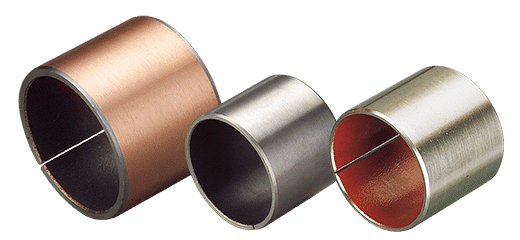

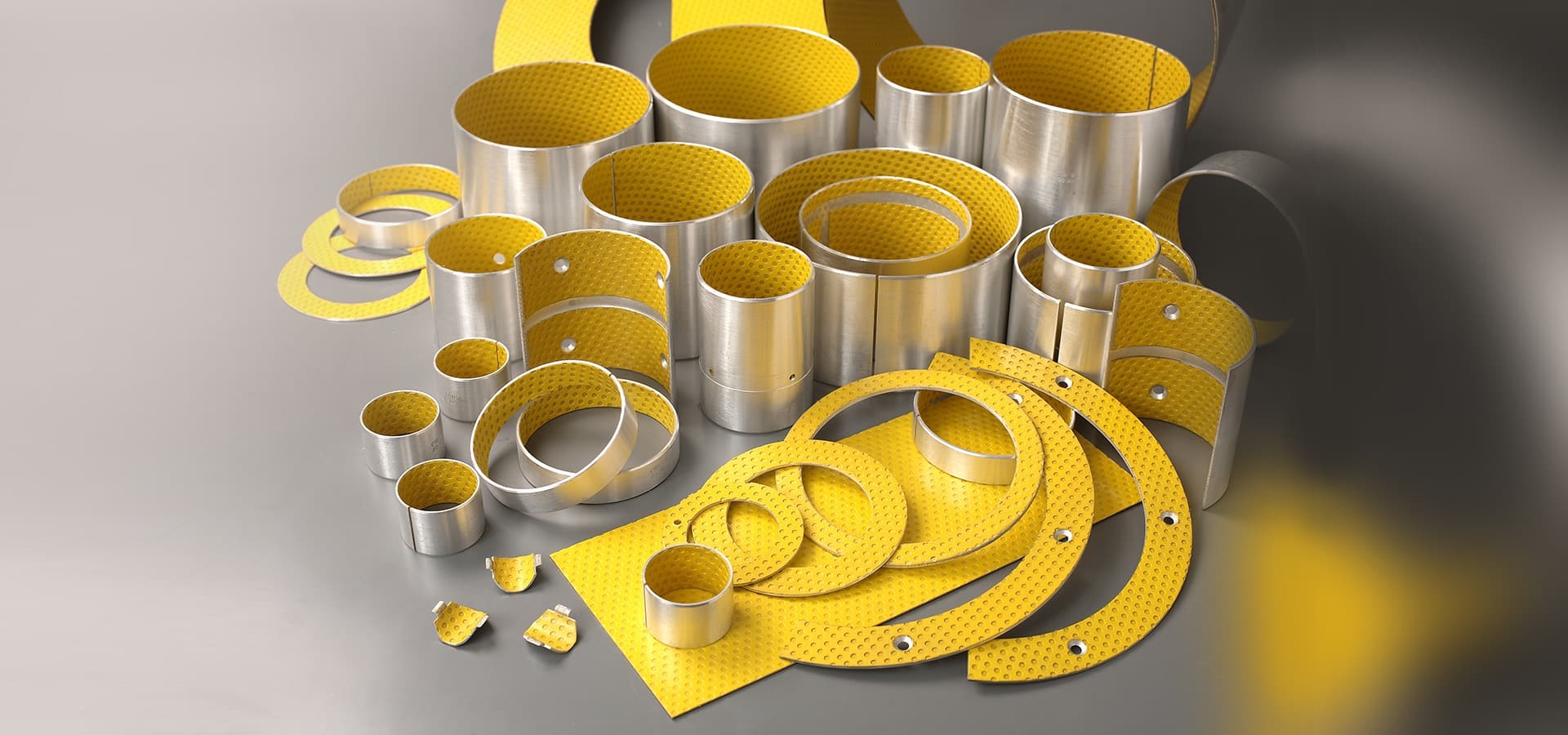

Metal-Polymer Sliding Bearing Self-Lubricated Bushing

Sliding bushing save costs and improve your technology

Metal composite self-lubricating material with high quality low carbon steel as the substrate, the middle sintered spherical porous copper powder layer, the surface tied with PTFE-based wear-resistant lubricating material as the working layer of the bearing, this material has excellent mechanical load-bearing capacity, the middle copper powder layer can not only timely transfer the heat generated during the operation of the bearing, but also improve the bonding strength of the plastic layer and the substrate. PTFE design is suitable for completely dry A wide range of materials have been developed to meet the requirements of lubrication, friction coefficient and durability. Our PTFE metal composites provide the best performance over the widest range of loads, speeds and temperatures, with or without external lubrication.

