about the company

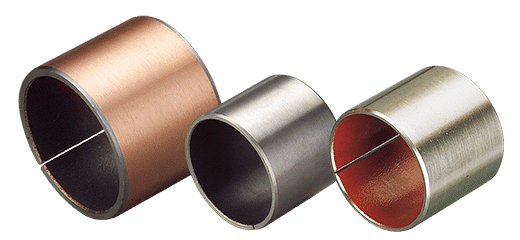

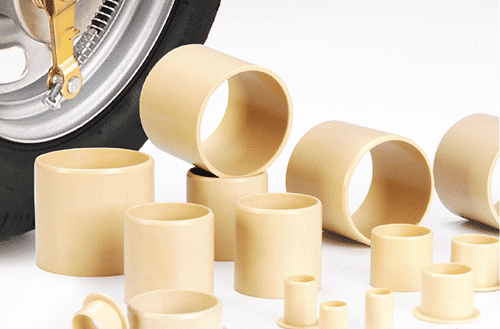

Plain bearings plastic

Plain bearings are self-lubricating, maintenance-free, chemical resistant, universally applicable and reduce costs by up to 60 percent. With their high wear resistance and frictionless surfaces, our plastic plain bearings ensure a longer service life for machine components. Our plain bearings can withstand temperatures of up to 310°C. Thanks to their high dimensional stability and low manufacturing tolerances, they can be used as precision components.

Product Quality Index

Energy Generation

Plastic Bushing For Long Life, Self-Lubricating Engineered Plastic Bearing

Experience in application of engineering plastic bearings in stacker, AGV and conveyer. Designed to be self-lubricating, wear-resistant, and maintenance-free, buy plastic sleeve bearings directly from China today!

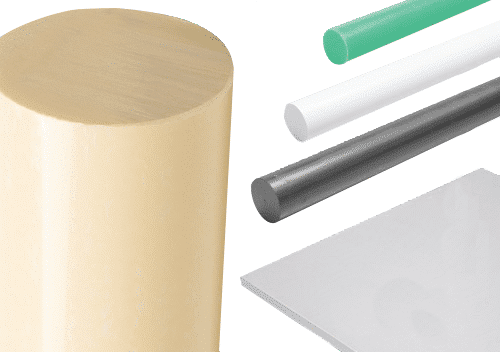

Engineering Plastics Bearing

Wear-resistant engineering plastics have the characteristics of low friction coefficient and excellent vibration damping performance, and have been recognized by the market. Now, sports plastics specialists make this material into plain bearings to suit the needs of the user’s application, especially for rotary and oscillating movements. Its low coefficient of friction ensures smooth movement, reduces the required driving force and saves additional costs such as maintenance. The age of industrial automation requires durable, cost-effective and energy-efficient machine components.

We manufacturer plastic bearing bushing tailored to your individual needs.

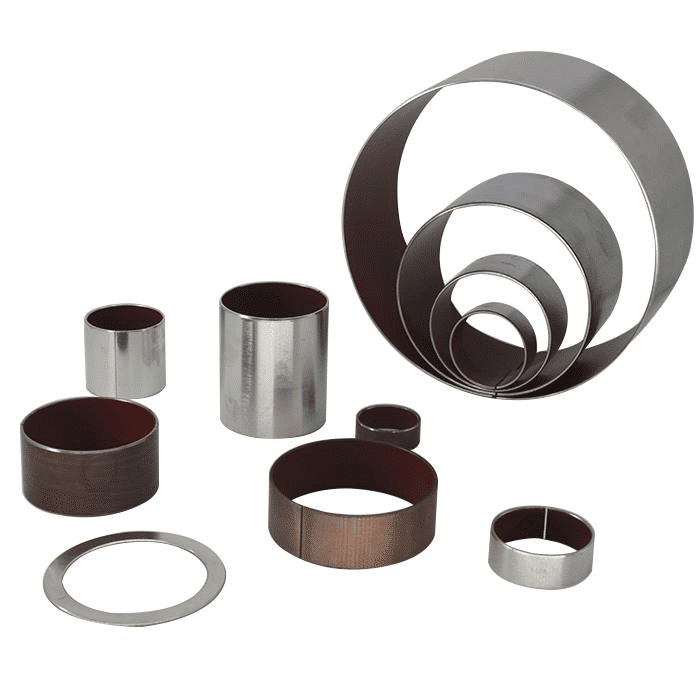

Self-lubricating Sleeve Bushings: A Breakthrough in Industrial Machinery

In the world of industrial machinery, reducing downtime and maintenance costs is always a top priority. One of the biggest contributors to downtime and maintenance costs is the need to frequently lubricate moving parts, such as bearings and bushings. However, a new type of bearing has emerged that promises to change the game – self-lubricating sleeve bushings.

Self-lubricating sleeve bushings are designed to reduce the need for regular lubrication and maintenance. These bushings are made of a combination of metal and plastic, with the metal sleeve providing structural support and the plastic layer acting as a lubricant. The plastic layer is designed to contain a special lubricant that is released gradually over time, ensuring that the moving parts remain lubricated even in harsh operating conditions.

