Lubricated Metal Bushings and Types of Metal Sliding Bearings

About Us

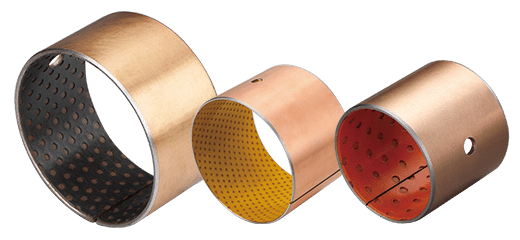

Self-lubricating bearings feature a metallic bushing made of a two- or three-layer aluminum and bronze alloy structure with a steel backing. Explore our high-quality range of metal bushes, oil-free bushings, and sliding bearings, including molded plain bearings, plain sleeve and flange bearing kits, sleeve thrust washers, and wear strips and plates.

Chinese Oil-Free Self-Lubricating Bushings, Split Sleeve Bearings

Real-life strategy to reach your goals.

Manufacturer of bronze bushing & self lubricating bushing according to customer’s drawing. Explore our extensive range of plain metallic bushing bearing to suit all applications. Offering a wide range of professional services to support your business. Browse, get a quote and order plain bearing bushing products easily in bushing eCatalog. If you faced any problem with ordering, We can help you. Sleeve bearings are available in different types and materials, all with a one-piece design. We ensure quality and on-time global shipping. Discover our bushing products and reach out to us today for cost-effective, high-performance solutions.

A Type of Bearing

Plain Bearing Bushes: Purpose of Bushings

Bushings are slender tubular components that improve efficiency while reducing vibration and noise in machinery with rotating or sliding shafts. They are commonly used in drilling jigs, hydraulic external gear pumps, and motors.

Product Quality Index

Energy Generation

We strive for diversity across the globe

Self-Lubricating Metallic Bushings

Tribology plays a crucial role in various applications. Upgrade from steel bearings to self-lubricating metal-polymer composite bushings that eliminate the need for grease and extend equipment lifespan. Our composite bearings feature a robust steel backing and a sintered bronze layer with an anti-friction coating. Explore the various types of sliding bushings and bearings, along with their technologies.

Custom self-lubricating metallic steel bushings from China.

Our team is highly qualified to help your business grow.

Proven Thin-Walled Bearing, Lubexpert

China OEM Metallic Bushing Bearing – Manufacturers & Suppliers.

We supply sleeve bearings crafted from CuSn8 and CuSn6 bronze, including wrapped bearings and flange bushings, engineered to endure extreme temperatures. Our globally used self-lubricating bearings and bushings are lead-free alternatives and offer superior lubricity, tightness, wear resistance, strength, hardness, and machinability by substituting lead with other elements.

Addressing Misconceptions About Thin-Walled Bushings, Sleeve Bearings, and Anti-Friction Solutions

Introduction

Bearings are critical for managing motion and friction in machinery. Common misconceptions often lead to suboptimal choices between thin-walled bushings, sleeve bearings, and anti-friction solutions. This clarification highlights why thin-walled, self-lubricating metallic bushings are often superior to traditional thick-walled bronze bushings.

Misconception 1: Thicker Walls Mean Better Strength and Durability

Reality:

Strength and durability depend on material composition and design, not wall thickness alone. Thin-walled bushings use advanced self-lubricating materials (e.g., composite polymers, graphite-infused bronze) that offer high wear resistance and load capacity. For example:

-

Thin-walled designs maintain structural integrity through optimized material properties.

-

Applications like automotive suspensions or harbor cranes benefit from lightweight yet robust solutions without compromising performance.

Misconception 2: Thin-Walled Bushings Can’t Handle High Loads/Speeds

Reality:

Thin-walled bushings excel in heat dissipation, critical for high-pressure and high-velocity (PV) applications. Key advantages:

-

Higher allowable PV values due to efficient heat transfer through thin walls, reducing wear.

-

Thick-walled bronze bushings retain heat, accelerating wear despite added material.

