where frequent lubrication is not practical or where traditional lubricants cannot be used. The choice of material will depend on the specific application requirements, such as load, speed, temperature, and environment.

self-lubricating bearing material types

Plain Bearing material type, which type of bearing metal is self

The so-called self-lubricating bearing materials are not even from the outside to provide lubricant itself can show the low friction characteristics of the material. Its representative is, tetrafluoroethylene resin and other plastics containing graphite, molybdenum fluorescence and other solid lubricants of plastic-bearing materials. In addition, there are also materials with solid lubricants synthesized with metals, bearing materials with graphite added to metal base materials, etc. Special examples include essential and rubber bearing materials. Broadly speaking, there are also oil-bearing materials with lubricating oil immersed in the material included in self-lubricating bearing materials.

Self-lubricating Bushing Bearing material characteristics

Plain bearing materials

Self-lubricating bearing materials also have the most common materials. Plastic bearing material is divided into solid lubricant dispersion type material, double layer type material, being compound type material, porous material. Solid lubricant dispersion type material is the solid lubricant dispersion into the plastic material, double layer type material is lined with metal and metal powder depletion layer and plastic layer composition of the material. Also, the compound material is the material to which the plastic and solid lubricant are attached on the surface of the base material such as metal. The porous material is a material consisting of plastic and metal eyelet, etc.

a. Solid lubricant dispersion type material

Plastic bearing material is the most used material in various applications. It is a bearing material in which solid lubricants such as graphite, molybdenum fluorescence, PTEE resin, etc. are mixed with lubricating oil and dispersed together in plastic, and then injection molding and compression molding, and also has the advantage that it can be processed into various shapes by mechanical processing.

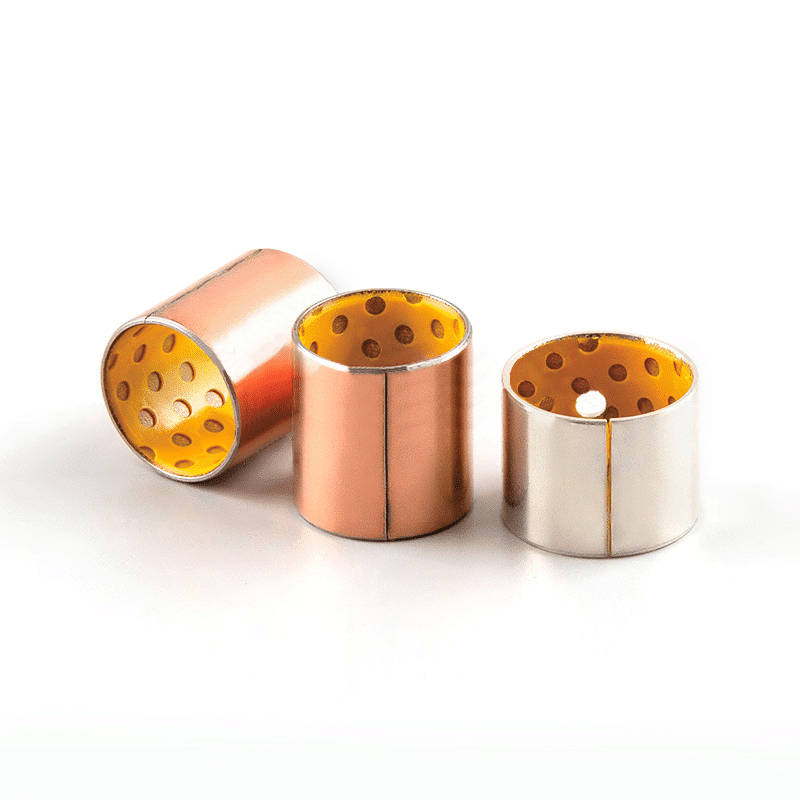

b. Double-layer material

Double-layer material is a double-layer structure of metal lining, metal powder sintered layer, and a plastic layer of bearing material. Since it is a double-layer structure, the heat generated by friction is quickly dissipated, and it also makes up for the weakness of plastic and its self-heating conduction. For this reason, it is a high-performance bearing material with good resistance to high loads compared to solid lubricant dispersion-type materials.

c. Compounded material

It is a material that forms a film of solid lubricant such as resin and molybdenum dichloride directly on the surface of the basic material such as metal and is used under less strict conditions.

d. Porous material

The porous material is a bearing material impregnated with tetrafluoroethylene resin, etc., in the metal eyelet space. The softness of the eyelet is used to sandwich it between the shaft and the sleeve to reduce the bearing clearance and prevent the shaft from loosening, and the resin (PTEE) inside has a low coefficient of friction.

For the above material, the main component of the friction surface is plastic. This material, the use of tetrafluoroethylene resin, polyacetal, polyamide, polysulfide benzene, polymethyl ethyl copper, and other thermoplastic resins and epoxy, carbolic acid, polyamide-imide, polyimide, and other thermosetting resins. As the choice of these materials, it is not all without lubricating oil parts, and thus can be used in lubrication, butter and water and a wide range of lubrication conditions, and according to its use, type to provide a variety of rich material bearings.

