Sphere Oscillating Bearing

Sphere Oscillating Bearing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Sphere Oscillating Bearing

Shop a large range of Spherical plain bearings rod end, JQB, JDBS spherical plain bearing thrust spherical plain bearing, rod ends bearings – maintenance-free self-lubricating at bronzelube.com. Support all your size range: Available from 12.7 mm – 600 mm (0.500 in. to 23.622 in.) bore … with excellent quality, to win customers of all ages.

JQB Sphere Oscillating Bronze Bearing Self Lubricating Long Lifespan

Applications

- Cylinders for mining trucks

- Equalizer track bars, lift and tilt cylinders, push blades, trunnion balls, and ripper blades for bulldozers

- Articulated joint upper and lower steering cylinders and boom and bucket cylinders for wheel loaders

- Stick and bucket cylinders for hydraulic excavators

- Additional applications for space shuttles, heavy movable structures, and miscellaneous vehicles

Sphere Oscillating Bearing, Spherical plain bearing – maintenance-free, thrust spherical plain bearing. RANGE OF APPLICATION Valve, barrage assets, ball valves, guide vane bearings, dampers, etc. Bronze ring material ASTM C86300, Outer ring is stainless steel,

Spherical bearing, self lubricating, Radial spherical plain bearings, Common Models: JQB-015, JQB-020, JQB-025, JQB-030, JQB-035, JQB-040, JQB-045, JQB-050, JQB-060, JQB-070, JQB-080, JQB-090 , JQB-100, JQB-110, JQB-120, JQB-130, JQB-140, JQB-150, JQB-160, JQB-180, JQB-200, JQB-220, JQB-240, JQB-260, JQB -280, JQB-300.

Revolutionary product characteristics that deliver distinctive performance benefits, including remarkable load-bearing capabilities, customizable re-lubrication choices, and exclusive patented configurations.

Understanding the 500 Spherical Bearings Unit: Plugged Graphite Revolution in Bearing Technology, Embedded Solid Lubricants

In the world of mechanical engineering and design, the introduction of the 500 Spherical Bearings Unit, especially those with plugged graphite, marks a significant advancement in bearing technology. These bearings have been engineered to address some of the most challenging aspects of mechanical design and maintenance, offering a blend of durability, efficiency, and performance.

The Design: A Fusion of Innovation and Functionality

At the core of the 500 Spherical Bearings Unit is the innovative use of plugged graphite. This material is renowned for its self-lubricating properties, which play a crucial role in the bearing’s operation. Plugged graphite bearings reduce the need for regular maintenance, as they do not require external lubrication. This feature is particularly advantageous in applications where lubrication is difficult or where contamination from lubricants is a concern.

The spherical design of these bearings allows for angular misalignment, making them ideal for applications where shaft alignment is a challenge. This flexibility in alignment not only simplifies installation but also enhances the operational lifespan of the bearings by reducing stress on the components.

High Load Capacity and Durability

One of the key attributes of the 500 Spherical Bearings is their ability to handle high loads. This capability stems from their robust construction, which typically involves high-grade materials such as high carbon chromium bearing steel. The durability is further enhanced by the presence of the graphite plugs, which provide continuous lubrication, minimizing wear and tear.

Applications: Versatility Across Industries

The versatility of the 500 Spherical Bearings Unit is evident in its wide range of applications. From heavy machinery in the construction industry to precision equipment in manufacturing, these bearings are suited for various environments and tasks. Their ability to withstand high loads and oscillating movements makes them particularly useful in sectors like automotive, aerospace, and renewable energy, where reliability and performance are critical.

Environmental and Economic Benefits

The self-lubricating nature of these bearings not only reduces maintenance requirements but also presents significant environmental benefits. By eliminating the need for lubricants, these bearings contribute to a cleaner operational environment and reduce the risk of contamination. Economically, the long service life and reduced maintenance needs of these bearings translate to lower operational costs over time, making them a cost-effective solution for many businesses.

Conclusion: A Step Forward in Bearing Solutions

The 500 Spherical Bearings Unit with plugged graphite is a testament to the continuous evolution in bearing technology. By offering high load capacity, durability, and self-lubricating properties, these bearings stand out as a superior choice for a wide array of applications. Their design not only meets the current demands of various industries but also paves the way for more innovative and efficient mechanical solutions in the future.

