CNC machining service

Online CNC Machining Service – Made in China

A broad range of CNC machining capabilities and materials to meet your part requirements. CNC Machining Services – Custom Parts Made Fast. High-quality rapid custom prototyping and manufacturing services for product development. CNC Quote Parts in Fast as 1 Day, Upload a drawing file to receive a quote and design analysis today. Strengthen your supply chain with on-demand machining that delivers parts within weeks. Guaranteed Exact Parts. Fast Lead Times. precision brass.

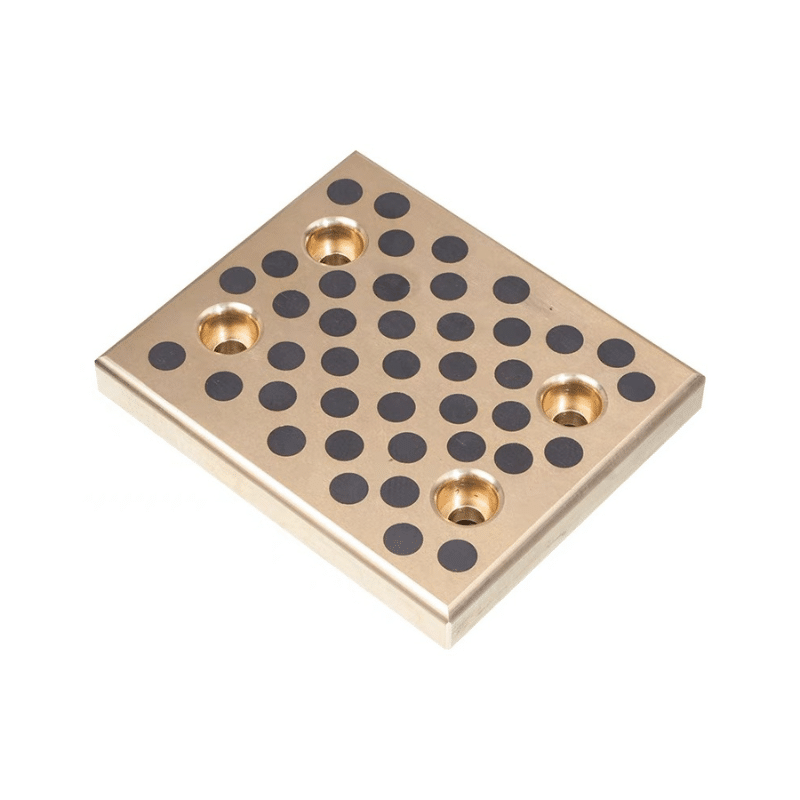

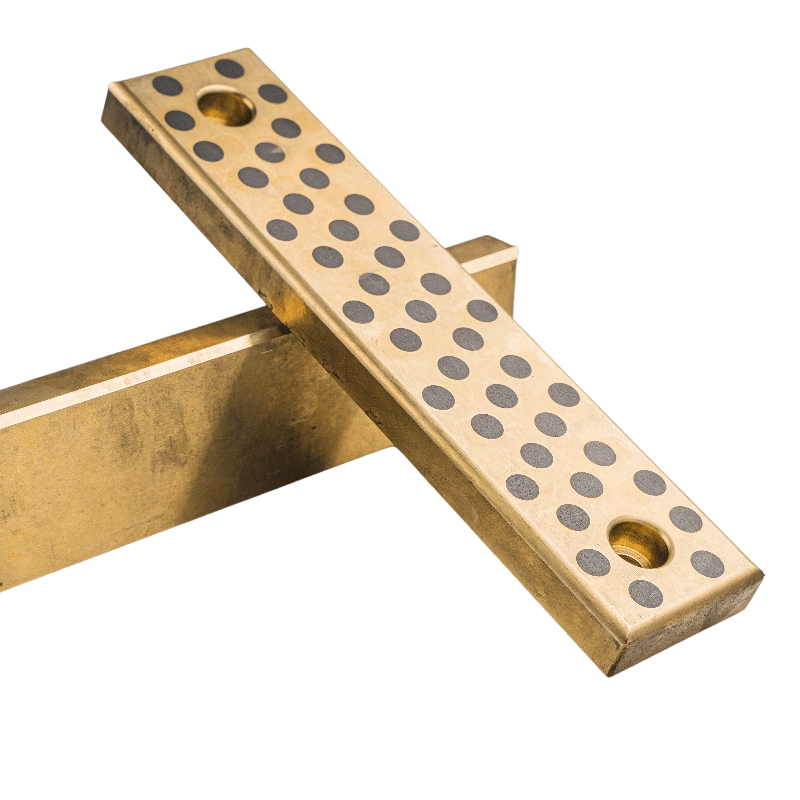

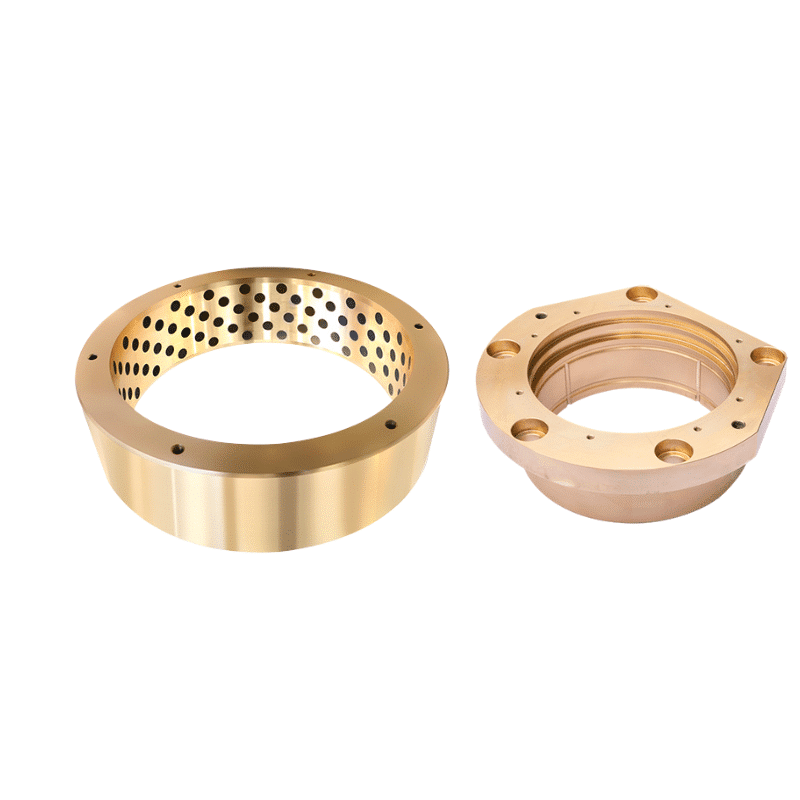

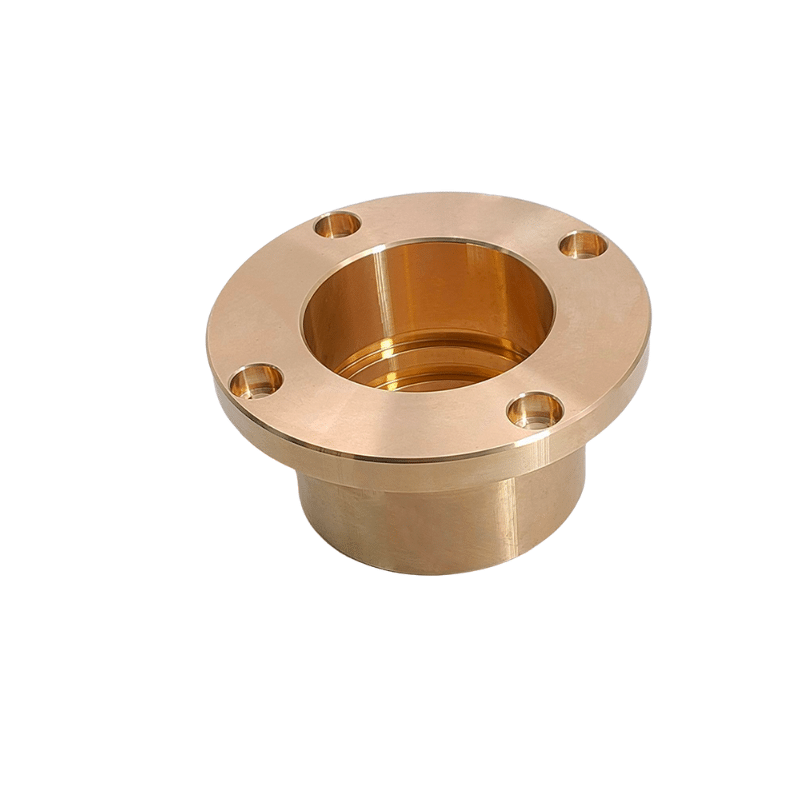

Brass and Bronze Bushings & Bearings, CNC Shop

Beautifully crafted leather products.

