polymer grease Bearing Bushing Size Chart

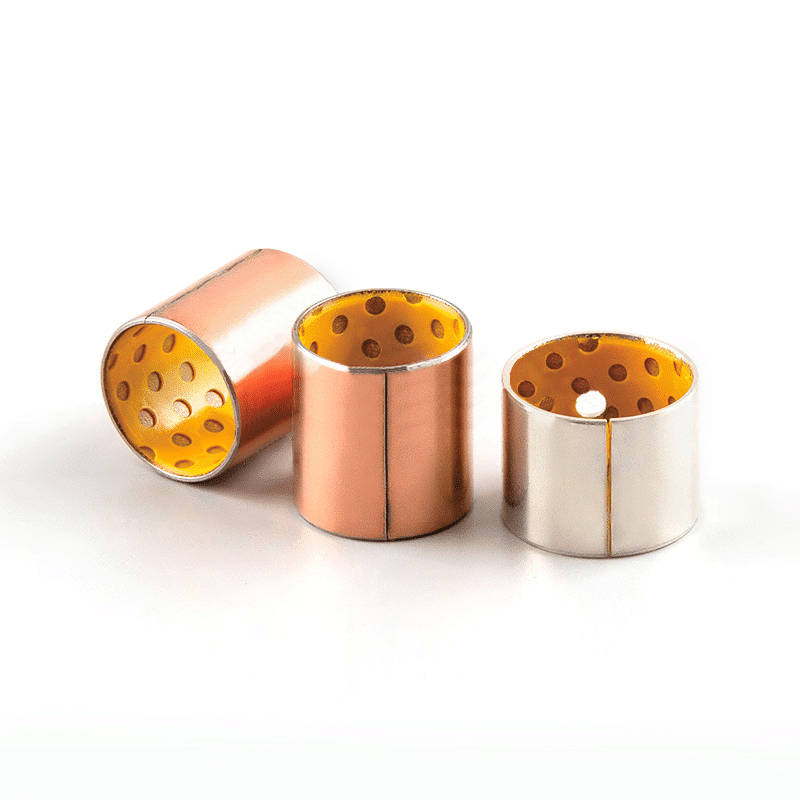

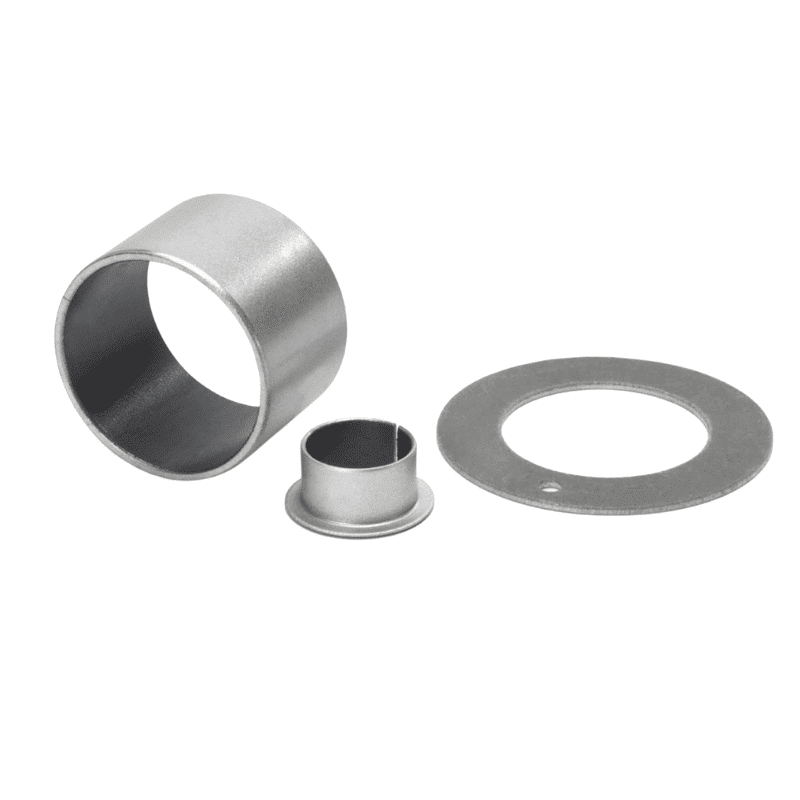

Metal-Polymer Plain Bearings Grease Lubricated Bushing, bushing: the global industry standard for marginally lubricated metal polymer plain bearings. Cylindrical bushes, thrust washers, …Bushings, thrust washers and strips · Principles of selection and application · Sliding material and bushing type selection guides · Selecting bearing bushing size.

Steel bronze POM bushings

Pricing and Availability: Steel bronze POM bushings can be easily found and purchased at wholesale prices from various suppliers, with options for custom manufacturing. Marginally lubricated bushings for grease or oil lubricated applications · Standard parts contain grease indents in the sliding layer; plain sliding layer. Bearings & Bushing By Size Chart – bronzelube.com, Bushings Manufacturing!POM Bushing Size Chart, Split Type! The bushing design provides for both conventional (flange outboard) and reverse (flange inboard) mounting configurations. Bushing Dimensions.

POM Bush Manufacturers & Suppliers, Self-Lubricating Multilayer Bushings with Composite PTFE/POM

Cylindrical bushes,Bush Size Search, Bushes manufacturers & suppliers, Standard Wrapped Bushes. Marginally lubricated bushings for grease or oil lubricated applications • Standard parts contain grease indents in the sliding layer; plain sliding size chart. Standard Bearing Bushings Size Chart, Get a Free Quote.

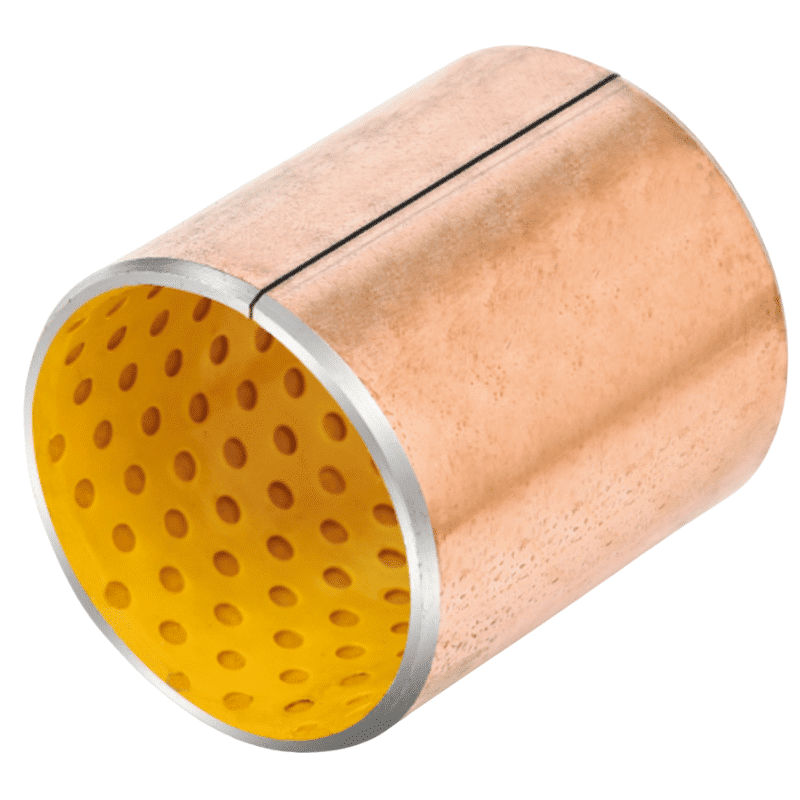

- Composite Material: These bushings are made from a combination of steel, bronze, and POM, which provides a strong and wear-resistant bearing surface.

