Self-lubricating Crane bearing

Self-Lubricating Bearings for Cranes, Use of Oil-Lubricated Bearings in Tower Cranes, and Selection of Solid Bronze Bushings. Specializing in Crane Self-Lubricating Bearing Parts:Our extensive experience in crane self-lubricating bearing parts is unparalleled, having worked extensively with renowned crane manufacturers such as Coles Cranes, Grove Cranes, and Krupp Cranes. We bring our in-depth knowledge and expertise to every transaction, ensuring you receive the right part, at the right time, in the perfect condition.

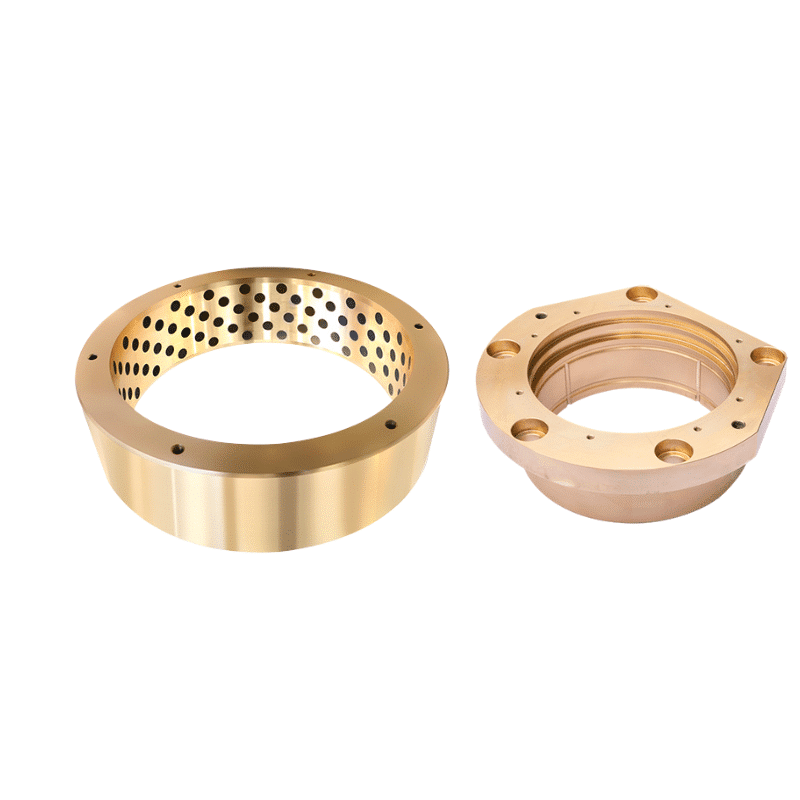

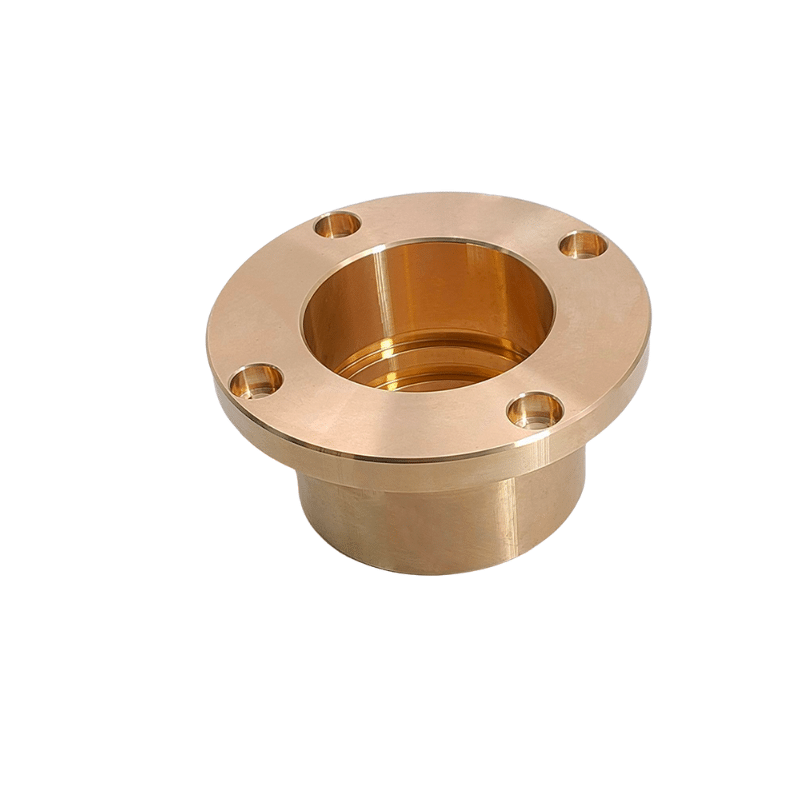

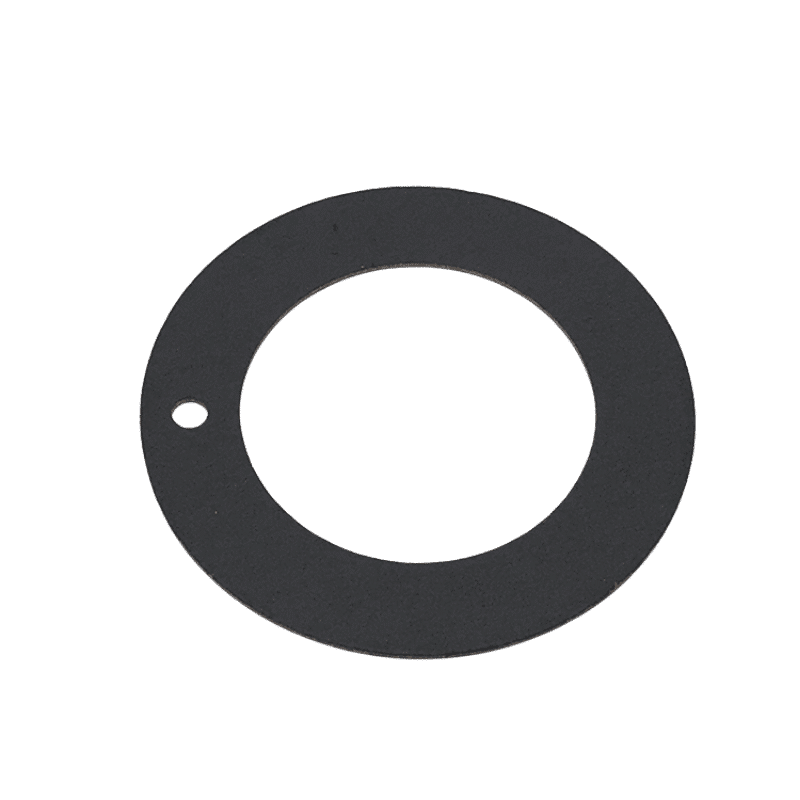

Bushings & Bearings – Sleeve, Flange, Thrust

Standard Bushing Types – Sleeve, Flange, and Thrust Bearings. Get a Quote! Custom Orders Available. Tailored Bronze Bushings Based on Your Specifications. Efficient Component Delivery Across Various Industries. Small Minimum Orders, Competitive Pricing… Explore Bronze Sleeve Bushing Specs at brnzelube.com. Supply Custom Bronze Bushings for Crane Parts! Includes Bearings for Port Machinery, Self-Lubricating Bearings, Plain Bearings, and Oil-Free Bushings!

CUSN8 wrapped tin bronze bushings are self-lubricating bearings made from tin bronze, known for their high load-bearing capacity and wear resistance, making them ideal for heavy-duty applications like cranes. The wrapped design protects the tin bronze from contamination, significantly extending its lifespan. Their self-lubricating feature minimizes maintenance, reducing downtime and upkeep costs.

In crane applications, CUSN8 wrapped tin bronze bushings are utilized in components like the boom, mast, and trolley, ensuring smooth operation under high loads and harsh conditions. They resist high temperatures and corrosion, making them suitable for outdoor use. CUSN8 wrapped tin bronze bushings are an excellent choice for crane applications, providing dependable, low-maintenance performance in demanding environments.