One of the key benefits of self-lubricating sleeve bushings is that they reduce the need for frequent maintenance. Unlike traditional bearings and bushings, which require regular lubrication, self-lubricating sleeve bushings can go for extended periods of time without the need for additional lubrication. This can save companies a significant amount of time and money, as they no longer have to shut down their machinery to perform regular maintenance.

Another benefit of self-lubricating sleeve bushings is that they can improve the reliability of industrial machinery. Traditional bearings and bushings are prone to wear and tear, which can lead to unexpected downtime and maintenance costs. However, self-lubricating sleeve bushings are designed to last much longer, thanks to their ability to self-lubricate and their tough construction.

Self-lubricating sleeve bushings are also ideal for use in harsh operating conditions. For example, in applications where traditional bearings and bushings would fail due to high temperatures, high speeds, or exposure to dust and other contaminants, self-lubricating sleeve bushings can continue to operate effectively. This makes them ideal for use in applications such as high-speed machinery, heavy-duty equipment, and machinery operating in harsh environments.

In conclusion, self-lubricating sleeve bushings are a breakthrough in the world of industrial machinery. By reducing the need for frequent maintenance, improving reliability, and operating effectively in harsh conditions, these bushings offer a new level of performance and cost savings for companies. If you’re looking to improve the efficiency and performance of your industrial machinery, consider self-lubricating sleeve bushings as a smart investment.

Self-lubricating plastic sleeve bushings

Self-lubricating plastic sleeve bushings are an innovative type of bearing solution that offer numerous advantages over traditional metal bushings. These bushings are made of high-performance plastic materials that incorporate self-lubricating additives to reduce friction and wear. This makes them ideal for use in applications where metal bushings may not be suitable, such as in corrosive environments or in applications where lubrication is difficult or costly to maintain.

One of the primary benefits of self-lubricating plastic sleeve bushings is their low friction coefficient, which helps to reduce wear and extend the life of the bearing. Unlike metal bushings that require regular lubrication to function effectively, self-lubricating plastic bushings contain special additives that continuously lubricate the bearing surface, reducing the need for maintenance and reducing the risk of failure.

Another advantage of self-lubricating plastic sleeve bushings is their ability to operate in corrosive environments. Unlike metal bushings that can corrode and become damaged over time, self-lubricating plastic bushings are made of materials that are resistant to corrosion, providing a more durable and reliable solution for applications in harsh environments. This makes them ideal for use in industries such as food processing, chemical production, and marine engineering, where corrosion can pose a significant problem.

In addition to their low friction coefficient and resistance to corrosion, self-lubricating plastic sleeve bushings are also lightweight and offer excellent impact resistance. This makes them ideal for use in applications where high loads or shocks are present, such as in machinery and equipment that are subject to heavy use and high stress levels.

Finally, self-lubricating plastic sleeve bushings are also easy to install and replace, reducing the time and cost associated with maintenance and repair. This makes them an ideal solution for applications where maintenance is required on a regular basis, as well as for applications where quick and easy replacement is essential.

In conclusion, self-lubricating plastic sleeve bushings offer numerous advantages over traditional metal bushings. Their low friction coefficient, resistance to corrosion, lightweight, impact resistance, and ease of installation make them an ideal solution for a wide range of applications in various industries. Whether you are looking for a solution for a corrosive environment or for an application where maintenance is difficult or costly to maintain, self-lubricating plastic sleeve bushings are an excellent option to consider.

plastic sleeve bushings and metal bearings

Plastic sleeve bushings and metal bearings are two different types of bearing solutions that are commonly used in various industries and applications. Both types of bearings have their own unique advantages and disadvantages, and the choice between them will depend on the specific requirements of the application.

Plastic sleeve bushings are typically made from high-performance plastic materials and are designed to offer low friction and wear resistance. These bushings are often self-lubricating and contain additives that continuously lubricate the bearing surface, reducing the need for maintenance and extending the life of the bearing. Additionally, plastic sleeve bushings are resistant to corrosion, making them ideal for use in harsh environments such as those found in food processing, chemical production, and marine engineering.

Metal bearings, on the other hand, are made from materials such as steel or bronze and are designed to offer high load-carrying capacity and stability. These bearings are typically lubricated with oil or grease and require regular maintenance to maintain their performance. Metal bearings are ideal for use in applications where high loads or shock loads

Plastic sleeve bushings material

Plastic sleeve bushings are an innovative type of bearing solution that are made from a variety of high-performance plastic materials. These materials have been specifically selected to offer low friction, wear resistance, and corrosion resistance, making plastic sleeve bushings ideal for use in a wide range of industries and applications.

One of the most commonly used materials in the production of plastic sleeve bushings is polytetrafluoroethylene (PTFE). PTFE is a high-performance plastic material that offers excellent wear resistance and low friction, making it an ideal choice for self-lubricating plastic sleeve bushings. PTFE is also highly resistant to chemicals and corrosive environments, making it ideal for use in harsh industrial applications.

