SPB Oilless Bushing

SPB Oilless Bushing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

SPB Oilless Bushing

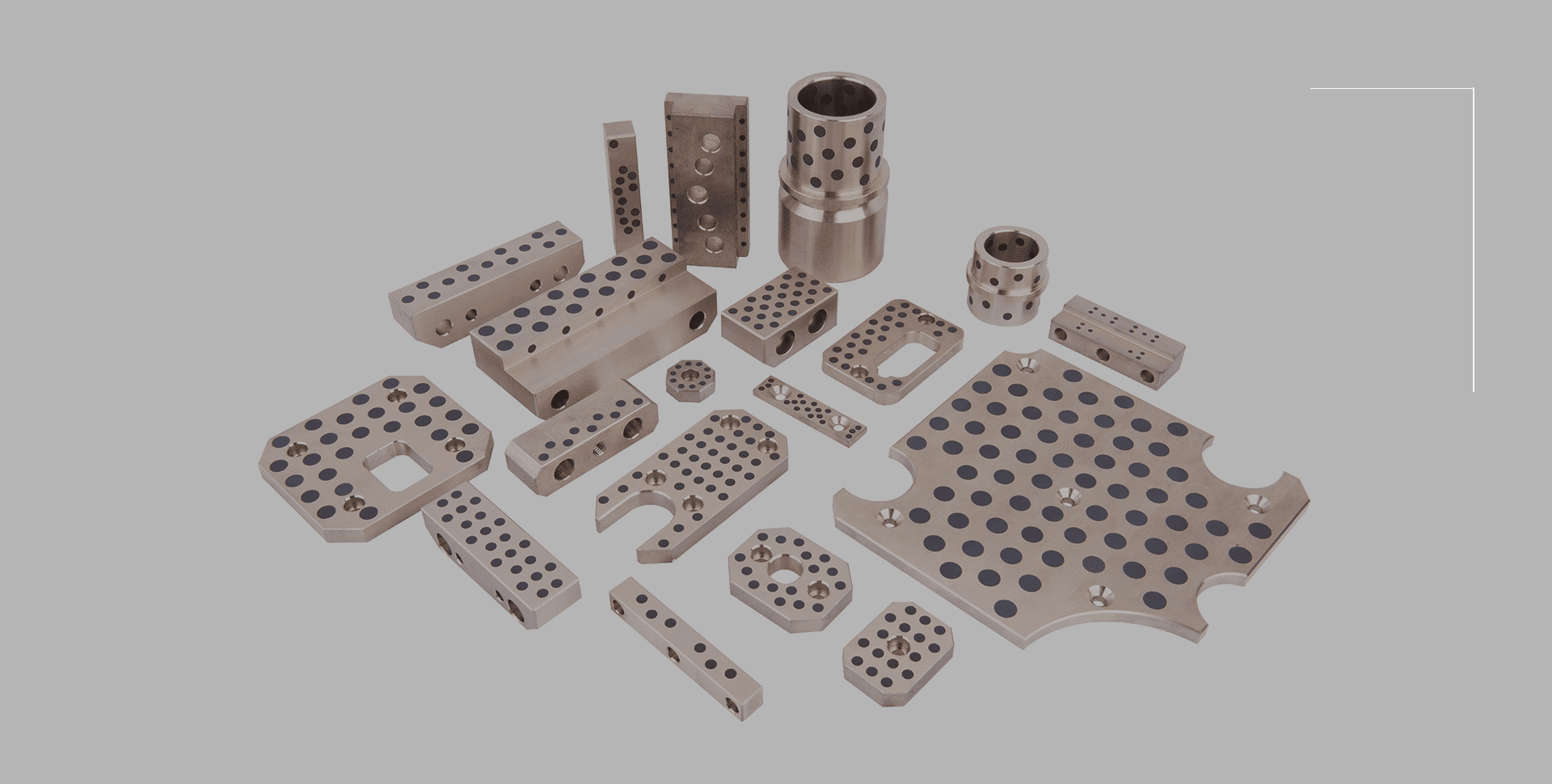

SPB Oilless Bushings serve as an essential component in various industrial and mechanical applications, offering a friction-reducing solution that enhances efficiency and reduces the need for regular maintenance.

Shop a large range of Standard dimensions Bushing (SPB) from China. We offer free CAD downloads, short lead times, competitive pricing, and no minimum order quantity.

