High Precision C90700 Tin Bronze “SAE 65”

About us

SAE 65 Bronze Bearing Alloys

C90700 Tin Bronze, also known as “SAE 65,” conforms to ASTM B505 standards. This alloy is used for castings of bearings, bushings, and gears, and is available in continuous cast forms such as bars, tubes, and plates.

SAE 65 bronze bushings properties, applications, and key benefits:

SAE 65 bronze bushings, also known as C90700 tin bronze bearings, offer several distinct advantages compared to other types of bronze bushings.

While different bronze alloys have their specific strengths, SAE 65 bronze bushings stand out for their combination of high strength, excellent corrosion resistance, and superior wear resistance. These properties make them particularly suitable for heavy-duty and marine applications where other bronze bushings might not perform as well. However, the choice of bushing material should always be based on the specific requirements of the application, considering factors such as load, speed, environment, and maintenance needs.

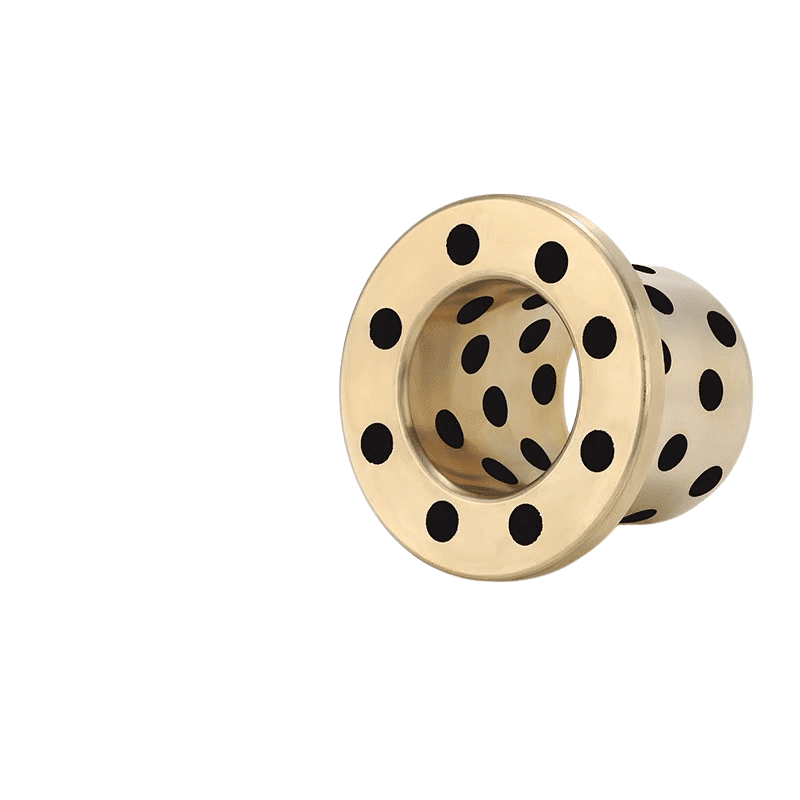

SAE 65 bronze bearings with graphite plugs

SAE 65 bronze bearings with graphite plugs offer a robust solution for high-load, low-speed applications where traditional lubrication methods are impractical. Their self-lubricating properties, combined with the mechanical strength of bronze, make them a reliable choice for demanding industrial environments.

Graphite Plugged Bearings Construction and Functionality

Graphite plugged bearings are constructed by embedding graphite plugs into the bronze material. The graphite acts as a solid lubricant, providing continuous lubrication without the need for external lubricants. This is particularly beneficial in applications where regular maintenance is challenging or impractical.

SAE 65 bronze bushings stand out due to their distinctive properties:

- Composition: Composed mainly of copper with tin and minor alloying elements.

- Strength: Offers high strength and hardness compared to other bronze alloys.

- Corrosion Resistance: Provides excellent resistance to corrosion, particularly in marine environments.

- Wear Resistance: Exhibits superior wear and fatigue resistance.

- Machinability: Moderately machinable, enabling custom fabrication.

In comparison, other bronze alloys like SAE 660 (C93200), a high-leaded tin bronze typically used for general-purpose bearings, or SAE 841, a sintered bronze designed for self-lubricating oil-impregnated bushings, and C86300 manganese bronze, noted for its high strength but differing corrosion resistance, offer varied compositions and properties.

Applications and Use Cases SAE 65 bronze bushings are especially suitable for:

- Heavy-duty applications involving high loads at low speeds.

- Marine environments, benefiting from excellent seawater corrosion resistance.

- Components like gears, worm wheels, pump components, and valve bodies.

