Self-lubricating split plain sleeve bearings and custom bushing solutions. Proven integrity, delivering value.

Bushing sleeves, or sleeve bearings, are cylindrical components that minimize friction between moving machine parts. They support loads on an operating shaft that slides between moving surfaces. We offer a wide selection of self-lubricating split sleeve bushings, split-type plain metric sleeve bearings, and metric sleeve bushings. Technical Bushing Bearing Standard Parts Experts – Fast and Convenient.

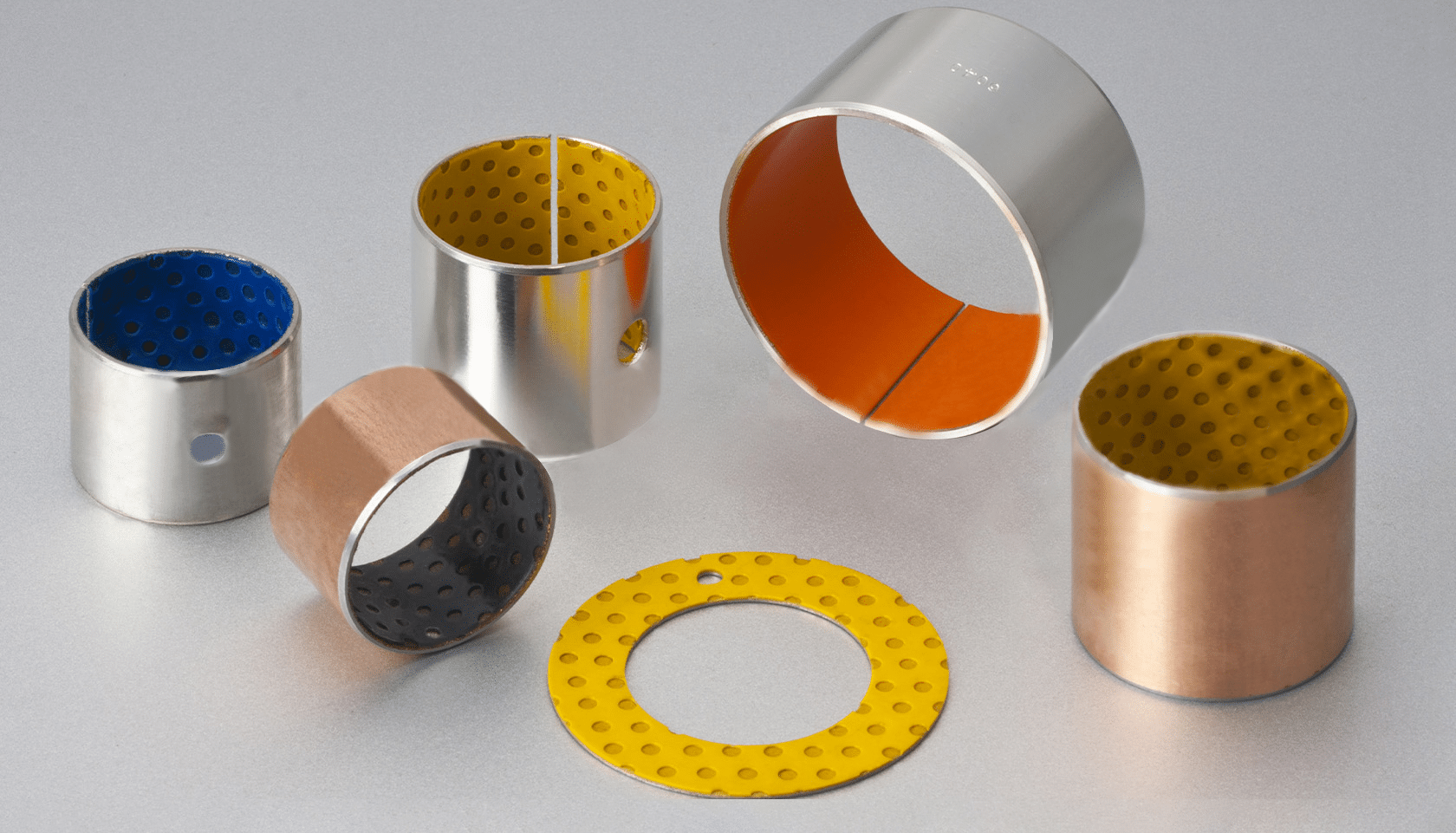

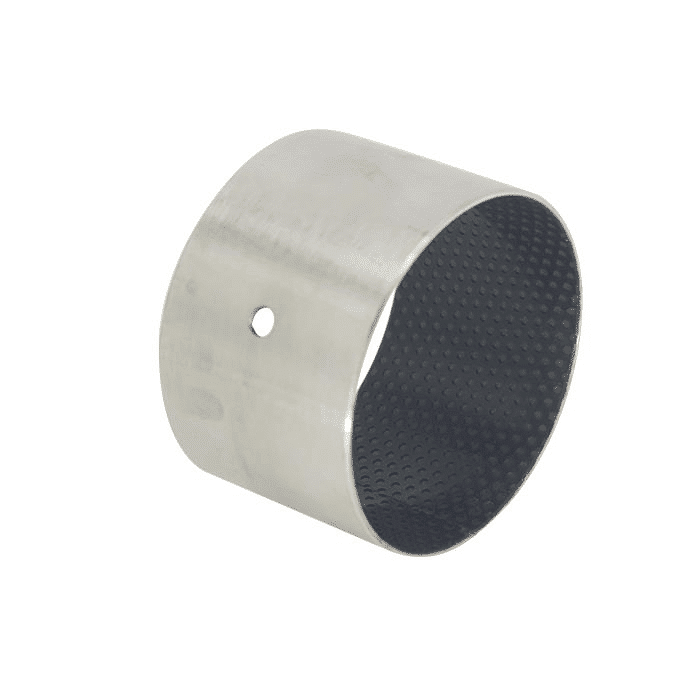

Metal-Polymer Anti-Friction Bearings

Real-life strategy to reach your goals.

Bushing sleeves facilitate linear or rotational movement with minimal friction. Available in various materials, they are often self-lubricating for low-maintenance use. Self-lubricating split PTFE bearing bushings provide excellent wear resistance and low friction across a wide range of loads, speeds, and temperatures in dry running conditions.