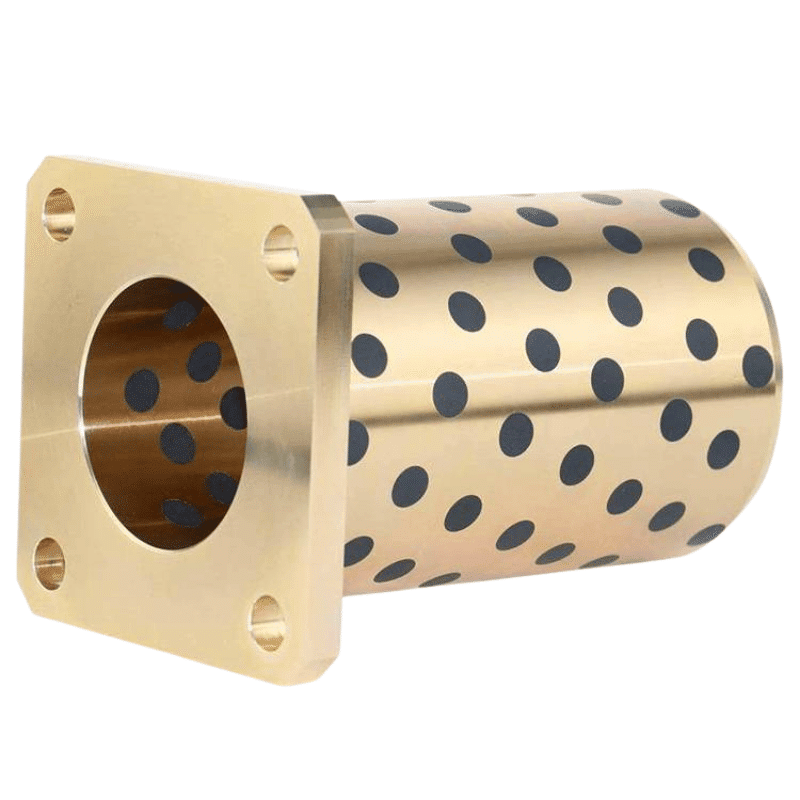

SPB material is made with high-strength copper alloy, and the inserted solid lubricant materials are made with graphite and PTFE.

According to the bushings’ working conditions, the bronze combination between the different metal basements and various solid lubricants can ensure that the product can perform under various temperatures, loads, movements and mediums as required.

Oilless bush is especially applied in oil-free high temperature, high load, low speed, contamination resistance, corruption resistance radiation resistance as well as the use under such special work conditions that cannot be lubricated, such as underwater and in vacuum space.

Key Characteristics:

1. May work without any oil for long period.

2. Extremely high load capacity, good anti-wear and low friction.

3. Particularly appropriate for low speed and high load.

4. Suitable single direction axial loads

5. Free design is possible on the shape and size

6. Can be used in wide range of temperature, from - 40℃+ 300℃

| Item No | ID | OD | Length | Material | CAD | Add to Quote |

|---|---|---|---|---|---|---|

| SPB202810* | 20 | 28 | 10 | Bronze/Graph | Download | Add |

| SPB202812* | 20 | 28 | 12 | Bronze/Graph | Download | Add |

| SPB202815 | 20 | 28 | 15 | Bronze/Graph | Download | Add |

Simplicity bushings, Base Metal, and Alloys Need A Quote? Start the process and Contact us today! Oil-free bearings supplier, SPB Straight Bushing – Metric, Bronze alloy with solid lubricant

RANGE OF APPLICATION Valve, barrage assets, ball valves, guide vane bearings, dampers, etc.

Straight type SPB Oilless Bush refers to a specialized self-lubricating bushing or bearing, widely utilized across various applications. Here’s a detailed overview:

Product Overview: SPB Oilless Bushings are engineered as self-lubricating bearings, aimed at diminishing friction and minimizing wear within mechanical assemblies. These bearings are integral in numerous sectors, including industrial machinery, automotive systems, and other equipment, ensuring smooth, low-maintenance functionality.

Construction Materials: Primarily composed of bronze alloy or comparable metallic blends, these bushings are embedded with solid lubricants. This unique composition enables them to function effectively without the need for continuous external lubrication.

Diverse Applications: Ideal for a myriad of uses, SPB Oilless Bushings are extensively employed in conveyor mechanisms, agricultural equipment, and automotive suspension systems. Their design allows them to bear substantial loads and deliver durable performance.

Low-Maintenance Design: A significant benefit of the SPB Oilless Bushings is their minimal maintenance requirement, attributed to their self-lubricating feature. This characteristic significantly cuts down on both downtime and maintenance expenses.

Shop For Graphite Impregnated Bushings At Bronzelube.Com, High-Performance Characteristics In Heavy Load And Low-Speed Operating Environments. Structure CuZn25Al6Mn4 Bronze with solid graphite lubricant inserts

(alternative specifications are available on request)

SPB Oilless Bushing Graphite Impregnated Bronze: A Reliable and Efficient Solution for Machinery

Straight Linear Plain Bushing Bearings (SPB-303840)

Metallic, Lubricant Impregnated Brass, 500 SP1 Series, Metric

Part Number: SPB-303840

· Mounting Shaft Fits: e7

· Mounting Hole Fits: H7

· Max. Allowable Surface Pressure Dimension P (n/mm2): 29

· Max. Allowable Velocity Dimension V (m/s): 0.5

· Maximum Allowable PV Value (N/mm2 ⋅ m/s): 1.65

Metallic Bearings: Advancements in the Age of Self-Lubrication

While metallic bearings have found extensive applications across industries, their need for constant lubrication often poses challenges. Overcoming these limitations, Oilless Bushes have revolutionized the bearing technology landscape. Made from high-strength brass alloy bases and embedded with solid lubricants, they offer an array of advantages that outstrip traditional metallic bearings.

