Reliable & Professional Dry Bush Solution Supplier

Breathtaking design for home living.

“Pom bushings alternative dx bushing” are widely used in general industrial machinery, heavy machinery, machining facilities, plants and automotive parts. Experience of over 10 years of successful projects on creating safe & reliable dry bushes designs all over the world. Full range provider. Robust and long-lasting quality products. Available stock. View Products. Make An Inquiry. View News. Fast & safe shipping. Every time. Everywhere. Self-Lubricating POM Bushings & Du Bushing Alternatives – www.bronzelube.com

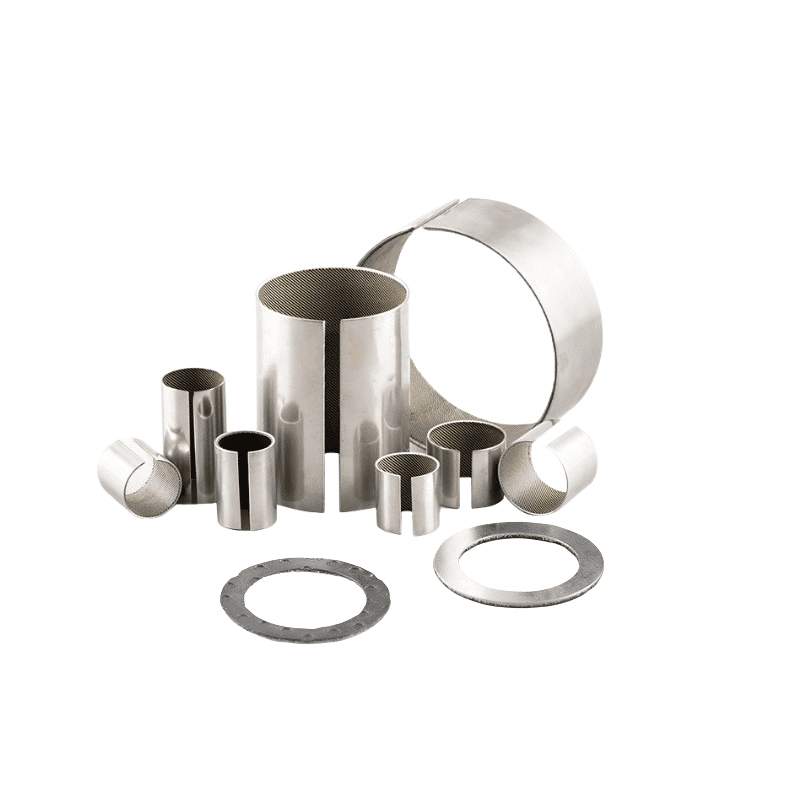

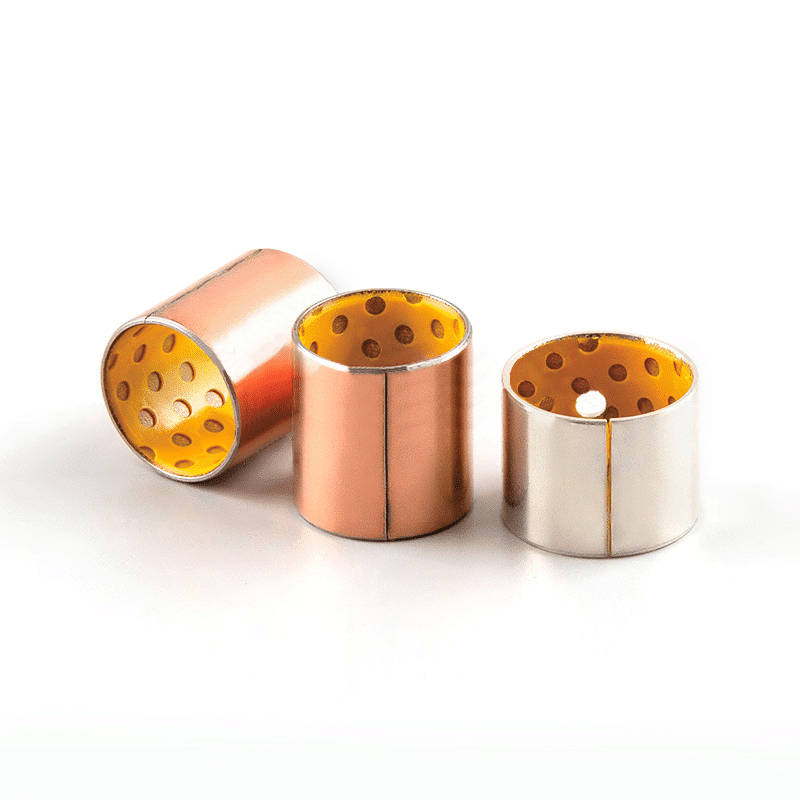

This wrapped composite bushings have a hardened steel backing with an inner lining POM. Cylindrical, flanged and thrust bushings forms are available. POM Composite Dry Sliding Bearings Bushing – Metric Size

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.

Pom Bushing Features

Dry bush designed completed reliably from production to delivery.

POM composite dry bushes are designed to operate under marginal lubrication conditions. The sliding surface of these plain dry bush contains grease.

This Pom composite dry bush works with grease or oil lubrication. All kind of movements are suitable for this sliding material. Dry bush has good resistance to dirt, is very robust and has a high load capacity.

High Quality POM Bushing

The promise of bulk order dry bush high quality, meet your requirement.

Dry Bushes Made To Order

Small minimum order value & quantity, fast delivery.

What is a Slide Bearing?

Sliding bearings facilitate precise linear motion and accommodate structural expansion.

Sliding bearing assemblies consist of structural pads, PTFE sliding surfaces, POM sliding surfaces (or other low-friction materials) and sliding bearing plates. Subtypes of sliding bearings include linear ball bearings and linear roller bearings. Sliding bearings may also be referred to as linear bearings, guide bearings or linear plain bearings.

They can be used in applications such as construction (expansion support for bridges) and precision tools.

In order to improve the frictional properties of the surface of the shaft tile and cast in its inner surface of the friction reducing material layer called bearing lining. Shaft shingles and bearing lining materials are collectively referred to as sliding bearing materials. Sliding bearing applications are generally in high-speed light load conditions.

Specialists in Slide Bearings: Understanding Specific Load and Sliding Speed

