IMPERIAL & METRIC SIZE

thrust washers – metric size order online!

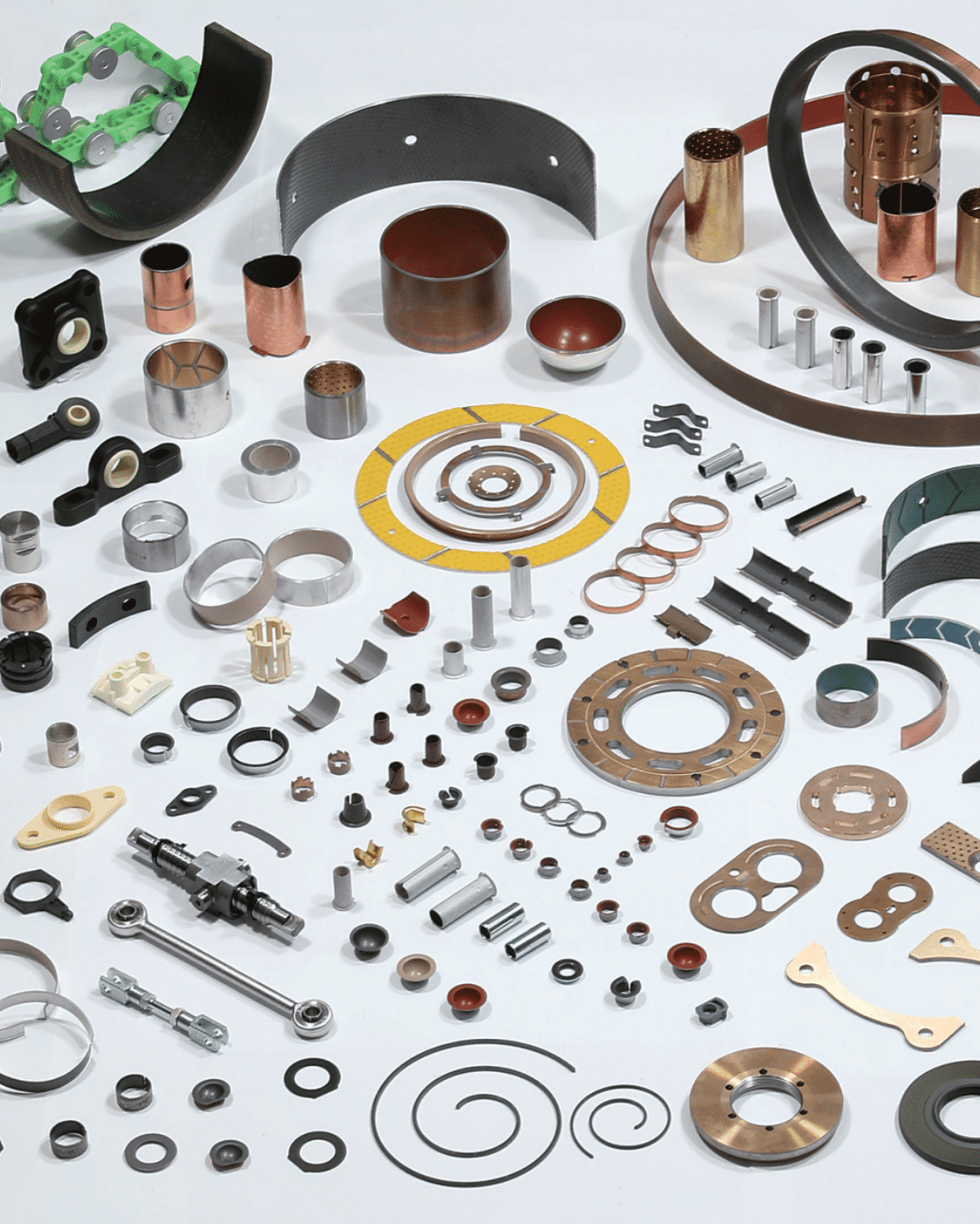

Standard-sized thrust washers are available. Reach out to dry bearing specialists for details on our plain bearings, self-lubricating bushings, and polymer coating solutions for your application.

High Quality Thrust Washer

- High-performance

- Self Lubricating PTFE Washer

- Wear-resistant

Custom Thrust Washer Solutions.

washer equivalent; competitively priced vs cast bronze washer.

