Bimetal Bushing Supplier

BIMETAL PLAIN BEARINGS FOR STANDARD SAE 792

Metal & Bimetal – Bronze Bearings – Steel Bushings

Explore our selection of metal and bimetal bearings, bimetal bushings, steel, and sintered bronze bearings for lubricated environments. We are a reputable manufacturer of Bimetal Bearings, offering bimetallic plain bushings for Truck Engines and Textile machines!

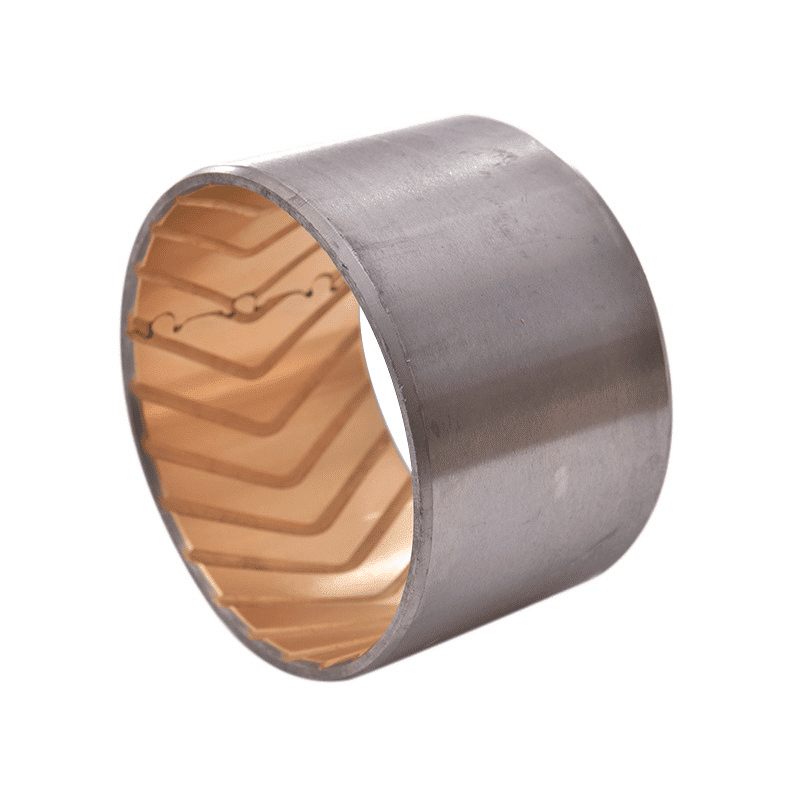

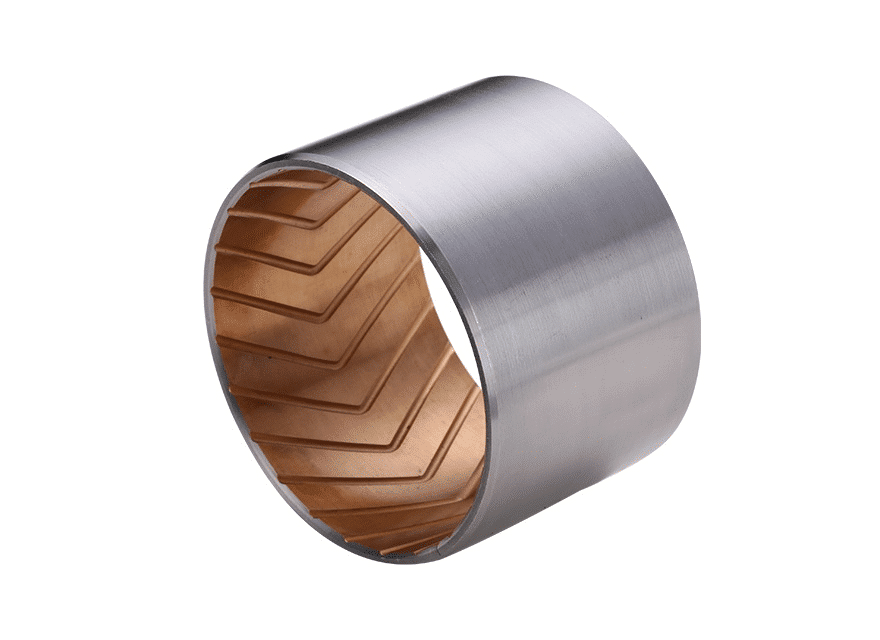

Our Bimetal bearings, made up of a steel base and a CuPb10Sn10 alloy overlay, are classified as plain bearings that meet Standard SAE 792 requirements.

