SWP Oilless Wear Plate

SWP Oilless Wear Plate

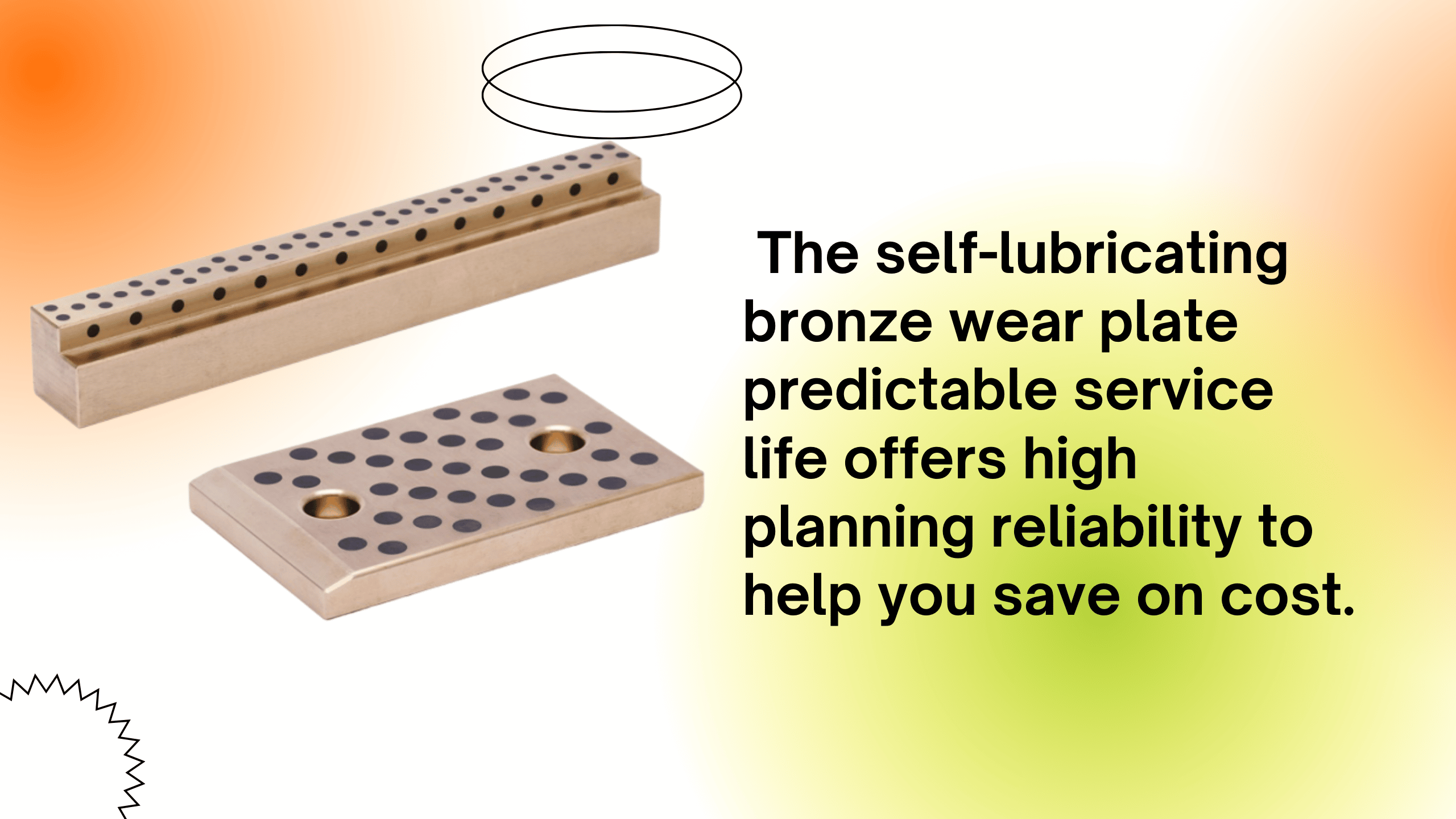

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

SWP Oilless Wear Plate

Bronze Wear Strips – Holes and Graphite. High tensile brass-based / solid lubricant embedded, These components are made of solid bronze with pre-drilled mounting holes and self-lubricating graphite. Contact us to find detailed information about bronze plate specifications and dimensions.

