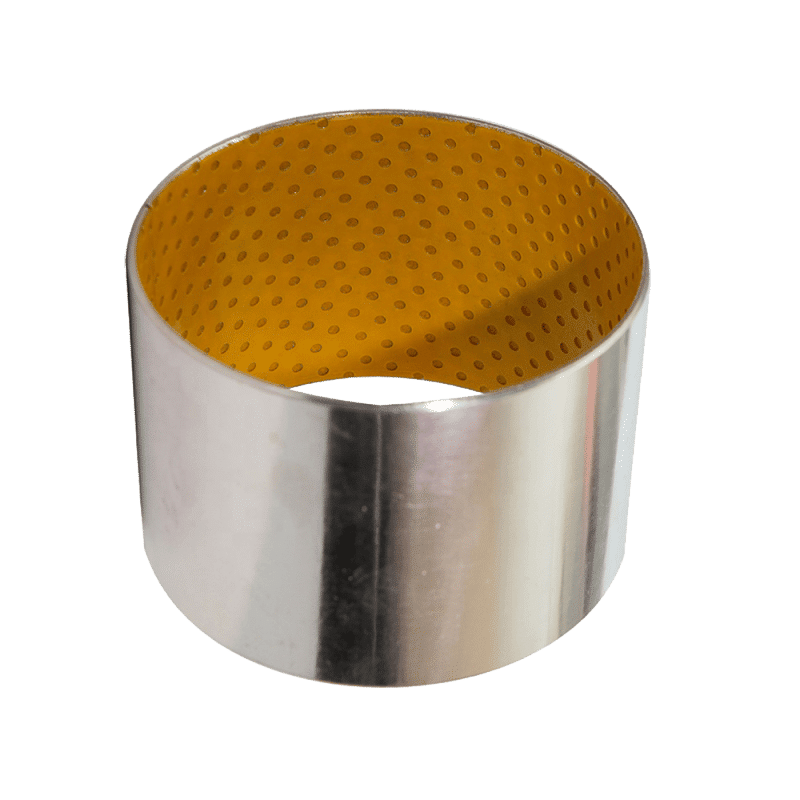

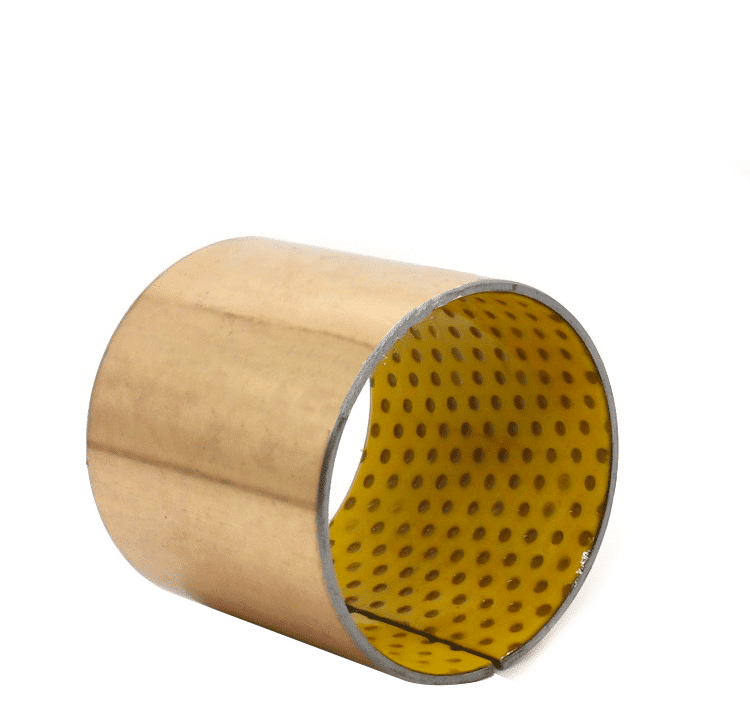

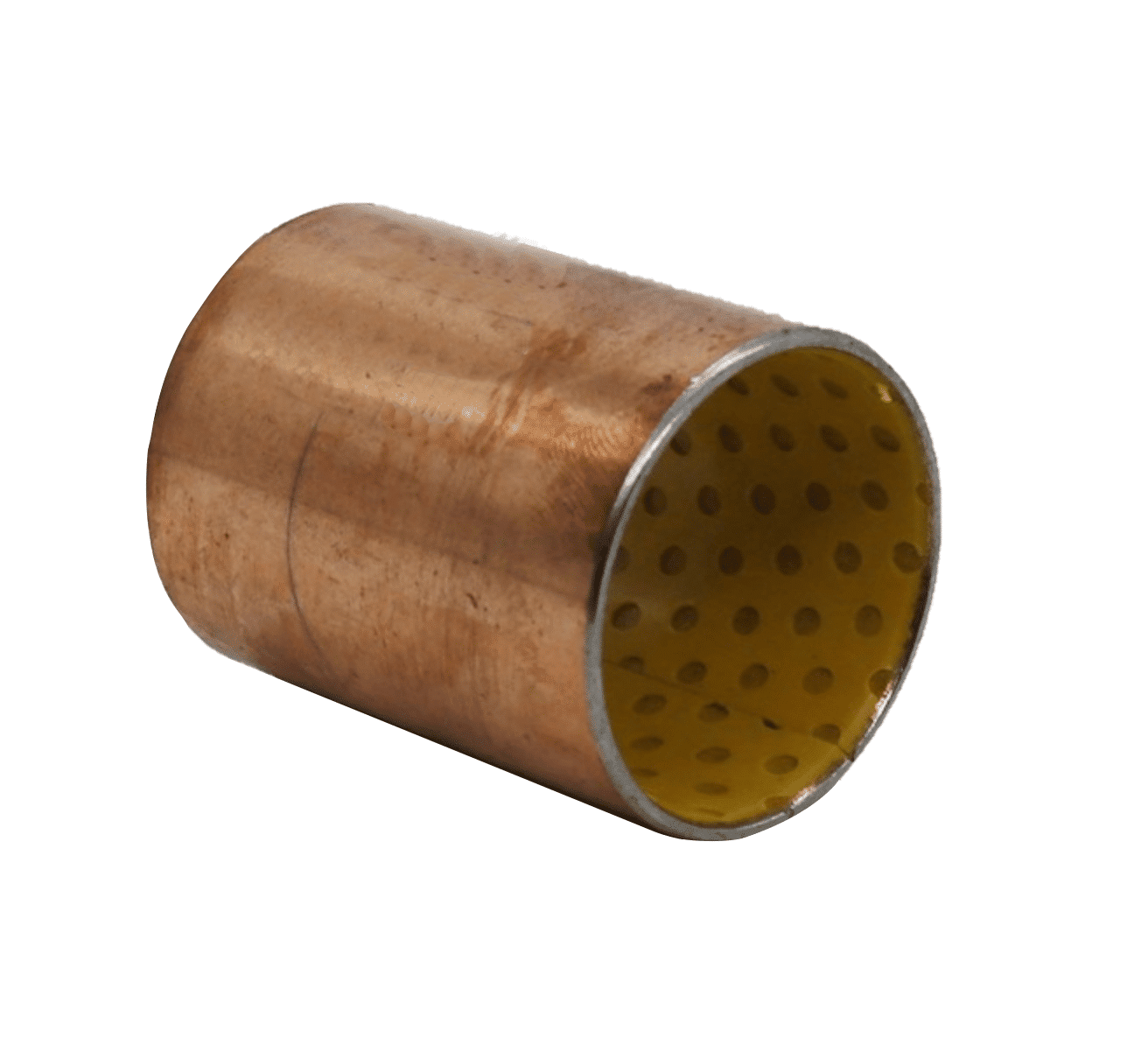

POM SLIDING BUSHING

Metal-Polymer Plain Bearings Grease Lubricated

Composite-bushings-sleeve-bearings, Large Customized Diameter Composite Bushings Now Available. POM (Polyoxymethylene) composite bushings, also recognized as acetal bushings, are designed from a composite material featuring POM as the primary sliding layer. These cylindrical bushings are engineered to offer a durable, low-friction surface capable of enduring substantial loads, minimizing friction, and wear. They are compatible with grease or oil lubrication and find utility across a broad spectrum of applications. These bushing type effectively fills the gap between fully lubricated and dry sliding bushings. WE offers a wide range of straight POM sliding composite bushings.

Composite sliding bushing self lubricating bearing

Key Benefits and Characteristics:

- Low Friction: The low friction coefficient of POM minimizes resistance during sliding actions, improving overall performance.

- High Load Capacity: Engineered for heavy-duty use, these bushings are adept at bearing significant loads.

- High Sliding Velocity: Capable of sustaining elevated sliding velocities, ensuring consistent performance.

- Low Maintenance: Typically pre-lubricated, POM composite bushings require minimal lubrication and are low maintenance.

- Excellent Wear Resistance: The wear-resistant properties of POM enhance the longevity of these bushings.

- Dimensional Stability: POM’s stable dimensions under stress and varying environmental conditions guarantee dependable functionality.

- Sliding layer POM with or without lubricant indents for machining