We strive for diversity across the globe

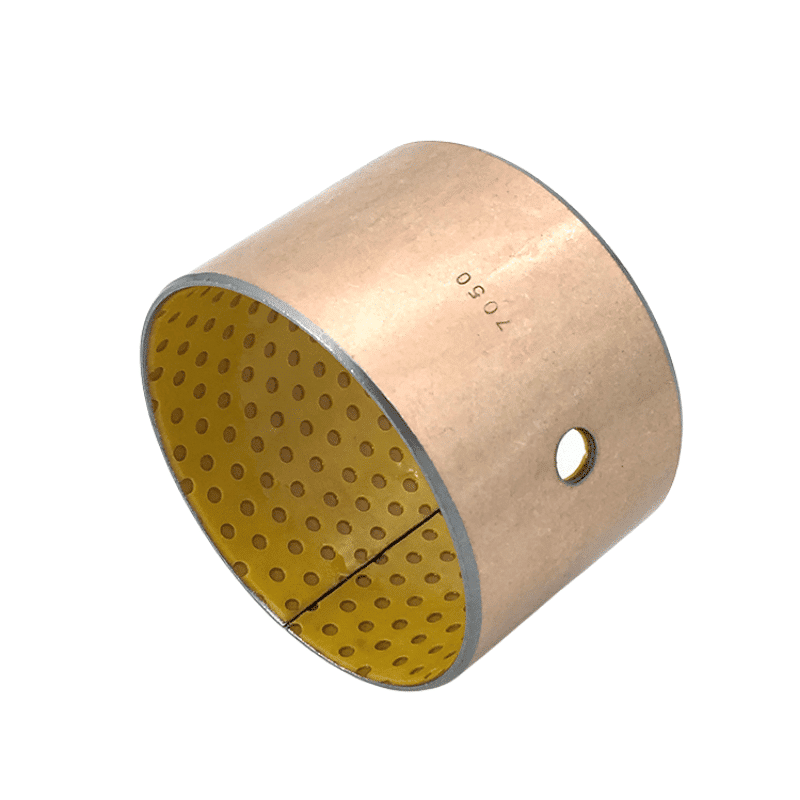

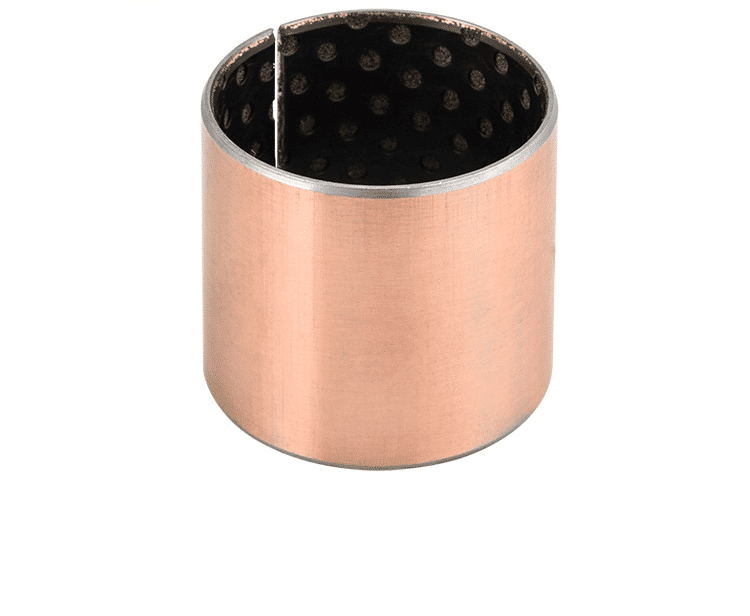

Split Bronze Bushings Bearing

CuSn8 Tin Bronze Split Bushing Self Lub DIN 1494 / ISO 3547. Split bronze bushings are primarily used in applications with radial rather than axial loads. They can be installed in any orientation and are ideal for situations with limited space for traditional bearing bushings.

Applications: These bushings are prevalent across various industries, including automotive, white goods, drilling tools, motors, and hydraulic systems. In the automotive sector, they are utilized in hinges, seat adjustment systems, and steering wheels.

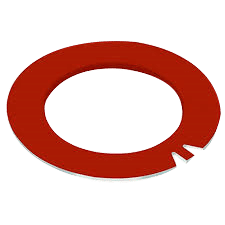

collar bushing

Self-lubricating bearings from Bronzelube.com cut costs by 40% and reduce weight by 80%.

Self-lubricating split bushing sleeve, corrosion-resistant & maintenance-free metal for industrial equipment. check out bushings and buy split sleeve bearing at an affordable price on bronzelube.com. Enjoy scrolling through China’s wholesalers offering quality split bearing sleeve bushing…

Custom Bearing Manufacture – Customized Bearing Solutions.

Guaranteed Quality & Service. Explore our selection of sleeve bearings, dry bearings, and dry-running sleeve bearings. Unlike rolling elements, plain and sleeve bearings utilize sliding motion to support heavy loads. Our diverse range of sleeve bushing materials is ideal for various applications. We offer split steel bushings, thin-walled OEM bearings, PTFE coated bearings, and custom specialty bearings tailored to meet specific requirements. Simply choose any item and inform us of your custom specifications.

Metal Bearing Solutions

Split Bushing Sleeves and Custom Bearings

Choose from our selection of self-lubricating, split-type plain metric sleeve bearings, including dry-running options. All items are in stock and ready to ship. We collaborate with customers to tackle engineering challenges. For more information, visit our Bushing Design Guide and browse our catalog of bushings, bronze bushes, and various bearings. Explore our extensive range and fill out the form to request drawings. We prioritize quality raw materials and expert support. Bronzelube improves motion efficiency with minimal friction through advanced plain bearing and surface engineering technologies. It is offered in flange sleeve bearings with a spherical outer diameter, providing an excellent price-performance ratio.

General-purpose bushing bearings are available in metric and inch sizes, sourced from China. They are affordable, self-lubricating, and maintenance-free.

Factory-Direct Bronze Bushings – Fast shipping from an experienced manufacturer in China.

Bushing Sleeve supplier

Reliable Guides and Bushings from Trusted Mechanical Engineering and Manufacturing Sources.

We provide solutions-oriented split bushing sleeve replacement parts for industrial self-lubricating bearings. Committed to sustainable plain bearing solutions, we aim to address challenges posed by technological advancements, envisioning a future where people and machines excel together. Our dedicated team strives to be the preferred service partner for decision-makers and end users across various industries. Learn more.