-

Example: In linear reciprocating motion (e.g., flight control actuators), thin-walled bushings maintain stable friction levels under extreme conditions.

Misconception 3: Bronze Bushings Are Superior Due to Material

Reality:

While bronze is traditional, self-lubricating materials outperform in modern applications:

-

Maintenance-free operation: Embedded lubricants (e.g., PTFE, graphite) eliminate relubrication needs.

-

Environmental compliance: Ideal for offshore or food industries where grease/oil is prohibited.

-

Example: VIIPLUS’ polymer-coated bearings reduce stick-slip effects, outperforming bronze in precision applications.

Misconception 4: Thick-Walled Bushings Last Longer

Reality:

Wear resistance depends on material, not thickness. Self-lubricating thin-walled bushings:

-

Reduce friction-induced heat, extending lifespan.

-

Avoid clearance issues caused by wear in bronze bushings.

-

Example: Agricultural machinery using thin-walled bushings shows longer service life due to optimized material blends.

Advantages of Thin-Walled Bushings

-

Weight Savings: Critical for automotive/aerospace (e.g., race cars, drones).

-

Tighter Tolerances: Less deformation risk vs. thick-walled designs.

-

Compact Design: Enables miniaturization in machinery.

-

Cost-Effective: Lower material use and freight costs.

Conclusion

Choosing between thin- and thick-walled bushings requires evaluating application needs, material properties, and thermal management. Thin-walled self-lubricating bushings offer:

-

Superior heat dissipation.

-

Reduced maintenance.

-

Weight and space efficiency.

-

Custom solutions for industries from agriculture to aerospace.

VIIPLUS leverages tribological expertise to deliver tailored, high-performance solutions, debunking the myth that “thicker is better.” By prioritizing material innovation and design precision, thin-walled bushings often outperform traditional options, aligning with modern demands for efficiency and sustainability.

Need a Solution? Consult our experts to optimize your bearing selection for performance, cost, and longevity. Let’s turn technical challenges into innovative solutions! 🛠️🚀

Comparison of plain bearing materials: bronze bushings and other alloys

Plain bearings, also known as bushings or sleeve bearings, are used to reduce friction and support loads in various types of machinery. One of the most common materials used for plain bearings is bronze, but there are also other alloy options available. Here is a comparison of bronze bushings and other alloy materials:

- Bronze: Bronze is a copper alloy that contains tin, which provides excellent strength, corrosion resistance, and wear resistance. Bronze bushings are commonly used in applications where the load is high and the speed is low. They are also resistant to chemical attack, making them suitable for use in harsh environments. Bronze bushings are easy to machine and can be produced in a variety of sizes and shapes. They are generally more expensive than other materials.

- Brass: Brass is another copper alloy that contains zinc. Brass bushings are less expensive than bronze bushings and are also easy to machine. However, they are not as strong or wear-resistant as bronze bushings, making them suitable only for low-load and low-speed applications.

- Aluminum: Aluminum bushings are lightweight and have good corrosion resistance. They are commonly used in applications where weight is a concern, such as in aerospace and automotive industries. However, they have low strength and wear resistance, making them unsuitable for high-load and high-speed applications.

- Stainless steel: Stainless steel bushings are corrosion-resistant and have good strength, making them suitable for high-load and high-speed applications. They are also resistant to chemical attack, making them suitable for use in harsh environments. However, they are more expensive than other materials and can be difficult to machine.

- Plastics: Plastic bushings, such as nylon and PTFE (polytetrafluoroethylene), are lightweight, low-cost, and easy to machine. They have good chemical resistance and are suitable for use in wet or corrosive environments. However, they have low strength and wear resistance, making them unsuitable for high-load and high-speed applications.

In conclusion, the choice of material for plain bearings depends on the specific requirements of the application, such as load, speed, environment, and cost. Bronze bushings are a good choice for high-load and low-speed applications, while stainless steel bushings are suitable for high-load and high-speed applications. Plastics are a good choice for low-load and low-speed applications, while aluminum is suitable for applications where weight is a concern.

