Project Description

THRUST BEARING WASHER

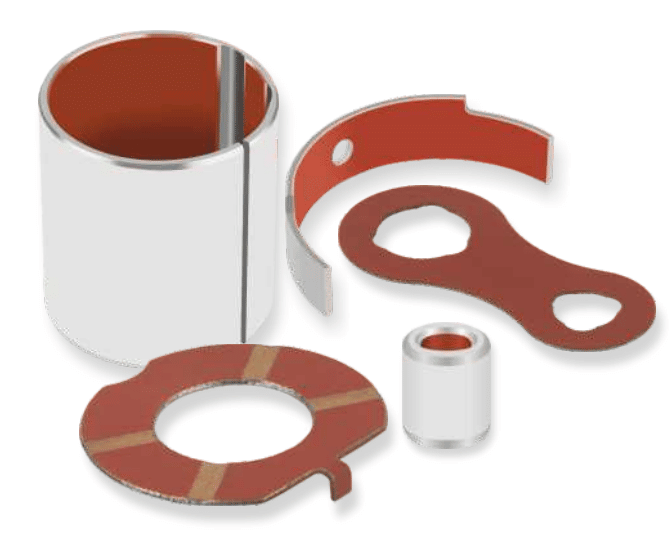

Bushings, thrust washers and strips

Dry thrust washers from china are self-lubrication for shaft materials; Low coefficients of friction in dry operation; Vibration-damping. As well as for composite bushings and strips, supply composite thrust washers as standard type PTFE and POM composite materials.

LEARN MORE THRUST BEARING WASHER

Top Quality Thrust Bearing Washer Products at Competitive Prices!

Bearing Washer, Professional bronze thrust washer, thrust bearing bushings supplier from China.

China Automotive Suspension Bushes Repair Services

THRUST BEARING WASHER

Self-Lubricating Thrust Bearing Washer Material

Large selection of Self-Lubricating thrust washer, Inch Thrust Washer made of Carbon Steel and bronze thrust washer. Thrust bearings washer are a type of rotating bearing that allows rotating parts to move smoothly by supporting axial loads (those parallel to the shaft) in one direction.

Top Quality

Self-Lubricating Composite Thrust Bearings Offer Maintenance-Free.

Sliding thrust washers

Composite dry sliding thrust washers are designed for applications in metric size and inch size.

Self-Lubrication & Customized Thrust Bearing Washer

Composite PTFE Thrust Washer

More self-lubricating thrust bearing washer products from china!

Dry Sliding Washer Available- Metric Self-lubricating Oilless Plain Slide Sleeve Dry Linear Shaft Split Oil Free Bushings

Ordering example:diameter, outside diameter, thickness,mm

Hydraulic special material for Maintenance Free Metal Dry Sliding Washer Available PTEF RED COLOR is designed according to the working principle of oil cylinder and shock absorber, which is more wear-resistant in the condition of no oil. In addition to the advantages of self-lubricating shaft sleeve, this product is especially suitable for occasions with large inclination force with frequent reciprocation.

Its performance is similar to that of overseas DP4. At present, this product has competitive price and is made in China. It is suitable for automobile, motorcycle shock absorber and various hydraulic cylinder fields.The material is lead-free and complies with the eu ROHS directive.

Technical Information

- Maximum bearing pressure: 140N/mm2

- Friction coefficient: 0.04~0.20

- Applicable temperature range: -195℃~280℃

- Maximum sliding speed: 3m/s

- Maximum allowable PV value (dry) : 3.8n /mm2.m/s

- Maximum allowable PV value (oil) : 50N/mm2.m/s

Gleitlager Washer Structure

- Tin-coated backside

- layer with sintered bronze

- sliding layer: Multilayer Sliding PTFE

Gleitlager Washer

With our extensive punching tools and flexible machinery, we can quickly produce gleitlager buchsen of any shape and size you need.