“Offshore Crane Bearings – Reliable Bronze Bushings from Your Trusted Global Supplier”

Cranepart is a premier global supplier of crane bronze bushings. We understand the urgency in the crane industry, so once you place an order, your part is already on its way.

We provide solid bronze bushings for port and container handling equipment that are resistant to shock, wear, and corrosion, making them perfect for industrial applications. Our selection includes custom sleeve and flanged bronze bushings designed specifically for crane suspension.

Our products feature self-lubricating bronze bushes and bimetal bearings that lower maintenance requirements with their dry running capabilities. For easy installation and dependable performance in dry conditions, contact us about our self-lubricating bearing solutions today.

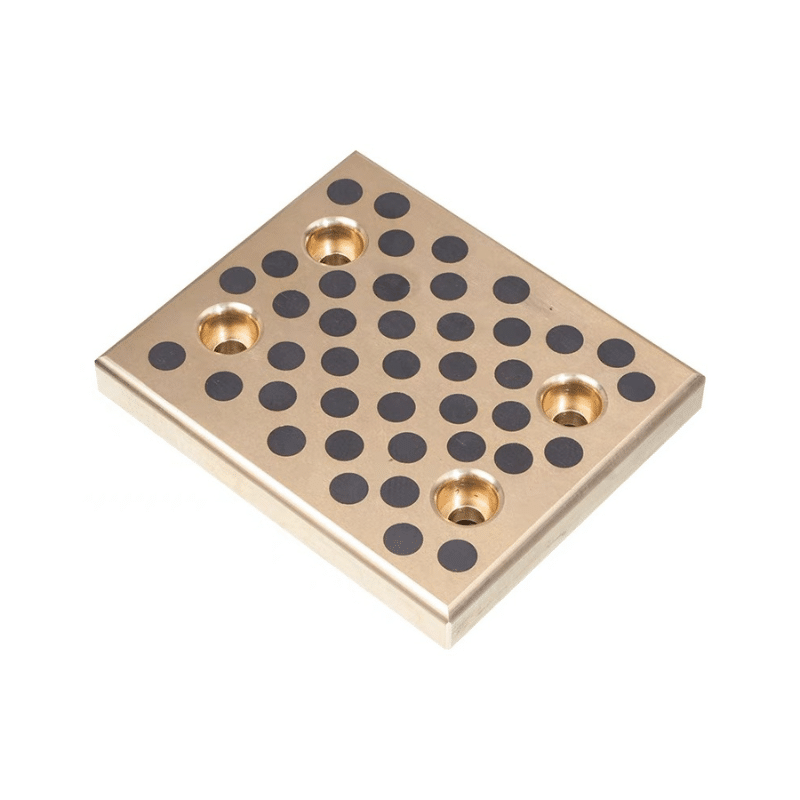

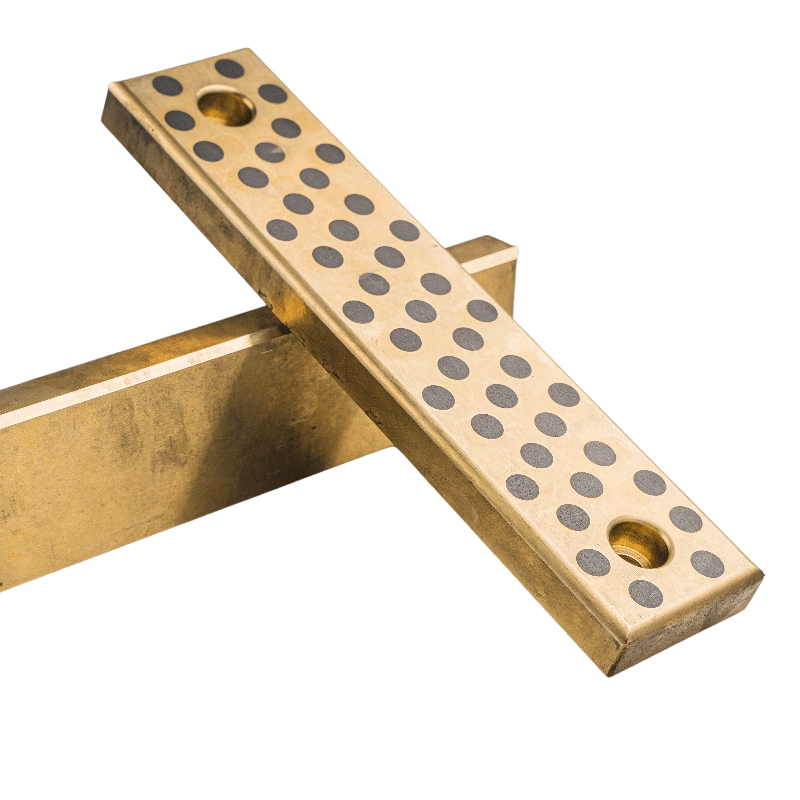

The CuAl10Fe5Ni5 bronze plain bearing and aluminium bronze slide plate block are widely used in crane applications, particularly for ship cranes. These lubrication-free bearings minimize maintenance costs while withstanding high loads, offering exceptional durability and reliability under extreme conditions. They provide superior corrosion and abrasion resistance, even in the toughest environments.

In crane systems such as Ship-to-Shore (STS) cranes, Rubber Tyred Gantry (RTG) cranes, and Rail-Mounted Gantry (RMG) cranes, parts like the wheel and axle units are exposed to dirt, dust, salt mist, high temperatures, and extreme cold. These harsh conditions often result in premature wear, especially in components like the steering axle bearings of the STS crane, which must support wheels and axles that move tons of cargo along tracks. This wear leads to costly downtime, which is a significant concern for ports that need to maintain high productivity and meet increasing competition.

To address this, VIIPLUS has introduced an alternative to traditional aluminium alloy materials in the form of bronze-based self-lubricating bearings. These bearings, with their flanged designs and embedded graphite lubrication, help reduce the issues related to traditional steel bearings, such as corrosion, fast wear, and the need for regular lubrication. This innovation helps lower maintenance costs and increase the lifespan of cranes, ultimately improving port productivity.