Change Your Bearing Now & Reduce Costs By 40%, Metal-Polymer Low Friction Plain Bearings!

Beautifully crafted leather products.

Bushing sleeves are available in various lubricating materials. Request a custom split bushing sleeve bearing. We offer high-quality steel bushing sleeves and are experts in hydraulic sales, service, and repair. Our sleeve bushings, thrust washers, and strips have a short lead time and exceptional quality. The PTFE bushing sleeve features a metal shell with a thin polymer (PTFE) coating on the inside.

maximizing style in limited areas

Tribological bushing sleeve

Customized Solutions for Bushing and Sleeve Bearing Materials.

– Split bearings

– Metal bushings

– Bearing shells

– Half bearings

– Half shell bearings (plain wrapped) with a PTFE/POM sliding layer, ideal for dry running.

Bushings with Sleeve Design

Composite & Self-Lubricating Bushings Tested!

Bushing sleeves in standard dimensions, offering dry friction sliding properties and a bronze substrate for enhanced corrosion resistance. High Quality Sleeve Bushings for Customers’s needs. Metal-Polymer Plain Bearings. Good performance in greased applications.

- Cylindrical bushes, split bushing sleeves

- Flanged bushes, flange sleeve bearings, mm

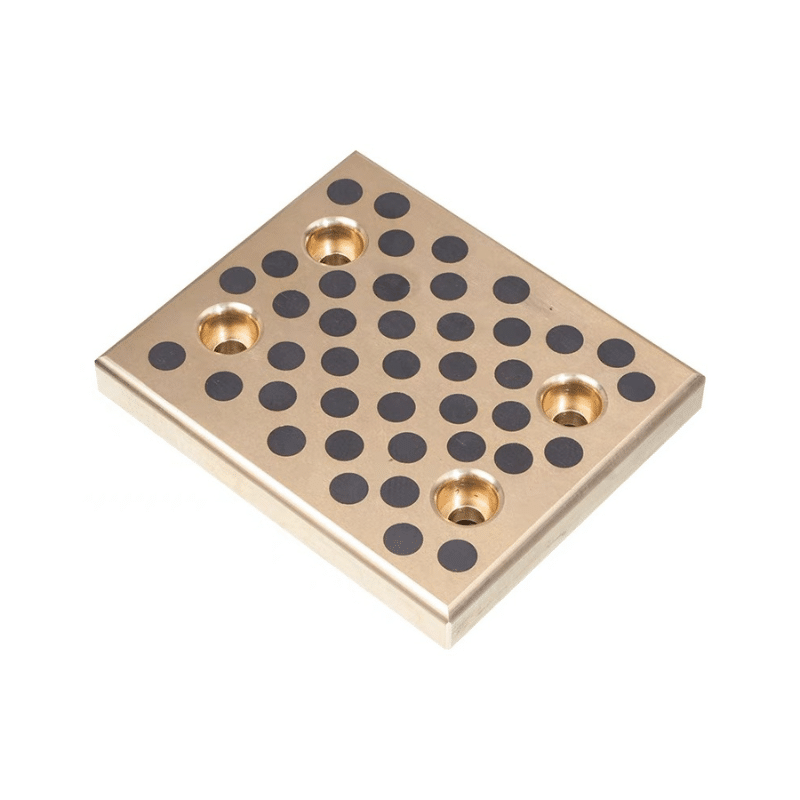

- Sliding plates

- Thrust washers, mm

- Thrust washers, imperial

Contact a oilless bearing bearings expert

Metal Self-lubricating Bearings, Need a oilless bearings? Produce your bushing bearings prototype at bronzelube.com using your preferred manufacturing method, starting immediately upon order receipt.

Have Your Custom Bronze Bushing Design Produced & Manufactured! Cost-Effective Wrapped Bronze Bearings Bushings for Quick Manufacturing. Plain bush & self-lubricating bearings Manufacturing Service to Your Exact Specifications: We offers over self-lubricating bushing bearings materials designed for wear resistance. Whether your application is exposed to high temperatures, chemicals or water – bronzelube.com has a solution.

Self-lubricating bearing

Custom Parts & Components: High-Performance Bearings and Bushings

Our custom parts service uses tribologically-optimized self-lubricating metal for improved friction and wear resistance, enabling quick production of custom machine bushing sleeves. Browse our catalogs of high-performance metal composite bearings in PDF format and get your custom design manufactured today! Plain bearing – Standard or custom made parts:

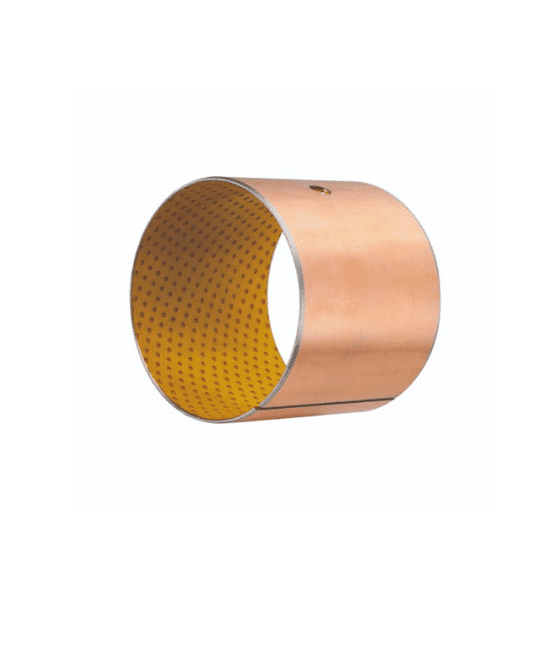

Metal-polymer composite bushing. metallic self-lubricating bushings.

Our CuSn8 bronze bearings, made from a rolled phosphor bronze alloy, are highly versatile and suitable for various applications. We are the most trusted and reliable supplier of bearing brand products, as highlighted in our Free Bearing Catalog.

Plain bearings are a reliable, cost-efficient solution, Metal-Polymer Composite Bearings. Ideal in Lubricated Applications.

Metal Bushing Sleeve For Long Life. Large selection of self-lubricating bushing bearings material delivered quickly and cost-effectively.