GE 45 ES-2RS equivalent graphite impregnated brass bush

Radial spherical plain bearing metric sizes

Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes a steel/steel sliding contact surface combination and a double-lip contact seal on both sides. The bearings require maintenance and can be relubricated via lubrication holes and an annular groove in both rings.

- Designed for radial and combined radial and axial loads

- Long service life

- Minimal maintenance

- Suitable for heavy static, alternating, or impact loads

Let our bronze bushing raise your project to the next level, NOW!

the ultimate Guide To Sourcing Bronze Bushing In China,

#500SP1 SL1 Oiles Bushing, Spherical Bearing (SPS), Can be used without lubrication and has an extremely long service life.

Tin bearing bronze Radial spherical plain bearing, requiring maintenance, sealed, metric sizes

We cast bushings, plain bearings, sliding plates, seals and various other wear parts in bronze.

- Totally free and full of resources

- Save your ton of time making a decision

- A must-have checklist for sourcing

Spherical Plain Bearing, Special spherical plain bearings with the maintenance-free ball, Maintenance-free

MATERIALS: Sliding Layer, Bronze alloy with solid lubricant

Technical Detail With sliding properties

- graphite type spherical plain bearings are maintenance-free

- Standard production according to DIN dimensions

- Special measurements and designs are produced at short notice!

- This sliding material causes no threat to health and the environment (if ordered lead-free)!

Joint bearing characteristics The structure of joint bearing is simpler than rolling bearing, which is mainly composed of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface. The joint bearing is generally used for low-speed oscillating motion (i.e. angular motion), because the sliding surface is spherical, it can also be tilted in a certain angle range (i.e. spherical motion), and can still work normally when the support shaft and the shaft housing hole are not concentric.

Self-lubricating spherical plain bearings are self-lubricating bearings that can be rotated or swung in any direction.

The self-lubricating spherical joint bearing is a kind of self-lubricating performance, that can be rotated or swung in any direction. It has the high bearing capacity, small coefficient of friction can automatically adjust the center can simultaneously withstand radial and axial load, self-lubricating maintenance-free, long service life, a wide range of applications, and other characteristics. Since the end of the last century, the product has been put on the market for the domestic water conservancy projects and various mechanical equipment to provide different specifications of self-lubricating joints bearing tens of thousands of sets, the actual use of many water conservancy projects proved that our company developed and produced a stable and reliable performance of self-lubricating joint bearing, in the national key water conservancy projects gradually replace the imported, representing the technology of domestic self-lubricating joint bearing reached the international advanced level!

Self-lubricating joint bearings are divided into three categories, namely radial joint bearings, thrust joint bearings, angular contact joint bearings

Self-lubricating thrust joint bearings: Self-lubricating materials have excellent friction reduction, wear-resistance and self-lubrication, and also have High bearing capacity and good dimensional stability, can meet the special self-lubricating joint bearings for hydraulic machinery. The self-lubricating material has excellent friction reduction, wear-resistance and self-lubrication.

Joint bearings can withstand large loads. According to its different types and structure, it can bear radial load, axial load or radial, axial at the same time combined load. Due to the inner ring of the outer spherical surface with composite materials, so the bearing can produce self-lubrication in the work. Generally used for low-speed swing movement, and low-speed rotation, but also in a certain angle range for tilting movement, when the support shaft and shaft shell-hole is not the center degree is large, but still can work normally. Self-lubricating joint bearings are used in water conservancy, professional machinery and other industries.