Another popular material used in the production of plastic sleeve bushings is polyethylene (PE). PE is a lightweight and flexible plastic material that offers excellent impact resistance and good wear resistance. This makes it an ideal choice for use in applications where high loads or shocks are present, such as in machinery and equipment that are subject to heavy use and high stress levels.

Another material used in the production of plastic sleeve bushings is polypropylene (PP). PP is a strong and stiff plastic material that is highly resistant to chemicals and corrosion. This makes it ideal for use in applications where harsh chemical environments are present, such as in food processing and chemical production.

Finally, some plastic sleeve bushings are also made from high-density polyethylene (HDPE). HDPE is a tough and durable plastic material that offers excellent impact resistance and low friction. This makes it ideal for use in applications where high loads or shocks are present, such as in machinery and equipment that are subject to heavy use and high stress levels.

In conclusion, plastic sleeve bushings are made from a variety of high-performance plastic materials, each of which offers its own unique advantages and disadvantages. Whether you are looking for a solution for a corrosive environment or for an application where low friction and wear resistance is important, plastic sleeve bushings are an excellent option to consider. By selecting the right material for your application, you can ensure that your plastic sleeve bushings provide the performance and reliability you need for a successful operation.

lowest coefficient of friction plastic

Plain bearings Bushing plastic, Self-lubricating

Plain bearings are self-lubricating, maintenance-free, chemical resistant, universally applicable and reduce costs by up to 60 percent. With their high wear resistance and frictionless surfaces, our plastic plain bearings ensure a longer service life for machine components. Our plain bearings can withstand temperatures of up to 310°C. Thanks to their high dimensional stability and low manufacturing tolerances, they can be used as precision components.