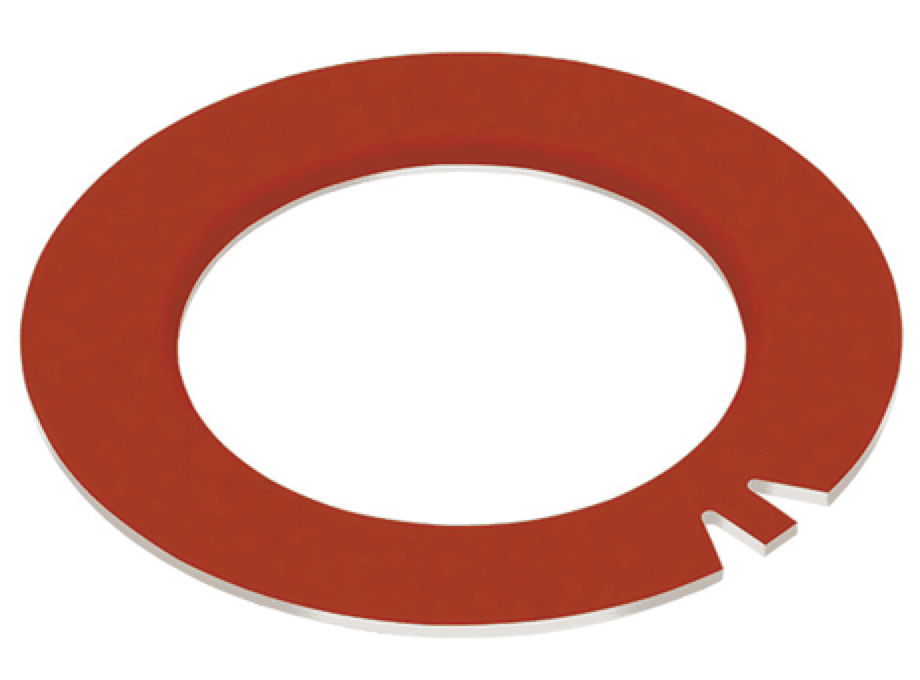

STRUCTURE

- Sliding layer RED PTFE + Fillers Porous Bronze Sinter Steel Backing

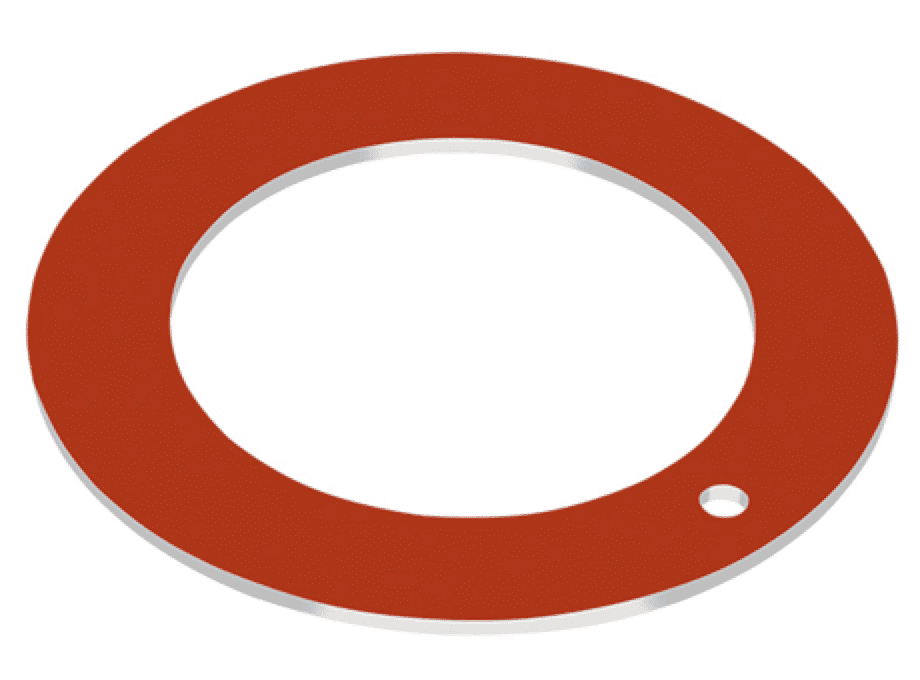

Grease Lubricated Washer

The promise of thrust washer high quality, meet your requirement.

Thrust Washer Size

Small minimum order value & quantity, fast delivery.

“Advanced lead-free sliding layer with strong steel backing, compliant with ELV and RoHS, offers superior lubricating properties.”.

- Copper plate + copper powder + (PTFE + filler)

- Stainless steel + copper powder + (PTFE + filler)

- Carbon Steel + Copper Powder + (PTFE + Filler)

Plain Bearings, Steel Backed Washer – Metal Polymer, Copper Plating

Bronzelube.com specializes in manufacturing and selling oilless lubrication bearings, offering a wide range of products without oil production. We ensure fast and reliable delivery from our high-quality factory. Our product lineup includes plain bearings with steel backing and RED PTFE, cylindrical and flanged bushes, as well as RED PTFE washers.

Thrust Washer Wear-resistant

The Thrust Washer exhibits excellent anti-abrasion properties, primarily due to the unique molecular structure of PTFE. The abrasion process can be divided into three phases, each with a distinct friction coefficient:

1. “Running-in” phase: In this initial phase, PTFE from the bushing transfers to the mating surface, creating a lubricating film. The friction coefficient is high, leading to rapid wear, as indicated in area I of the graph.

2. “Stabilization” phase: Following the running-in phase, friction occurs between PTFE surfaces, resulting in a lower and steady friction coefficient. Consequently, the wear rate stabilizes at a low level, as shown in area II of the graph.

3. “Sharp” phase: As the PTFE in the porous layer depletes, inadequate lubrication increases both the friction coefficient and wear rate. When 70% of the bronze surface becomes exposed, the Thrust Washer approaches the end of its service life, as depicted in area III of the graph.

* Self-Lubricating Multilayer Composite Thrust Washer Supplier.

Sleeve Bushing Technical Data

| Performance | Date | |

| Load capacity P | Static load | 250N/mm² |

| Load capacity P | Dynamic load | 140N/mm² |

| Load capacity P | Oscoillation Load | 60N/mm² |

| Max line speed V | Dry friction | 2.5m/s |

| Max line speed V | Oil lubrication | >5m/s |

| PV value limit | Dry friction | 1.8N/mm²· m/s |

| PV value limit | Oil lubrication | 3.6N/mm²· m/s |

| Friction coef μ | Dry friction | 0.08~0.20 |

PTFE Bushing Technical Data

| Performance | Date | |

| Friction coef μ | Oil lubrication | 0.02~0.08 |

| Mating Axis | Hardness | >220 HB |

| Mating Axis | Roughness | Ra=0.4~1.25 |

| Working temperature | -200~+280℃ | |

| Thermal conductivity | 40W/(m·k) | |

| Coefficient of linear expansion | 11×10-6K-1 | |

| Outside surface Plating | copper/tin | |

| We can also develop according to customers special request while out of this table. | ||