Slide bearings are essential components that facilitate the smooth and reliable movement between interacting mechanical parts. These bearings operate under sliding friction, making them ideal for applications that convert directional motion into rotary motion, like in reciprocating piston engines. Common materials used for slide bearings include bearing alloys (such as Bachmann or white alloys), wear-resistant cast iron, and copper- and aluminum-based alloys. Other materials include powder metallurgical substances, plastics, rubber, hardwood, carbon-graphite, polytetrafluoroethylene (PTFE or composite slide layer), and modified polyformaldehyde (POM).

The primary function of sliding bearings is to absorb and transmit forces between moving parts, maintaining their position and accuracy. In liquid-lubricated systems, the sliding surfaces are separated by a lubricating oil layer, preventing direct contact. This arrangement minimizes friction loss and surface wear, while also offering vibration absorption capabilities. However, these bearings may exhibit significant starting friction resistance.

The part of the shaft supported by the bearing is known as the journal, and the corresponding matching parts are referred to as shingles.

Need Advice?

Our engineers are ready to assist you in selecting the ideal slide bearing bushing for your specific application. Reach out for expert guidance tailored to your needs.

Slide Bearing structure

Sliding friction occurs when the sliding bearing works; the size of sliding friction mainly depends on the manufacturing accuracy; and the size of friction of sliding bearing mainly depends on the material of the sliding surface of the bearing. Sliding bearings generally have self-lubricating function on the working surface; sliding bearings are divided into non-metallic sliding bearings and metallic sliding bearings according to the material. Non-metallic sliding bearings are mainly plastic bearings, plastic bearings are generally made of better performance engineering plastics; more professional manufacturers generally have engineering plastics self-lubricating modification technology, through the fiber, special lubricants, glass beads, etc. on the engineering plastic self-lubricating enhancement modification to make it reach a certain performance, and then use the modified plastic through injection molding processing into self-lubricating plastic bearings.

Metal slide bearing in the early twenty-first century is the most used three-layer composite bearing, this bearing is generally carbon steel plate as the substrate, through sintering technology in the steel plate first sintered layer of spherical copper powder, and then in the copper powder layer sintered layer of about 0.03mm PTFE lubricant; the middle layer of spherical copper powder is the main role is to enhance the combination between the steel plate and PTFE strength, of course, when working It also plays a certain role of bearing and lubrication.