Other self-lubricating bushing bearing materials

In addition to plastic class (bearing material), there are solid lubricant and metal synthesis of solid lubricant dispersion type material, rod graphite, and other solid lubricants filled into the copper alloy solid lubricant filling type bearing material, or lubricant dipped into the copper alloy, iron alloy and become oil-containing sintered bearing material. In addition, special also have wood type bearing material, rubber type bearing material, etc.

Bushing Bearing Company: Building Trust and Long-Term Partnerships

In today's highly competitive market, earning the trust of leading customers is crucial for any business to succeed. This is especially true in the industrial sector, where reliable and high-quality products are essential for the smooth functioning of machinery and equipment. One such company that has earned the trust of leading customers in the industry is the Bushing Bearing Company.

Bushing Bearing Company is a leading manufacturer and supplier of bearings and bushings for various industrial applications. The company has been in business for over three decades and has built a reputation for providing high-quality products and exceptional customer service. One of the key factors that have contributed to the success of the company is its ability to build long-term partnerships with its customers based on mutual trust and success.

So, how does Bushing Bearing Company earn the trust of leading customers and build long-term partnerships? Here are some key strategies that the company employs:

- Providing High-Quality Products: The first and foremost strategy of Bushing Bearing Company is to provide high-quality products that meet or exceed customer expectations. The company uses advanced manufacturing techniques and quality control processes to ensure that its products are of the highest standard. By providing products that are reliable, durable, and perform well, the company earns the trust of its customers.

- Exceptional Customer Service: In addition to providing high-quality products, Bushing Bearing Company also places a strong emphasis on exceptional customer service. The company has a team of highly trained and experienced customer service representatives who are always available to assist customers with their inquiries and concerns. By providing timely and efficient service, the company builds a strong relationship with its customers.

- Customization and Flexibility: Bushing Bearing Company understands that every customer has unique requirements and preferences. Therefore, the company offers a wide range of customization options and is flexible in its approach to meet customer needs. This approach helps the company to build a strong relationship with its customers and earn their trust.

- Continuous Improvement: Finally, Bushing Bearing Company is committed to continuous improvement. The company regularly reviews its processes and products to identify areas for improvement. By implementing changes that lead to better products and services, the company builds a reputation for excellence and earns the trust of its customers.

In conclusion, the Bushing Bearing Company has been able to earn the trust of leading customers and build long-term partnerships by providing high-quality products, exceptional customer service, customization and flexibility, and a commitment to continuous improvement. These strategies have helped the company to establish itself as a reliable and trustworthy supplier of bearings and bushings, and it is likely to continue to do so in the future.

The Self-Lubricating Bearings Bushings Type

Plain & Self-Lubricating BUSHING, No bullshit. Quality Bearings.

Self-lubricating plain bearings excel in high-temperature applications. As the leading supplier of tribology self-lubricating bushing bearings in China, we provide tailored manufacturing components and professional engineering techniques to meet diverse customer needs. Our expertise enables our plain self-lubricating bearings to function effectively on any surface, regardless of shape or material.

We offer a comprehensive range of products to satisfy the most demanding surface engineering requirements, including metallic polymers, engineered plastics, fiber-reinforced composites, metal and bimetal bearings, as well as supporting components, liners, and thrust plates. Our extensive professional knowledge drives innovation in polymer coatings within the field of tribology. Explore our plain bearing bushings.

Making Small Bearing Bushing Parts, Making a Big Difference.

Beautifully crafted leather products.

We are a supplier of self-lubricating bearings in China, offering manufacturing components and professional engineering services to help clients with their unique requirements. Our expertise ensures that our plain bearings operate effectively on any surface, regardless of shape or material. Discover the ideal self-lubricating bushing for your application! Our high-strength brass self-lubricating bearings eliminate the need for feeder systems and provide superior load capacity, impact resistance, and wear resistance.

Bimetal Bushing - Plain Metallic Bushing

Beautifully crafted leather products.

Common sliding bearing materials include bimetallic bushings, wear-resistant cast iron, copper and aluminum alloys, powder metallurgy, steel-back bushings, bronze-back bushings, plugged graphite bushings, polytetrafluoroethylene (PTFE), and modified polyoxymethylene (POM).

Self-lubricating plain bushings absorb and transmit forces between moving parts, maintaining positional accuracy while converting linear motion into rotary motion (e.g., in reciprocating piston engines). These high-quality bearings operate effectively in high-temperature and submerged environments, where grease, oil, and plastics fail. They reduce costs and downtime while enhancing reliability, are non-galling, and can run dry.

What is a plain bearing?

Beautifully crafted leather products.