Annual global maintenance costs for lubrication-related issues are extremely high. Despite lubrication efforts, failures still occur due to insufficient lubrication. The use of lubrication-free sliding bearing technology can reduce maintenance costs, conserve labor resources, and extend crane service life—especially important in industries facing skilled labor shortages.

While most lubrication-free bearings are made from injection-molded engineering plastics, these materials may not provide sufficient mechanical stability for heavy-duty applications like crane chassis bearings. For such high-pressure applications, metal aluminium bronze bearings with embedded solid lubricants offer a much more robust solution. These bearings provide high durability and low wear, making them ideal for demanding environments such as those in STS cranes.

By using solid lubricants, these bronze bearings also experience reduced wear, further enhancing their performance and reliability in extreme conditions. The addition of solid lubricants ensures that the bearing operates with minimal friction, increasing its operational lifespan and reducing the need for frequent replacements.

In summary, the use of aluminium bronze bearings with embedded solid lubricants in heavy-duty applications like cranes significantly improves performance, reduces maintenance costs, and increases the overall efficiency of port operations.

Self-Lubricating Bearings for Machinery & Heavy Equipment

At our company, we specialize in manufacturing self-lubricating bearings that are perfectly tailored to meet the needs of your crane and heavy equipment operations.

Self-Lubricating Bronze Bushings for Offshore Crane Bearings

Self-lubricating bronze bushings play a crucial role in ensuring the smooth operation and long lifespan of heavy-duty machinery, particularly in the offshore industry. These bearings are engineered to endure the tough challenges of offshore environments, including high load conditions, corrosive sea air, and constant exposure to saltwater.

As the name implies, self-lubricating bronze bushings reduce friction between moving parts without requiring regular external lubrication. This is achieved by embedding lubricating materials within the bearing itself, significantly decreasing maintenance needs while ensuring reliable, efficient performance in conditions where traditional lubrication would be difficult or impractical.