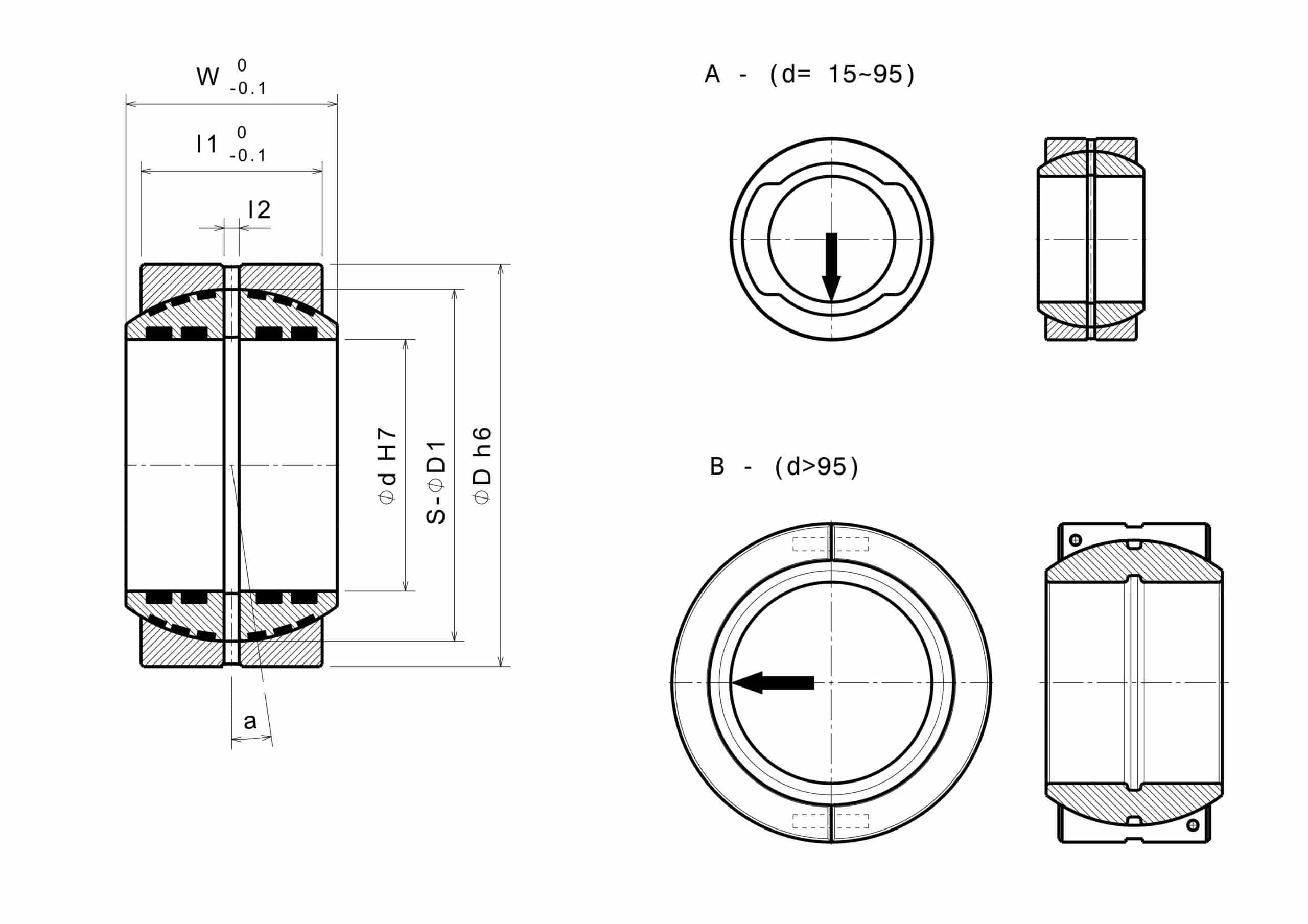

Sphere Oscillating Bearing Introduction:

A self-lubricating plain bearing is a kind of space motion plain bearing with self-lubricating performance, which can rotate or swing in any direction. The self-lubricating plain bearing consists of the inner ring and outer ring.

Product features:

The product has a high bearing capacity, small friction coefficient, automatic self-aligning, can bear radial and axial loads at the same time, no maintenance, long service life, wide application range, and so on.

Product Application:

The product is widely used in hydraulic machinery arc gates, plane gates, miter gates, a hydraulic hoist and tubular turbine water guide mechanism and other equipment.

