Triple-layer bushing

Triple-layer bushing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Triple-layer bushing

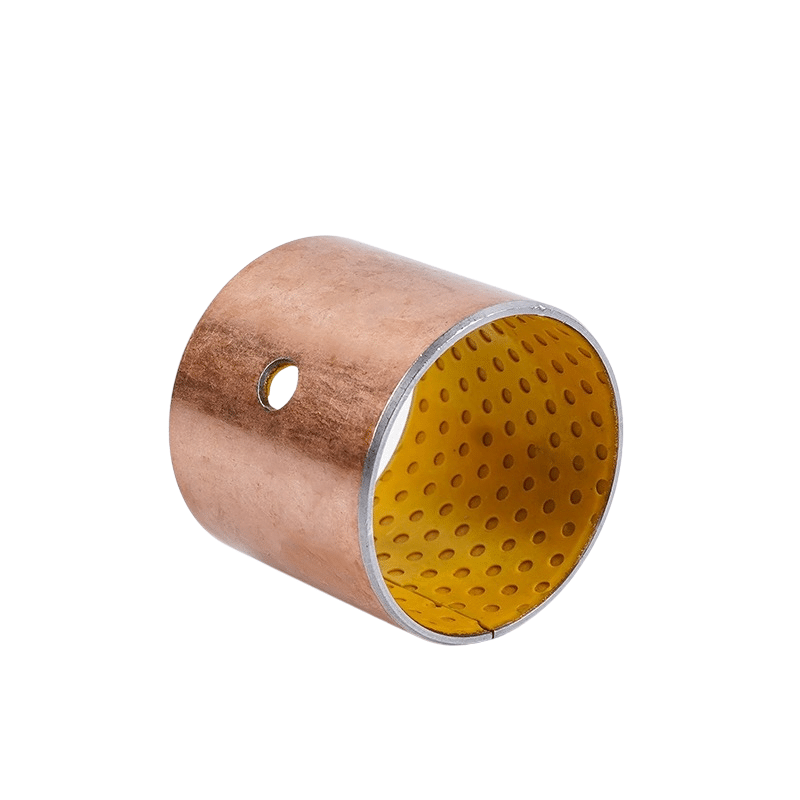

Triple layer bearing composed of an acetal pom layer grease pockets., sintered bronze, and a copper-plated steel with anti-corrosive properties.

- Material Composition:

- Steel Backing: This is the outermost layer, providing structural integrity and support. The steel backing ensures the bearing can withstand high loads and offers a robust foundation for the other layers.

- Sintered Bronze: The middle layer is made of sintered bronze, a porous material that can retain lubricant. This characteristic is crucial for reducing wear and extending the bearing’s lifespan. The sintering process provides the bronze with a unique structure that can hold lubricant, ensuring consistent lubrication during operation and reducing maintenance requirements.

- Acetal Resin Sliding Layer (Orange Color): The innermost layer, in direct contact with the moving parts, is made of acetal resin, known for its excellent wear resistance and low coefficient of friction. The orange color of the acetal resin does not impact its performance but serves as a visual identifier. This layer is designed to reduce friction and wear, contributing to the bearing’s efficiency and longevity.

- Key Features and Benefits:

- Low Friction: The acetal resin layer offers a low coefficient of friction, which minimizes the energy lost due to heat and wear, enhancing the overall efficiency of the machinery in which it’s used.

- Durability: The combination of a steel backing and sintered bronze provides a strong, durable foundation that can withstand high loads and stresses.

- Lubrication Efficiency: The sintered bronze’s ability to retain lubricant reduces the need for frequent maintenance and ensures that the bearing can operate smoothly over extended periods.

- Versatility: These bearings are suitable for a wide range of applications, including those involving oscillatory motion, high loads, and varying operational speeds.

- Applications:

- These bearings are versatile and can be used in various industrial applications, including automotive, aerospace, machinery, and more. They are particularly valuable in settings where durable and low-maintenance components are crucial.

In summary, the multilayer metal-polymer bearing with an orange acetal resin sliding layer is a high-performance component designed for efficiency, durability, and low maintenance, suitable for a wide array of industrial applications.

Triple layer bushing Characteristics:

- Suitable for Dirty and Tough Environments: The bearings are designed to operate efficiently in environments where they may be exposed to dirt, debris, or harsh conditions. This could be due to outdoor usage or the nature of the industrial process itself.

- Requires Little Maintenance (Prelubricated): These bearings are prelubricated, which means they come with lubricant already applied, reducing the need for frequent maintenance. The lubrication helps to minimize friction and wear, extending the life of the bearing.

- Long Life in Normal Operations: The construction and materials used in these bearings ensure they have a prolonged operational life under standard conditions. This longevity is beneficial for reducing downtime and maintenance costs in industrial applications.

- Multiple Areas of Use (Universal Bearing): Their design and characteristics make them versatile for a variety of applications, qualifying them as “universal bearings.”

Areas of Use:

- Forest Machinery: Used in machines that operate in forestry, handling the rugged and often unpredictable outdoor conditions.

- Packaging Machinery: Utilized in the packaging industry, where reliability and efficiency are key to maintaining continuous operation.