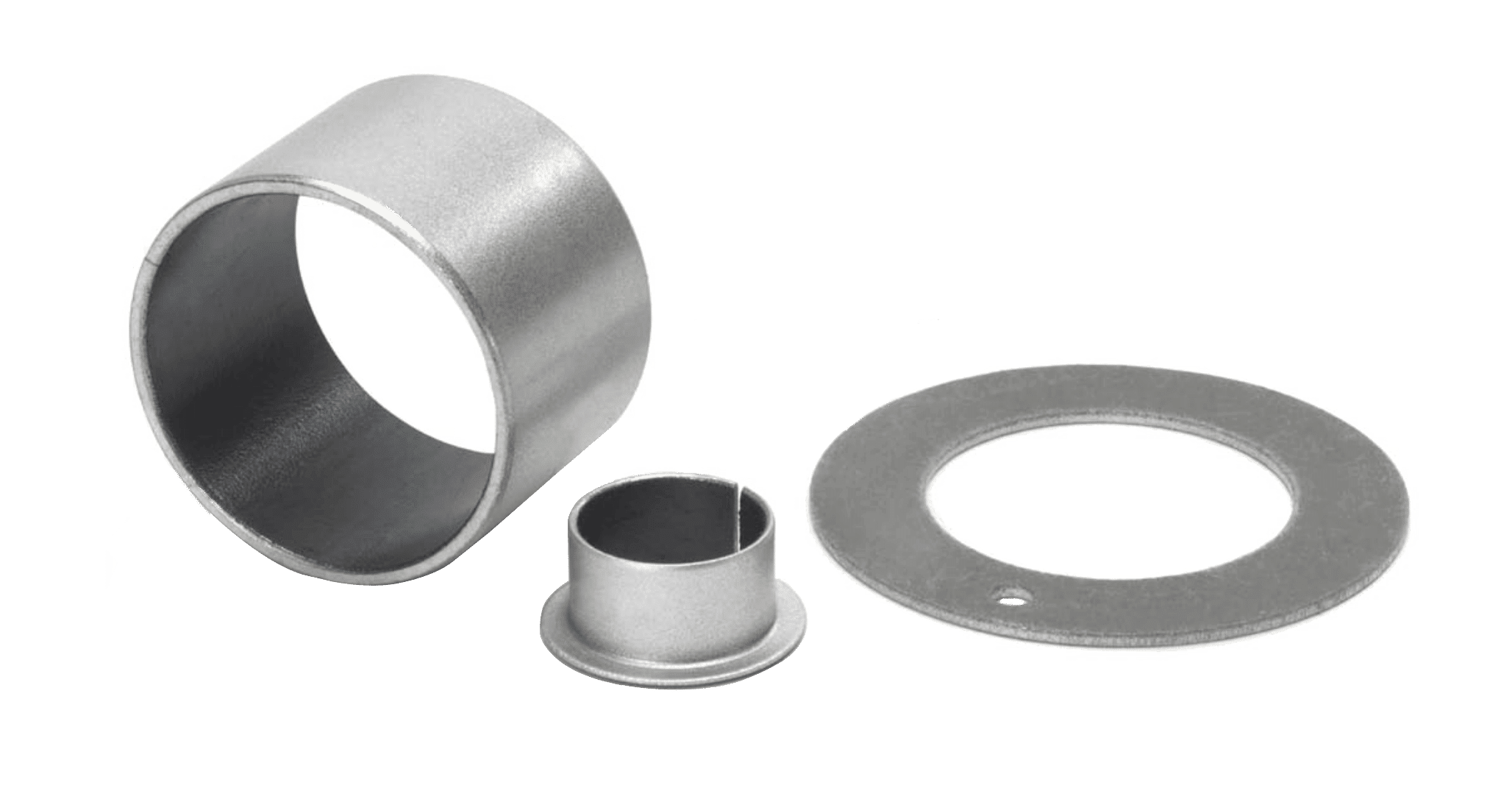

Maintenance Free Slide Bearings Available

A wide range of materials from bushing types are sleeve bushings, flange bushings, gaskets and sliding plates available.

Gleitlager Washer Feature

| Maximum load, p | Static N/mm 2 250 |

| Operating temperature | Min °C – 200 |

| Coefficient of linear thermal expansion | Parallel to the surface 10 -6/K 11 |

| Normal to the surface | 10 -6/K 30 |

| Maximum sliding speed, U | 2.5 |

| Maximum pU factor | N/mm 2 x m/s 1.0 |

| Coefficient of friction | 0.04 – 0.25 * |

| Maximum sliding speed, U | 5.0 |

| Maximum pU factor | 10.0 |

| Coefficient of friction | 0.02 – 0.08 |

| Shaft surface roughness, Ra | Dry µm 0.3 – 0.5 |

| Shaft surface hardness | Unhardened acceptable, improved bearing life > 200HB |

Gleitlager Washer Characteristics

- self-lubricating/ maintenance free for low sliding speed

- low mechanical wear and excellent operating life

- low static and dynamic coefficient of friction

- high corrosion resistance

Special Manufacturing

For gleitlager buchsen parts prepared according to your drawings, please send us an inquiry.

Fitting tolerances

housing H7

shaft ø <=55: f7; >55: h8

Assembling instructions

The edges of the mounting hole and the shaft must be chamfered. It is recommended to use an arbour press. Please avoid damaging the sliding surface. The butt joint should not be in load direction.

Replacement Parts

- Suitable for high loads

- Multiple areas of us (universal bearing)

- Long life

- Wide temperature range

Red PTFE is recommended if RoHS compliance is required.

Bronze backed bushing gleitlager scheiben should be used if better corrosion resistance is required.

Standard gleitlager scheiben are manufactured to company standards and to DIN ISO.

We also provide you with suitable stamping parts according to the drawings, and label and package as required.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Parts Now

Always tested. Always proven. Always Bronzelube.com