Characteristics and application of joint bearing, oilless bushing supplier

The outer layer of the self-lubricating spherical joint bearing is a steel ball, which can be quenched to improve the load-carrying capacity, and the inner ball combines the wear resistance of copper alloy (ZCuZn24Al6, SAE430B) and the self-lubricating property of solid lubricant so that it does not need oiling and maintenance during the use. We also have an oil groove on the outside of the design so that it is easy to refuel, which can greatly improve the life of the product if it is in use, so the product is widely used in high load, intermittent, or rocking motion, such as steam locomotive production line, hydraulic turbine, reservoir work/accident door, plastic machinery, etc. Various types of copper alloys are available depending on the operating conditions used.

| Standard No. | d(H7) | D1(h6) | B | C | D | b | Alignment Angle (°) | Allowable Radial Load (kN) | Allowable Thrust Load (kN) |

|---|---|---|---|---|---|---|---|---|---|

| JQB-015 | 15 | 26 | 12 | 9 | 22 | 4 | 8 | 6.5 | 0.5 |

| JQB-020 | 20 | 32 | 16 | 14 | 28 | 4 | 4 | 12.6 | 1.4 |

| JQB-025 | 25 | 42 | 21 | 18 | 36 | 4 | 5 | 21.8 | 2.5 |

| JQB-030 | 30 | 50 | 27 | 23 | 44 | 4 | 6 | 32 | 3.5 |

| JQB-035 | 35 | 55 | 30 | 26 | 49 | 4 | 5 | 43.7 | 4.8 |

| JQB-040 | 40 | 62 | 33 | 28 | 55 | 4 | 6 | 54.7 | 5.7 |

| JQB-045 | 45 | 72 | 36 | 31 | 62 | 4 | 5 | 69.7 | 7.2 |

| JQB-050 | 50 | 80 | 42 | 36 | 70 | 4 | 5 | 92.4 | 10 |

| JQB-060 | 60 | 100 | 53 | 45 | 90 | 4 | 6 | 143 | 16 |

| JQB-070 | 70 | 110 | 58 | 50 | 99 | 4 | 5 | 181 | 20 |

| JQB-080 | 80 | 130 | 70 | 60 | 115 | 4 | 6 | 254 | 30 |

| JQB-090 | 90 | 140 | 76 | 65 | 125 | 4 | 6 | 313 | 36 |

| JQB-100 | 100 | 160 | 88 | 75 | 145 | 6 | 6 | 544 | 64 |

| JQB-110 | 110 | 170 | 93 | 80 | 155 | 6 | 5 | 642 | 73 |

| JQB-120 | 120 | 190 | 105 | 90 | 170 | 6 | 6 | 797 | 94 |

| JQB-130 | 130 | 200 | 110 | 95 | 180 | 6 | 5 | 880 | 105 |

| JQB-140 | 140 | 210 | 90 | 70 | 180 | 6 | 7 | 668 | 56 |

| JQB-150 | 150 | 220 | 120 | 105 | 200 | 6 | 5 | 1135 | 129 |

| JQB-160 | 160 | 230 | 105 | 80 | 200 | 6 | 8 | 891 | 73 |

| JQB-180 | 180 | 260 | 105 | 80 | 225 | 6 | 6 | 1002 | 74 |

| JQB-200 | 200 | 290 | 130 | 100 | 250 | 6 | 7 | 1434 | 117 |

| JQB-220 | 220 | 320 | 135 | 100 | 275 | 6 | 8 | 1577 | 118 |

| JQB-240 | 240 | 340 | 140 | 100 | 300 | 9 | 8 | 1720 | 118 |

| JQB-260 | 260 | 370 | 150 | 110 | 325 | 9 | 7 | 2075 | 143 |

| JQB-280 | 280 | 400 | 155 | 120 | 350 | 9 | 6 | 2455 | 172 |

| JQB-300 | 300 | 430 | 165 | 120 | 375 | 9 | 7 | 2630 | 172 |

Maintenance-free features quite long service life. Conforms to ISO Standard E type bearings. High precision. The inner surface of the inner ring is subject to sliding. Suitable for higher load than other self-lubricating spherical bearings. Customized design can be made on your requirement.

A plain bearing is a kind of sliding bearing with a special structure, which is mainly composed of an inner ring with an outer sphere and an outer ring with an inner sphere. It can swing and rotate in any direction. Generally, it can bear a large load and has the characteristics of high load-bearing, impact resistance, wear resistance, self-aligning and good lubrication.Because the outer sphere of the inner ring is usually inlaid with composite materials, the joint bearing can produce self-lubrication in operation. Generally used for low-speed swing motion and low-speed rotation, but also in a certain Angle range of tilt motion, when the supporting shaft and shaft shell hole concentricity is large, it can still work normally. Widely used in low-speed swing motion, tilt motion, and rotary motion, such as nuclear power, aerospace, engineering hydraulic cylinder, forging machine tools, construction machinery, automation equipment, automotive shock absorber, hydraulic machinery, and many other industries and fields, is the core components to determine the host operation performance.