Crane Bearings in the Offshore Industry

Offshore cranes are vital for the operation of oil rigs, drilling platforms, and wind farms, handling the lifting, moving, and assembling of heavy equipment. These cranes must endure intense loads, and the bearings they use need to be robust enough to withstand high levels of strain. Additionally, given the extreme environmental conditions found at sea, bearings must offer resistance to corrosion, wear, and tear.

Self-lubricating bronze bushings are ideal for these demanding applications. Their high load capacity, excellent wear resistance, and inherent self-lubricating properties make them a practical and efficient choice for crane bearings used in offshore operations.

Key Advantages of Self-Lubricating Bronze Bushings

The benefits of using self-lubricating bronze bushings in offshore crane bearings are numerous:

- Reduced Maintenance: Their self-lubricating nature minimizes the need for routine maintenance, saving both time and resources.

- High Load Capacity: Bronze bushings can handle heavy loads, making them perfect for offshore cranes that frequently lift large, heavy objects.

- Corrosion Resistance: Bronze is naturally resistant to corrosion, which is crucial in offshore environments where machinery is regularly exposed to salty seawater and air.

- Long Service Life: Thanks to their wear resistance and self-lubricating properties, these bushings typically last longer than other bearing materials.

- Environmental Resistance: Self-lubricating bronze bushings can perform well under extreme temperature variations, from freezing cold oceans to the heat produced by heavy machinery.

In summary, self-lubricating bronze bushings offer a durable, reliable, and low-maintenance solution for crane bearings in the offshore industry, ensuring efficient and continuous operation even in the most challenging environments.

Self-Lubricating Bronze Bearings: A Reliable Solution for Crane Packing Companies

For over a century, Crane Packing Company has been a trusted supplier of crane packing solutions, known for their innovative products that ensure smooth crane operations. Bearings, as one of the most crucial components in cranes, must be durable and capable of withstanding harsh operational conditions.

Traditionally, bronze bearings were widely used in cranes due to their strength and durability. However, these bearings require regular maintenance and lubrication, which can be both time-consuming and costly, leading to increased downtime and reduced productivity.

To solve this problem, Crane Packing Company has introduced self-lubricating bronze bearings, eliminating the need for regular lubrication and maintenance. These bearings are designed to function without any external lubrication, making them ideal for applications where regular upkeep is difficult or impractical.

These self-lubricating bronze bearings are crafted from a special bronze alloy containing solid lubricants such as graphite or molybdenum disulfide. These lubricants are evenly distributed throughout the bearing material, providing a low-friction surface that reduces wear and tear, thus eliminating the need for external lubrication.

Benefits of Self-Lubricating Bronze Bearings

- No Maintenance Required: With no need for regular lubrication, these bearings reduce downtime, boosting productivity.

- Corrosion Resistance: These bearings are resistant to corrosion, making them suitable for harsh operating environments.

- High Durability: Their solid lubricants ensure a long service life, even under heavy loads and shock loads.

- Improved Productivity: The extended lifespan and reduced maintenance needs help keep cranes operational, improving port and facility efficiency.

Crane Packing Company offers a variety of self-lubricating bronze bearings in different sizes and configurations, with custom designs available to meet specific requirements. These bearings are a perfect solution for companies looking to increase crane performance and reliability while reducing maintenance costs.

Tribological Properties of Self-Lubricating Bearings: A Game-Changer for Industrial Applications

In machinery and heavy equipment, traditional bearings often require regular lubrication to prevent friction and wear, leading to increased downtime and operational costs. Self-lubricating bearings, with their superior tribological properties, eliminate the need for external lubrication and significantly reduce maintenance demands.

Tribology, the study of friction, wear, and lubrication, plays a key role in determining the suitability of materials for specific applications. Self-lubricating bearings are designed to have low coefficients of friction, reducing wear, improving energy efficiency, and extending the equipment’s lifespan. These bearings are also highly resistant to abrasion, corrosion, and chemical degradation, making them ideal for harsh environments.

Benefits of Self-Lubricating Bearings

- Reduced Maintenance: No need for external lubrication reduces maintenance efforts and associated costs.