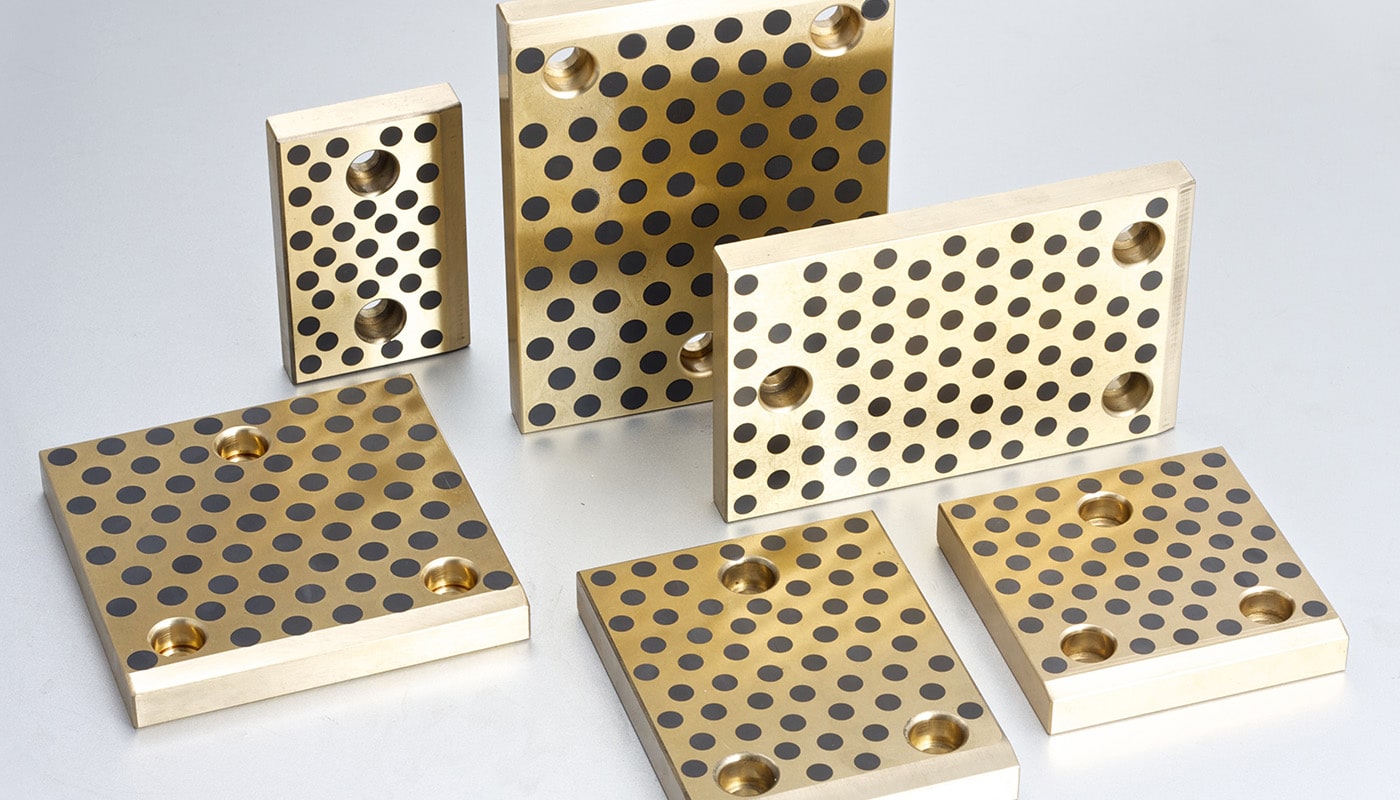

CNC Bronze Parts Supplier, Extensive Inventory Of Sizes. Buy Direct and Save. Get A Quick Quote from the China. Bronze Team of Bearing and Bushing Experts Today. Buy Bronze Bushings Online In stock order online. In Stock. Large Inventory. Delivers Components For a Variety of Industries Efficiently. Small Minimums, Bronze Bushings at Bronzelube.com- Pick Specs & Dimensions Online! Custom bronze parts can be manufactured using CNC machining services. Several companies offer precision CNC machining for bronze components, allowing the production of complex parts with high accuracy. These parts can include bronze bushings, bearings, wear plates, and custom components tailored to specific industrial applications. Bronze is a favorable material for such parts due to its excellent machinability, low friction properties, and suitability for low-stress components. The use of CNC machining ensures the production of high-quality custom bronze parts based on exact specifications, contributing to their durability and cost-effectiveness

We Custom CNC Machining Parts Instant Free Quote

CNC Milling

For High Quality CNC Parts. Bronze Bearing Prototype. CNC milling machine is also called CNC (Computer Numerical Control) milling machine. In English, it means a milling machine controlled by digital signals with an electronic meter.

