Bushing Online Solution

Professional Manufacture for POM Bushings.

A specific kind of POM (Polyoxymethylene) bushing that’s designed for a variety of applications, from vehicle chassis to machine tools, metallurgical machinery, and hydraulic industry applications. These bushings, with their self-lubricating and boundary lubricating properties, are designed to reduce friction and wear, enhance performance, and prolong the life of machinery. The structure you mentioned includes:

- Carbon Steel: This forms the backing layer, providing structural strength and rigidity.

- Copper Powder: This layer is typically sintered onto the steel, creating a porous structure that can absorb and retain lubricants.

- POM + Pb (Lead): This forms the sliding layer. POM is chosen for its excellent low-friction properties, and the lead further improves the self-lubricating characteristics of the bushing.

These bushings have excellent anti-abrasion and load capabilities, making them suitable for heavy-duty applications. Moreover, they offer good corrosion resistance, which allows them to be used in environments where they may be exposed to moisture or corrosive substances. Bushings are environmentally friendly and lead-free. This seems to contradict the inclusion of lead (Pb) in the sliding layer. If the product is indeed lead-free, it’s likely that an alternative to lead is used to achieve similar self-lubricating properties.

Steel Backed with POM Plastic Liner – Inch and Metric

The POM Series Bushings consist of a steel backing, a porous bronze sinter, and a 0.30–0.50 mm POM surface layer that provides high wear resistance, low friction, and self-lubrication. They can be used as both POM and PTFE composite bearings in boundary lubrication applications.

In a truck’s sleeve axle, a POM bushing reduces friction and allows smooth rotation between the axle and surrounding components. POM, or polyoxymethylene, is an engineering thermoplastic noted for its high stiffness, low friction, and excellent dimensional stability, making it ideal for these applications. Many POM bushings include small indentations to store lubricants, further enhancing their self-lubricating performance. This layered design delivers excellent load capacity and wear resistance, even under demanding conditions such as high speeds, oscillating movements, or heavy loads.

Standard Bushing Production

Sliding bearing with lubrication pockets, The pom bushings produced by your Requirements.

This pom bushing is designed for the marginal lubrication bearing. Find the pom bushings size chart! POM (Polyacetal), Oil Free Bushings, Resin Type, pom bushing! Material: Polyacetal Resin.

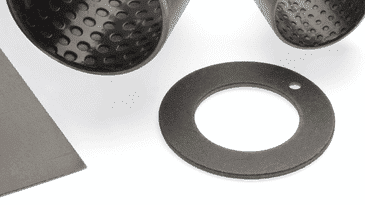

Materail Structure

- POM with lead 0.3~0.5mm.

- Porous bronze 0.2~0.3mm.

- Steel backing 0.4~2.2mm.

- Copper plating 0.008mm.

Copper backed steel pom bushings feature

- It is backed with copper plated steel with porous bronze sintered on it and polymers (POM) embedded in the bores of the bronze.

- The steel back provides the products with high-quality low carbon steel.

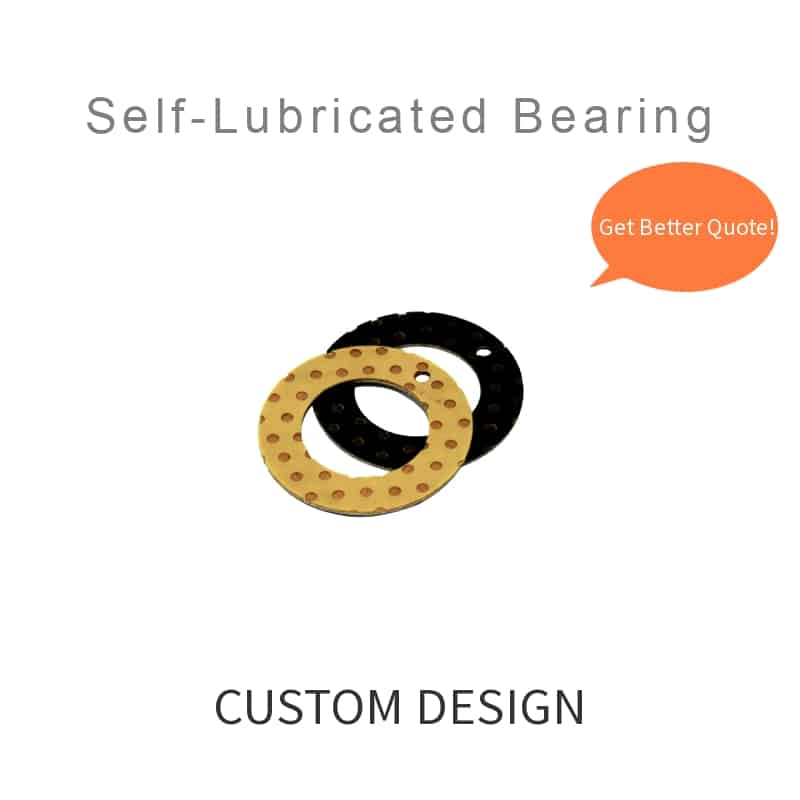

Various design bushing

The promise of pom bushing high quality, meet your requirement.