- Self-Lubricating: The POM material is self-lubricating, making these bushings suitable for applications where conventional lubrication is difficult or not possible.

- Load Capacity: Steel bronze POM bushings have a high load capacity and can be used in a variety of applications, from vehicle chassis to machine tools and metallurgical machinery.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

Find The pom Bushings For Your Project

Self Lubricating Bearings – Excel In Hi Temp Applications, Bearing Bushing are most commonly found in pumps, motors, and gearboxes. Both split and solid styles are available. Plain Bearings, Self-lubricating Bushings Supplier, POM Bushing Products- Long-Term Wear Resistance, Sliding Bearing Technologies.

- Material Options: In addition to steel bronze POM bushings, there are also other bushing materials available, such as steel-backed bronze bi-metal, filament wound, plastic, PTFE, PEEK, aluminum alloy, and graphite impregnated.

- Applications: These bushings are used in a wide range of applications, including textile and agriculture machinery, where they can handle high static and dynamic loads.

- Performance Specifications: Some bushings have specific performance specifications, such as static and dynamic load ratings, maximum line speed, and friction coefficient.

Tribology Surrounds You

Bronzelube.com offers a wide range of high-quality bushing materials ideal for most bushing bearing applications. Our general-purpose seals come in various stock sizes. We guarantee quality with on-time worldwide shipping. Explore our products, request a quote today, and contact our experts for tailored solutions. Our oilless self-lubricating and grease-lubricated metal-polymer plain bearings are available in standard and custom sizes, including both metric and inch specifications, with various grades and profiles.

Metal Polymer Bushings for High Loads – Online Sourcing

Metric & Imperial Bushings – POM bushing

QUALITY ENGINEERED BEARINGS:

POM Lined Wrapped Bearings: The Perfect Choice for Industrial Engineers and Specialists. Our Bushing Bearings Series includes metric and imperial plain, flanged, washers, and strip options. These are the global standard for marginally lubricated metal polymer plain bearings, featuring cylindrical bushes and bearing thrust washers. Our bushings have a steel backing with a POM layer and grease lubrication indents. Thin-walled bearings are designed for high loads at low speeds, including DX Type Split Bearing Bushes. These bush bearings are commonly used in the machinery industry. (Inside Diameter x Outside Diameter x Length). We are professional manufacturers of lead-free boundary self-lubricating bearing bushings in China and welcome customized orders.

POM Parts Selection, Bushing Size Chart

Metal-Polymer Plain POM Bearings Grease Lubricated

Metal Bushing

Steel Backed Polymer Bushings

Metal-polymer plain bearing, For heavy duty and harsh environments. Unique chemical, erosion and wear resistance. Polymer bushing: the best ever global industry standard for marginally lubricated metal polymer plain bearings. Cylindrical bushes, thrust washers.

DX Type Split Bearing Bushes, The POM Bush Bearings are widely used in the Machinery Industry. (Inside Diameter x Outside Diameter x Length) Measured in Metric and Inches.