China CNC Machining Prototype. 3 & 4 & 5 Axis Machining. Tolerances as Low As +/-0.025mm.

CNC milling machine is a kind of automatic processing equipment developed on the basis of general milling machine, the processing process of both is basically the same, the structure is also somewhat similar. CNC milling machines are divided into two categories: those without tool magazines and those with tool magazines. Among them, the CNC milling machine with tool magazine is also called machining center.

CNC milling is a special form of computer numerically controlled (CNC) machining. Milling itself is a process similar to drilling and cutting, enabling many of the operations of cutting and drilling machines. Like drilling, milling uses a rotating cylindrical cutting tool. However, the tool in a milling machine is able to move along multiple axes and can create a variety of shapes, slots and holes. In addition, the workpiece often moves in different directions through the milling tool, unlike the single-axis motion of a drill.

CNC milling machines are the most widely used type of CNC machine tools. Typically, they are grouped by the number of operating axes, labeled with various letters. x and y indicate horizontal movement of the workpiece (front-to-back and side-to-side in a plane). z represents vertical, or up-and-down, movement, while w represents diagonal movement in a vertical plane. Most machines offer 3 to 5 axes, providing performance along at least the X, Y and Z axes. Advanced machines, such as 5-axis milling centers, require CAM programming for optimal performance due to the incredibly complex geometries involved in the machining process. These machines are extremely useful because they are able to produce shapes that would be nearly impossible using manual tooling methods. Most CNC milling machines also incorporate a device for pumping cutting fluid to the cutting tool during the machining process.

Computer numerically controlled machining centers are used to produce a wide range of parts, and the cost of the tools involved continues to become more affordable. Generally speaking, high volume production requiring relatively simple designs is better served by other methods, although CNC machining can now meet a wide range of manual manufacturing needs. CNC milling centers are the ideal solution for everything from prototyping and short-run production of complex parts to the manufacture of unique pre-finished parts.

CNC Turning, Online CNC Turning Service – Low Cost, On Time, To Spec

Turning is a form of machining, a material removal process used to create rotating parts by cutting away unwanted material. The turning process requires a lathe or lathe, workpiece, fixture and cutting tool. The workpiece is a pre-formed piece of material that is held in a fixture that is itself attached to the lathe and allows for high speed rotation. The tool is usually a single-point cutting tool that is also secured to the machine, although some operations use a multi-point tool. The cutting tool enters the rotating workpiece and cuts away the metal in small pieces to form the desired shape.

Turning is used to produce rotating, usually male axis symmetrical parts that have many features such as holes, slots, threads, tapers, steps of various diameters, and even contoured surfaces. Parts manufactured entirely by turning typically include a limited number of components, perhaps for prototyping, such as custom-designed shafts and fasteners. Turning is also commonly used as an auxiliary process to add or refine the characteristics of parts made using a different process. Because turning can provide high tolerances and surface finish, it is ideal for adding precision rotating features to parts whose basic shape is already formed. The results show that high efficiency as well as high accuracy can be attained by CNC turning.

Turning is a machining process in which the cutting tool, usually a non-rotating head, describes a spiral tool path by a more or less linear motion while the workpiece rotates. The axis of motion of the tool may really be a straight line, or it may be along some curve or angle, but they are essentially linear (in a non-mathematical sense). Often, the term “turning” is reserved for producing an outer surface by this cutting action, while the same basic cutting action is referred to as “boring” when applied to an inner surface (i.e., a certain type of hole). Thus, the phrase “turning and boring” classifies the larger (and essentially similar) family of processes. Cutting faces on a workpiece (i.e., surfaces perpendicular to the axis of rotation), whether with a turning tool or a boring tool, is referred to as “facing” and can be classified as a subset of both. Today, the most common type of such automation is computerized digital control, better known as CNC. (In turning, a piece of relatively hard material (such as wood, metal, plastic or stone) is rotated and the cutting tool is moved along 1, 2 or 3 axes of motion to produce precise diameters and depths. Turning can be done on the outside of a cylinder or on the inside (also known as boring) to produce tubular parts in a variety of geometries. Although now quite rare, early lathes could even be used to produce complex geometries and even platonic solids; although since the advent of CNC technology, it has become unusual to use non-computerized toolpath control for this purpose. Turning operations are usually performed on lathes, considered to be the oldest machines, and can be of four different types, such as straight, tapered, profiling or external groove turning. These types of turning operations can produce various shapes of materials such as straight, round, curved or slotted workpieces. In general, turning uses simple single point cutting tools. Each group of workpiece materials has an optimal set of tool angles that have evolved over the years. Scrap metal chips from turning operations are known as swarf (North America), or chips (UK). In some areas, they may be referred to as turning.