These bearings feature steel backings covered with a layer of lead bronze, specifically the CuPb10Sn10 alloy. The bronze overlay provides exceptional qualities such as lubrication, wear resistance, and corrosion resistance, making it ideal for a wide array of applications. These applications include sliding bearings exposed to high surface pressures, as well as rolling bearings for vehicles and components that endure peak loads of up to 60MPa.

We manufacture bimetal bearing bushings tailored to your specific requirements.

Bimetallic Bushing Material: Understanding the Benefits and Characteristics

Bimetallic bushing material is a specialized composite material used in various industrial and mechanical applications. This material is made from two different metals that are joined together to create a composite material with unique properties and performance characteristics. In this article, we will explore the benefits and characteristics of bimetallic bushing material, and how it is used in various industries.

What is Bimetallic Bushing Material?

Bimetallic bushing material is a composite material made from two different metals. The metals are carefully selected based on their specific properties, such as low-friction, wear resistance, and corrosion resistance. The combination of these properties provides a bimetallic bushing with excellent performance, durability, and longevity.

Benefits of Bimetallic Bushing Material

One of the main benefits of bimetallic bushing material is its low-friction performance. The combination of two different metals provides a low-friction interface, reducing wear and extending the lifespan of machinery. This is especially important in high-load or high-speed applications, where friction reduction is critical to performance.

In addition, bimetallic bushing material is highly durable, as the combination of two different metals provides improved wear resistance. This means that the material is less likely to fail, even under heavy loads or high-speed conditions. Furthermore, the materials used in the construction of bimetallic bushing material can also have anti-corrosion properties, which helps to protect the components from damage and increases their lifespan.

Another benefit of bimetallic bushing material is its versatility. It can be used in a wide range of applications, from high-load machinery to low-speed equipment. This makes it a popular choice in many industries, as it can provide reliable performance in a wide range of conditions.

Characteristics of Bimetallic Bushing Material

- Bimetallic bushing material has several key characteristics that make it an excellent choice for various industrial and mechanical applications. Some of these characteristics include:

- Low-Friction Performance: The combination of two different metals provides a low-friction interface, reducing wear and extending the lifespan of machinery.

- Durability: The combination of two different metals provides improved wear resistance, making the material highly durable and less likely to fail, even under heavy loads or high-speed conditions.

- Versatility: Bimetallic bushing material can be used in a wide range of applications, from high-load machinery to low-speed equipment.

- Anti-Corrosion Properties: The materials used in the construction of bimetallic bushing material can have anti-corrosion properties, helping to protect the components from damage and increases their lifespan.

Applications of Bimetallic Bushing Material

Bimetallic bushing material is used in a variety of industries, including automotive, industrial machinery, and heavy equipment. It is often used in high-load or high-speed applications, where low-friction performance is critical to performance.

In the automotive industry, bimetallic bushing material is used in engines, transmissions, and suspension systems. It is also used in industrial machinery, such as pumps, compressors, and conveyor systems. In heavy equipment, bimetallic bushing material is used in cranes, excavators, and other construction equipment, helping to reduce wear and extend the lifespan of these components.

Conclusion

Bimetallic bushing material is a specialized composite material used in various industrial and mechanical applications. With its combination of low-friction, wear resistance, and corrosion resistance, bimetallic bushing material is an

Bimetal Bearing Bushes: The Advantages and Applications

Bimetal bearing bushes are specialized components used in various industrial and mechanical applications. They are designed to provide a low-friction interface between two moving parts, helping to reduce wear and extend the lifespan of machinery. In this article, we will explore the advantages of bimetal bearing bushes and their applications in various industries.

What are Bimetal Bearing Bushes?

Bimetal bearing bushes are bearings made from two different metals, which are joined together to form a composite material. The two metals are carefully selected for their specific properties, such as low-friction, wear resistance, and corrosion resistance. The combination of these properties provides a bearing bush with excellent performance, durability, and longevity.

Advantages of Bimetal Bearing Bushes

One of the main advantages of bimetal bearing bushes is their low-friction performance. The combination of two different metals provides a low-friction interface, reducing wear and extending the lifespan of machinery. This is especially important in high-load or high-speed applications, where friction reduction is critical to performance.

In addition, bimetal bearing bushes are also highly durable, as the combination of two different metals provides improved wear resistance. This means that the bushes are less likely to fail, even under heavy loads or high-speed conditions. Furthermore, the materials used in the construction of bimetal bearing bushes can also have anti-corrosion properties, which helps to protect the components from damage and increases their lifespan.

Another advantage of bimetal bearing bushes is their versatility. They can be used in a wide range of applications, from high-load machinery to low-speed equipment. This makes them a popular choice in many industries, as they can provide reliable performance in a wide range of conditions.