Product Quality Index

Energy Generation

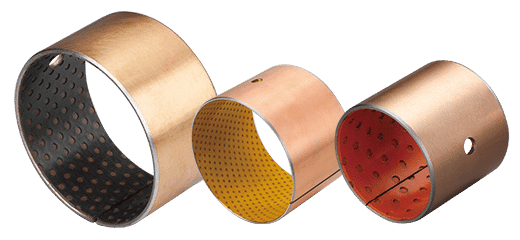

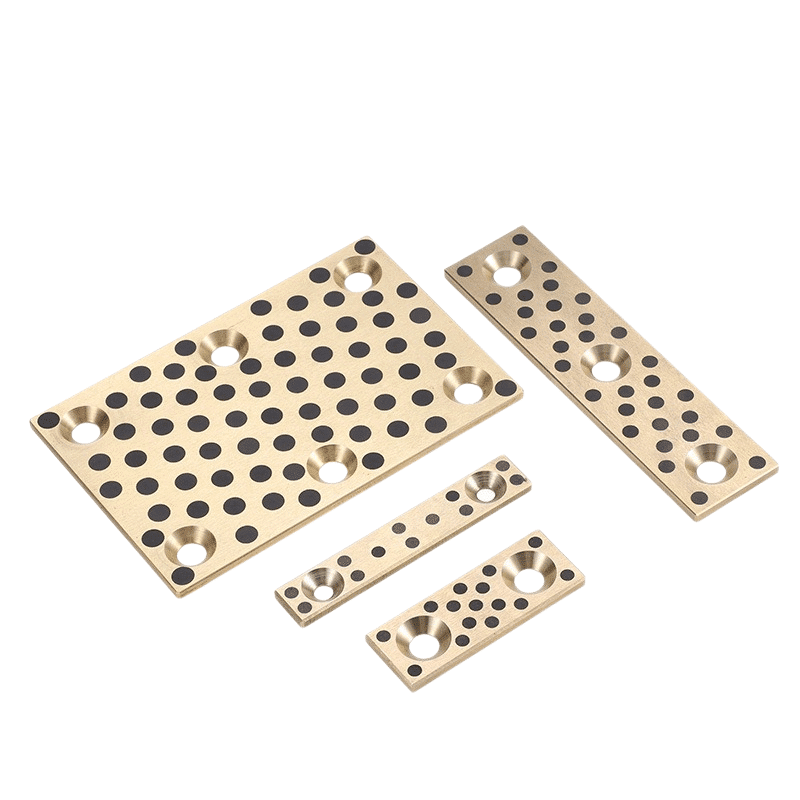

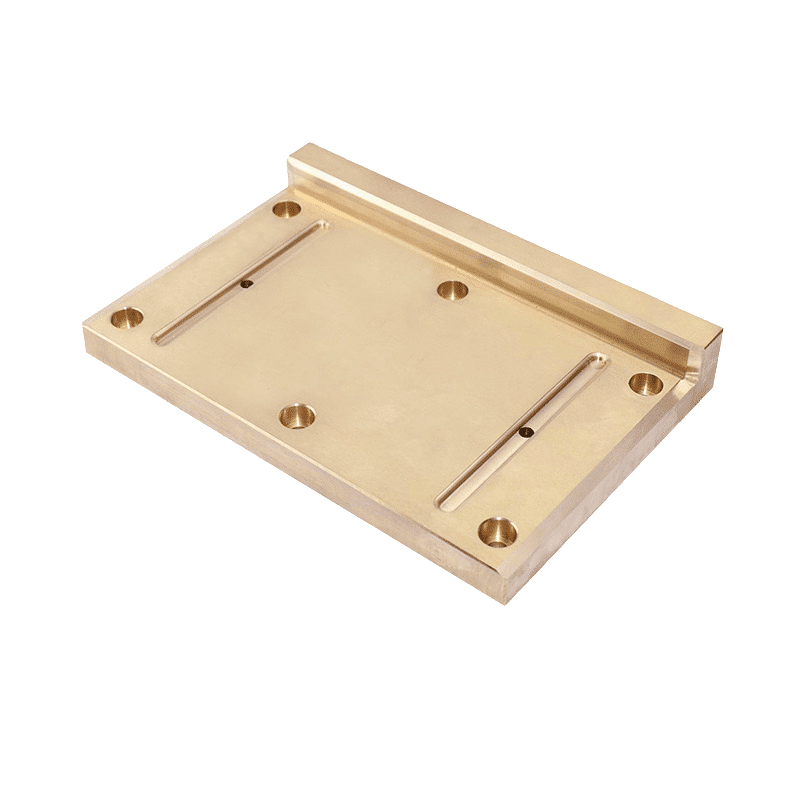

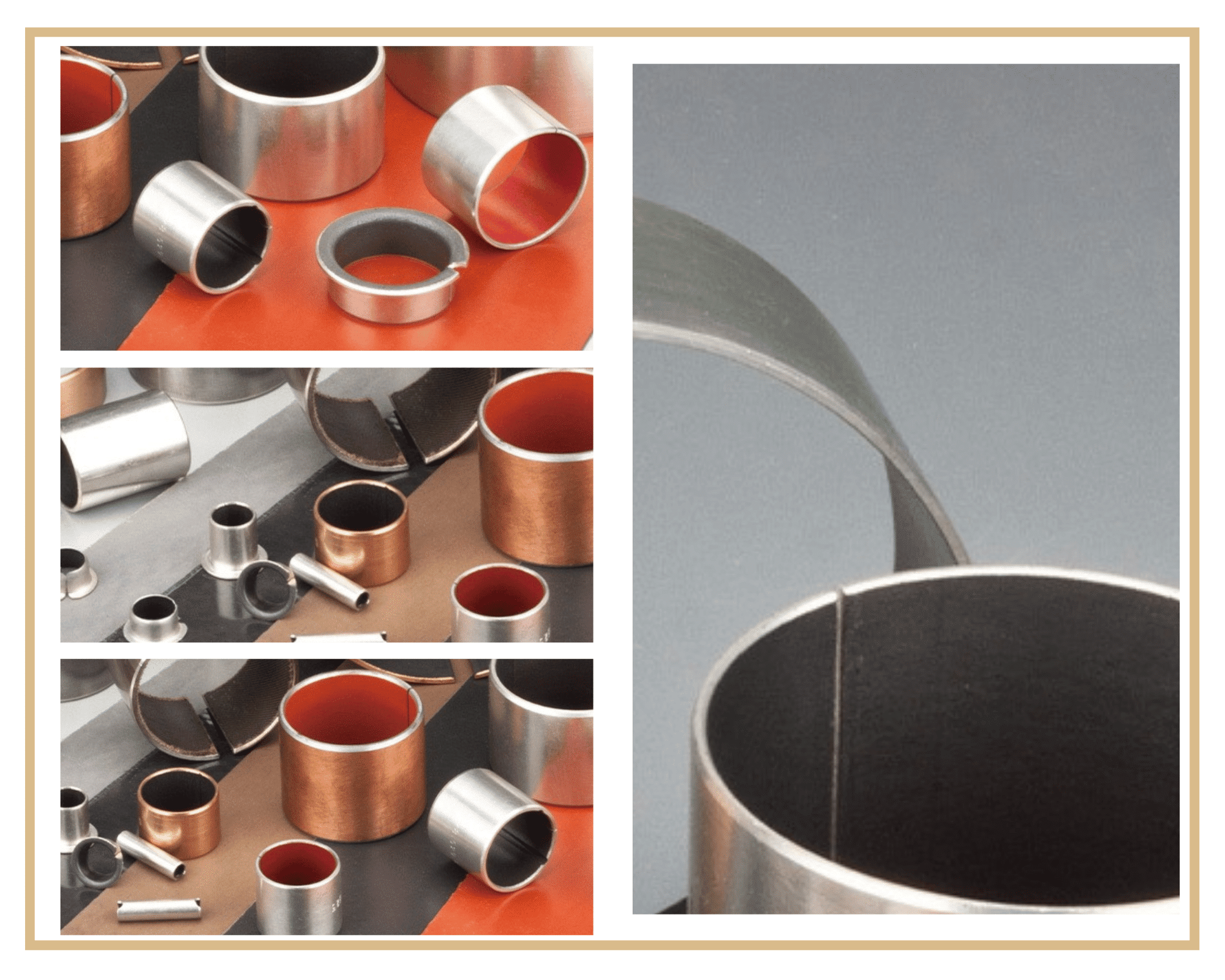

Plastic metal self-lubricating plain bearings

Engineering plastic, extended life, engineering plastic bearings

It is a new engineering plastic introduced by engineering plastic experts to make precision strong wear-resistant parts with extended service life. For the manufacturing of precision parts, we are a good choice for you. High precision plastic self-lubricating bearings, resulting in the construction of extremely small size parts. The surface of the tooth tip made by this process is so smooth that no post-processing is required. Performing the process results in more wear-resistant engineering plastic parts, and the parts will last significantly longer in mobile applications.