Copper self-lubricating Plate – Plugged Graphite – Oil-free Slide Plate – Select, configure, order. We deliver punctually & offer fair prices. SLP Copper self-lubricating L-shaped rail, SWP Copper self-lubricating block.

Wear Resistant Plate, Precision Wear Plates – with or without graphite, abrasion resistant plates!

Graphite Copper Slide Wear Blocks are self-lubricating components used to reduce friction in mechanical systems without the need for external oil or grease.

Non-lubricated bushings/washers are bearing components that do not require lubrication. Since bearings typically receive a lot of frictional resistance that generates heat, a lubricant such as oil or grease is used to prevent a seizure or abnormal wear that may result from this frictional heat. Lubrication-free bushings do not require lubrication because the bearing body has a lubrication structure that is achieved by a lubricant or embedded solid lubricant or similar in the bearing body. Non-lubricated washers are washers that can accept thrust loads and have the same lubrication structure as non-lubricated bushings. They are typically used in conjunction with non-lubricated bushings. Both lubrication-free bushings and washers are very effective in situations where the use of lubricant is difficult due to the operating environment or structure. They also greatly reduce maintenance costs by eliminating the need for periodic lubrication and provide long-term stable operation.

Graphite Embedded Bronze Wear Plate · Small Minimum Order Quantity: Material: ZCuZn25AI6Fe3Mn3

Oil-Free Self-Lubricating Graphite Copper Slide Wear Block

Bronze Plate Stock – Metal Bronze Plate,

Wear Plate With Graphite manufacturers & suppliers

Made in China. Highlights: Save Time And Money

High-temperature resistant copper alloy self-lubricating wear plates

High strength brass Graphite inlay Plate

Abrasion Resistant Plates Product description

Production process: centrifugal casting

Product advantage: no oil

Common material: high force brass

Self-lubricating slide plate -copper alloy plate

The chemical formula of Golik brass is ZCuZn24Al6Fe4Mn3 , the copper content du about 62%.

High force brass has strong wear resistance, high strength, hardness and chemical corrosion resistance. There are also excellent mechanical properties for cutting and machining. High-force brass is often made into the manufacture of plates, strips, bars, tubes, casting parts and so on.

High force brass has good plasticity and can withstand hot and cold processing, JDB solid inlay bearing is a new product inlaid with solid lubricant on high force brass substrate. The general solid lubricant accounts for 20-30% of the friction surface area. The lubrication principle of graphite brass inlay self-lubricating bearing is that during the sliding friction of shaft and bearing, a part of graphite particles is transferred to the friction surface of shaft and bearing, forming a more stable solid lubricating diaphragm to prevent the direct adhesive wear of shaft and bearing. This rational combination integrates the respective performance advantages of metal alloy and non-metallic wear reducing material to complement each other, that is, with the high load-bearing capacity of metal and the lubricating performance of wear reducing material. So it is especially suitable for no oil, less oil, high temperature, high load or water, and other environments. It breaks through the limitations of general bearings relying on oil film lubrication. Suitable for high temperature. It is suitable for high temperature, high load, corrosion resistance, or cannot be oiled. Its hardness is higher than the general copper bush, and its wear resistance is also good. At present, the product is widely used in a metallurgical continuous casting machine, rolling equipment, mining machinery, ships, steam turbines, injection molding machines and production lines. The product is made of specially formulated high-strength brass with high mechanical properties, good casting performance, and good corrosion resistance, and the surface is inlaid with specially formulated solid lubricant at a certain angle and density, which is processed with precision. The products are widely used in injection molding machines, continuous casting machines, mining machinery, ships, gas turbines, etc.