Spherical Plain Bearing, graphite oilless bushing/bearing Size, Self Lubricated Radial Spherical Plain Bearing

JQB Metric Spherical Bushes Size Chart

| JQB Model | JDBS Model | Size (mm) |

|---|---|---|

| JQB15 | JDBS-15 | 15 |

| JQB20 | JDBS-20 | 20 |

| JQB25 | JDBS-25 | 25 |

| JQB30 | JDBS-30 | 30 |

| JQB35 | JDBS-35 | 35 |

| JQB40 | JDBS-40 | 40 |

| JQB45 | JDBS-45 | 45 |

| JQB50 | JDBS-50 | 50 |

| JQB60 | JDBS-60 | 60 |

| JQB70 | JDBS-70 | 70 |

| JQB80 | JDBS-80 | 80 |

| JQB90 | JDBS-90 | 90 |

| JQB100 | JDBS-100 | 100 |

Graphite Plain bearing on processing solutions. Custom Bearing Services. Cost-Efficient Parts. Wide Range Of Products. Services: Engineering.

Spherical Plain Bearing, Shop for Copper Bushings at BRONZELUBE.COM

Engineered for a Longer More Reliable Service Life, Metric Spherical Plain Bearing.

High Strength Spherical Plain Bearing, Customized Processing Self Lubricating Bearing – Resistant

Spherical Plain Bearing, Graphite Copper Bushing Self Lubricating Materials High Strength.

Spherical plain bearings and rod ends, Spherical Plain Bearings

According to its different types and structure, it can bear radial load, axial load or radial, and axial combined load. It can be generally divided into centripetal joint bearings, angular contact joint bearings, thrust joint bearings, rod end joint bearings, and other types.

Graphite bearing, Low coefficient of thermal expansion, low friction coefficient.

Spherical Plain Bearing Supplier, Industrial Graphite Bearings – Graphite Bearings

Focus, the pursuit of “spirit”, and always continuous innovation, customer and social needs as the guidance, constantly moving forward, with the advantages of on the self-lubricating material technology, can provide products to satisfy different working conditions of self-lubricating bearing joints, including engineering plastics modified joint bearing, metal base self-lubricating bearing joints, and used in high temperature, high load conditions of special products.

Application of Spherical Plain Bearing :

-Self-lubricating spherical plain bearings Application

Self-lubricating spherical joint bearings have been widely used in the hydraulic machinery of arc gates (supporting hinge bearings), flat gates (fixed wheel bearings)

bearing), flat rate (fixed wheel bearing), herringbone gate (bottom pivot bearing i.e. bearing shaft nest ball liner), hydraulic

The bearings have been widely used in the arc gates (supporting hinge bearing), flat gates (fixed wheel bearing), herringbone gates (bottom pivot bearing, i.e. bearing nesting ball liner), hydraulic open and close machines and hydraulic turbine generator sets (water guide mechanism of cross-flow turbine), as well as lifting and transportation equipment, port machinery (shore bridge), metallurgical equipment (coking machine), engineering machinery and other industries. With the increase of market development, the application field of self-lubricating spherical joint bearings will continue to expand. Self-lubricating radial joint bearings are mainly used in arc gate support hinge bearings, plane

gate fixed wheel bearings; self-lubricating radial joint bearings, self-lubricating thrust off

The self-lubricating radial spherical joint bearing and self-lubricating thrust joint bearing are mainly used in the bearing of the hydraulic opening and closing machine support; the ball liner of the bearing axis of the bottom pivot of the herringbone gate is generally inlaid bearing.

Sphere Oscillating Bronze Bearing self-lubricating

Basically, general-purpose products, are suitable for various circumstances Including high or low load, high or low temperature, with oil or oil lubrication, or even In the water. With its matrix made of high-strength brass, Its hardness doubles than of normal bronze bushings and the wear performance improves to a large degree, so it is applicable for continued pitching machines, and conveyors of the metallurgy industry. It could also be used in plastic injection machines, in the automatic switch of high-tension electricity, in the luffing and supporting parts of construction machines, hydraulic gate supporters, pulley, drive wheels of water control projects, and also for drying tunnel of paper machines, auto die, sliding parts for ships unmooring, etc.