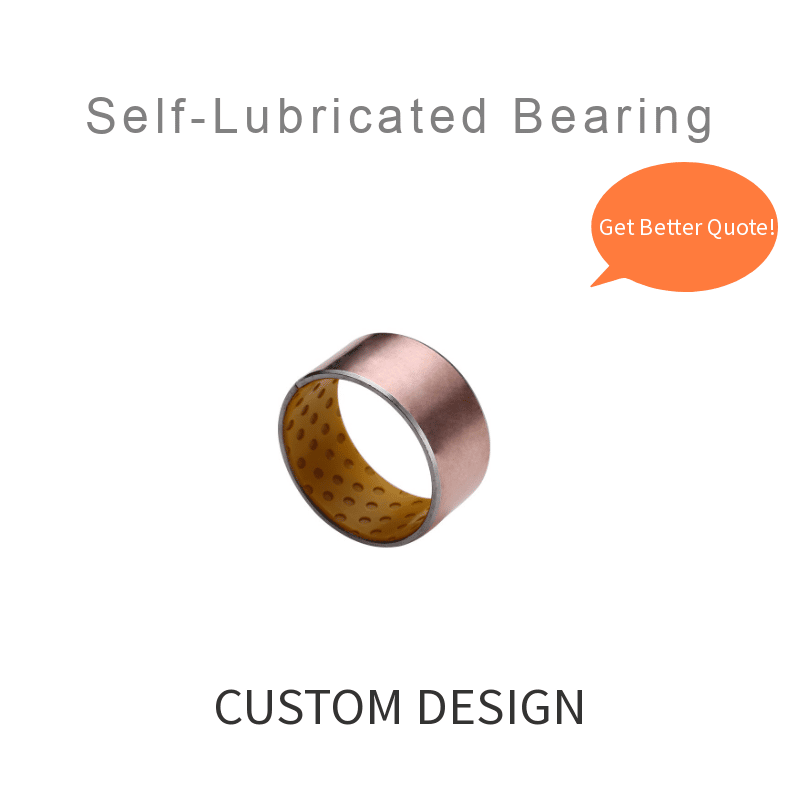

Cylindrical bushings

Small minimum order value & quantity, fast delivery.

Self-lubricating POM bushings, thrust washers and strips online sales. Inquiry now!

Composite Self-lubricating Bushings – Steel Shell With POM Plastic Liner – Inch & Metric, Select your self-lubricating sliding bearings size! A self-lubricating bushing is a mechanical component that reduces friction between two parts without requiring additional lubrication. It’s commonly used in a variety of mechanical assemblies, including trucks. When used in a truck’s sleeve axle, it provides smoother operations and extends the life of the parts. If the self-lubricating bushings on your truck’s sleeve axle are worn out or damaged, you’ll likely notice some common symptoms, such as unusual noises (squeaking or groaning), difficulty in steering, excessive vibration, or premature tire wear.

We supply oilless dry composite bearing bushing

tailored to your individual needs.

POM bushings

These bushings require minimal lubrication (any grease or oil for plain bearings). POM bushings offer excellent sliding properties and are suitable for rotary and oscillating movements. They feature low friction, low edge-load sensitivity, and effective damping properties; they can also be post-machined and have long intervals between re-lubrication.

Designed for semi-dry friction with limited lubrication, they have circular depressions on the sliding surface that are filled with lubricant during assembly. The sliding layer is polyacetal anchored in porous bronze on a sintered steel substrate.

A POM bimetallic strip includes a 0.25 mm thick polyacetal layer over a bronze interlayer, allowing post-machining. While it has good conformability and resists edge pressure, it is not suitable for dry operation.

Initially, friction is low when lubricated with grease and increases over time. If the initial lubricant supply is insufficient, repeated re-lubrication can extend the service life. POM bimetallic products exhibit excellent sliding properties and operate from -40°C to +110°C, with short-term peaks up to +130°C.

Equivalent bushings include PM…, PCM…M, PAP…P20, GLY.AB…, MX…, and SF-2…. In a truck’s sleeve axle, POM bushings can reduce friction and wear, enhance ride comfort, lower noise, and require minimal maintenance due to their self-lubricating design.

The POM bearing sliding bushings supplier.

A small amount of lubricant is required for these bushings; any grease or oil designed for plain bearings is suitable.