- Agricultural Machinery: Essential for various agricultural equipment, enduring the dust, soil, and varied weather conditions typical in farming environments.

- Food Industry: Their ability to perform in clean or potentially messy food processing environments makes them suitable for this sector.

- Hydraulic Cylinders: The bearings are used within hydraulic cylinders to ensure smooth operation and reliability under pressure.

Triple layer bushing Shapes & Forms:

- Plain Cylindrical Bearings: These are the standard form, designed to support radial loads and allow for smooth rotation.

- Thrust Washers: These components are designed to support axial loads, helping to prevent movement along the axis of rotation.

- Sliding Plates: These plates provide a sliding surface for moving parts, reducing wear and friction in machinery components.

These bearings are engineered to provide reliable performance under challenging conditions, making them an excellent choice for industries requiring durability and low maintenance.

- Material Composition:

- Copper-plated steel layer: This is the outermost layer, designed to offer corrosion resistance. The copper plating helps protect the steel from rusting, which is crucial in environments where the bearing might be exposed to moisture or chemicals.

- Sintered, multiporous bronze layer: The middle layer is made of sintered bronze. Sintering is a process where powdered metal is heated to a temperature below its melting point, causing the particles to bond. The “multiporous” aspect suggests that this layer is designed to retain lubrication, improving the bearing’s lifespan and reducing maintenance needs.

- Acetal plastic layer (with grease pockets): The innermost layer is made of acetal plastic, a strong, wear-resistant material. The mention of “grease pockets” indicates that this layer has cavities or pockets designed to hold lubricant, ensuring consistent lubrication during operation.

- Tolerances:

- Shaft Diameter Tolerances:

- f7: This tolerance applies to shaft diameters less than 55 mm. The “f7” indicates a specific range of tightness or looseness that the shaft can fit into the bearing. It’s a precise measurement that ensures the shaft will fit snugly without too much play or friction.

- h8: This tolerance is for shaft diameters greater than 55 mm. The “h8” tolerance is slightly looser than f7, accommodating larger shafts while still maintaining an effective fit.

- Housing Tolerance: H7 indicates the tolerance for the housing or bore in which the bushing will be fitted. The H7 tolerance ensures a snug fit, minimizing movement and wear.

- Shaft Diameter Tolerances:

These specifications suggest a high-quality, durable bearing designed for specific applications where precise tolerances and material properties are crucial. The triple-layer construction offers a balance of strength, wear resistance, and corrosion protection, suitable for environments where bearings are subject to varying stresses and exposure to potentially corrosive elements.

describes an orange-colored POM orange bearing, a high-quality, multi-layer bearing designed for durability and efficiency in various mechanical contexts. Here’s an overview based on your description:

Triple layer bushing Composition and Features:

- Copper-Plated Steel Frame: This is the outer layer that provides structural integrity and corrosion resistance.

- Sintered Bronze Middle Layer: This layer offers good wear resistance and embeds the lubricant for sustained release, enhancing the bearing’s lifespan.

- Acetal Plastic (POM) Sliding Surface: The orange POM layer is notable for its durability and low friction. It contains grease pockets for lubricant storage, which gradually release during operation, and can embed dirt and small particles, preventing damage to the shaft.

- Load Capacity: The POM bearing is designed to withstand high loads and is suitable for applications involving rotary and oscillating movements, especially in scenarios with frequent starts and stops.

Assembly Instructions:

- The POM orange layer bearings are manufactured ready for assembly, eliminating the need for additional machining such as boring or grinding.

- When press-fitting the bearing into its housing, it’s designed to remove any mating gap, ensuring a snug fit.

- The assembly should ensure that the bearing’s mating point is not aligned with the load zone to avoid uneven wear or damage.

Handling and Modification Guidance:

- When cutting or modifying the bearing, always move from the softer acetal layer to the harder steel layer to prevent separation of the layers and ensure that any potential burrs face away from the sliding surface.

Triple layer bushing Lubrication:

- These bearings come pre-lubricated, but additional lubrication with grease or oil is recommended to enhance performance and longevity.

- The incorporation of oil-resin in the POM layer allows the bearing to operate under “dry” conditions temporarily without failure.

- The POM material is chemically inert with lubricants, meaning it won’t react adversely to different types or additives found in lubricants.

This comprehensive design and the specific guidelines ensure that the POM orange bearings are versatile and reliable components suitable for a wide range of industrial applications, offering ease of use and maintenance.

Special bushing manufacturing, Triple layer bushing

On request, we can offer inch sizes, special lengths, and items acc. to drawing.

| Technical data | |

|---|---|

| Material: | Steel-backed/sintered bronze /acetal resin sliding layer |

| Standard: | Multilayer metal-polymer bearings |

| Sliding layer (thickness): | 0.3-0.5mm |

| Tensile strength Rm: | – |

| Yield strength Rp 0.2: | – |

| Elongation in % A10: | – |

| Hardness: | – |

| Friction coeff: | 0.05-0.25µ |

| Thermal conductivity: | 40W/m·K |

| Temperature range: | -40°C/110°C |

The multilayer metal-polymer bearing you’re describing is a sophisticated engineering component designed for a variety of applications, offering a blend of strength, durability, and low-friction performance.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.