Applications of Bimetal Bearing Bushes

Bimetal bearing bushes are used in a variety of industries, including automotive, industrial machinery, and heavy equipment. They are often used in high-load or high-speed applications, where low-friction performance is critical to performance.

In the automotive industry, bimetal bearing bushes are used in engines, transmissions, and suspension systems. They are also used in industrial machinery, such as pumps, compressors, and conveyor systems. In heavy equipment, bimetal bearing bushes are used in cranes, excavators, and other construction equipment, helping to reduce wear and extend the lifespan of these components.

Conclusion

Bimetal bearing bushes are specialized components that provide a low-friction interface between two moving parts, helping to reduce wear and extend the lifespan of machinery. With their combination of low-friction, wear resistance, and corrosion resistance, bimetal bearing bushes are an excellent choice for many industrial and mechanical applications. Whether in automotive, industrial machinery, or heavy equipment, bimetal bearing bushes play a critical role in ensuring that machinery operates smoothly and efficiently.

Bimetal Bearing,Bimetallic Plain Bushes, Metal Sleeve Bushing

Beautifully crafted leather products.

We provide lead-free Bimetal Bearings. As heavy-duty industrial production grows, now is the perfect time to offer customized eco-friendly self-lubricating solutions. Bimetallic bearings may have a thicker lead bronze layer for situations needing machining after installation. The lead bronze layer material can be tailored to meet the specific needs of the application. Bi-metal Steel split bushing with bronze coating inside!

- Rather high load capacity

- Possibility to machine the inside diameter after mounting

- High level thermal conductivity

Bimetal Bushing Bearing

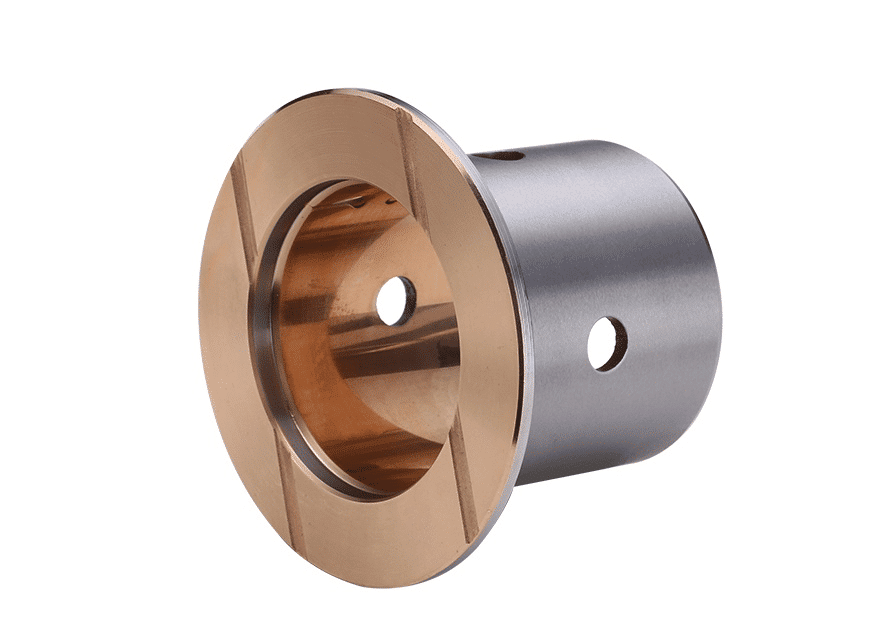

Bimetal-bearing is a type of bearing made of steel sheets with a layer of lead bronze. Bimetal plain bearings have a steel backing and bronze overlay, ideal for high specific loads with oscillating motion and low frequency. They are used to create sliding plates, half-bearings, thrust washers, flanged bushes, and cylindrical bushes in different shapes and sizes.