Sliding Bushing Configuration

Self-lubricating Bronze Bushing PTFE Material Solution

We are a professional supplier of export self-lubricating bronze bushing, sliding bushing PTFE material and so on. We focus on offering fair and competitive prices, together with high quality service and packaged with customer-oriented solutions. These sliding bushings are made of bronze backed with bronze powder PTFE/Pb, are dry bushings.

Projects

Make your space useful and different

Experience of over 10 years of successful projects on creating unique and modern interior designs all over the world.

Learn More

Custom Sliding Bushing Design

Metal-Polymer Composite Self-lubricating Bushing Material:

PTFE Sliding Bushings: These bushings are designed for dry operation, featuring a low friction coefficient, reduced wear, and enhanced sliding characteristics. They create a protective transfer film on the mating metal surface, making them ideal for both rotary and oscillating movements.

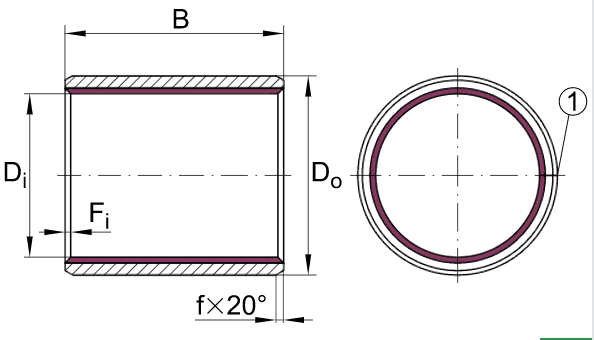

Composition of Sliding Bushing PTFE Material:

A bronze backing that offers robust load-bearing capabilities and excellent heat dissipation, along with superior corrosion resistance.

A porous bronze sinter layer, measuring 0.20-0.35mm, maximizes thermal conductivity away from the bushing’s surface and acts as a repository for the PTFE/lead blend.

A top layer of PTFE and lead, ranging from 0.01 to 0.03mm, produces an exceptional initial transfer film. This film coats the mating surfaces of the hub assembly, establishing a durable oxide-type lubricating film.

Maintenance-free

The promise of order ptfe sliding bushings high quality, meet your requirement.

PTFE Material

Ptfe slide bearing, Small minimum order value & quantity, fast delivery.