JSP slider/JSL slider is a self-lubricating slide slider made of a high-quality copper alloy as the substrate and embedded with solid lubricant on the working surface of the substrate. The bearing bears the majority of the load in the friction process on the metal substrate. By friction, the solid lubricant in the hole or slot is transferred or counter-transferred to the friction surface, forming a well-lubricated, firmly attached, and uniformly covered solid transfer film on the friction surface, significantly reducing frictional wear. With the friction, the solid lubricant embedded in the friction surface is continuously provided, to ensure long-term operation of the friction vice of good lubrication the bearing breaks through the general bearing relying on the boundaries of oil film lubrication, with high bearing capacity, impact resistance, high-temperature resistance, small friction coefficient, small wear, no noise, self-lubricating performance and other advantages, and no wear on the shaft, use will not appear card shaft and other characteristics. Especially suitable for heavy load, low speed, reciprocating or oscillating, and other difficult to lubricate and form oil film field Basic hardness: HB210~270

Friction coefficient μ:<0.16

Operating temperature: 350

Sliding speed: dry 0.4m/s oil 5m/s

Bronze-Plated Wear Plates – Die Mould Equipment

The products are self-lubricating bearings, sliding bearings, composite bearings, bushings, bushings, oil-free bearings, solid inlay bearings, dry bearings, shaft tiles, flat bearings, guide bushings, bimetallic bearings, self-lubricating bearings, oil-free bearings, flanged bearings, reciprocating bearings, stainless steel self-lubricating bearings, gear oil pump bearings, thrust spacers, ball guide bushings ( roller cage), mold guide pillar, mold frame, mold guide bush, tilting wedge and other automotive mold standard parts. These products are mainly used in the automotive industry (steering knuckle bushings, rocker arm bushings, booster pump bushings, shock absorbers), valves, pumps and valves, lifts, hydraulic trucks, power tools, textile machinery, rubber machinery, printing machinery, food machinery, packaging machinery, lifting machinery, mining machinery, fitness equipment, water conservancy machinery, machine tools, hydraulic turbines, steam turbines, injection molding machines, plastic molding machines, metallurgical equipment, molds, hydraulic machinery, cylinders, pneumatic components, cylinders, petroleum machinery, plastic machinery, pharmaceutical machinery, automation equipment, engineering machinery, construction machinery, forging equipment, chemical machinery, steel rolling equipment, etc.

SWP Oiless Wear Plate Copper self-lubricating Plate

Flat Plate Oilless Flat Plate with Graphite Plugs, High tensile brass based / solid lubricant embedded

SWP Oiless Wear Plate material is made with high-strength copper alloy, and the inserted solid lubricant materials are made with graphite and PTFE.

High-strength copper alloy as base material, according to the use conditions by a certain percentage of its working surface machined hole and fill one solid lubricant. High-strength copper alloy provides a high load-carrying capacity and the solid lubricant can be formed at lower friction. Under dry friction conditions of our pre-designed layer of lubricating film in the bearing surface to ensure that in the shortest possible time will be transferred to the solid lubricant on the coupling member and form a valid solid lubricant film.

Graphite Slide Plates – Bronze Products

Graphite Slide Plates. Graphite oilless bronze plate, bronze slide plates for higher temperature applications.

According to the bushings’ working conditions, the bronze combination between the different metal basements and various solid lubricants can ensure that the product can perform under various temperatures, loads, movements and mediums as required.

Oilless bush is especially applied in oil-free high temperature, high load, low speed, contamination resistance, corruption resistance radiation resistance as well as the use under such special work conditions that cannot be lubricated, such as underwater and in vacuum space.

Below is a table chart of SWP Oilless Wear Plate sizes. Please note that this table is an example and may not represent the entire range of sizes available. For accurate measurements and more options, refer to the manufacturer’s datasheets.

| Wear Plate Size | Length (L) | Width (W) | Thickness (T) |

|---|---|---|---|

| Size 1 | 50 mm | 50 mm | 2 mm |

| Size 2 | 100 mm | 50 mm | 2 mm |

| Size 3 | 100 mm | 100 mm | 2 mm |

| Size 4 | 150 mm | 100 mm | 3 mm |

| Size 5 | 200 mm | 100 mm | 3 mm |

| Size 6 | 200 mm | 200 mm | 3 mm |

| Size 7 | 250 mm | 200 mm | 4 mm |

| Size 8 | 300 mm | 200 mm | 4 mm |

| Size 9 | 300 mm | 300 mm | 4 mm |

| Size 10 | 400 mm | 300 mm | 5 mm |

| Size 11 | 500 mm | 300 mm | 5 mm |

| Size 12 | 500 mm | 500 mm | 5 mm |

| Size 13 | 600 mm | 500 mm | 6 mm |

| Size 14 | 700 mm | 500 mm | 6 mm |

| Size 15 | 800 mm | 500 mm | 6 mm |

This table provides information on the length (L), width (W), and thickness (T) of the SWP Oilless Wear Plates. To find the appropriate wear plate size for your application, check the manufacturer’s guidelines for the correct dimensions and tolerances.