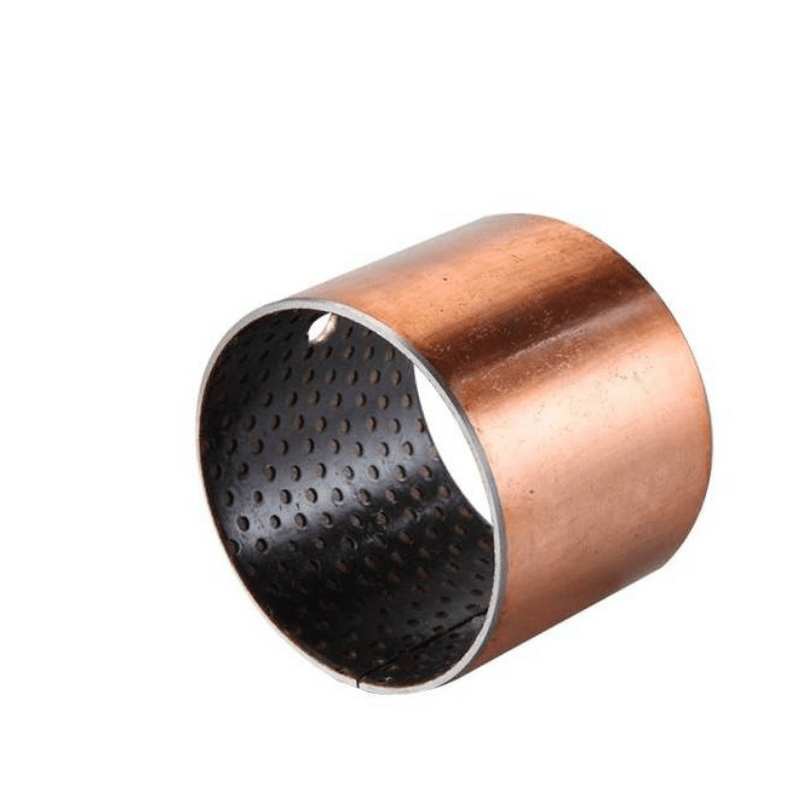

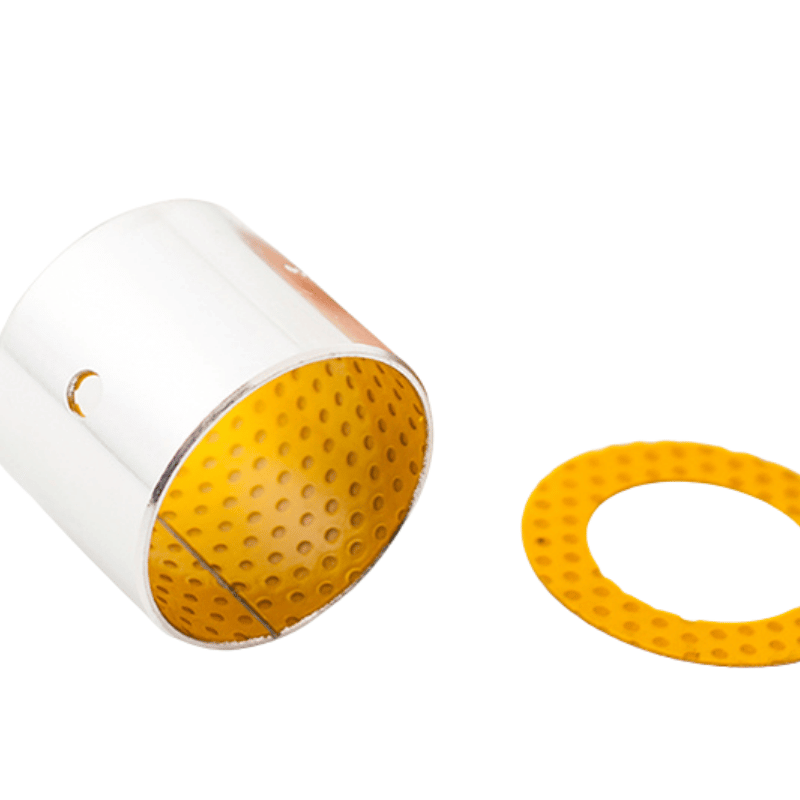

Steel copper-plated or tin-plated Intermediate layer Sintered bronze POM (MoS2)/lubrication pockets

Wrapped sliding bearing, wrapped bushing, steel/POM sliding layer, DIN 1494/ISO 3547, Low-maintenance