Flange Bimetal, Manufacturer of Professional Bimetal Bearings

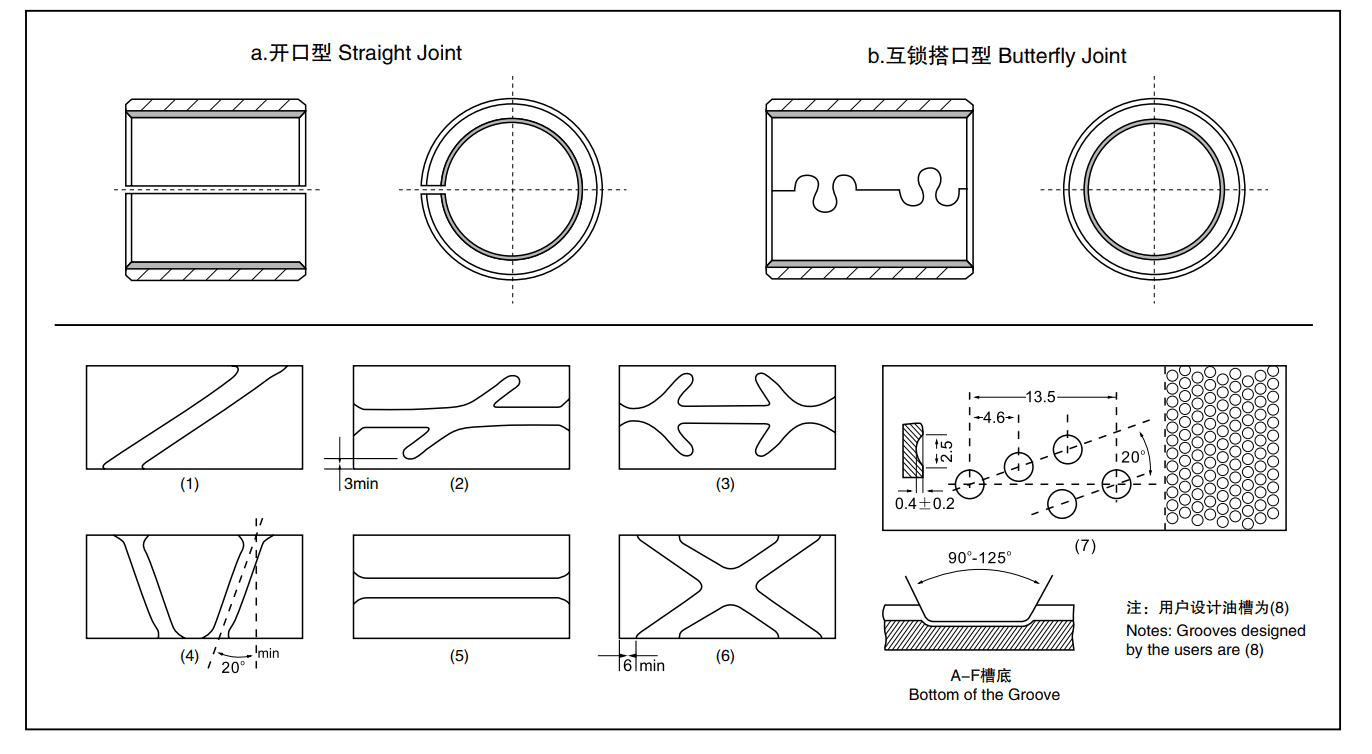

Standard size bearings are lubricated with indentations on the running surface. In the case of standard bearings, the steel backing is typically bronze-plated to enhance corrosion resistance. The lead bronze layer enables the use of relatively long lubrication intervals for these bearings.

Bimetal Plain Bearings To Standard SAE 792, standard bimetal bushes

Beautifully crafted leather products.