Anti-Friction Bushings: What They Are and How They Work? Trusted Sleeve Bushing Supplier

Anti-friction bushings are a type of mechanical component that are designed to reduce friction between two moving parts. These bushings are used in a wide variety of applications, from automobiles to industrial machinery, and play a critical role in reducing wear and tear on mechanical components, improving performance, and extending the life of machinery. In this article, we will discuss what anti-friction bushings are, how they work, and why they are so important in many applications.

What are Anti-Friction Bushings?

Anti-friction bushings are typically made from materials such as bronze, polytetrafluoroethylene (PTFE), and polyurethane, and are designed to reduce friction between two moving parts. They are typically cylindrical in shape and have a hole in the center, allowing a shaft or other component to pass through. The bushings are installed between two moving parts, such as a shaft and a housing, to provide a low-friction interface between them.

How do Anti-Friction Bushings Work?

Anti-friction bushings work by providing a low-friction interface between two moving parts, reducing the amount of friction between them. This reduction in friction leads to reduced wear and tear on the components, improved performance, and increased life of the machinery. The materials used in the construction of anti-friction bushings are carefully selected to provide the best balance of low-friction and durability, ensuring that the bushings will perform well over time.

The design of anti-friction bushings is also critical to their effectiveness. The cylindrical shape of the bushings allows them to rotate, reducing friction and preventing wear on the components. The central hole in the bushing allows for easy installation and allows for the components to rotate freely, further reducing friction.

Why are Anti-Friction Bushings Important?

Anti-friction bushings are important for several reasons. Firstly, they help to reduce wear and tear on mechanical components, which can lead to improved performance and longer component life. By reducing friction, the components are subjected to less stress, which reduces the risk of failure and extends their life.

In addition, anti-friction bushings can also improve the performance of machinery. By reducing friction, the components can move more freely, which can result in improved efficiency and faster operation. This can be especially important in high-speed or high-load applications, where friction reduction is critical to performance.

Another advantage of anti-friction bushings is that they can improve safety. By reducing friction and wear, they reduce the risk of components failing, which can be a safety hazard in certain applications.

In conclusion, anti-friction bushings are an essential component in many applications, providing a low-friction interface between moving parts, reducing wear and tear, improving performance, and increasing component life. Whether in automobiles, industrial machinery, or other applications, anti-friction bushings play a critical role in ensuring that machinery operates smoothly and efficiently.

Sleeve Bearing Bushing, Anti-friction Bushing with Flange

Plain Bearings and Sleeve Bearings

Anti-Friction Bushing Flanges: Understanding their Function and Benefits

Anti-friction bushing flanges are an important component in many industrial and mechanical applications, and are designed to reduce friction and wear between moving parts. These flanges are typically made from materials such as bronze, polytetrafluoroethylene (PTFE), or polyurethane, and are used to provide a low-friction interface between two components. In this article, we will explore the function and benefits of anti-friction bushing flanges, and how they are used in various applications.

What are Anti-Friction Bushing Flanges?

Anti-friction bushing flanges are cylindrical-shaped components that are designed to reduce friction between two moving parts. They have a hole in the center, allowing a shaft or other component to pass through, and are typically installed between two parts to provide a low-friction interface. The flanges are typically made from materials that are selected for their low-friction and durability characteristics, making them well-suited for use in a variety of applications.

How do Anti-Friction Bushing Flanges Work?

Anti-friction bushing flanges work by reducing friction between two moving parts. The cylindrical shape of the flange allows for rotation, which reduces friction and prevents wear on the components. The central hole in the flange also allows for easy installation and allows the components to rotate freely, further reducing friction.

The materials used in the construction of anti-friction bushing flanges are also critical to their effectiveness. These materials are carefully selected to provide the best balance of low-friction and durability, ensuring that the flanges will perform well over time.

Why are Anti-Friction Bushing Flanges Important?