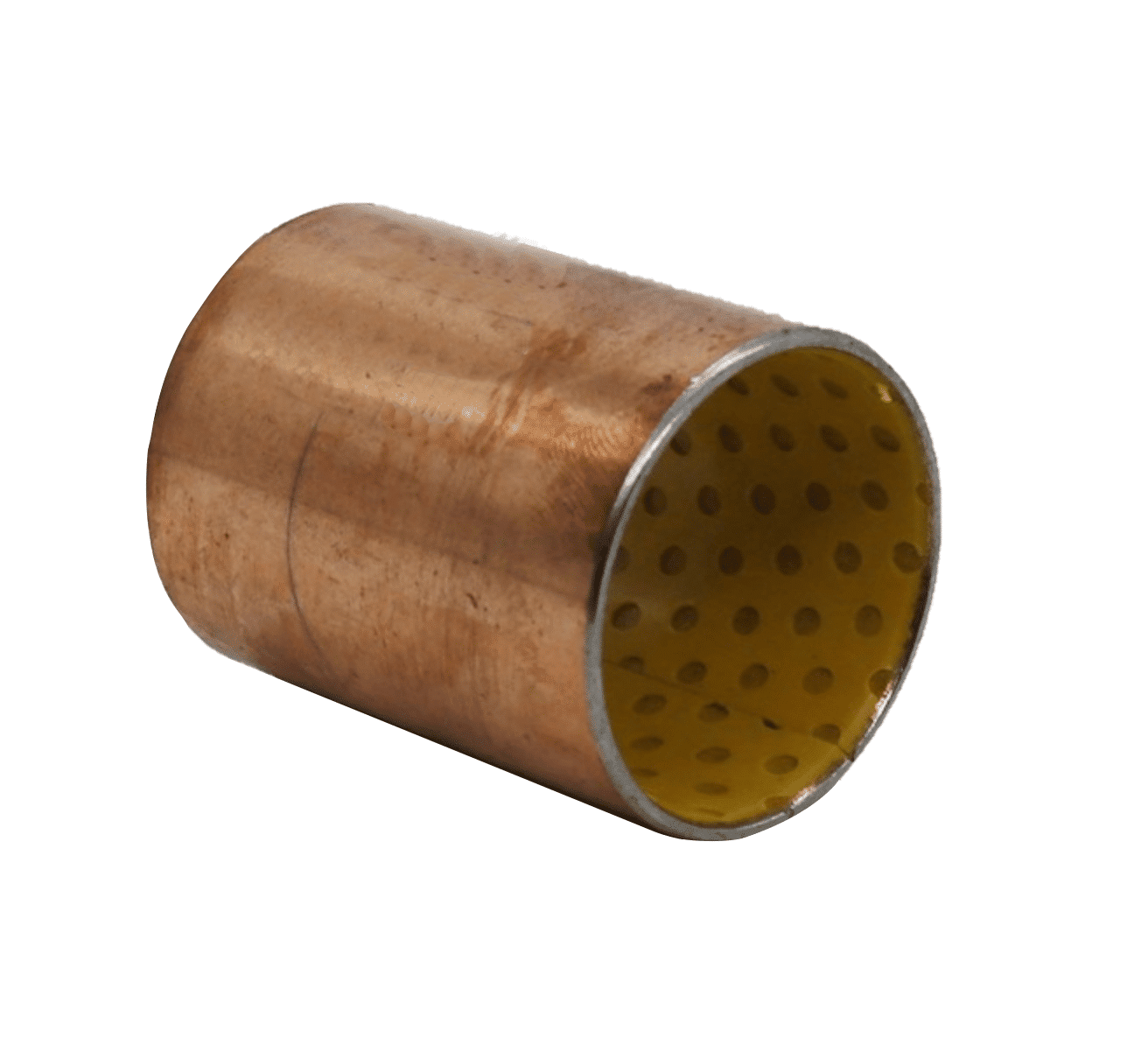

Bronze is a popular material for bearings due to its excellent wear resistance, high strength, and good thermal conductivity. However, in many applications, bronze alone may not provide the necessary performance or durability. That’s where intermediate layers and coatings come in. Two common coatings for bronze bearings are steel copper-plated or tin-plated intermediate layers, and sintered bronze with POM (polyoxymethylene) and MoS2 (molybdenum disulfide) lubrication pockets.

