Leaded (Tin) Bronze SAE660, also known as C93200, is well-suited for a variety of medium-load applications.

About us

Manufacturing C93200 (SAE 660) High Lead Tin Bearing

C93200 (SAE 660) High Lead Tin Bearing Bronze is a lead-containing bronze alloy known for its excellent friction resistance, adequate strength and hardness, appropriate ductility, and superior machinability. This alloy is commonly used to manufacture bearings, bushings, light-load gears and sprockets, impellers, wear strips, plates, automotive parts, and washers. It is widely employed in pumps, cylinders, machine tools, earthmoving machinery, and various general applications. It Offers Robust Resistance To Seawater And Brine, Making It Ideal For Use In The Valve And Pump Industry.

Leaded, Phosphor And Aluminium Bronzes Bearing,

Search Our Material Alloy

C93200 high lead tin bearing bronze, SAE 660 Bronze Bushings, sae 660 bronze bushing

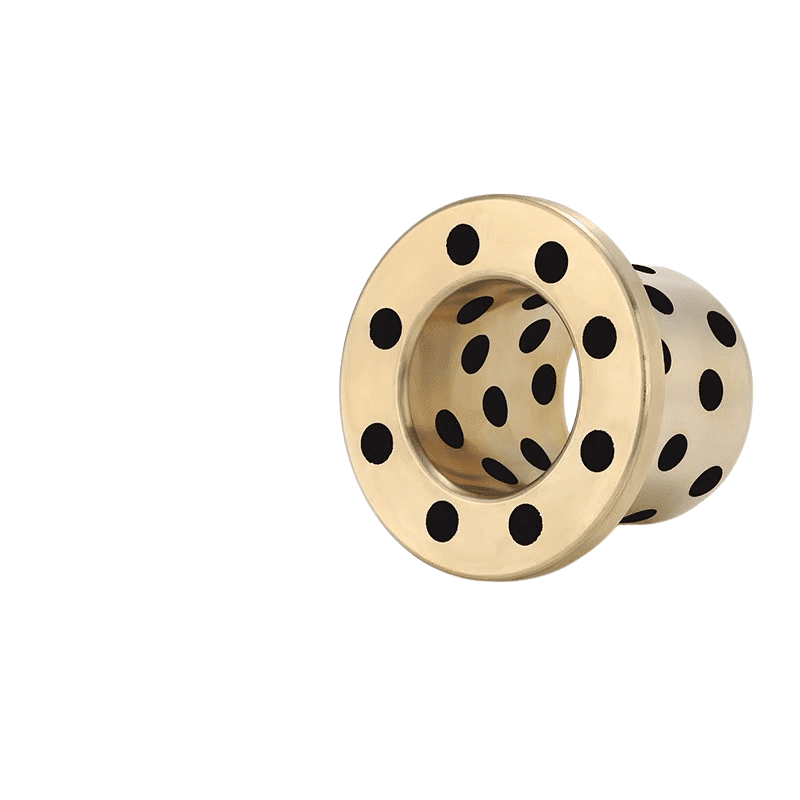

Self-lubricating graphite bushings, they are typically made from graphite-containing materials. Graphite is valued for its inherent lubricating properties, which can reduce friction and wear, allowing for operation without external lubrication. C93200 high lead tin bearing bronze, due to its own properties, can be one of the materials used to manufacture self-lubricating graphite bushings, especially in applications requiring high load and high wear resistance.

SAE 660 Bronze, also known as C93200 Bearing Bronze, is a widely used bearing alloy, commonly utilized in the manufacture of bearings, bushings, and washers. Here are some key details about SAE 660 Bronze:

Chemical Analysis: The typical chemical composition of SAE 660 bronze includes:

- Copper (Cu): 81.0% to 85.0%

- Tin (Sn): 6.3% to 7.5%

- Lead (Pb): 6.0% to 8.0%

- Zinc (Zn): 2.0% to 4.0%

SAE660 or C93200 is a leaded (tin) continuously cast bronze that sets the industry standard for light to medium bearing applications.

SAE 660 Bronze boasts excellent strength and wear resistance, good anti-friction properties, as well as commendable machinability and load-bearing capabilities. It is typically available in forms such as round, hollow, and rectangular bars, as well as bronze tubes.

The chemical composition of SAE 660 Bronze typically includes copper (Cu), tin (Sn), lead (Pb), and zinc (Zn), with varying proportions. A typical chemical analysis might include 81.0/85.0% copper, 6.3/7.5% tin, 6.0/8.0% lead, and 2.0/4.0% zinc.

The typical mechanical properties of this bronze include a minimum tensile strength of 35,000 psi, a minimum yield strength of 10,000 psi, and a minimum elongation of 10% over a 2-inch length, with a Brinell hardness ranging from 55 to 65.

Quality Leaded (Tin) Bronze SAE660 / C93200 Bronze Bushing – Shop Today!

Applications of SAE 660 Bronze are extensive and include, but are not limited to: thrust washers, pumps, bushings, mechanical components, spindle bearings, machine tool bearings, hinge bearings, roll neck bearings, crane bearings, mill bearings, press bushings, fuel pump bushings, water pump bushings, diesel engine connecting rod bushings, pump fixtures, insert bearings, hydraulic press main bushings, hydraulic press stuffing boxes, forging press connecting rod bearings, and pump impellers.

C93200 (SAE 660) bronze is produced through continuous casting, ensuring superior quality and performance. The continuous casting process ensures a uniform bronze structure in the bearings, devoid of the porosity and hard particle inclusions typically found in other casting processes.

The characteristics exhibited by Alloy 932/SAE 660 make it suitable for light-duty applications. Typical products using 932 bearing bronze as the construction material include bearings and bushings in light-load applications.

C93200 (SAE 660) bronze bars provide a high-quality, smooth machined surface, suitable for general-purpose bearings and bushings, and offer high resistance to impact, wear, and corrosion.

C93200 Leaded Tin Bronze (C932) – sae 660 bronze bushing

Experience the Strength of Self-lubricating Bearings

Leaded, Phosphor And Aluminium Bronzes Plates and Bearing,

Wear Plates – Mold and Die Products, Search Our Material Alloy

SAE 660 Bronze Graphite Bearing

The SAE 660 Bronze Graphite Bearing is a widely utilized bearing material across various industries, notable for its excellent characteristics. This alloy typically comprises 83% copper, 7% tin, 7% lead, and 3% zinc, and is also referred to as C93200 or SAE660 bearing bronze.

SAE 660 bronze, also known as C932 bronze, is a type of bronze alloy commonly used for bushings and bearings due to its excellent wear resistance and machinability.

Grade Summary: SAE 660 bronze, known as Bearing Bronze, is widely used in bushings and bearings. It is easy to machine and offers a long lifespan, which is crucial in applications where wear is a significant factor.

Applications: The primary applications for SAE 660 bronze include bushings and bearings.

Available Products: Manufacturers offer SAE 660 bronze in various forms, including round bars and round tubes.

Quality SAE 660 Bronze Lubricating Bushing- Shop Today!

SAE 660 Bronze is a high quality material that is especially suitable for the manufacture of lubricating bushing.

Customizability: This material can be customized according to different application needs to meet specific performance requirements.

USA ASTM B505, ASTM B271 C93200 (SAE 660) bearing

SAE 430B Manganese Bronze Bearing and Custom Parts for Your Projects. C86300 manganese bronze SAE 430B is a high-strength copper alloy that typically contains elements like manganese, aluminum, and iron. These components provide it with excellent wear resistance and load-bearing capabilities. When combined with graphite, it forms a self-lubricating bearing material that is highly popular in industrial applications.