SWP plate is made with high-strength copper alloy, and the inserted solid lubricant materials are made with graphite and PTFE.

According to the bushings’ working conditions, the bronze combination between the different metal basements and various solid lubricants can ensure that the product can perform under various temperatures, loads, movements, and mediums as required.

Oilless bush is especially applied in oil-free high temperature, high load, low speed, contamination resistance, corruption resistance radiation resistance as well as the use under such special work conditions that cannot be lubricated, such as underwater and in vacuum space.

Wear Plate General Purpose Plate Key Characteristics:

1. May work without any oil for long period.

2. Extremely high load capacity, good anti-wear, and low friction.

3. Particularly appropriate for low speed and high load.

4. Suitable single direction axial loads

5. Free design is possible on the shape and size

6. Can be used in a wide range of temperatures, from - 40℃+ 300℃

Bronze Wear Strips – Holes- Graphite, Bronzelube.com

High tensile brass based / solid lubricant embedded plat

| Slide Bronze Wear Plate SWP-100100 |

| Slide Bronze Wear Plate SWP-100125 |

| Slide Bronze Wear Plate SWP-100150 |

| Slide Bronze Wear Plate SWP-100200 |

| Slide Bronze Wear Plate SWP-100250 |

| Slide Bronze Wear Plate SWP-125150 |

| Slide Bronze Wear Plate SWP-125200 |

| Slide Bronze Wear Plate SWP-125250 |

| Slide Bronze Wear Plate SWP-150150 |

| Slide Bronze Wear Plate SWP-150200 |

| Slide Bronze Wear Plate SWP-150250 |

| Slide Bronze Wear Plate SWP-48100 |

| Slide Bronze Wear Plate SWP-48125 |

| Slide Bronze Wear Plate SWP-48150 |

| Slide Bronze Wear Plate SWP-4875 |

| Slide Bronze Wear Plate SWP-75100B |

| Slide Bronze Wear Plate SWP-75125 |

| Slide Bronze Wear Plate SWP-75150 |

| Slide Bronze Wear Plate SWP-75200 |

| Slide Bronze Wear Plate SWP-7575B |

The specifications and dimensions of the Bronze Wear Plate may not be fully covered. For exact details, refer to manufacturer oilless bearing catalogs.

Injection mold in the sliding parts basically need to do oil groove, with lubricating oil to ensure the smooth movement of the mold structure, wear and lubrication, such as: slant pin, slider, top block and other parts. Oil groove applicable parts: slider, slider insert, slant pin, wear-resistant block, wedge block, top block and other moving parts of the sliding surface must be processed oil groove. I. Oil groove design standards: 1. Design non-standard slider (overall slider), slider inserts, top block need to draw 3D, 2D, and mark the size of the nearest edge of the rubber surface to the oil groove in 2D (to avoid processing errors). 2. When designing slant pins, slider guide blocks, wedge tight blocks, oil grooves do not need to draw 3D, 2D oil grooves, made into a standard specification file can be. II. Oil groove processing standard Applicable parts: slider, slider insert, tilt pin, wear-resistant block, wedge block, top block and other moving parts of the sliding surface must be processed oil groove. Description: 1. Circle-shaped oil groove: diameter Φ10, Φ8, Φ6, Φ2.5 circle, circle center distance are 8*8, 6*6, 5*5, 2*2 (unit: mm) oil groove depth is 0.3±0.05mm (for the slider, slant pin) 2. ±0.05mm; for sliding parts with face width below 5.5mm (for slant pins). Processing basis: strictly in accordance with the standard oil groove processing schematic for each part. Machining process: Standard parts: Standard parts of the old factory are processed by the standard parts group (grinder, milling machine) of the machining department; all slant pin oil grooves are processed by the standard parts group (EDM); Non-standard parts: Non-standard parts are processed by the machining section (grinder, milling machine) of each department; Machining Remarks: Screw holes, part edges, etc. are not to be broken during machining.