- Porous Bronze Sinter

- Carbon steel Backed Bushings

Metric POM sliding bushings and imperial size bushings made to order:

Standard bushing types in metric dimensions, thrust washer, inch size bushings, self-lubricant holes and machined grooves, customized bushing designs!

Purchasing pom sliding bushing standard dimensions online.

APPLICATIONS: POM sliding layer, DIN 1494/ISO 3547 .

POM composite cylindrical bushings present a robust option for scenarios demanding efficiency in low friction, high load support, and low maintenance. Their adaptability and reliability make them a favored selection across various sectors.

Automotive – Steering gear, power steering, pedal bushes, seat slides, king-pin bushes, tailgate pivots, brake caliper bushes, etc. Industrial – Mechanical handling and lifting equipment, machine slides, hydraulic cylinders, hydraulic motors, pneumatic equipment, medical equipment, textile machinery, agricultural equipment, scientific equipment, etc.

Grease lubricated bushings.

POM Sliding bushing material is known by various names such as DX or DXR equivalent bushings. Buying a pom composite bushings bearing from china or its guarantees that you receive a right type equivalent bushing;

Selection Considerations: When choosing POM composite bushings, it’s crucial to assess application-specific factors like load, speed, lubrication needs, surface roughness, and temperature conditions, as these elements influence bushing performance.

* Customization Options: These bushings can be tailor-made in metric and imperial sizes to suit specific needs, including bespoke designs available on a short lead time, offering tailored solutions for diverse requirements.