Engineering plastic. This plastic has been friction-optimized to be more wear-resistant. Another advantage of the new material is that it is completely free of lubrication and maintenance. This is due to the large number of tiny solid grease particles integrated in the material, which are gradually released during the movement of the part.

Plastic Plain Bearing Materials

Plain bearings Composite Bushing

Self-lubricating plastic bushings have been proven to deliver a longer service life than oil-impregnated sintered bronze bearings. Experience Innovation. Connecting with Customers. Reliable & safe exporter and supplier for all branches of industry! The promise of plastic bushings Maintenance-free plain bearings quality! Find Metric Plastic Flanged Sleeve Bearings supplier, manufacturer, High Precision Plain Bearings. Precision linear sleeve bearings have the same dimensional accuracy as metal ball linear bearings, but they have higher load capacity and extremely low operating noise. Plain Sleeve Bearing & Solutions: Designed to be self-lubricating, wear-resistant, and maintenance-free, buy plastic sleeve split bearing directly from china today! Get a free quote! Our Plain Sleeve Bearings Guarantee High Precision, Productivity and Log-Term Reliability.

Product Quality Index

Energy Generation

Plastic Sleeve Bushings

Application of engineering plastics products and solutions in logistics industry

Engineering plastic sleeve bushing supply solutions and products for the logistics automation industry, help your equipment to speed up operation, improve reliability and prolong life, while simplifying installation, reducing noise & avoiding lubrication pollution.

Maintenance-free and lubrication-free.

Maintenance-free plastic plain bearings.

Choose from our selection of plastic bushings, including over Metric Cylindrical Bushes products and Metric Plastic Flange Bushing Bearing (Lubrication-Free Bushing). Easy to install clips. While the Split bearing Easily assembled via incorporated slot. The slot compensates for holding tolerances, allows low plain plastic bearing bushings clearance and ensures easily assembled.

Top Quality

Excellent cost-effectiveness. Sleeve bearings – maintenance-free, made of plastic.

Plastic Sleeve Bearings

Small minimum order value & quantity, fast delivery.

Testing plain bearings bushings guarantee predictable service life

What material has the lowest coefficient of friction: Plain bearings are manufactured from innovative high-performance plastics for a wide range of applications. Typical applications include medium to high loads, medium sliding speeds and medium temperatures. Agricultural machines Construction, machinery Machine building Sports and leisure Automotive, etc.

Engineering plastic self-lubricating bearings

“Online- shop with large selection of plastic bushings materials and dimensions.”Save your purchasing Oil Free Bushings & Sleeve Bearings Made From Plastic budget for your project. Tech up, Cost down! Ready to choose the best plastic bearings bushings for your application!

Plastic Self-lubricating Bearing Characteristics

With 15+ years of experience. Elastic and break-proof

Long service life

Large range of Bushing & Plain Bearings from china.

Plastic bushings are chemical resistant, resist high temperatures up to +482°F, and are lubrication- and maintenance-free. The comprehensive wear resistance of engineering plastic bearings is improved by embedding high strength fiber and special solid grease into the bearings with high performance engineering plastic as the base material through polymer modification technology. The high strength fiber network structure enhances the material strength, and the special solid grease compound makes the plastic bushings series engineering plastic bearing have excellent self-lubrication and wear resistance. Whether it is automotive, high speed, underwater, high temperature and corrosion resistant applications, or food industry requiring FDA standards, We provides different solutions to the global industry.

* Our enterprise, is one of the undisputed supplier of the highly competitive plastic bushings industry in china.

Injection Molded Plastic Self-Lubricating BushingsInjection Molded Thermoplastic Series – Metric Series Bushings are new economic self-lubricating bearings made by kinds of resin with additive fiber as base material produced by injection molding machines.

Plastic bushings are made of a variety of resins combined with reinforcing fibers and solid lubricants to provide excellent wear resistance and low friction in both dry and lubricated operating conditions over a wide range of applications. EPB material is an economic solution for mass production designs.

