The Ultimate Guide to Aluminum Bronze Alloys: C95400, C95500, and C95900

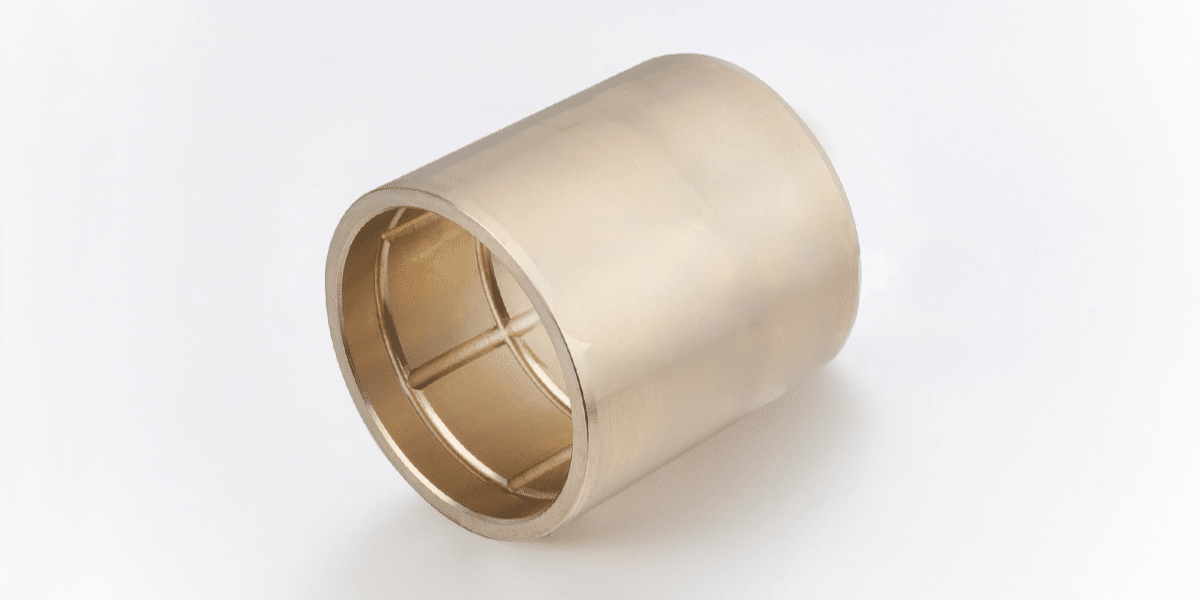

viiplus Manufacturer of custom machined bronze parts bearing

When selecting materials for high-stress environments, aluminum bronze emerges as a top-tier copper alloy renowned for its strength, corrosion resistance, and durability. Ideal for industries like marine, aerospace, and chemical processing, this guide delves into the specifics of three key alloys—C95400, C95500, and C95900—and their advantages over traditional bronze.

What is Aluminum Bronze?

Aluminum bronze is a copper-based alloy with 9–14% aluminum, often enhanced by iron, nickel, or manganese. This composition boosts its mechanical properties, making it resistant to wear, corrosion, and high temperatures. Unlike traditional tin-based bronze, aluminum bronze excels in harsh environments, from seawater exposure to heavy machinery.

Why Choose Aluminum Bronze? Key Advantages

- Exceptional Strength: Tensile strength ranges from 550–900 MPa, rivaling medium-carbon steel.

- Superior Corrosion Resistance: A protective aluminum oxide layer defends against saltwater, acids, and chemicals.

- High Wear Resistance: Ideal for abrasive or high-friction applications.

- Heat Treatability: Alloys with >9.5% aluminum can be heat-treated for enhanced hardness.

- Thermal Conductivity: Better than steel, though lower than pure copper.

Aluminum Bronze Alloys Compared

C95400 Aluminum Bronze

- Composition: 83% Cu, 10–11.5% Al, 3–5% Fe, ≤1.5% Ni.

- Properties: Excellent wear resistance, moderate impact strength.

- Applications: Bushings, bearings, gears, and marine components.

- Best For: Heavy loads in abrasive, non-impact environments (e.g., industrial machinery).

C95500 Aluminum Bronze

- Composition: Higher nickel and iron content than C95400.

- Properties: Superior strength and corrosion resistance, slightly lower impact toughness than C95400.

- Applications: Aerospace components, chemical valves, and marine hardware.

- Best For: High-stress, corrosive environments requiring durability.

C95900 Aluminum Bronze

- Composition: Optimized for seawater resistance (exact composition varies).

- Properties: Exceptional corrosion resistance in marine settings.

- Applications: Propeller shafts, underwater fittings, and offshore equipment.

- Best For: Abrasive and saline environments where corrosion is a primary concern.

Aluminum Bronze vs. Traditional Bronze

| Feature | Aluminum Bronze | Traditional Bronze (Tin Bronze) |

|---|---|---|

| Primary Alloy | Aluminum | Tin |

| Strength | Higher tensile/yield strength | Moderate strength |

| Corrosion Resistance | Excellent in marine/chemical settings | Good, but less robust in harsh conditions |

| Cost | Generally lower (aluminum is cheaper) | Higher (due to tin content) |

| Applications | Marine, aerospace, heavy machinery | Decorative, low-stress applications |

Industrial Applications

- Marine: Propellers, pump components, and seawater piping.

- Chemical Processing: Valves, pumps, and heat exchangers.

- Industrial Machinery: Wear plates, bushings, and heavy-duty gears.

Manufacturing Insights

- Casting: Ideal for complex shapes like valve bodies.

- Machining: Use sharp tools and cooling to manage hardness.

- Welding: Requires TIG/MIG methods for strong joints.

- Heat Treatment: Enhances hardness in high-aluminum alloys.

Selecting the Right Alloy

- High Loads & Abrasion: Opt for C95400.

- Corrosive Environments: Choose C95500 or C95900.

- Temperature Resistance: Ensure the alloy’s thermal limits match operational needs.

Conclusion

Aluminum bronze alloys like C95400, C95500, and C95900 offer unmatched performance in demanding settings. By understanding their unique properties—from C95400’s wear resistance to C95900’s marine-grade durability—engineers can optimize material selection for longevity, cost-efficiency, and reliability. Whether in the depths of the ocean or the extremes of aluminum bronze proves to be a versatile and indispensable solution.