Chinese (Simplified)

Injection mold on the sliding parts basically needs to do oil groove, with lubricant to ensure smooth movement of the mold structure, wear-resistance, and lubrication, such as slant pin, slider, top block, and other parts. Oil groove applicable parts: slider, slider inserts, slant pin, wear-resistant block, wedge tight block, top block, and other moving parts on the sliding surface of the necessary processing oil groove. I. Oil groove design standards: 1. Design non-standard slider (overall slider), slider inserts, top block need to draw 3D, 2D, and mark the size of the nearest edge of the rubber surface to the oil groove in 2D (to avoid processing errors). 2. When designing slant pins, slider guide blocks, wedge tight blocks, oil grooves do not need to draw 3D, 2D oil grooves, made into a standard specification file can be. II. Oil groove processing standard Applicable parts: slider, slider insert, tilt pin, wear-resistant block, wedge block, top block and other moving parts of the sliding surface must be processed oil groove. Description: 1. Circle-shaped oil groove: diameter Φ10, Φ8, Φ6, Φ2.5 circle, circle center distance are 8*8, 6*6, 5*5, 2*2 (unit: mm) oil groove depth is 0.3±0.05mm (for slider, slant pin) 2. ±0.05mm; for sliding parts with face width below 5.5mm (for slant pins). Processing basis: strictly in accordance with the standard oil groove processing schematic for each part. Machining process: Standard parts: Standard parts of the mold factory are processed by the standard parts group (grinder, milling machine) of the processing department; slant pin oil grooves are all processed by the standard parts group (EDM); Non-standard parts: Non-standard parts are processed by the processing section (grinder, milling machine) of each department; Processing Remarks: Screw holes, part edges, etc. are not to be broken during processing.

Frequently Asked Questions about Wear Plates

Can I use two copper-plated wear plates in a mold and have the two plates rub against each other?

This is not recommended (having the two plates rub against each other). The material to rub against the copper-plated wear plate should be different and harder than the copper-plated plate. It is recommended that the material intended to rub against the copper-plated wear plate should have a difference of at least 6-8 HRc hardness points (higher) compared to the surface hardness of the copper-plated wear plate itself.

I operate a clean room facility. What kind of residue do I expect the wear plate to leave behind?

Materials. Copper and tin. In this case, it is recommended that the wear plates be placed as far away from the cavity as possible. Use grease or oil to reduce wear.

I want to drill holes in a self-lubricating wear plate. How can I find out where the graphite insert is located?

Please contact our engineering company for assistance. You will need to provide your specific part number.

Is there an upper-temperature limit for copper-plated wear plates, slides, and skids?

Copper-plated wear plates, slides, and gears can be used at operating temperatures up to 400°F (204°C).

What are copper-plated wear plates, slides, and gears made of?

Copper-plated wear plates, slides, and gears are made from low carbon, ultra-fine grain steel plated with a bronze alloy. Bronze has a minimum hardness of approximately 180 Bhn (for hardness conversion tables, please refer to the Die Holders and Stencils catalog). The bronze plating has natural lubricity and is ideal when used against hardened steel. We recommend using any good grade of light machine oil suitable for application in a mechanical manner to extend the life of the wear surface.

What is the coefficient of friction of your bronze-plated wear plates, guides, and capstans?

Self-lubricating wear plates are made of aluminum bronze alloy and have oil-impregnated graphite plugs.

What is the difference between copper-plated wear plates and self-lubricating wear plates?

Self-lubricating wear plates are made of aluminum bronze alloy and have oil-impregnated graphite plugs.

What is the maximum pressure that can be applied to a copper-plated wear plate?

2700 PSI (pounds per square inch).

When should I replace a copper-plated wear plate?

After 0.003″ (approximately 0.076 mm) of maximum wear.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.