Plastic Plain Bearing Bushing Series Features

- Designed for dry and maintenance-free

- Lower friction, excellent wear resistance

- Higher load capacity

- Excellent chemical resistance

- Lower moisture absorption

- Thin wall thickness design,

- reduced space and weight

- Can significantly reduce costs when mass produced

- No special requests needed for mating material

Plastic Plain Bearing Bushing Application

The application for high load with lower speed and lower friction request, like automotive industries, lift machineries, copier, OA machines, sports machines, food industries, chemical machines etc. Compared with the metal bushes, the weight and cost is much lower. The EPB Plastic Sleeve Bushing Series is well suited for large production runs with low cost and short delivery time. The user can select the bearing by temp. of work environment, wear resistance request, moving method, installation method, the cost of the material etc. Normally, the temperature, load, and PV value should be considered first. Bronzelube recommends designing towards a lower PV value since it will lead to longer service life. The thermoplastic materials can be specially formulated to match the requirements of a wide variety of applications including:

- Economical

- High-Performance

- Anti-corrosive

- Food use

- Anti-wear

- Anti-water

- Electric Conductivity

- High Temperature

- High Strength

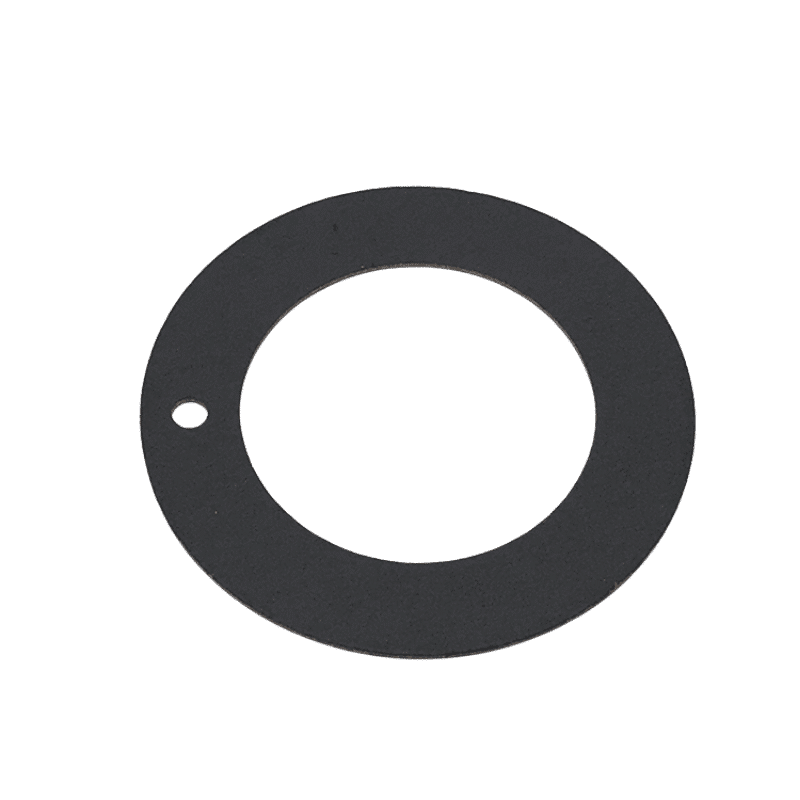

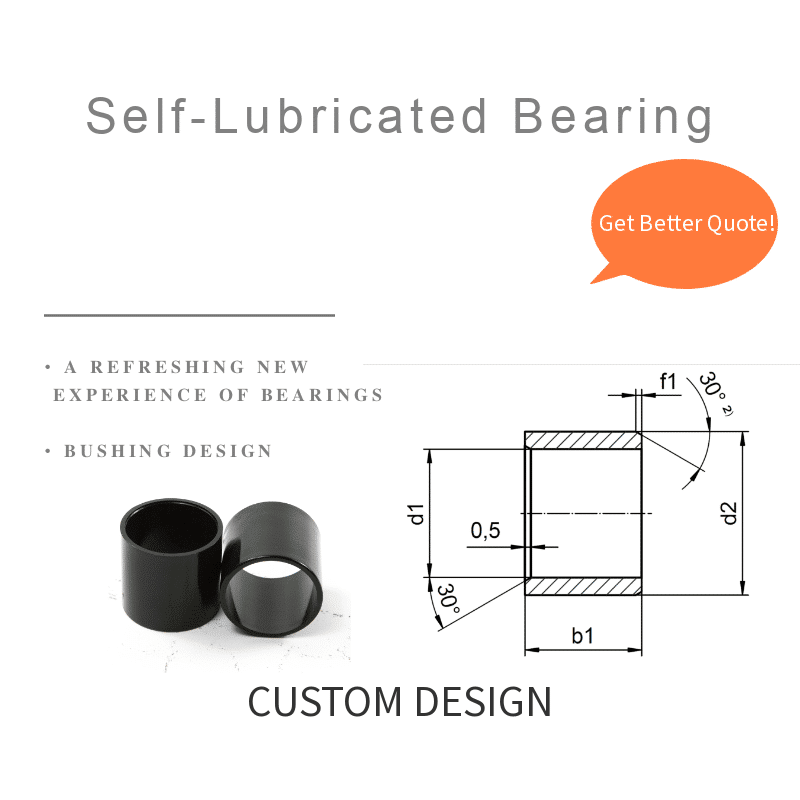

Plastic Plain Bearing Bushing Type

- Plastic Series – Straight Bushings

- Plastic Series – Flanged Bushings

- Plastic Series – Thrust Washer Bushings

Find a plastic bushing for your application, Plastic bushings to replace oil-impregnated sintered bronze bearings.