Steel copper-plated or tin-plated intermediate layers are applied to bronze bearings to improve corrosion resistance and reduce friction. The steel copper-plated layer provides a barrier against corrosion, while the tin-plated layer acts as a lubricant to reduce friction and wear. This coating is often used in applications where the bearing is exposed to harsh environments, such as saltwater, chemicals, or high temperatures. The coating can also improve the performance of the bearing in applications with high loads or speeds, where friction and wear are a concern.

Sintered bronze with POM (MoS2)/lubrication pockets is another popular bearing material. This material is made by sintering bronze powder, which creates a porous structure with excellent oil retention and lubrication properties. POM is a thermoplastic polymer that provides good mechanical strength, low friction, and wear resistance. MoS2 is a solid lubricant that is added to the POM matrix to improve lubrication properties. The lubrication pockets in the material ensure that the bearing is continuously lubricated, even in applications where there is minimal or no external lubrication.

The combination of sintered bronze, POM, and MoS2 makes this material ideal for applications where low friction, high wear resistance, and good mechanical properties are required. It is often used in applications with high loads, low speeds, and intermittent or oscillating motion. The material can also operate in a wide range of temperatures, making it suitable for both high and low-temperature applications.

Both steel copper-plated or tin-plated intermediate layers and sintered bronze with POM (MoS2)/lubrication pockets offer significant advantages over traditional bronze bearings. They can improve corrosion resistance, reduce friction and wear, and provide better performance in high-load or high-speed applications. When selecting a bearing material, it’s essential to consider the specific application requirements to ensure that the material will perform well under the intended conditions.

In conclusion, steel copper-plated or tin-plated intermediate layers and sintered bronze with POM (MoS2)/lubrication pockets are two common coatings for bronze bearings that offer excellent performance and durability. By improving corrosion resistance, reducing friction and wear, and providing better performance in high-load or high-speed applications, these coatings can extend the life of the bearing and reduce maintenance costs.

Use Self-Lubricating Bushings Multilayer With Composite PTFE Bearings for High Performance and Low Maintenance. Hi-Temp Bearing Solution. Non-galling. Run dry & keeps running. Reduced costs & downtime. Increased reliability. Services: Custom Design, Engineering Support, Short Lead Times.

Also defined as dry bearings due to their platinum layer, they offer various advantages in their own right.

– They are maintenance-free

– They are easy to assemble

– They have good frictional properties, low wear and high load capacity

– High creep speed

– Very high operating temperature range

– Negligible stick-slip effect

– Content operating game

– Good chemical resistance

– Low oil absorption, water absorption and swelling

– Inert to most chemical gases and solvents

– Does not store static electricity

Business Impact Through Experience

They consist of a mild steel armature with mechanical strength, coated externally with 2 μm copper or other protective treatment. On the inside, the walls have a layer of sintered porous bronze that ensures good adhesion of the PTFE layer to the steel. They can be machined, except on the creeping surface in addition to any sliding lubricant in the pipe. These bushings can have a protective treatment of copper, tin or zinc on the outer surface (the latter is also suitable for awning construction, for example), protecting the bearings from oxidation and corrosion. Such products are ideal for versatile designs.

Bronze (paramagnetic) or stainless steel walls can also be used.

Self-Lubrication Bushing Sleeve

During the initial break-in phase, some of the platinum is transferred to the contact surfaces, forming a lubricating film that reduces friction without the need for lubrication. The discrete addition of abrasive substances, used in conjunction with oil, is excellent for reducing heat on sliding surfaces by extending the life of the bushing, in addition to lubrication. On the other hand, the use of grease is not recommended because it tends to detach Ptfe if not maintained regularly. Do not use MoS2 based additives.

TYPICAL APPLICATIONSThese industries are the most diverse. From hydraulic systems to household appliances, to industries such as the automotive industry (hinges, shock absorbers, pedal boats, etc.), 3D printers, motorcycles, pharmaceuticals, food and gymnastic equipment. Especially where there are high loads and low to medium speeds or even oscillations.