- Energy Efficiency: The low friction of these bearings improves energy efficiency, reducing operational costs and enhancing sustainability.

- Environmental Resistance: Self-lubricating bearings can withstand a wide range of temperatures, making them suitable for industries like mining, construction, and agriculture.

In summary, self-lubricating bearings represent a breakthrough in reducing maintenance requirements and improving machinery reliability. Their low-maintenance nature and ability to operate in extreme conditions make them an ideal solution for a variety of industrial applications.

Bronze Bearings with Solid Graphite Lubricants: An Innovative Solution

Traditional bronze bearings are renowned for their durability, but they require external lubrication. To address this challenge, an innovative solution—bronze bearings with solid graphite lubricants—has been introduced. These bearings integrate solid graphite lubricants, which are compressed into circular recesses within the bearing, offering several advantages over traditional bearings.

Key Advantages of Solid Graphite Lubricants

- Low Friction: Solid graphite reduces friction, extending the bearing’s lifespan and improving efficiency.

- High Temperature Resistance: These bearings withstand high temperatures and harsh environments, making them suitable for demanding machinery applications.

- Minimal Maintenance: The solid graphite lubricant ensures continuous lubrication, even under heavy loads, reducing maintenance requirements.

These bearings are ideal for applications where traditional lubrication is difficult or impractical, and they provide a more environmentally friendly alternative to oil or grease-lubricated bearings.

Custom Engineering & Testing

Our engineers bring a wealth of knowledge in metallurgical, mechanical, and structural disciplines. We offer a wide range of engineering services, from alloy and material selection to prototype and production testing. Our comprehensive testing includes friction coefficient and wear testing, performed in-house or by independent laboratories. Additionally, we provide AutoCAD drafting, bearing design, consulting, and on-site engineering services to ensure the perfect solution for your needs.

Metal Bushing for Extended Crane Service Life

Ports & Cranes Bearings – Cost-effective solutions at excellent prices! Discover Crane Metal Bearings and Crane Duty Bimetal Bearings. Explore our high-tech bushing for the crane industry at bronzlube.com. Focus: Sliding Bearings – a reliable, quiet option for your equipment. Our self-lubricating bearings are ideal for cranes. Flange bronze graphite bearing bushings are widely utilized in cranes and heavy machinery. Made from a bronze alloy with a graphite layer to minimize friction and wear, the flange adds support and stability. When preparing a crane for transport, protecting the flange bronze graphite bearing bushings is crucial. This involves carefully disassembling the crane, removing the bushings, and securely packaging them with protective materials like foam or bubble wrap. Ensure containers are clearly labeled to avoid confusion during reassembly, and store the bushings in a dry, clean environment to prevent corrosion. Proper packaging and storage are essential for the crane’s safe and efficient operation post-transport.

about the company

Bushing Application Examples, Tested & Proven!

Our metal and bimetal bearings are reliable for many years in crane installations, backed by a Quality Guarantee. We offer custom-made special alloy bronze sleeve bushings along with the industry’s largest variety of standard bronze sleeve bushings. Our crane bushings support mechanical rotation, reduce friction, and ensure accuracy. We provide a wide selection of self-lubricating bearings at competitive prices, with fast shipping from Allied. We also handle exports and offer easy payment options, along with visual bushing finders. Types include Metal, Bimetal, Wrapped Bronze, and Solid Bronze Bushings. From Sleeve Bearings to Architecture to Marine Applications, We Have the Bronze You Need. Our support team is always ready to assist you with any questions or queries regarding your spare parts requirements, ensuring you find the exact part you are looking for.

Cranes in port facilities must perform exceptionally under heavy loads, prolonged use, and diverse weather conditions. Our bushing and metal bearings are designed for just this purpose, having demonstrated their corrosion resistance, maintenance-free qualities, and long service life in various ports for years. They are suitable for applications involving bimetal bearings, which are made from high-quality low-carbon steel combined with low-friction copper alloys (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni). These bearings can be customized with various oil grooves and holes to meet operational requirements.

Bimetal Bearing Long Service life – 80 % less installation space

Product Quality Index

Energy Generation