Anti-friction bushing flanges are important for several reasons. Firstly, they help to reduce wear and tear on mechanical components, which can lead to improved performance and longer component life. By reducing friction, the components are subjected to less stress, which reduces the risk of failure and extends their life.

In addition, anti-friction bushing flanges can also improve the performance of machinery. By reducing friction, the components can move more freely, which can result in improved efficiency and faster operation. This can be especially important in high-speed or high-load applications, where friction reduction is critical to performance.

Another advantage of anti-friction bushing flanges is that they can improve safety. By reducing friction and wear, they reduce the risk of components failing, which can be a safety hazard in certain applications.

In conclusion, anti-friction bushing flanges are an essential component in many industrial and mechanical applications, providing a low-friction interface between moving parts, reducing wear and tear, improving performance, and increasing component life. Whether in automobiles, industrial machinery, or other applications, anti-friction bushing flanges play a critical role in ensuring that machinery operates smoothly and efficiently.

Metallic bearing bushings type

As the name implies, these bushings are two or three layer structures made of metal or metal alloys with steel backing. These bushings have a very high mechanical strength, making them suitable for high speed and load applications involving lubrication. The metal used depends on the industrial environment or the type of application. These bushings are available in different lubrication methods, depending on their size, composition and application.

Metal bushings are further classified into 6 main types, including.

Bronze Bushings

Bronze is the material of choice for bushings because it is typically available in a variety of alloys and compositions. You can use bronze bushings for a variety of applications in industrial production.

Compared to other materials, bronze bushings are more resistant to deformation and fracture. Like plastic, bronze bearings are strong and rust resistant. There are also self-lubricating bronze bushings on the market that you can use in a variety of applications.

You can use bronze bushings in a variety of ways for numerous applications, including food processing, injection molding, automotive machinery, earthmoving machinery, steel fabrication, and more.

Graphite Oilless Bushings

Graphite bushings are used in many applications because of their unique mechanical and physical properties. Because of their low coefficient of friction, graphite bushings help improve the efficiency, productivity and performance of spinning machinery.

Graphite, a naturally occurring oily mineral, is the best bushing material because it reduces friction without the use of additional fluids. Bronze bushings with graphite plugs are used to make graphite lubricated bearings. Graphite has the highest temperature stability, retaining its shape and structure at temperatures up to 5000°F.

Machined graphite is widely used in high temperature environments such as load capacity systems where metal lubricants and greases have deteriorated. You can use graphite bushings for countless applications including furnaces and ovens, food applications, chemical industry, automotive industry, metals, and more.

Steel Bearing Bushings

As the term implies, steel bushings are made of steel or stainless steel. These bushings are made of highly durable steel, making them the perfect tool for low-speed pivot applications. Steel bushings are produced using eco-friendly production methods that increase material yield and reduce swarf.

Brass Bearing Bushings

Brass bushings, also known as brass sleeves, are usually made of brass. Brass bushings are an integral part of the pivot shaft and help protect the shaft body from any damage caused by forces transmitted through the shaft.

You can use brass bushings for a range of applications, including electric motors, automotive engines and more. In addition, brass bushings are available in a range of sizes, as they can be applied to thin and thick walls, flanges, cylinders, flanges and more.

Aluminum Bearing Bushings

Aluminum bushings are favored for their hardness, which ensures a long service life. Initially, it was used in bicycles, but later on it was used in automobiles and currently in different kinds of machines.

Aluminum bushings can withstand significant axial and radial loads, making them a worthy candidate for the aerospace and agricultural industries. Some of their more common applications include their use in hydraulic cylinders for mounting instruments (such as drain plugs/fluid fills, liquid sight glasses or breathing elements), vessels and tanks.

Bimetallic Bearing Bushings

As the name implies, a bimetallic bushing is made of two different metals. In particular, it involves metal strips of two different metals; in most cases, the first metal is steel, while the other substance may vary from copper to aluminum or even brass. This bimetallic layer acts as an internal covering for the bushing and provides good protection against wear. They are particularly useful in applications with medium loads running at medium speeds or high loads running at low speeds.