POM metal-bearing bushings have strong mechanical properties and excellent wear resistance. They are ideal for producing precise self-lubricating metal composite bearings, offering high surface strength, smooth operation, minimal tension, and a low friction coefficient. By retaining the traditional benefits of plastic bearings, POM bushings can handle more precision and higher-speed applications. Of all plastic bearings, POM plastic bearings are the most commonly used, typically made with POM metal composite material.

Characteristics of POM metal-bearing bushings:

1. High rigidity, hardness, and impact strength, even at low temperatures

2. Excellent elasticity and creep resistance

3. High thermal stability and dimensional stability

4. Good sliding properties and wear resistance

5. Physiologically inert, making them suitable for food contact

6. Not resistant to strong acids or oxidizers, and challenging to paint or bond

Main uses:

Electromechanical equipment, fitness equipment, food machinery, furniture, and decorative building materials.

Plan Bearing Supplier

We provide plain bearings, plain bushings, thrust bearing washers, and other products for your applications. Our PTFE plain bearings offer high reliability, long service life, and minimal maintenance requirements. They accommodate both rotary and rocking motions while requiring minimal radial space.

Our POM bushings are self-lubricating, corrosion-resistant, and dust- and dirt-resistant, with a low coefficient of friction. They operate quietly, are lightweight, suitable for short-stroke applications, have low magnetism, reduce maintenance costs, and are easy to install.

We also offer professional maintenance-free, high wear-resistance solutions for a wide range of industries. Our expertise covers material selection, performance testing, and application support to help you solve challenges and reduce costs. Our engineers are ready to assist and look forward to working with you.

Acetal Sleeve Bearings: The Ideal Solution for High-Speed and High-Moisture Environments

Acetal sleeve bearings are self-lubricating components made from a high-performance thermoplastic known for excellent wear resistance, low friction, and dimensional stability. They perform exceptionally well in high-speed and high-moisture environments, where metal bearings often fail due to corrosion or insufficient lubrication. These bearings see wide use in food processing equipment, packaging machinery, medical devices, marine applications, and various consumer products.

Thanks to their low friction coefficient, acetal sleeve bearings require minimal or no additional lubrication and offer excellent wear resistance under high speeds. Their resistance to moisture absorption and corrosion also allows them to maintain dimensional stability in humid or wet conditions, making them ideal for marine environments. In addition, they operate quietly and reduce noise and vibration.

Installation and maintenance are simple: they can be easily pressed into place and require little upkeep. However, different industries demand different properties—some require high temperature resistance, others need corrosion resistance or electrical conductivity, and some must operate underwater. Tailoring materials accordingly provides self-lubricating, maintenance-free bearings capable of meeting these varied requirements.

For applications needing high-speed operation, moisture and corrosion resistance, and low maintenance, acetal sleeve bearings deliver reliable and long-lasting performance. Their wear resistance, low friction, and dimensional stability make them a top choice for numerous industrial and consumer uses.

Self-lubricating boundary bushing POM material, Standard Bushings Are available- Metric & Inch Size

The POM bushings are available in standard sizes like cylindrical DX bushings, DX thrust washers, and DX strips. In addition, you mentioned that special designs can be produced in a short time, suggesting the manufacturer’s capability to provide customized solutions to meet specific application requirements. In All Cases, The Use Of POM Bushings Should Be Determined Based On The Specific Needs And Requirements Of The Application, Taking Into Account Factors Such As Load, Speed, Operating Temperature, And Environmental Conditions. It’s Always Best To Consult With A Professional Or The Manufacturer To Ensure The Right Bushing Is Selected For Each Application.

This Pom Bushing Can Operate At -40~+120℃ And Still Maintain Good Performance.

- Good load capacity & wear-resistant.

- Optimum performance under relatively high loads and low speeds.

- Suitable for linear, oscillating and rotating movements.

Pom composite bushing boundary lubrication.

The boundary lubrication material is based on steel plate, intermediate sintered spherical bronze powder, surface rolling modified polyformaldehyde (POM), and contains oil pit. It is suitable at room temperature and low speed.

- Maximum bearing pressure: 70N/mm2

- Friction coefficient: 0.05~0.25

- Applicable temperature range: -40℃~130℃

- Maximum sliding speed: 2.5m/s

- Maximum allowed PV value: 22N/ m22.m /s

* The material has been widely used in automobile chassis, forging and pressing machine tools, metallurgical mining machinery, construction machinery, hydropower, steel rolling industry and other fields.

Committed to the implementation lubrication bearing quality standards.

POM bushes with lubrication pockets are self-lubricating bearings designed for diverse operating conditions. They consist of three layers: a steel back for rigidity and load support, a porous bronze sinter created by heating below the melting point to form a lubricant-retaining structure, and a POM (polyoxymethylene) sliding layer with lubrication indents for low friction. These bushings resist wear, offer strong load capacity, and perform reliably under harsh conditions such as high speeds or oscillating movements. Common applications include automotive components, agricultural machinery, and construction equipment.