A plain bearing, specifically a self-lubricating sliding bearing, operates under sliding friction. These bearings function smoothly, reliably, and quietly. When liquid lubrication is present, the sliding surfaces are separated by oil, minimizing direct contact, friction loss, and surface wear, while also providing some vibration absorption. However, they do experience high starting friction resistance. The shaft portion supported by the plain bearing is known as the journal, and the components that interact with it are called shingles. To enhance the frictional properties, a layer of friction-reducing material, known as the plain bearing lining, is cast on the inner surface. The shaft and the liner materials are collectively referred to as plain bearing sliding bearing material. Plain bushing bearings are typically used in low-speed, heavy-load conditions or in environments where maintenance and lubrication are challenging.

We manufacturer self-lubricating bearings

tailored to your needs.

Self lubricating bushings manufacturer

Self-lubricating Bearings Top Deals at Factory Price. Confidently Place Self-lubricating Bearings Orders Online! Payment Assurance! Will Provide You With High-Quality Self-Lubricating Bearing Products & Professional Solutions For All Industries In The World. Contact Us And Start Saving On Your Costs. Ship Self-Lubricating Bearing From Anywhere In China To Global.Self-Lubricating Bearing Solutions Are Mainly Applicable To The Following Industries: Aerospace, Automotive, Industrial, Agricultural, Construction, Oil And Gas, Energy, Fluid Power, Major Metals, Entertainment, Solar Energy, Packaging, Etc.

How do self lubricating bearings work?

What is the principle of self-lubricating bearings? Self-lubricating bearings working principle: Self-lubricating bearing using composite material is a new type of anti-polar pressure solid lubrication material, by the metal substrate and embedded in the substrate hole or slot of solid lubricant paste composition. Self-lubricating bearings with copper as the substrate, inlaid graphite material, in the work of the metal substrate to bear most of the friction load. After friction, the solid lubricant in the hole or slot is transferred or counter-transferred to the friction surface, forming a well-lubricated, firmly attached and uniformly covered solid transfer film on the friction surface, significantly reducing frictional wear. As the friction proceeds, the embedded solid lubricant is continuously provided to the friction surface, ensuring good lubrication to the friction substrate during long-term operation.

Self-Lubricating Plain Bearings: How They Work? Self-lubricating plain bearings working principle!

How does self lubricating bearings work? Bearings are a mechanical component often used in machine tools, but some industrial enterprises work and production environment is relatively harsh, often accompanied by sulphur dioxide and other corrosive gases and dust in the work of mechanical equipment damage, resulting in machine tools in the work of friction and wear serious, in order to reduce the occurrence of such situations, self-lubricating bearings began to be developed and applied in the use of machine tools machinery, we take a look at self-lubricating What is the working principle of self-lubricating bearings.

Self-lubricating bearings using composite materials is a new type of anti-pressure solid lubricating material, by the metal substrate and embedded in the substrate of the hole or slot in the solid lubricant paste composition. In the friction process, the metal substrate bears most of the load. After friction, the solid lubricant in the hole or slot is transferred or counter-transferred to the friction surface, forming a well-lubricated, firmly attached and uniformly covered solid transfer film on the friction surface, which greatly reduces frictional wear. As the friction proceeds, the embedded solid lubricant is continuously provided on the friction surface, ensuring good lubrication for the frictional subsets during long-term operation.

The emergence of self-lubricating bearings for industrial production reduces a lot of manpower and material resources, reduces the friction or bite phenomenon between the bearings and other parts in the operation, ensures the normal operation of the machine tool mechanical parts, for the production of continuous operation to do a guarantee. The self-lubricating bearings produced by our company can be used without or with less lubricating oil, with good wear resistance and small friction coefficient, and have a long service life.

Design a better self-lubricating bearings

Your Best Self-lubricating Bearings Supplier in China. Competitive Lubricating Bushing Price & Safe & On Time Delivery. High Performance Self-lubricating Bearings Metal-Polymer Self-lubricating and Maintenance-free Bearing Solutions! Explore All Type of Self-lubricating Bronze Bushings! Always tested. Always proven. Always Bronzelube.com

- Smart Design

- Perfect Fit

- Long Life

- Low Noice Bearings

Bushing Bearing Company: Fostering Trust and Lasting Partnerships

We are a bushing supplier in Germany and have had a long-standing partnership with Viiplus. They are an excellent partner, offering competitively priced bronze parts and top-notch service. We truly appreciate their professionalism and quality.

Angelina

Bearing Bushing Company

Please ship self-lubricating bronze bearings from China to us. All our self-lubricating bearing needs are managed by Viiplus, which offers professional solutions and competitive pricing for our large parts, such as bushings for excavators and cranes. Their extensive experience in exporting sliding bearings is especially valuable.

Dario Pineda

LUBE BEARINGS INC

Our engineers offer expertise to help customers in sliding bearing surface engineering understand tribological solutions and fundamental concepts for designing self-lubricating bushings, manufacturing plain bearings, and applying sliding bearings in industrial equipment.

Richard Davidson

Auto Parts Company