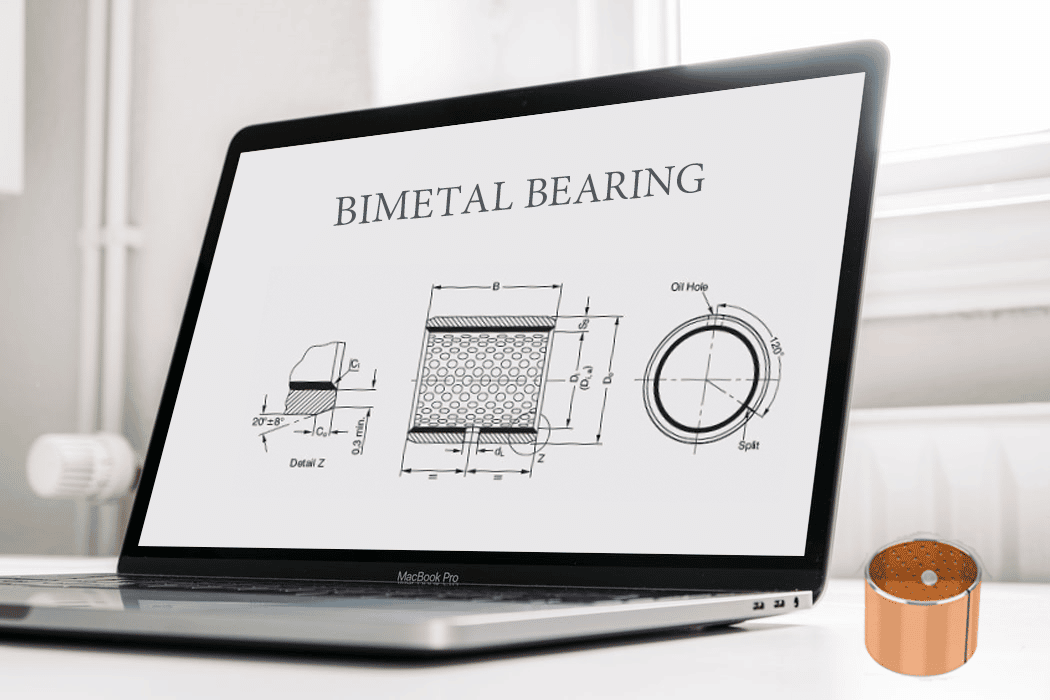

Bimetal bearing with steel backing and bronze overlay. Contact us for support. We will help you find the right product. Bi-metal bearings: Materials and construction: Material: Copper plated steel backing, lead bronze layer (CuPb10Sn10) bimetal bearing bushing material. Bimetal Bush. Bi-metallic composite bearing is made of steel backed with low friction and excellent wear resistance bonze powder as bearing layer! Cylindrical bimetallic bearings for high loads and rough operating conditions. Bimetallic bronze thrust bearing washer with steel backing. Bimetallic bearings for lubricated applications, bimetal plain bearing materials each consisting of a steel backing to which is sintered a lead bronze sliding layer.

Bimetal bearing types available in standard dimensions:

Bimetal Bearing designed completed reliably from manufacturing to shipment.

We support the quality of our bimetal bearings, bronze bushings, and hardened steel bushing products along with flange bushing parts. A bimetal bearing consists of steel sheets wrapped with a layer of lead bronze. We are manufacturers of Engine Bearings, Bushings, Thrust Washers, Alloy Powder, and Bimetallic Strips. Our Plain Bearing offers performance and benefits. Applications of Bimetal Bearings, Bimetallic Bush Supplier: Engineered solutions for demanding applications highlight tribological bearing solutions from BronzeLube bi-metal bushings. The Bi-metal Bearing material, known as steel-backed bronze bushings, ensures quality. Purchasing Bimetal Bearing & Bushings from us guarantees authenticity. Bi-metal Bushing Sliding Alloy Material: SAE-792, SAE-794 & SAE-49… Our New High Load Tribological Solution, the Bi-metallic composite bearing material, comprises a steel backing with lead bronze or lead-free copper alloy (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu) lining, suitable for oil/grease lubricated applications.

Bimetal Steel Bushing Material Top Quality

The promise of bimetal bearing bushing high quality, meet your requirement.

Bimetal Bearings

Bimetallic Bushing Engine Bearings Plain Bushings, Small minimum order value & quantity, fast delivery.

Bimetal Bearing Manufacturer, Bimetal Bushing Supplier

Friction bimetal bearings: Depends from the material and the performance of the layer.

The High Quality Bimetal Bearings Standards in Quality Bimetal Bearings Production

bimetal metal bushing sleeve

“Explore More cylindrical bimetal bearings products from china.”

Bimetal Bearings China Factory price

Bimetal Bush Manufacturers & Suppliers, Bimetallic Solid Self-Lubricating Plain Bearings at China Factory Price.

Bimetal Bearing with High Load Capacity, Excellent Resistance to Fatigue Strength at High Temperatures. Cylindrical Bushing made of Steel and Bronze with Pre-Filled Lubrication Pockets, Maintenance-Free.

Metal Bushing Sleeve for Bimetal Bearing Application.

The CuPb10Sn10 alloy composition in these bearings typically comprises around 80% copper, 10% lead, and 10% tin. Available in various configurations such as cylindrical, flanged, and thrust bushings, they offer customization options to cater to specific business requirements, encompassing different materials, sizes, and designs.

These bimetal bearings find applications across automotive and industrial products, including transmissions, truck brakes, agricultural machinery, mechanical handling equipment, and lifting applications. Their versatility extends to dusty environments or situations where lubrication is challenging due to the alloy’s excellent embeddability.

We provide a diverse range of these bearings, and our commitment to delivering top-notch products is underscored by our utilization of advanced technology and equipment in the manufacturing process. Discovery of The Right Bimetal Bushing for Your Application!

Bimetallic Bearing Design Freedom, Metal Bushing Sleeve Supplier

Easy to Customize

Customized Bi-Metal Bearings to meet specific indentation and shape needs.

Extra strength and steel-backed bushing, compact designs. Beyond Bearings, Most metallic substrates.Chemical and corrosion protection. Easy to Assemble, Excellent fatigue strength under dynamic and shock load conditions.