Slide Bearings Manufacturing materials

Metal materials, such as bearing alloys, bronze, aluminum-based alloys, zinc-based alloys, etc.

Switch to Dry Sliding Bearings – Dry Bushing

We are automating tomorrow, Reduces Cost By 75%

Providing dry bearing bushing solutions. See Our Online Catalog & Request A Quote! Dry Sliding Bearing & Self-lubricating dry Materials Made To The High Standards. Shop Our Huge Range of slide bearing bushing type. Call Or Email Us Today!

Dry bush typical application

Yoga takes you into the present moment. The only place where life exists.

Pom bushing is a low maintanence dry bush material with MoS2 sliding layer and lubrication pockets. An initial greasing during installation is necessary, after that, periodic greasing with oil or grease is mandatory. Make every dry bush production detail perfect and limit the number of details to perfect. The dry bush is widely used in truck cranes, agriculture machines, hydraulic cylinders, construction machinery, tale gates.

High Quality Dry Bush Design & Online Sales

Yoga takes you into the present moment. The only place where life exists.

More Dry Sliding Bearings products from china

We have professional production and design team. Welcome merchants both domestic and overseas to place dry bushes orders with supplied designs and samples.

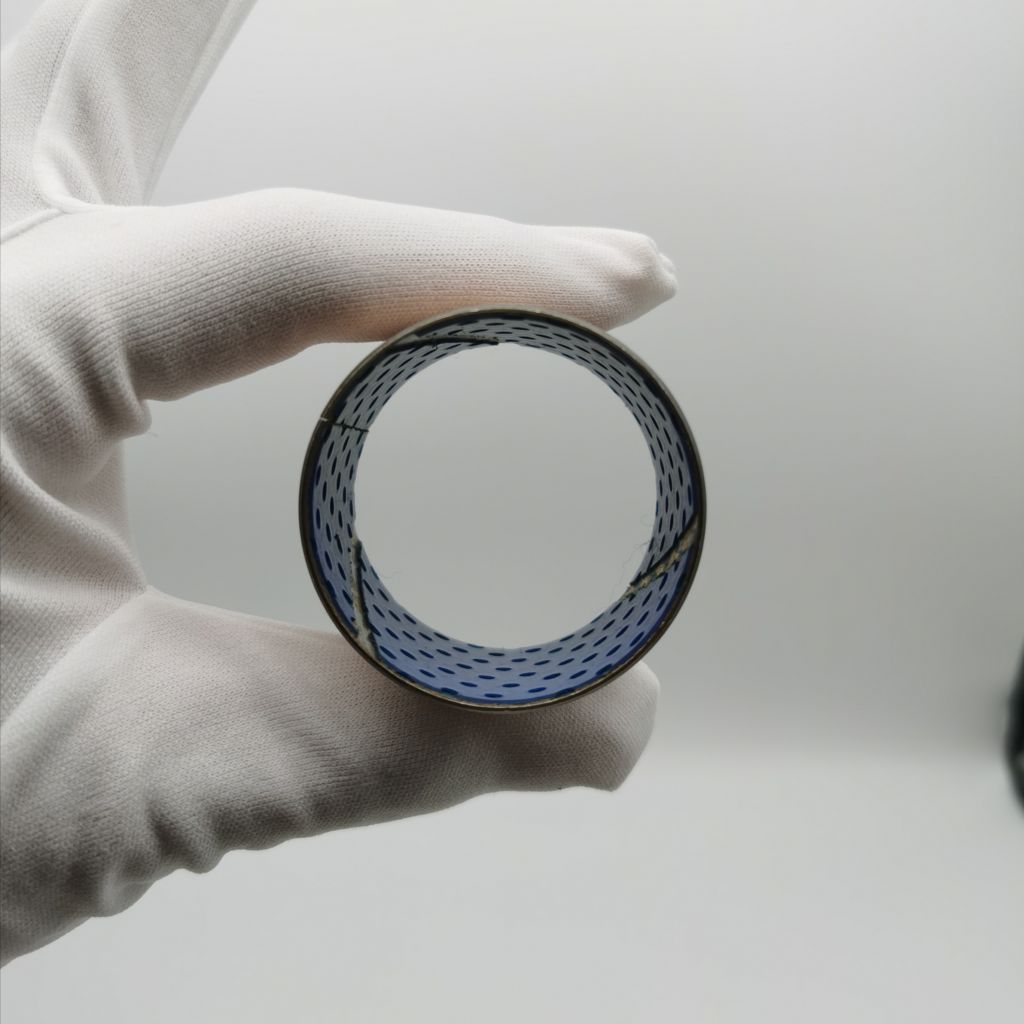

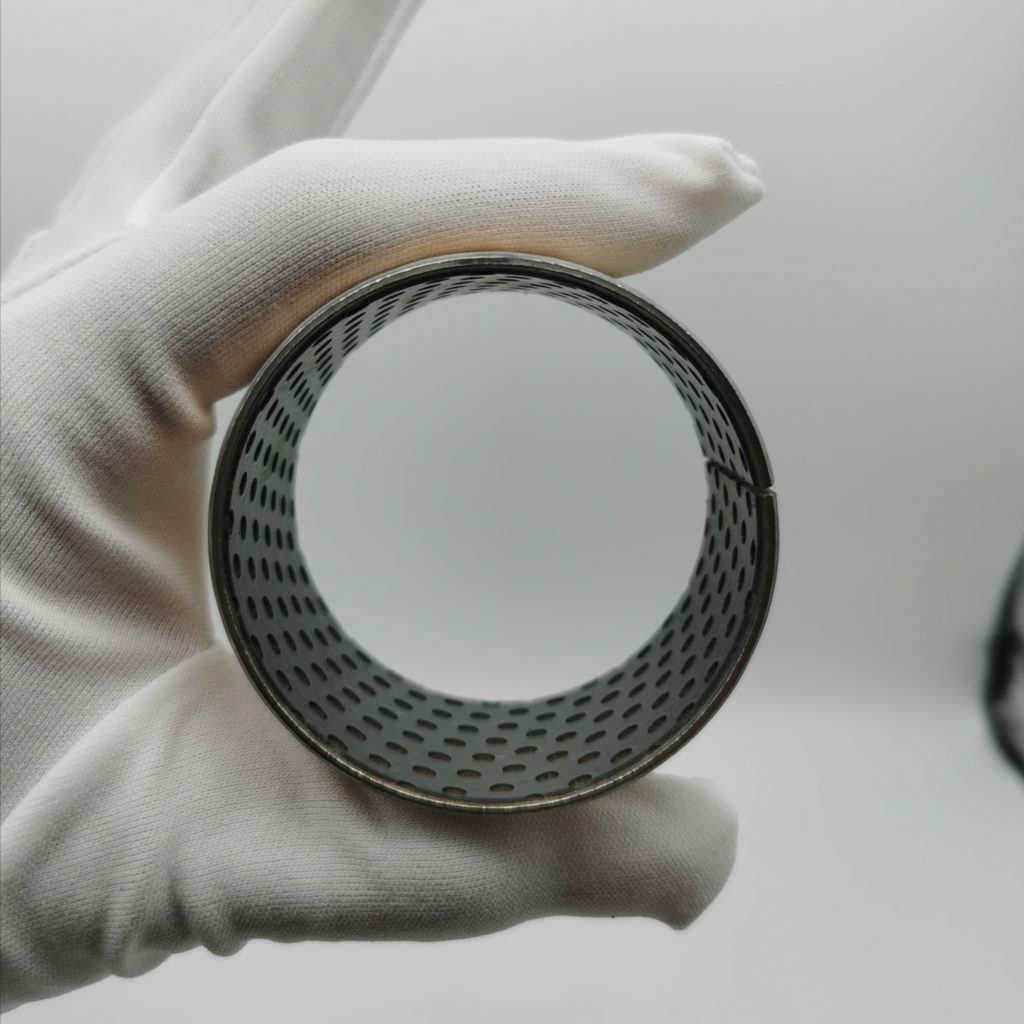

POM bushing material

- Support material: Steel copper-plated or tin-plated

- Intermediate layer: Sintered bronze

- Sliding layer: POM (MoS2)/lubrication pockets

High-quality & Dry Sliding Bearings.