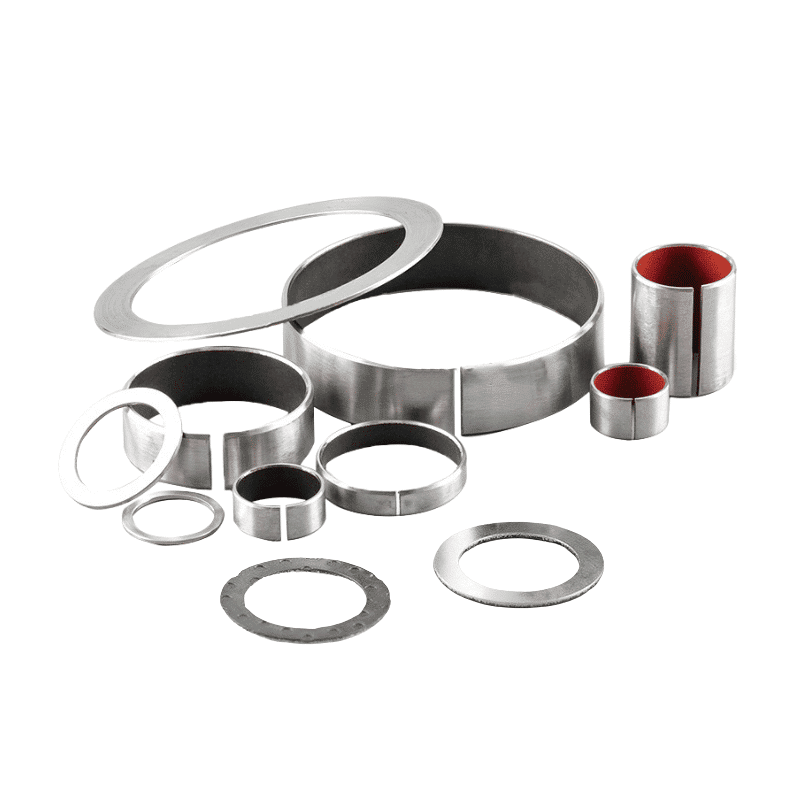

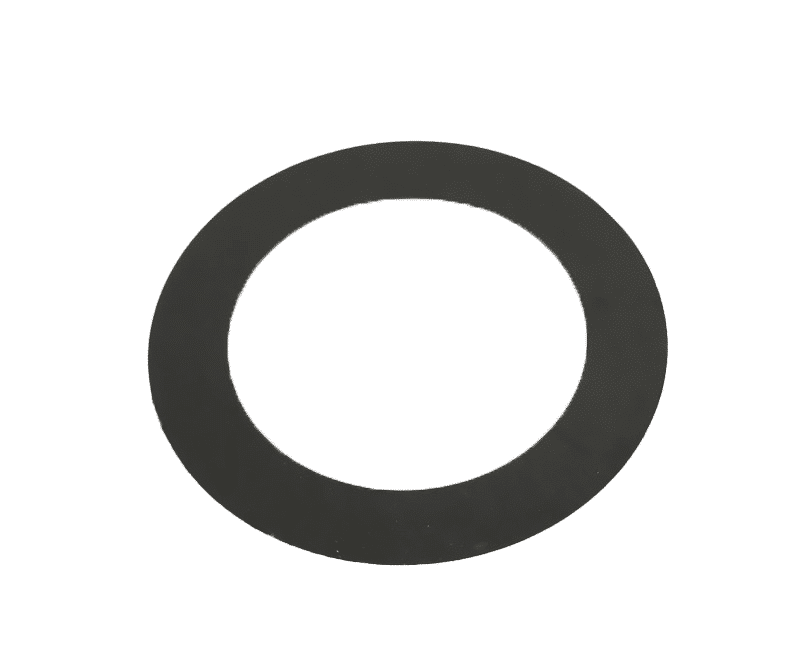

PTFE Thrust Bearing & Washer

Beautifully crafted leather products.

Slip sleeve with PTFE composite, flange bearing and thrust washer supplier. Thrust plain bearing with PTFE layer. Thrust ring plain bearing, POM composite washer. These bushings are suitable for rotary, oscillating and linear movements. The product range includes bushings, flanged bushings, thrust rings and strips. The different materials are designed for different applications.

Axial sliding washer with PTFE composite layer on a base of steel plate and sintered bronze self-lubricating (dry friction), maintenance-free. suitable for relatively slow rotational and oscillatory movements. Operating temperature range: -200 °C to +280 °C. The picture is for illustration only! No liability is accepted for the information provided! Manufacturer

Inch & Metric PTFE Bushing Bearings

Dry plain bearings have a common structure consisting of a steel backing bonded to a porous sintered bronze layer impregnated and covered with PTFE lined bearing material. Dry plain bearings take advantage of PTFE’s excellent dry bearing properties and combine them with strength, stability and good wear resistance, excellent thermal conductivity and low thermal expansion. Our PTFE-based metal-polymer materials offer exceptionally low friction and high wear. Superior PTFE and thermoplastic-based metal-polymer bearings. Contact us for a free quote! Bushing material applications : Dry plain bearings meet the requirements for long life and trouble-free performance, with or without lubrication, in a variety of equipment such as hydraulic systems, valves, automotive, agriculture, material handling, etc. Dry plain bearings are suitable for

- Rotating

- oscillating

- Reciprocating motion

- Sliding motion

Features of a composite bearing bushing

Lubrication-free operation: These dry plain bearings are designed to function without the need for lubrication.

Exceptional Load Capacity: Capable of handling both high static and dynamic loads effectively.

Wide Operating Temperature Range: Suitable for use in extreme temperatures, ranging from a minimum of -200°C (-328°F) to a maximum of 280°C (536°F).

Advanced Design: Incorporates dry sliding bearing and bushing technology, ensuring oilless and self-lubricating capabilities, ideal for a variety of applications where Sliding Bearings or Bushings are required.