Wrapped sliding bearing, wrapped bushing, steel/POM sliding layer, DIN 1494/ISO 3547, Low-maintenance. we have extremely high requirements in terms of bearing design, noise, and cost, and Red PTFE Bushing fits the requirements perfectly. With innovative bearing and surface technology and design, rail applications can greatly reduce the risk of bearing failure, and self-lubricating bearing solutions can also reduce noise and prevent quality problems while improving safety at a competitive price. Custom Part & Component Manufacturing Service to Your Exact Specifications Self-lubricating and maintenance free Free from rust and corrosion resistance Impact resistance, can withstand edge load Resistant to dust and wet conditions More cost-effective

Custom Bushing Sleeve Self-lubricating

The most popular bushing bearing material worldwide offers an excellent price/performance ratio. Our custom parts service leverages tribologically optimized high-performance metal for superior friction and wear resistance. This allows us to manufacture your custom machine bushing sleeve or component quickly. Looking for a metal-polymer plain bearing with grease lubrication?

Material-Specific Bushings:

-

- POM Bushings: Self-lubricating with good wear resistance, suitable for heavy loads at low speeds.

- PTFE Bushings: Made of polytetrafluoroethylene and metal, suitable for high-temperature applications across various industries.

- Nylon Bushings: Durable, low-noise, and resistant to weak acids and alkalis.

- Metal Bushings: High mechanical strength, suitable for high-speed and high-load applications.

- Bronze Bushings: Rust-resistant, durable, and long-lasting but require lubrication.

- Graphite Bushings: Low friction coefficient and high temperature stability.

- Steel Bushings: Durable for low-speed pivot applications.

- Brass Bushings: Used in electric motors and automobile engines.

- Aluminum Bushings: Hardness ensures a long service life, used in aerospace and agricultural industries.

- Bimetallic Sleeve Bearings: Made of two different metals, useful for moderate to high loads at medium to low speeds.

Load and Speed Limits: Bushings are typically used for heavier loads at slower speeds. The suitability of a bushing for an application can be determined by calculating the pressure velocity (PV) value and comparing it with the manufacturer’s limiting PV value.

Experience seamless motion with our Lubrication-Free Bushing Sleeves—your solution for Maintenance-Free, Dry Operation. Our Metal-Polymer Low Friction Plain Bearings provide exceptional wear resistance and low friction performance across a broad spectrum of dry conditions, loads, speeds, and temperatures. They excel in both unlubricated and greased applications. Ideal for linear, reciprocating, and rotary movements, these bearings are highly resistant to corrosion in damp or saline environments and are crafted from lead-free materials complying with ELV, WEEE, and RoHS standards. Our sleeve bearings, also known as bushings or journal bearings, support smooth linear movement between parts and offer numerous benefits. Simply upload your CAD file and detail your application’s unique requirements.

Materials:

- Sliding Layer: PTFE or POM + Fillers

- Porous Bronze Sinter

- Backing: Steel or Bronze

- Types of sleeve bushings available with CAD models.

Discover the Perfect Oilless Bushing Bearing Material for Your Project! At bronzelube.com, we provide self-lubricating bearing bushing materials suited for a wide range of applications, whether facing high temperatures, exposure to various media, or wear-intensive conditions. Our Metal & Bimetal bearings need no external lubrication, are corrosion-resistant when used with a steel or bronze backing, solid lubricants, and fibers, and operate quietly. This makes them a cost-effective and efficient alternative to traditional steel ball bearings.

Self-lubricating Bronze Bearings from Bronzelube.com

Reduce Costs by 50%.

Self-lubricating Bearing, split bushings Bushes Equivalent Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings, thrust washers & strips | Short lead time, high quality

Supplier of Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings, Fast delivery, Competitive price. All the self-lubricating Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings parts are made of premium steel-backed, stainless backed, bronze backed bushing or other metal-backed sliding bushing material. Professional Service. Perfect Service System, Strong Technical Strength.

Take Your Market Intelligence to The Next Level, Metric bearings and imperial bushings made to order from china.

Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings Types

Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings forms available in standard dimensions:

- Cylindrical Bushes

- Flanged Bushes

- Sliding Plates

- Thrust Washer– stamped/deep drawn shapes

- Flanged washers – customized designs

Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings forms available in Non-standard dimensions:

- Modified Standard Components

- Half Bearings

- Flat Components

- Deep Drawn Parts

- Pressings

- Stampings

Description of the Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings

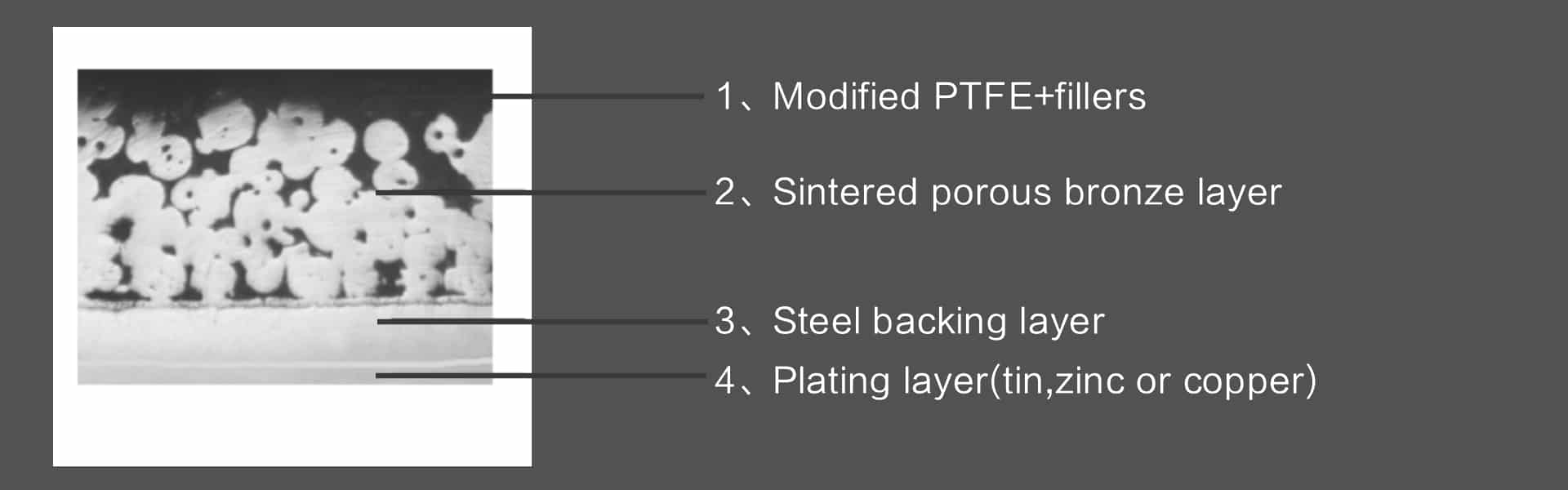

The Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings is made of three-layer composite material. It is supported by a tinned steel back with porous bronze sintered on it and polymers embedded in the bronze holes. The tinned steel back provides products with greater mechanical strength and load capacity. By combining metals and polymers together. the tin-bronze back has good heat conduction capacity. This type of self-lubricating bearing is also called Polytetrafluoroethylene bearing bushing, PTFE coated bearing bushing, bearing bushing made of split steel and etc.

Professional supplier of Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushing High Quality, Good Service, Your Best Choice!

Equivalent split bushings Bushes Material For Quick Learning

STRUCTURE & COMPOSITION

Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings Lead-free Metal-Polymer Plain Bearing Material is a composite bearing material. It consists of a Lead-free Metal-Polymer Plain Bearing Material steel beam, to which a porous sintered brown intermediate layer is bonded, which is coated and impregnated with polytetrafluoroethylene (PTFE), which contains a mixture of inorganic fillers and special polymer fibers. The Lead-free Metal-Polymer Plain Bearing Material steel beam ensures mechanical strength and the sintered bronze layer ensures a strong mechanical connection of the filled Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings lining.

Composition

Steel Back + Porous Bronze Sinter + PTFE + Filler

Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings-Metric Self-lubricating Oilless Plain Slide Sleeve Dry Linear Shaft Split Oil Free Bushings

Lead-free Metal-Polymer Plain Bearing Material Sleeve Tri-layer Bushings have a base of lower carbon steel backed bushings, onto which a porous bronze layer is sintered. PTFE mixtures are impregnated into the of this bronze layer after rolling process completed. It has good physical & mechanical properties, also has certainly chemical properties. It is suitable for rotary, oscillating movement with performance of self-lubricating. Anti-wear, lower noise.

Structure

-Metal-Polymer Composite Bushing Material

1. PTFE/Polymer fibres mixture thickness 0.01~0.03mm. Lead-free bearing layer provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE mixture.

3. Steel backing, provides high load carrying capacity, excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

After rolling process completed, PTFE mixtures are filled in intersice of bronze layer. Under normal operation, Part of PTFE mixture on top layer will be removed and transferred on the mating surface, forms a physically lubricating film, which will reduced the firction coe. and protect the mating shaft.

Among these professional manufacturers of special hydraulic pumps for Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings in China, we invite you to buy custom and cheap hydraulic pumps, hydraulic cylinder liners, special hydraulic bearing sleeves or receive a free sample from our factory.

SELECT YOUR GLACIER BUSHES

Split Steel Bushing, Customized High Quality Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushing

Welcome Your Inquriy and Trial Order !

Technical data

| Performance | Data | |

| Maximum load | Static load | 250N/mm² |

| Dynamic load | 140N/mm² | |

| Line speed | Dry friction | 2.5m/s |

| Oil lubrication | 5m/s | |

| Maximum PV value | Dry friction | 3.8N/mm²・m/s |

| Oil lubrication | 50N/mm²・m/s | |

| Coefficient of friction | Dry friction | 0.04~0.20 |

| Oil lubrication | 0.02~0.07 | |

| Operating temperature | -195℃~+280℃ | |

| Thermal Conductivity | 42W/m・K | |

| Thermal expansion coefficient | 11×10-6/K | |

In particular, depending on the dry running conditions, Lead-free Metal-Polymer Plain Bearing Material materials have the following performance advantages:

Dry conditions

• Good friction and wear performance in light service conditions

• Particularly suitable for intermittent oscillating and reciprocating movements

• Maintenance free, as no external lubrication is required

• Resistant to seizures.

Lubricated conditions

• Good wear and friction characteristics over a wide range of loads, speeds and temperatures.

• High wear resistance in boundary operating conditions

• High resistance of the bearing surface under cavitation and erosion conditions

• Suitable for work in various liquids (oil, fuel, solvents, refrigerants, water).

- Housing ØH7

- Bushing inner-Ø after mountingH9

- Shaft tolerancef7 or h8

Metric Cylindrical Metal Polymer Red PTFE Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings

Lead-free Metal-Polymer Plain Bearing Material Sleeve Feature

• Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushing low friction bearings provide good wear and low friction performance over a wide range of loads, speeds and temperatures under dry operating conditions

• Very good performance in lubricated applications

• Good performance in greased applications

• Suitable for linear, oscillating and rotary movements

• Lead-free material

Lead-free Metal-Polymer Plain Bearing Material sleeve bushing material is a maintenance-free material due to the PTFE sliding layer. Outstanding sliding and wear performance. High load capacity and very versatile bushing.

The surface polymer is resistant to chemical corrosion, so its corrosion resistance mainly depends on the steel back and the surface plating. Copper or tin plating on steel back surface can effectively prevent atmospheric corrosion; If working in corrosive medium, steel back can be galvanized, etc.

Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushing Characteristics

• Good friction properties with negligible slip

• High static and dynamic load capacity

• Suitable for rotating, oscillating, alternative and sliding movements

• Compact size and low weight

• Pre-finished which does not require any work after assembly

• Possibility of browning to reduce the operating clearance

• No water absorption and therefore dimensionally stable

• Suitable for a wide range of operating temperatures from -200 to +280 ° C

The so-called “self-lubricating bearings” means no or less oil is added. The goal of our research is to ensure that the composite bearing can still perform well under such conditions and extend its service life as much as possible. Self-lubricating bearing is the basic working principle of solid lubricant on the surface of the bearing in the early operational stage due to the friction of ask each other to form a transfer film and coat the to eventually form solid lubrication film on the grinding parts to achieve the purpose of self lubrication, which partition the direct contact between the workpiece and good protection of grinding extend the service life of the bearing and artifacts.