Plastic sleeve bushings, sleeve bearing with flange, mm, Quality Built To Last

Self-lubricating plastics sleeve bearing online design

Sleeve Bearings Made From Plastic, made to order from china.

Select your bushing size, Cost-effective Price.

Plastic plain bearings use high performance plastics as a raw material, and also fill high-strength fibers and special solid lubricants with polymer compound technology to improve the wear resistance of composite materials.

In the automotive industry with high durability requirements, high speed applications, underwater applications, high temperature and anti-corrosive applications, or in the food industry with FDA requirements, VIIPLUS can always provide different solutions for customers.

Plastic Sleeve Bushings Material and Color

Plastic sleeve bearings from bronzelube.com. Selection according to shaft diameter, bearing width or outer diameter. Online shop with large selection plastic sleeve bushings material.

Reliable & safe – producer and supplier Plastic Sleeve Bushings for all branches of industry.

Widely-applicable materials

| Common Capability | Unit | EPT | EPG | EPH | EPX | EPJ | EPS |

| Density | g/cm³ | 1.46 | 1.46 | 1.65 | 1.49 | 1.24 | |

| Color | Black gray | Dark grey | Grey | Black | Yellow | Beige | |

| Max.water absorption,23℃/ 50% | [% weight] | 0.2 | 0.7 | 0.1 | 0.3 | 2.02 | |

| Max.water absorption | [% weight] | <1.2 | <4 | <0.3 | <0.5 | <1.3 | <0.1 |

| Dynamic friction /steel | μ | 0.05-0.15 | 0.08-0.18 | 0.07-0.20 | 0.09-0.27 | 0.06-0.18 | 0.05-0.15 |

| Max.PV(dry) | MPa•m/s | 0.4 | 0.5 | 1.37 | 1.32 | 0.34 | 0.4 |

| Mechanical behavior | |||||||

| E-module | MPa | 2,300 | 7,800 | 12,500 | 8,100 | 2,400 | 830 |

| Tensile strength,20℃ | MPa | 80 | 200 | 175 | 170 | 73 | 18 |

| Compressive strength | MPa | 65 | 80 | 90 | 150 | 35 | 10 |

| Max.static pressure of the surface,20℃ | MPa | 35 | 80 | 150 | 90 | 20 | 10 |

| Shore D hardness | 70 | 112 | 87 | 85 | 74 | 73 | |

| Physical and thermal properties | |||||||

| Continuous work tempreature | ℃ | +80 | +130 | +200 | +250 | +90 | +260 |

| short-time work tempreature | ℃ | +120 | +220 | +240 | +315 | +120 | +310 |

| Minimum operating temperature | ℃ | -40 | -40 | -40 | -100 | -50 | -200 |

| Thermal conductivity | W/m•K | 0.2 | 0.25 | 0.60 | 0.60 | 0.25 | 0.24 |

| Max.water absorption,23℃ | K-1•10-5 | 7 | 9 | 4 | 5 | 10 | 12 |

| Conductivity | |||||||

| Volume resisticity | Ωcm | >1012 | >1013 | <104 | <105 | >1013 | >1015 |

| Surface resisticity | Ω | >1015 | >1011 | <105 | <103 | >1012 | >1015 |

Get your free quote!

PLASTIC SLEEVE BUSHING TOLERANCE

Plain Bearing Installation

The Plastic Sleeve Bushing Tolerance

| d mm² | Tolerance after fit E10 | Fit Housing H7 | Fit Shaft h9 |

| >0~3 | +0.014~+0.054 | 0~+0.010 | 0~-0.025 |

| >3~6 | +0.020~+0.068 | 0~+0.012 | 0~-0.030 |

| >6~10 | +0.025~+0.083 | 0~+0.015 | 0~-0.036 |

| >10~18 | +0.032~+0.102 | 0~+0.018 | 0~-0.043 |

| >18~30 | +0.040~+0.124 | 0~+0.021 | 0~-0.052 |

| >30~50 | +0.050~+0.150 | 0~+0.025 | 0~-0.062 |

| >50~80 | +0.060~+0.180 | 0~+0.030 | 0~-0.074 |

| >80~120 | +0.072~+0.212 | 0~+0.035 | 0~-0.087 |

| >120~180 | +0.085~+0.245 | 0~+0.040 | 0~-0.100 |

Plastic Sleeve Bushings Series vs Metal Bearings

Change your bushings today!

self-lubricating plastic bushings are proven to deliver a longer service life than oil-impregnated sintered bronze bearings.

Because the grease immersed in the solid plastic material, the lubricating will be valid continuously no matter how long the bearings are working. Therefore, the traditional sintered oilless bearings provide the lubricating function by utilizing the impregnated oil in the tiny porosities of the material. When the impregnated oil would have been run out of dried, the bearing wear will be increased sharply and the bearing life will be terminated at the same time.