MOLD COMPONENTS

mold components are designed and manufactured to exceed demanding customer expectations for quality, reliability, and performance. With an extensive product selection supported with superior customer service, you can count on us to meet your needs. Online CNC Machining Services for Custom Parts And Production Parts. China CNC Machining Prototype | Custom Parts & Rapid Prototyping. Order Status Tracking.

CNC Machining Online – Fast Turnaround Times. CNC parts online, Start A New CNC Quote, Don’t see what you need?Free manufacturing quote, Now offering economy lead time discount. Choose from a broad selection of self-lubricating and metal materials. Material certifications and a variety of finishing options are available. CNC Machining Quotes – Low Cost, On Time, To Spec! Quick-Turn CNC Machining – Hit Your Deadline – Fast Quote

Prototyping & Low-Volume Production Of End-Use Components….

Online CNC Machining Service – Low Cost, On Time, To Spec

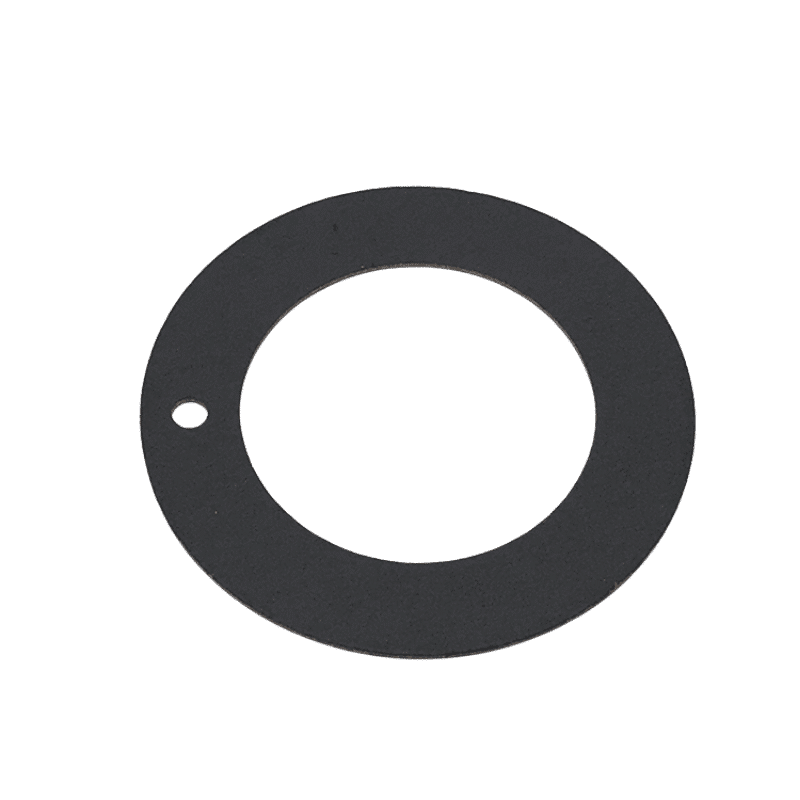

SELF-LUBRICATING

SHOULDER BUSHINGS – SOLID BRONZE

Machining Services. Get instant quotes on custom metal and bronze machined parts. Make quick turn prototypes and production part, fast delivery. CNC metal machining, bronze bearings, CNC machining parts

MOLD COMPONENTS

STRAIGHT BUSHINGS SOLID BRONZE

CNC Machining Service, Get an Online CNC Quote. CNC, or computer numerical control machining, is a subtractive manufacturing method that leverages a combination of computerized controls and machine tools to

CNC Machining – You Design It, We’ll Make It

CNC Services: Precision Brass Bearing,Machining, Turning, and Milling.

Competitive Prices. Rapid CNC Machining Service – High precision, Small batch, Custom CNC Quote.

Metal CNC Machining Materials, The Materials You Need

Bushing Bearing Selection

CNC machining parts, Looking for Custom Bronze Materials?

Reliable CNC Machining Service

CNC Machining Quote – Prototyping Services

Ready to growth your business?

Choose your correct self-lubricating bearing for your agricultural machinery. CAD File Quotes, CNC Milling, Turning & Cutting. Maintenance free! Longer life! We offer economical way to reduce material removal amount and improve machining process. Our facilities are equipped with the most cutting edge, high precision machines.

Precision CNC machining, Get quality machined parts in as fast delivery! Custom Manufacturing, Factory Direct!

Call us

24/7 emergency callout