POM Sliding Bushings

Dry slide bearing, POM lined Bushing, View Our Sliding bushes Products. Contact Us Today. High-end Production Lines. Extreme Stable & Durable. Long-term Wear Resistance. A small amount of lubricant is required for these bushings (All greases or oils designed for lubricating plain bearings). The POM bushings have good self-lubricating effect, Bushing Manufacturer.

Special sliding bushings dimensions and imperial sizes are available on request.

Standard sized parts for a wide range of sliding bushings products with basic dimensions (inner diameter, outer diameter, length, etc.) according to international standards are available.

- Straight Sliding Bushings

- Flanged Sliding Bushings

- Thrust Washer Sliding Bushings

- Strip Sliding Bushings

- Customized Sliding Bushings

Exacting standards of product quality and a strong reliability in service and high quality performance.

We are experts in self-lubricating bronze bushings. Bronze PTFE Bushing Characteristics: Good wear and friction performance over a wide range of load, speed and temperature conditions without lubrication. Also can perform well with lubrication.

*Bronze based PTFE sliding bushing is widely used in steel metallurgy industry, cement grouting pumps and scrow conveyers of machine, marine and offshore equipment, dyeing machinery and so on.

The Self-lubricating Bushings that can do more – Custom Bearings Size Options

Maintenance-free, Sliding bearings – Bushings – Safe & On Time Delivery

Leave your self-lubricating bronze bearings & multi layer bushings goods and let us handle the rest.

Online Support: We are always here to support your business. Browse our Range of Plain Bearings Materials!

Explore More PTFE Bushing Dry Slide Bearings from china

We supply PTFE sliding bearing & oilless axial washer tailored to your individual needs.

Wrapped sliding bearing, bronze/PTFE sliding layer, DIN 1494/ISO 3547, Maintenance-free

Always tested. Always proven. Global website www.bronzelube.com PTFE Sliding Bearing Supplier – in China, PTFE Bearings – High Performance Metal Bushing. High Quality Metal Bushing Part Machining. Custom & Standard Components. Call Today! Large Material Inventory. Custom Bearings/Bushings. Custom Sliding Bearings. CNC Machining Services. CNC Manufacturing. Custom CNC Machining.

Saves You Time & Money In Bushing Research, Design & Production Costs.

Bearings are an essential component in many machines and equipment, ensuring smooth and efficient operation. Bronze has long been a popular material for bearings, thanks to its excellent wear resistance, high strength, and good thermal conductivity. However, bronze alone may not always provide the necessary performance or durability. That’s where intermediate layers and coatings come in, and one such combination that has proven highly effective is bronze intermediate layer sintered bronze sliding layer PTFE.

Bronze intermediate layer sintered bronze sliding layer PTFE bearings offer many benefits over traditional bronze bearings. The intermediate layer of bronze provides excellent strength and resistance to wear, while the sintered bronze sliding layer offers high porosity and excellent lubrication properties. PTFE (polytetrafluoroethylene), is a highly durable and low-friction material that reduces wear and tear on the bearing.

The bronze intermediate layer provides the necessary mechanical strength to withstand high loads and stresses, while the sintered bronze sliding layer ensures excellent lubrication and low friction, reducing wear and extending the life of the bearing. PTFE is highly resistant to heat, chemicals, and corrosion, making it an ideal material for use in bearings that are exposed to harsh environments.

Bronze intermediate layer sintered bronze sliding layer PTFE bearings are used in a wide range of applications, including in the automotive, aerospace, and industrial sectors. They are commonly used in applications that require high load capacities, low friction, and resistance to wear and corrosion. They are also used in applications that require low noise and vibration, such as in medical equipment and electronic devices.

One of the significant advantages of bronze intermediate layer sintered bronze sliding layer PTFE bearings is their ability to operate at high speeds without overheating or seizing up. The excellent lubrication properties of the sintered bronze and PTFE sliding layer ensure that the bearing stays cool and operates smoothly, even at high speeds.

In addition to their excellent performance, bronze intermediate layer sintered bronze sliding layer PTFE bearings are also easy to install and maintain. They require little to no external lubrication, reducing maintenance costs and downtime. They are also highly resistant to corrosion and wear, reducing the need for frequent replacements.