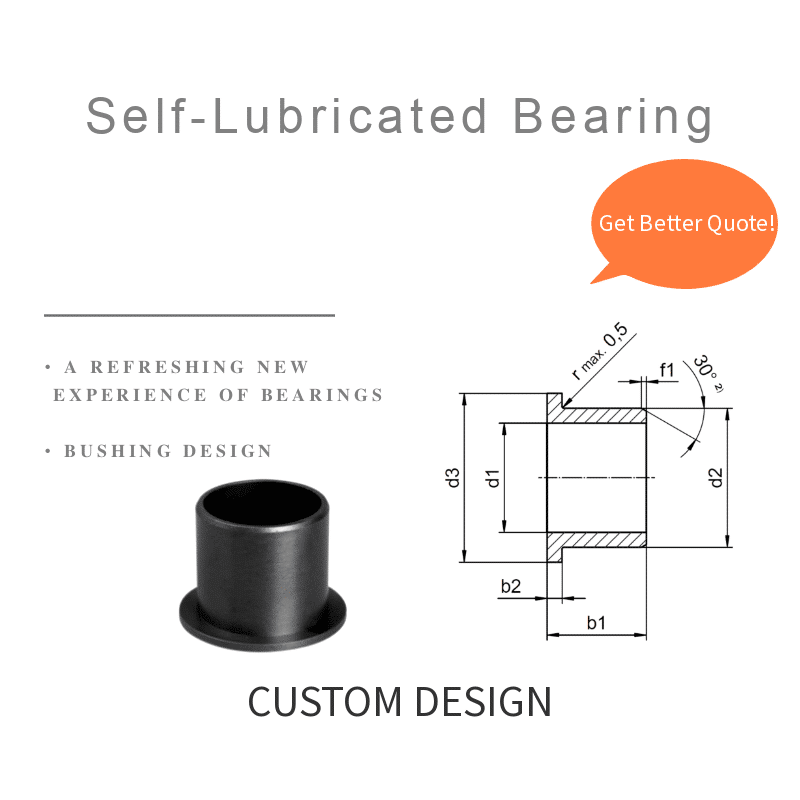

Plastic Sleeve Bushings Metric Size made to order from china at Excellent price

Part no.

Ø d1 [mm]Outer diameter d2 [mm]

Flange diameter d3 [mm]

Bearing length b1 [mm]

Flange thickness b2 [mm]

Flange Sleeve Bushing Type Made to Order from china at Excellent price

sleeve bearing with flange, mm

Part no.

Ø d1 [mm]Outer diameter d2 [mm]

Flange diameter d3 [mm]

Bearing length b1 [mm]

Flange thickness b2 [mm]

Plastic Sleeve Bushing Application

Agriculture

Automotive

Aviation

Boats and yachts

Beverage production & packaging

Bicycles

Building material manufacturing

Bulk Material Handling

Camera and film technology

Car wash systems

Composting plants

Construction Machinery

Energy

Fitness/ physical therapy equipment

Food production and packaging

Furniture/ industrial design

Heavy machinery/ plant construction

Indoor and EOT Cranes

Infrastructure

Forklifts

Locks & dock facilities

Machine tools

Material handling

Medical technology

Mining

Motorcycles & scooters

Oil and Gas

Offshore

Packaging

Plastic machines

Port and Terminal Cranes

Printers

Prostheses

Railway technology

Service robotics

Shipbuilding

Shore power

Solar technology

Steel mills

Textiles

Theatre / Stage construction

Truck & Trailer

Vending machines

Vertical farming

Wind power stations

Woodworking

3D printers

Industry solutions

plastic sleeve bushings replacement for bronzelube.com

Buy Self-lubricating Plastic bearings online bronzelube.com

Designed to be self-lubricating, wear-resistant, and maintenance-free, buy plastic sleeve plain bearings directly from china at Excellent price today!

Cost-Effective & Grease-Free Plain Bearings Bushings Exist!

Types of plain bearings, The General Purpose Bearing

–the most sold plain bearings & plastic bushings worldwide.

- Flange plastic bearings bushings

- Sleeve plain bearings

- Thrust washer

- Customized plastic bushings

- Linear plastic bearings bushings

- Thin-walled plastic bearings

Custom Bearings – Choosing the sleeve bushing by feature!

Find your ideal self-lubricating sleeve bushing bearings in wide range of materials in Metal, Bronze, Multilayer and Composite. Reliable Quality, Complete Model, Sufficient Supply, Fast Delivery, OEM & Wholesale. Inquire Now, Get A Free Quote. Improving productivity and save the cost and time with various kind of shapes and materials, etc. Good After sales Service. Made In China. Types: Bronze Bearing, Bronze Bearings, Thrust Bearing, Thrust Washer!

Self-lubricating sleeve bushing for longer life – bronzelube.com

Self-Lubricating bushing consist of pre-lubricated metal wrapped bushing bearing and bronze bushing, bimetal bushes, which varies in shape. .