- Use in industrial machinery within the textile and paper industries.

Alternative bronze bushings are used in different settings:

- SAE 660 is preferred for general-purpose bearings across various industries.

- SAE 841 is chosen for applications that require self-lubrication.

- C86300 is optimal for demanding tasks in steel mills, the wood pulp industry, and earth-moving machinery.

Key Advantages of SAE 65 Bronze Bushings

- Superior Strength: SAE 65 bushings provide higher strength and hardness, making them ideal for heavy-load applications.

- Excellent Corrosion Resistance: Their outstanding corrosion resistance, especially in seawater, makes them a top choice for marine applications.

- Wear and Fatigue Resistance: These bushings are highly resistant to wear and fatigue, which contributes to a longer service life under tough conditions.

- Versatility: Capable of being used in a broad range of applications, from heavy machinery to marine equipment.

- Custom Fabrication: Thanks to their moderate machinability, SAE 65 bronze can be tailored to meet specific industrial needs.

- Performance in Extreme Conditions: These bushings excel under high loads and in corrosive settings where other alloys might not perform as well.

CuSn10 Bronze Bearings

Composition and Properties:

CuSn10, commonly identified as Phosphor Bronze C51000, is composed of about 89-91% copper and 9-11% tin, with a trace of phosphorus. These elements provide high wear resistance, a low friction coefficient, and favorable thermal and electrical conductivity.

Applications:

CuSn10 bronze bearings are typically used in:

- Bearings and bushings

- Thrust washers

- Gears

- Valve components

- Sectors such as automotive, aerospace, marine, and machinery

Advantages:

- Exceptional wear resistance

- Reduced friction coefficient

- Reliable thermal stability

- Strong corrosion resistance, particularly in marine and industrial conditions

- Suitable for moderate to heavy-load applications

Each of these materials is engineered to meet specific requirements, making them indispensable in their respective roles across various industries.

| Property | C90700 Brass Bushings | CuSn10 Bronze Bearings |

|---|---|---|

| Primary Composition | Copper (88-90%), Tin, Zinc, Lead, Iron, Phosphorus | Copper (89-91%), Tin (9-11%), Phosphorus |

| Wear Resistance | Excellent | Superior |

| Corrosion Resistance | Good, especially in marine environments | Excellent, particularly in marine and industrial environments |

| Load Capacity | Suitable for heavy loads | Suitable for moderate to heavy loads |

| Applications | Bearings, gears, pump impellers, marine fittings | Bearings, bushings, thrust washers, gears |

| Thermal Stability | Moderate | Good |

| Friction Coefficient | Moderate | Low |

In summary, both C90700 brass bushings and CuSn10 bronze bearings offer excellent mechanical properties, making them suitable for various industrial applications. C90700 is more suited for heavy-duty applications with heavy loads and low speeds, while CuSn10 is preferred for applications requiring superior wear resistance and low friction, such as in automotive and aerospace industries.

Insert Graphite cuSn12 Bronze Bushing: Self Lubricating Bronze Bearings, Slide Bearing

Experience the Strength of Self-lubricating Bearings

Graphite Plugged Bearings

These bearings are ideal for applications requiring durability, reduced friction, and minimal maintenance.

Graphite plugged bearings made from SAE 65 bronze, also known as C90700 tin bronze, combine the mechanical strength of bronze with the self-lubricating properties of graphite.

SAE 65 Bronze (C90700) Characteristics

SAE 65 bronze, or C90700 tin bronze, is a high-tin bronze alloy known for its excellent wear resistance, high strength, and good corrosion resistance. It typically contains:

- Copper (Cu): 88.00 – 90.00%

- Tin (Sn): 10.00 – 12.00%

- Lead (Pb): 0.50% max

- Zinc (Zn): 0.50% max

C90700 Tin Bronze, SAE 65 Graphite Bearing

This material is employed across a range of applications, with common uses including gears and bearing bushings.

C90700 (SAE 65) Tin Bronze is a durable and robust alloy known for its excellent corrosion resistance, particularly in seawater, making it highly effective for wear and fatigue applications.

Advantages:

- Self-Lubricating: Graphite plugs provide a constant source of lubrication, reducing friction and wear.

- High Load Capacity: Suitable for heavy load applications due to the strength of the bronze and the lubricating properties of graphite.

- Corrosion Resistance: Effective in humid or mildly corrosive environments.

- Wide Temperature Range: Can operate effectively across a broad range of temperatures.

- Maintenance-Free: Reduces the need for regular maintenance and lubrication, recognized to cost savings.