Bushing Sleeve Selection

With soaring energy prices and rising raw material prices, production costs are generally rising.

It has become more urgent and necessary to improve competitiveness by reducing costs and increasing efficiency.

We are now offering our Optimized Bearing Sleeve Sizing Service to optimize oil-free bearings and self-lubricating plain bearings for your energy supply system free of charge, balancing performance and cost factors to secure the “best” solution.

What is the need to optimize the Sleeve sleeve type?

① Over-performance and active cost reduction. Performance-oriented customers tend to give preference to higher performance products in their initial selection process. Then, in the actual application, they may find that they have under-utilized the material. For example, they use a higher performance self-lubricating graphite bushing series where steel backed bronze bushing can meet the application requirements; in light oil application scenarios (occasional oil splash contact, not direct immersion), they generally use steel backed bronze sleeve PTFE bushing, a cost reduction of approximately 50% over the bronze backed ptfe bushing series of self-lubricating metal composite bearings. In all these cases, we can consider optimizing and actively reducing the cost without affecting the application performance.

② Same price, higher performance. Every year we add hundreds of specifications and sizes of self-lubricating bearings, some of which are structural optimization of existing products to improve performance, and some of which are new product sizes based on customer demand. If you share our engineers’ desire to “refine technology and reduce costs,” consider optimizing your self-lubricating sleeve bushing to get a higher performance product at the same price. For example, the original use of rolling bearings in some application scenarios, can be replaced with self-lubricating plain bearings, with the same price to obtain higher performance; the same metal thrust shims, the price is similar, we can meet the bend more aspects do not understand the shape of the self-lubricating bearing design applications, saving installation space of about 25%.

If this is exactly your application status, or not sure how to choose the type, welcome to contact us.

online sourcing service

Contact our sales engineers for a one-on-one selection service for custom bearings in small quantities.

If you don’t know the contact information of our sales engineers in your region, please write us an email directly.

Online Service

If you are very clear about the technical parameters required for the selection, you can fill in the size and material selection or share the drawings directly emailed to our official. Or online chat consultation. Receive our self-lubricating bearings e-catalog.

This optimized selection service is free of charge. We want to help our customers get the most cost effective solution for self-lubricating bearings, to minimize the cost while maintaining performance, or to get higher performance for the same price. The highest performance is also the cheapest, hold it together!

Bushing sleeve selection for high performance and low cost

Looking for the optimum plain bearing? We would be glad to assist you!

To determine the optimum plain bearing for your application, we would need to consider several factors, including:

- Load: The amount of weight or force that the bearing will need to support is a crucial factor in determining the best bearing material and design. The load will determine the required load capacity of the bearing, which will impact the choice of material and size.

- Speed: The speed of the application can affect the bearing material selection and design, as it will impact the required lubrication, heat dissipation, and wear resistance.

- Temperature: The operating temperature of the application is another important factor that can affect the choice of material and lubrication. High temperatures can affect the strength and wear resistance of the bearing, while low temperatures can cause the lubrication to become thick and ineffective.

- Environment: The environment in which the bearing will be used will also affect the choice of material and design. For example, bearings used in wet or corrosive environments may require materials with good corrosion resistance, while bearings used in cleanroom environments may require materials that do not generate dust or debris.

- Lubrication: The choice of lubrication is also an important factor, as it can affect the performance and lifespan of the bearing. The type and frequency of lubrication required will depend on the bearing material, design, and operating conditions.

Once we have this information, we can recommend the best material and design for your application. Some of the most commonly used materials for plain bearings include bronze, brass, stainless steel, and various types of plastics. Each material has its own strengths and weaknesses, and the choice of material will depend on the specific requirements of the application. Additionally, the design of the bearing, such as the type of bearing (i.e. bushing, flanged, thrust), as well as the clearance, length, and diameter of the bearing, will also be factors to consider in selecting the optimum plain bearing.

tech up cost down

Looking for the best-priced plain bearings from trusted brands such as Motion? If so, you’ve come to the right place. A large and diverse catalog of bearings is available, including plain bearings of all shapes and sizes.