Composite series metal composite self-lubricating materials with high quality low carbon steel as the substrate, sintering porous spherical copper powder layer, the surface of copper is given priority to with PTFE wear-resistant lubricating materials as bearing layer, the material has excellent mechanical bearing capacity, the middle copper powder layer can not only transfer the heat generated by the bearing during operation in time, but also increased the strength of the combination of the plastic layer and substrate. PTFE is designed for full dry friction and a variety of materials have been developed according to lubrication, friction coefficient and durability requirements. VIIPLUS’s PTFE metal composites provide the best performance over the widest range of loads, speeds and temperatures with or without external lubrication.

HIGH QUALITY GLACIER BUSHES SUPPLIER

Lead-free Metal-Polymer Plain Bearing Material SLEEVE BUSHINGS ADVANTAGES

1. Can be used where no oil can be applied or the oil is difficult to apply.

2. Low wear, low friction and long service life. The load will be distributed over a wider area due to the elastic nature of the bearing material.

3. Low sliding properties of the stick guaranteeing the machine’s operating precision at low sliding speed

4. Low vibration, low noise and non-pollution in operation.

5. PTFE and lead charge are transferred to the coupling shaft to improve the operating properties.

6. Can be used in low hardness of the coupling shaft, so that the processing of the shafts is easy.

7. The machine will be compact because of the thin thickness and low weight of the bush.

8. Electro plating is possible to prevent corrosion.

Sliding Bearing Friction Sleeve Composite Dry Bushing Split Steel Bushing Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings

Given the performance characteristics under both dry and lubricated operating conditions, Lead-free Metal-Polymer Plain Bearing Material bearing materials are widely used in a variety of automotive and industrial applications,such as:

Automotive

Braking systems, clutches, gearbox and transmissions, hinges – door bonnet and boot, convertible roof tops, pedal systems, pumps – axial, radial, gear and vane, seat mechanisms, steering systems, struts and shock absorbers, wiper systems.

Industrial

Aerospace, agricultural, construction equipment, food and beverage, marine, material handling, office equipment, packaging equipment, pneumatic and hydraulic cylinders, railroad and tramways,textile machinery, valves.

TYPICAL APPLICATIONS: The split friction sleeve sleeve with friction friction bearing is widely applied in various sliding movements of different types of machines, such as textile machines, tobacco machines, hydraulic vehicles, automobiles, agricultural machinery, etc.

MAINTENANCE-FREE Lead-free Metal-Polymer Plain Bearing Material SLEEVE BUSHINGS

Lead-free Metal-Polymer Plain Bearing Material Sleeve Bushings Properties

DRY |

||

| Maximum sliding speed, U | m/s | 2.5 |

| Maximum pU factor | N/mm² x m/s | 1.0 |

| Coefficient of friction | 0.04 – 0.25 * | |

OIL LUBRICATED |

||

| Maximum sliding speed, U | m/s | 5.0 |

| Maximum pU factor | N/mm² x m/s | 10.0 |

| Coefficient of friction | 0.02 – 0.08 * | |

RECOMMENDATIONS |

|||

| Shaft surface roughness, Ra | Dry

Lubricated |

µm

µm |

0.3 – 0.5

≤ 0.05 – 0.40 * |

| Shaft surface hardness | Unhardened acceptable, improved bearing life > 200HB | ||

* Depending on operating conditions

Lead-free Metal-Polymer Plain Bearing Material sleeve bushing Size Model

Avalibility

Bearing forms made to order: cylindrical bushes, thrust washers, sliding plates, half-bearings, special shapes obtained by stamping, customized bearing designs

GLACIER BUSHES EQUIVALENT CATALOG

split bushings Bushes Catalog | Bronzelube.com |Bushing

split bushings Bushes Bearings Catalog

Check out our online split bushings Bushes product catalog with more than 20,000 bushing products Catalog with full specifications & CAD drawings available for download – all free of charge!

DX AND DU TYPE BEARING WASHERS

DX AND DU Style bearing washers are a range of wrapped acetal lined bearings that are suitable for rotary and oscillating movement applications. Available in both metric and imperial sizes.

Split Bearing Bushes

DU Type – Plain Metric

DU Type – Plain Imperial

DU Type – Flanged

DU Type Washers

DU Type Strip

DX Type – Plain Metric

DX Type – Plain Imperial

DX Type Washers

DX Type Strip

self-lubricating bronze bushings catalog

DU BUSHING SIZE CHART

BUSHING METRIC SIZE

| 0203DU | 2 | 3.5 | 3 | H6 | h6 | 2.048 | 2 | 0.054 | 0 |

| 0205DU | 2 | 3.5 | 5 | H6 | h6 | 2.048 | 2 | 0.054 | 0 |

| 0303DU | 3 | 4.5 | 3 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| 0305DU | 3 | 4.5 | 5 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| 0306DU | 3 | 4.5 | 6 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| 0403DU | 4 | 5.5 | 3 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0404DU | 4 | 5.5 | 4 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0406DU | 4 | 5.5 | 6 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0410DU | 4 | 5.5 | 10 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| 0505DU | 5 | 7 | 5 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| 0508DU | 5 | 7 | 8 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| 0510DU | 5 | 7 | 10 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| 0604DU | 6 | 8 | 4 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0606DU | 6 | 8 | 6 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0608DU | 6 | 8 | 8 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0610DU | 6 | 8 | 10 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| 0705DU | 7 | 9 | 5 | H7 | f7 | 7.055 | 6.99 | 0.083 | 0.003 |

| 0710DU | 7 | 9 | 10 | H7 | f7 | 7.055 | 6.99 | 0.083 | 0.003 |

| 0806DU | 8 | 10 | 6 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 0808DU | 8 | 10 | 8 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 0810DU | 8 | 10 | 10 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 0812DU | 8 | 10 | 12 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| 1006DU | 10 | 12 | 6 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1008DU | 10 | 12 | 8 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1010DU | 10 | 12 | 10 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1012DU | 10 | 12 | 12 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1015DU | 10 | 12 | 15 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1020DU | 10 | 12 | 20 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| 1208DU | 12 | 14 | 8 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1210DU | 12 | 14 | 10 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1212DU | 12 | 14 | 12 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1215DU | 12 | 14 | 15 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1220DU | 12 | 14 | 20 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1225DU | 12 | 14 | 25 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| 1310DU | 13 | 15 | 10 | H7 | f7 | 13.058 | 12.99 | 0.092 | 0.006 |