The bushings should be installed by interference in the connection zone opposite to the direction of the load, using a staircase spindle and providing an inviting chamfer of 15 ° / 20 ° on the H7 tolerance seat, while the shaft in tolerance f7 (over d.75 = h7) recommended hardness HB 300 ÷ 600 and roughness less than 0.4 μm (in the case of cast iron 0.3 μm). If it is necessary to fix, you can use synthetic adhesives.

The PTFE/fiber blend is 0.01-0.03mm thick and provides a good initial transfer film which effectively covers the mating surface of the bushing assembly, forming an oxidized solid lubricating film. Sintered bronze powder, 0.20-0.35mm thick, provides maximum thermal conductivity away from the bushing surface and also acts as a reservoir for the PTFE-fiber mixture.

Steel-backed PTFE wire bushings Mild steel with extremely high load-bearing capacity and good heat dissipation. Copper/tin plating thickness of 0.002mm provides good corrosion resistance.

Copper-backed ptfe wire jacket: Copper-backed, providing exceptionally high load-bearing capacity, excellent heat dissipation and very good corrosion resistance.

Stainless steel backing. Stainless steel backing, providing very good corrosion resistance.

Switch to Metal-Polymer Plain Bearings Grease Lubricated

Oil-free Slide POM Plain Bushing Standard Size

Composite Bush manufacturers & suppliers

Thin walled bearings suitable for high loads at low speeds, bushes are Steel Backed with POM coating contained grease lubrication indents. Choose from our selection of bronze strips in a wide range of type and sizes. POM bushing: the global industry standard for marginally lubricated metal polymer plain bushes. Cylindrical bushes, thrust washers…

Choose from our selection of DX bushings in a wide range of sizes and materials. In stock and ready to ship.

Dx Bushings equivalent, self-lubricating bushings offer very good wear and low friction performance over a wide range of loads of products. Get the best price on bronzelube.com dx bushing when you shop the garlock bushings dimensions online selection at bronzelube.com. Browse your bushing size chart.

- Backing Material: Steel POM composite bearings

- Operating Temperature Range -328 to +536 °F

- Maximum PV Value 100000

- Maximum P Value 44000 psi

- Maximum V Value 2000 fp/min

High Quality

The promise of high-quality bushing and bearing washers that meet your requirements.

POM coated Bushings

Low minimum order value and quantity, quick delivery.

Metal-Polymer Composite Bushes Material. All Dimensions In Metric Size Or Inches. DX Bushing & Strip. Du Metric Range Bushes & Washer, Self-Lubricating Parts!

We Design POM coated bushing, Metal-Polymer – Superior Bushings for Lubricated Applications

POM-coated washers, also known as DX washers, dry bushings, or rolled composite bushings, feature a steel backing with a PTFE sliding layer. These metal-polymer plain bearing washers are designed for heavy-duty and harsh environments, offering exceptional resistance to chemicals, erosion, and wear. Numerous DX bush options are available, including flange type, straight type, and thrust washers.

COMPOSITION

- Metal-Polymer Composite Bushing: Steel backing, porous bronze sinter, and POM with lubrication indents.

Our company is a leading supplier in China’s competitive market for bulk order flange bushings, washers, and dx housing applications.

Metal-Polymer Hydrodynamic Composite Bearings

Easily browse, obtain quotes, and order metal-polymer composite bushings from China.

Custom-made composite bearing shapes encompass a variety of forms and configurations, including cylindrical bushes that provide essential support, thrust washers designed to withstand axial loads, and sliding plates that facilitate smooth movement. Additionally, there are half-bearings specifically crafted to enable effective operation in constrained spaces, along with specially shaped stamped components tailored to unique applications. Other variations include bearings that feature locating notches for precise placement, lubricant holes to ensure adequate lubrication during operation, and machined grooves that enhance performance. Furthermore, there are also options for tailored designs that can be customized to meet specific requirements and operational conditions.