Plain Sleeve & Flanged Bearings

Plain bearings are a reliable, cost-efficient solution for applications with multi-directional, self-aligning movements.

Self-Lubricating, Split-Type Plain Sleeve Bearings

What is a plain bearing?

Bearings can be divided into various types, such as flange bearings and plain bearings. Plain bearings are some of the simplest types of bearings and are some of the most widely used in a variety of industries. They consist of two sliding parts and are used for three different forms of motion: linear, journal, and thrust.

What are the uses of plain bearings?

Sliding bearings are most often used to help carry loads or to facilitate sliding or rotational motion within a machine. They allow different parts of the machine or equipment to operate in parallel, while also helping to reduce the level of wear on the joints and support points of the machine. They can be used in dozens of industries, including automotive and engineering.

The best plain bearings

Plain bearings are a key component of many machines and equipment and can help you find the right plain bearing for your needs, including.

Bushing Bearings – Bushing bearings are the most common type of plain bearing used today. They are housed in a housing and can be replaced when they wear out.

Integral – Integral plain bearings are actually built directly into the machine of the equipment they are used in.

Two-piece bearings – Two-piece bearings, as the name implies, are made up of two separate parts and are typically used in large-diameter applications such as crankshafts.

Buy Plain Bearings Online

If you’re looking for any type of plain bearing, from small bushing bearings to large two-piece units, this is a great place to look.

Not only do we have a large selection of plain bearings and other types of bearings, but we are also committed to keeping our prices as low as possible, providing great value for every order.

OEM Spare Parts – producing plain bushes parts, Machined bronze bushings

Real-life strategy to reach your goals.

We are confident in the quality of our sliding bearings and bushings. Discover our premium range, featuring bronze bushings, plug graphite bearings, flange bearings, and wear plates. Learn about the different types of bushings to find the ideal option for your needs.

Self-Lubricating Bronze Bearings and Guide Bushings

We continuously monitor our inventory and production processes to maintain our status as the preferred supplier. Our reputation hinges on reliability, availability, and value. A major focus in tribology is creating lubricating bearing materials that are highly wear-resistant, capable of bearing heavy loads, and self-lubricating. Tribological coatings offer design flexibility for efficient surface solutions that mitigate friction, wear, and lubrication issues. Self-lubricating brass bearing materials and surface engineering are crucial for addressing friction challenges.

Bearing bushing model selection: Our experts are ready to help you find the right solution for your specific application.

Metal / Sleeve Bearings / Bushings & Bushed Bearings

We purchased metallic bronze bushing bearings from VIIPLUS in China for shipment to Poland. They provided excellent logistics support, advising on the optimal sea shipping solution and supplying all necessary documentation. Their professional team secured the bushings in the container, and we were impressed by the quality of the packaging upon arrival, with no damage to the items. We are grateful for their service. With the arrival of the bronze bushings, VIIPLUS also provided the required documents. Their oilless bronze lube bushings are ideal for our business, saving time and money while reducing shipping costs. We appreciate their professionalism and quality parts.

Solid Bronze Bearings – Manufacturing Plain Bushings and Types of Bronze Bushings

Beautifully crafted leather products.

A bushing is a tubular bearing used in machinery with rotating or sliding components. It is also known as a friction bushing, plain bearing, cylindrical bearing, or sleeve bearing.

China OEM plain bearings and metallic bushings are available from manufacturers and suppliers. High-quality solid bronze bushings come in metric sizes and can be straight or flanged. Lubrication options include oil or grease, and solid bronze bushings can be ordered online.

Trusted Supplier of Metallic Self-Lubricating Bushings with Proven Integrity

Flange Groove Bronze Bearing, Cusn7zn4pb7 Continuously Cast Bronze, Made To Order Custom Parts Manufacturing Capability. The Most Extreme Bearings: Solid Bronze, Sintered Bronze, Wrapped Bronze, PTFE, POM Composite, and Metallic Bushings!