| 1320DU | 13 | 15 | 20 | H7 | f7 | 13.058 | 12.99 | 0.092 | 0.006 |

| 1405DU | 14 | 16 | 5 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1410DU | 14 | 16 | 10 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1412DU | 14 | 16 | 12 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1415DU | 14 | 16 | 15 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1420DU | 14 | 16 | 20 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1425DU | 14 | 16 | 25 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| 1510DU | 15 | 17 | 10 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1512DU | 15 | 17 | 12 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1515DU | 15 | 17 | 15 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1520DU | 15 | 17 | 20 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1525DU | 15 | 17 | 25 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| 1610DU | 16 | 18 | 10 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1612DU | 16 | 18 | 12 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1615DU | 16 | 18 | 15 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1620DU | 16 | 18 | 20 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1625DU | 16 | 18 | 25 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| 1720DU | 17 | 19 | 20 | H7 | f7 | 17.061 | 16.99 | 0.095 | 0.006 |

| 1810DU | 18 | 20 | 10 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 1815DU | 18 | 20 | 15 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 1820DU | 18 | 20 | 20 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 1825DU | 18 | 20 | 25 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| 2010DU | 20 | 23 | 10 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2015DU | 20 | 23 | 15 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2020DU | 20 | 23 | 20 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2025DU | 20 | 23 | 25 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2030DU | 20 | 23 | 30 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| 2215DU | 22 | 25 | 15 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2220DU | 22 | 25 | 20 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2225DU | 22 | 25 | 25 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2230DU | 22 | 25 | 30 | H7 | f7 | 22.071 | 21.99 | 0.112 | 0.01 |

| 2415DU | 24 | 27 | 15 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2420DU | 24 | 27 | 20 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2425DU | 24 | 27 | 25 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2430DU | 24 | 27 | 30 | H7 | f7 | 24.071 | 23.99 | 0.112 | 0.01 |

| 2515DU | 25 | 28 | 15 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2520DU | 25 | 28 | 20 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2525DU | 25 | 28 | 25 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2530DU | 25 | 28 | 30 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2550DU | 25 | 28 | 50 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| 2815DU | 28 | 32 | 15 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 2820DU | 28 | 32 | 20 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 2825DU | 28 | 32 | 25 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 2830DU | 28 | 32 | 30 | H7 | f7 | 28.085 | 27.99 | 0.126 | 0.01 |

| 3010DU | 30 | 34 | 10 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3015DU | 30 | 34 | 15 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3020DU | 30 | 34 | 20 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3025DU | 30 | 34 | 25 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3030DU | 30 | 34 | 30 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3040DU | 30 | 34 | 40 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| 3220DU | 32 | 36 | 20 | H7 | f7 | 32.085 | 31.99 | 0.135 | 0.015 |

| 3230DU | 32 | 36 | 30 | H7 | f7 | 32.085 | 31.99 | 0.135 | 0.015 |

| 3240DU | 32 | 36 | 40 | H7 | f7 | 32.085 | 31.99 | 0.135 | 0.015 |

| 3520DU | 35 | 39 | 20 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3530DU | 35 | 39 | 30 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3535DU | 35 | 39 | 35 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3540DU | 35 | 39 | 40 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3550DU | 35 | 39 | 50 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| 3720DU | 37 | 41 | 20 | H7 | f7 | 37.085 | 36.99 | 0.135 | 0.015 |

| 4020DU | 40 | 44 | 20 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4030DU | 40 | 44 | 30 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4040DU | 40 | 44 | 40 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4050DU | 40 | 44 | 50 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| 4520DU | 45 | 50 | 20 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4530DU | 45 | 50 | 30 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4540DU | 45 | 50 | 40 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4545DU | 45 | 50 | 45 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 4550DU | 45 | 50 | 50 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| 5020DU | 50 | 55 | 20 | H7 | f7 | 50.11 | 49.99 | 0.16 | 0.015 |