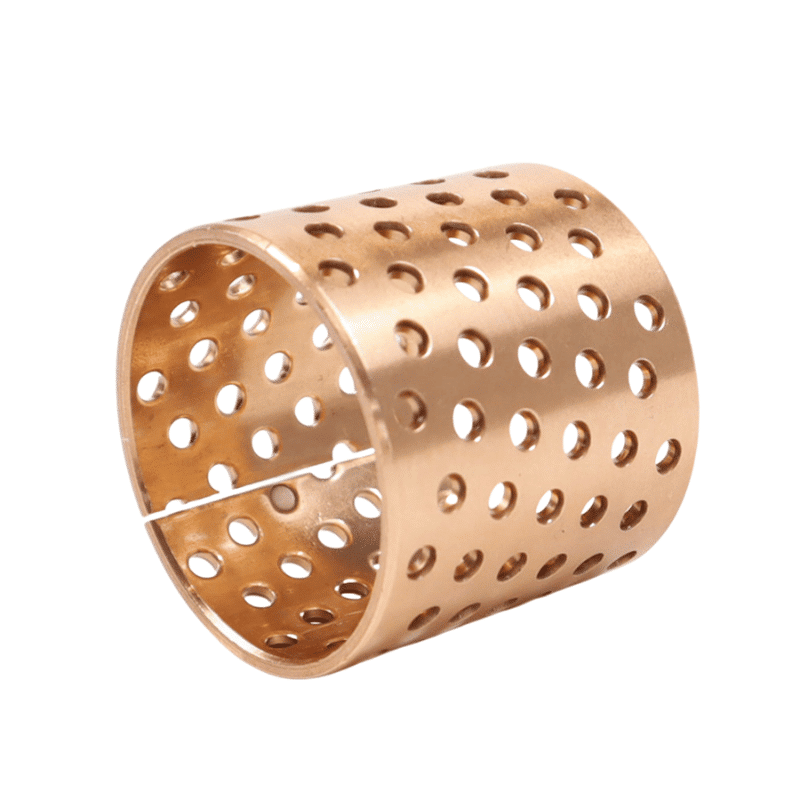

Bronze Sliding Bearings, POM Composite Bushings

Low maintenance POM sliding layer with grease holes,Bronze plating on OD,Boundary lubricated bearing can be extended to the field of environmental protection. At present, the product has been used in imported textile equipment, plunger pump swing parts, automotive joystick parts and other medium load, medium speed, grease lubrication occasions.

- Sleeve made of steel strip with POM composite material with lubrication chamber.These sleeves have high wear resistance and can operate from -40 o C to + 100 o C.

- They are most commonly used in industry, automobiles and agricultural machinery.

- Recommended for swing and slide work.

- Sizes range from 10 mm to 300 mm.

Dry Sliding Bearings China | High Quality, Factory Price

On this page you can find the complete product range of low maintenance bushings from china,High-Quality Chinese Sliding Bearings.:www.bronzelube.com

Design Guides Bushings & Support

Our experts align with your technical team to engineer superior composite sliding bearing for your projects.

Foundation technical parameters

- Low maintenance POM sliding layer with grease holes

- Coated steel backed bushing

- Lead free, RoHS compliant

- For lubrication applications

STEEL BACKED BRONZE POM BUSHES Composite Bearing

Dry Sliding Bearings Characteristics

- for rotating and oscillating applications

- low maintenance

- long maintenance rates

- low wear

- good damping behaviour

- no water absorption

Structure of Composite Material

- copper plated steel backside

- porous layer of sintered bronze

- void filling and conversion coating : resin of acetal

Dry Sliding Bearings Technical data

static surface pressure 140N/mm²

temperature range: -40°C – +130°C

Fitting Tolerances

- housing H7

- shaft h8

SHAPES & FORMS

- Cylindrical bushes

- Flanged bushes

- Thrust washers

- Flanged washers

- Sliding plates

Assembling Instructions

The edges of the mounting hole and the shaft must be chamfered. It is recommended to use an arbour press. Please avoid damaging the sliding surface. The butt joint should not be in load direction.

Dry Sliding Bearing Application

The multilayer sliding bushing dry sliding bearings have been widely used in automotive chassis, forging machine tools, metallurgical mining machinery, engineering machinery, hydropower, steel rolling industry and other fields.