Copper base inlay type self-lubricating joint bearing outer bearing steel sleeve, inner JDB solid inlay type bearing

It is on the substrate of high-force brass. A high-performance solid lubrication product inlaid with graphite or MoS2 solid lubricant. It breaks through the limitation of general bearing relying on oil film lubrication. In the process of use, through frictional heat to make solid lubrication and shaft friction, the formation of oil, powder coexistence lubrication excellent conditions, it can replace the traditional flange linear motion bearings, linear slide bearings Both to protect the shaft does not wear, but also the solid lubrication characteristics eternal.

Spherical plain bearing Alloy materials

Spherical bearing, self lubricating. Article properties: Base Material. Special Brass (SO#50SP2). Self-lubricating Lubricant. Graphite.

| Model | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Grade China Brands GB1776-87 |

ZCuZn25 AI6Fe3Mn3 |

ZCuSn6Zn6Pb3 | ZCuAI10Fe3 | ZCuSu10P1 | Steel+ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| International ISO1338 |

GCuZn25 AI6Fe3Mn3 |

GCuSn6Zn6Pb3 | GCuAI10Fe3 | CuSn12 | Steel+CuSn6Zn6Pb3Fe3Ni5 | – | B1 |

| Germany DIN |

G-CuZn25 AI5 |

GB-CuSn5Zn5Pb5 | GB-CuAI10Ni | GB-CuSn10 | Steel+CuSn6Zn6Pb3Ni | – | 100Cr6 |

| Japanese JIS |

HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| United States ASTM/UNS |

C86300 | C83600 | C95500 | C90800 | C83600 | Class40 | 52100 |

| British Standard | HTB2 | LG2 | AB1 | PB4 | LG2 | – | – |

Material alloy chemical composition

| Chemical Elements | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Cu ( % ) | Rest | Rest | Rest | – | – | ||

| Sn ( % ) | – | 6 | – | 10 | 6 | – | – |

| Zn ( % ) | 25 | 6 | – | – | 6 | – | – |

| Ni ( % ) | – | – | – | – | – | – | – |

| AI ( % ) | 6 | – | 10 | – | – | – | – |

| Fe ( % ) | 3 | – | 3 | – | – | Rest | Rest |

| Mn ( % ) | 3 | – | – | – | – | 0.905 – 1.3 | 0.20 – 0.40 |

| Cr ( % ) | – | – | – | – | – | – | 1.30 – 1.65 |

| C ( % ) | – | – | – | – | – | 2.5 – 4 | 0.95 – 1.05 |

| Si ( % ) | – | – | – | – | – | 1.0 – 1.3 | 0.15 -0.35 |

| Pb ( % ) | – | 3 | – | – | 3 | – | – |

Technical Parameters

| Performance | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Max.load P ( N/mm² ) | 100 | 60 | 70 | 60 | 250 | ||

| Max.speed V ( m/s ) | Dry0.4 oil5 | 2 | 2 | 0.5 | 0.1 | ||

| Max.PV ( N/mm²·m/s ) | 3.8 | 0.5 | 0.6 | 0.8 | 2.5 | ||

| Density ρ( g/cmsup3 ) | 8.0 | 8.0 | 7.6 | 7.3 | 7.8 | ||

| Tensile strength ( N/mm² ) | > 600 | > 250 | > 500 | > 250 | > 1500 | ||

| Elongation ( % ) | > 10 | > 4 | > 10 | – | – | ||

| Hardness ( HB ) | > 210 | > 80 | > 80 | > 160 | HRC> 55 | ||

| Max.temp ( ℃ ) | 300 | 350 | 300 | 400 | 350 | ||

| Friction coef. ( μ ) | Oil lubrication: 0.03 | Friction(dry): 0.16 | |||||

Spherical bushings – Bearings and Components for Engineering

We primarily manufacture custom parts as per drawings and specifications provided by the customer. We provide consistent on-time delivery, excellent quality, and a fair price! We look forward to receiving valued inquiries for Bronze Bushing, and Self-lubricating bearing Components from you. Bring in wealth and treasure!

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.