| 5030DU | 50 | 55 | 30 | H7 | f7 | 50.11 | 49.99 | 0.16 | 0.015 |

| 5040DU | 50 | 55 | 40 | H7 | f7 | 50.11 | 49.99 | 0.16 | 0.015 |

| 5050DU | 50 | 55 | 50 | H7 | f7 | 50.11 | 49.99 | 0.16 | 0.015 |

| 5060DU | 50 | 55 | 60 | H7 | f7 | 50.11 | 49.99 | 0.16 | 0.015 |

| 5520DU | 55 | 60 | 20 | H7 | f7 | 55.11 | 54.99 | 0.17 | 0.02 |

| 5525DU | 55 | 60 | 25 | H7 | f7 | 55.11 | 54.99 | 0.17 | 0.02 |

| 5530DU | 55 | 60 | 30 | H7 | f7 | 55.11 | 54.99 | 0.17 | 0.02 |

| 5540DU | 55 | 60 | 40 | H7 | f7 | 55.11 | 54.99 | 0.17 | 0.02 |

| 5550DU | 55 | 60 | 50 | H7 | f7 | 55.11 | 54.99 | 0.17 | 0.02 |

| 5555DU | 55 | 60 | 55 | H7 | f7 | 55.11 | 54.99 | 0.17 | 0.02 |

| 5560DU | 55 | 60 | 60 | H7 | f7 | 55.11 | 54.99 | 0.17 | 0.02 |

| 6020DU | 60 | 65 | 20 | H7 | f7 | 60.11 | 59.99 | 0.17 | 0.02 |

| 6030DU | 60 | 65 | 30 | H7 | f7 | 60.11 | 59.99 | 0.17 | 0.02 |

| 6040DU | 60 | 65 | 40 | H7 | f7 | 60.11 | 59.99 | 0.17 | 0.02 |

| 6050DU | 60 | 65 | 50 | H7 | f7 | 60.11 | 59.99 | 0.17 | 0.02 |

| 6060DU | 60 | 65 | 60 | H7 | f7 | 60.11 | 59.99 | 0.17 | 0.02 |

| 6070DU | 60 | 65 | 70 | H7 | f7 | 60.11 | 59.99 | 0.17 | 0.02 |

| 6530DU | 65 | 70 | 30 | H7 | f7 | 65.11 | 64.99 | 0.17 | 0.02 |

| 6550DU | 65 | 70 | 50 | H7 | f7 | 65.11 | 64.99 | 0.17 | 0.02 |

| 6570DU | 65 | 70 | 70 | H7 | f7 | 65.11 | 64.99 | 0.17 | 0.02 |

| 7040DU | 70 | 75 | 40 | H7 | f7 | 70.11 | 69.99 | 0.17 | 0.02 |

| 7050DU | 70 | 75 | 50 | H7 | f7 | 70.11 | 69.99 | 0.17 | 0.02 |

| 7070DU | 70 | 75 | 70 | H7 | f7 | 70.11 | 69.99 | 0.17 | 0.02 |

| 7560DU | 75 | 80 | 60 | H7 | f7 | 75.11 | 74.99 | 0.17 | 0.02 |

| 7580DU | 75 | 80 | 80 | H7 | f7 | 75.11 | 74.99 | 0.17 | 0.02 |

| 8040DU | 80 | 85 | 40 | H7 | h8 | 80.155 | 80.02 | 0.201 | 0.02 |

| 8060DU | 80 | 85 | 60 | H7 | h8 | 80.155 | 80.02 | 0.201 | 0.02 |

| 8080DU | 80 | 85 | 80 | H7 | h8 | 80.155 | 80.02 | 0.201 | 0.02 |

| 80100DU | 80 | 85 | 100 | H7 | h8 | 80.155 | 80.02 | 0.201 | 0.02 |

| 8530DU | 85 | 90 | 30 | H7 | h8 | 85.155 | 85.02 | 0.209 | 0.02 |

| 8560DU | 85 | 90 | 60 | H7 | h8 | 85.155 | 85.02 | 0.209 | 0.02 |

| 85100DU | 85 | 90 | 100 | H7 | h8 | 85.155 | 85.02 | 0.209 | 0.02 |

| 9060DU | 90 | 95 | 60 | H7 | h8 | 90.155 | 90.02 | 0.209 | 0.02 |

| 90100DU | 90 | 95 | 100 | H7 | h8 | 90.155 | 90.02 | 0.209 | 0.02 |

| 9560DU | 95 | 100 | 60 | H7 | h8 | 95.155 | 95.02 | 0.209 | 0.02 |

| 95100DU | 95 | 100 | 100 | H7 | h8 | 95.155 | 95.02 | 0.209 | 0.02 |

| 10050DU | 100 | 105 | 50 | H7 | h8 | 100.155 | 100.02 | 0.209 | 0.02 |

| 10060DU | 100 | 105 | 60 | H7 | h8 | 100.155 | 100.02 | 0.209 | 0.02 |

| 100115DU | 100 | 105 | 115 | H7 | h8 | 100.155 | 100.02 | 0.209 | 0.02 |

| 10560DU | 105 | 110 | 60 | H7 | h8 | 105.155 | 105.02 | 0.209 | 0.02 |

| 105115DU | 105 | 110 | 115 | H7 | h8 | 105.155 | 105.02 | 0.209 | 0.02 |

| 11060DU | 110 | 115 | 60 | H7 | h8 | 110.155 | 110.02 | 0.209 | 0.02 |

| 110115DU | 110 | 115 | 115 | H7 | h8 | 110.155 | 110.02 | 0.209 | 0.02 |

| 11550DU | 115 | 120 | 50 | H7 | h8 | 115.155 | 115.02 | 0.209 | 0.02 |

| 11570DU | 115 | 120 | 70 | H7 | h8 | 115.155 | 115.02 | 0.209 | 0.02 |

| 12050DU | 120 | 125 | 50 | H7 | h8 | 120.21 | 120.07 | 0.264 | 0.07 |

| 12060DU | 120 | 125 | 60 | H7 | h8 | 120.21 | 120.07 | 0.264 | 0.07 |

| 120100DU | 120 | 125 | 100 | H7 | h8 | 120.21 | 120.07 | 0.264 | 0.07 |

| 125100DU | 125 | 130 | 100 | H7 | h8 | 125.21 | 125.07 | 0.273 | 0.07 |

| 13060DU | 130 | 135 | 60 | H7 | h8 | 130.21 | 130.07 | 0.273 | 0.07 |

| 130100DU | 130 | 135 | 100 | H7 | h8 | 130.21 | 130.07 | 0.273 | 0.07 |

| 13560DU | 135 | 140 | 60 | H7 | h8 | 135.21 | 135.07 | 0.273 | 0.07 |

| 13580DU | 135 | 140 | 80 | H7 | h8 | 135.21 | 135.07 | 0.273 | 0.07 |

| 14060DU | 140 | 145 | 60 | H7 | h8 | 140.21 | 140.07 | 0.273 | 0.07 |

| 140100DU | 140 | 145 | 100 | H7 | h8 | 140.21 | 140.07 | 0.273 | 0.07 |

| 15060DU | 150 | 155 | 60 | H7 | h8 | 150.21 | 150.07 | 0.273 | 0.07 |

| 15080DU | 150 | 155 | 80 | H7 | h8 | 150.21 | 150.07 | 0.273 | 0.07 |

| 150100DU | 150 | 155 | 100 | H7 | h8 | 150.21 | 150.07 | 0.273 | 0.07 |

| 16080DU | 160 | 165 | 80 | H7 | h8 | 160.21 | 160.07 | 0.273 | 0.07 |

| 160100DU | 160 | 165 | 100 | H7 | h8 | 160.21 | 160.07 | 0.273 | 0.07 |

| 180100DU | 180 | 185 | 100 | H7 | h8 | 180.216 | 180.07 | 0.279 | 0.07 |

| 200100DU | 200 | 205 | 100 | H7 | h8 | 200.216 | 200.07 | 0.288 | 0.07 |

| 210100DU | 210 | 215 | 100 | H7 | h8 | 210.216 | 210.07 | 0.288 | 0.07 |

| 220100DU | 220 | 225 | 100 | H7 | h8 | 220.216 | 220.07 | 0.288 | 0.07 |

| 250100DU | 250 | 255 | 100 | H7 | h8 | 250.222 | 250.07 | 0.294 | 0.07 |

| 300100DU | 300 | 305 | 100 | H7 | h8 | 300.222 | 300.07 | 0.303 | 0.07 |

Maintenance-free sleeve bushing

Reliable, cost-effective, and efficient, our maintenance-free Metal-Polymer Low Friction Plain Bearings operate without lubrication, improving technology and reducing costs.