In conclusion, bronze intermediate layer sintered bronze sliding layer PTFE bearings offer a winning combination of strength, durability, and lubrication properties. They are highly effective in applications that require high load capacities, low friction, and resistance to wear and corrosion. They are also easy to install and maintain, reducing downtime and maintenance costs. When selecting a bearing material, it’s essential to consider the specific application requirements to ensure that the material will perform well under the intended conditions.

Oilless Bushing with PTFE coating.

PTFE slip sleeves are suitable for high loads with a requirement for maintenance-free operation. Operating temperature range 200 – 250C. Shaft tolerance f6 – h7. Tolerance of housing H7. Bushing Selection,Custom Design, Online Sourcing, Save Cost, Bushing Production

Thrust ring, PTFE composite bushing washer Manufacturer:

Material: PTFE composite bushing and ring washer

Flange bushing Request individual offer

Product description

Slip sleeves made of metal and bimetal material

Dry sliding bushings made of three-layer composite bushing. Suitable for rotary and rocking movements under radial load and for maintenance-free operation in confined spaces. No relubrication required.

Slip sleeves made of M

Dry sliding bushings made of three-layer composite M. Suitable for rotary and rocking movements as well as for linear movements under radial load. Proven in maintenance-free operation in space-constrained fits and in fits with un-guaranteed alignment, edge loading or heavy contamination.

slip sleeves

Dry sliding bushings made from a composite of binder and coiled fibre. Suitable for rotary and linear movements under relatively heavy loads without any maintenance, especially where alternating, impact or rocking loads are present, where misalignment may lead to severe edge loading or shaft deflection, or where chemical resistance is required.

Slip flange bushings made of bimetal bearing bushing

Dry sliding bushings made of three-layer POM composite with a flange on one side. Suitable for rotary and rocking movements under radial load and simultaneously applied unidirectional axial load. They are used in maintenance-free applications and in space-constrained housings. They do not require relubrication.

Axial slip rings made of metal polymer bearing bushing material

Axial slip rings made of three-layer bimetal composite. Suitable for axial, confined space and maintenance-free operation. No relubrication required.

Axial slip rings made of M material

Axial slip rings made of three-layer composite M. Suitable for axial, space-limited fits in maintenance-free operation where misalignment or slight contamination occurs. Requires initial lubrication.

B material slide belts

Three-layer bimetal material composite slip belts. They can be bent, pressed, cut and otherwise modified to suit the specific application. They have proven themselves in space-constrained, maintenance-free fits for sliding movements of all types. They do not require relubrication.

Sliding belts made of PTFE or POM

Three-layer composite slide belts in PTFE material. They can be bent, pressed, cut and otherwise modified to suit the application. They have proven themselves in space-constrained, maintenance-free fits for sliding movements of all types. Particularly suitable for fits requiring additional machining in moderate to heavy contamination

Thrust plain bearing with PTFE coating and AXIAL SLIP RING.

The PTFE oilless bearing is made of a metal strip with a PTFE layer. The bearings are mainly designed for rocking motion, for fits with frequent repetitive starting or where dry friction without lubricant is required. The bearings are resistant to most media. The thin layer that forms the sliding surface needs to be protected during assembly. Operating temperature -200°C to 250°C. Shaft tolerance f6 – f7. Tolerance of the body H7.

Also available in special versions: stainless steel base, bronze base, lead-free sliding layer.

Applications: lever jacks, pneumatic cylinders, textile machines ……….

Dry PTFE sliding bearing bushing

Dry sliding bearing & plain bushes consist of a unique combination of materials, including a carbon steel backing plate, a sintered bronze interlayer and a self-lubricating polytetrafluoroethylene (PTFE) sliding liner consisting of a sintered bronze interlayer and a self-lubricating PTFE sliding liner. This combination provides a resilient, centralized unit that prevents metal-to-metal contact in dynamic, high-load applications. Dry sliding bearings also offer good wear resistance, excellent thermal conductivity, low thermal expansion, and low friction over a wide range of load speeds and temperatures. They are suitable for reciprocating, oscillating, rotating, and sliding movements. PTFE Bushing Design, Depending on your unique application, we offer a range of dry plain bearing materials and design options to meet your performance requirements. The most common designs are made of carbon steel, sintered bronze, and filled PTFE or PTF. PTFE or loaded PTFE. Dry plain bearings are used in a wide variety of industries, including:

- Agriculture

- Hydraulic systems and valves

- Automotive

- Material handling

- Vehicles

- Outdoor Equipment

- Medical Equipment

Call us

24/7 emergency callout