Features of Oilless Bushes

Self-Lubrication: The primary advantage of Oilless Bushes is their self-lubrication capability. They perform optimally under high-load and low-speed operations without the need for regular lubrication.

High Wear Resistance: Unlike traditional metallic bearings, Oilless Bushes demonstrate superior wear resistance in environments where oil film is seldom produced – for example, during reciprocating motions, oscillation, frequent starts and stops, etc.

Superior Chemical and Corrosion Resistance: The high-strength brass alloy base, combined with solid lubricants, makes Oilless Bushes resistant to chemicals and corrosion, extending their life span and ensuring consistent performance.

Availability of Various Standard Products: Oilless Bushes come in different standard sizes and types to cater to diverse needs. This includes:

- Bushings (SPB): Ideal for applications requiring low friction and long wear life.

- Flange Bushings (SPF): These are designed with a flange at one end to provide axial location, making them suitable for heavy loads and shock-resistant applications.

- Thrust Bushings (SPFG): Perfect for applications requiring high strength and resistance to shock loads.

- Thrust Washers (SPW): These are designed to prevent movement along the axis and are used in applications with axial loads.

With their unmatched performance under demanding conditions, Oilless Bushes have carved a unique niche for themselves in the bearing technology market. They are increasingly becoming the go-to choice for industries looking for high-performance, low-maintenance, and cost-effective bearing solutions. With their myriad advantages, Oilless Bushes have truly marked a paradigm shift in the world of metallic bearings.

Oilless Bushings: The Cutting-Edge Technology in Bearing Solutions

In the realm of manufacturing and mechanical industries, the significance of bearings cannot be overstated. They are critical components that enable machinery parts to move with minimal friction. As technology advances, the quest for more efficient, durable, and maintenance-free bearings has led to the development of SPB Oilless Bushings.

SPB Oilless Bushings are unique in that they function without the need for constant lubrication. This innovative attribute not only reduces maintenance requirements but also provides various other advantages, which will be detailed below.

What are SPB Oilless Bushings?

These bushings are a type of self-lubricating bearing that comprises copper brass plugged with graphite. This combination ensures long-lasting and efficient performance. The graphite serves as a lubricating agent, enabling the smooth operation of the machinery components.

Key Features of SPB Oilless Bushings

Self-Lubricating: The graphite plugs in these bushings provide a self-lubricating feature. This means there’s no need for additional lubrication, which can significantly decrease maintenance time and cost.

High Durability and Longevity: The robust structure and composition of these bushings ensure they offer long-lasting performance. The wear-resistant nature of graphite ensures that these bushings can withstand demanding conditions.

Versatility: SPB Oilless Bushings are versatile and adaptable, designed to meet a wide range of application requirements. Their precision and strategic plug placement ensure optimal performance.

Advantages of Using SPB Oilless Bushings

Ease of Use and Maintenance: Thanks to their self-lubricating nature, SPB Oilless Bushings require less maintenance, which can result in considerable savings in time and cost.

Environmental Friendliness: With no need for continuous lubrication, these bushings contribute to reducing environmental pollution associated with lubricant waste.

Competitive Pricing: SPB Oilless Bushings offer a cost-effective solution for businesses, without compromising on quality or performance.

Applications of SPB Oilless Bushings

SPB Oilless Bushings have a wide range of applications across various industries. They are particularly beneficial in hydraulic cylinders, serving as an intermediate trunnion bushing. This ability to accommodate various application requirements makes them an indispensable component in modern equipment.

SPB Oilless Bushings represent the convergence of efficiency, durability, and environmental consciousness. They are a testament to how bearing technology continues to evolve, striving to meet the ever-changing demands of the manufacturing industry.

Oilless graphite bronze bearings, such as the 500SP1-SL1 bushings, are innovative solutions designed to reduce the need for constant lubrication while delivering exceptional performance in various applications. Manufactured using a specific bronze alloy (termed 500SP1), these bearings are embedded with solid lubricant plugs, which provides them with their oilless or self-lubricating characteristics.

Design and Composition:

The 500SP1-SL1 oilless graphite bronze bushing is primarily composed of a metallic bearing layer made of a bronze alloy. This layer is then embedded with solid lubricant plugs, typically graphite, following a precise pattern over the bearing surface. The material combination and specific design offer this bearing its unique characteristics.

SPB stands for Self-lubricating Plain Bearing, signifying the self-lubricating feature of these bushings, which is one of their primary selling points.

Benefits of 500SP1-SL1 Bushings:

- Self-Lubricating: Thanks to the graphite plugs, these bushings can operate without constant oil lubrication. The graphite acts as a solid lubricant, minimizing friction during operation.

- Lower Maintenance: The self-lubricating nature of these bushings significantly reduces the need for maintenance, making them ideal for use in hard-to-reach areas or applications where regular maintenance is challenging.

- High Load Capacity: The 500SP1 bronze alloy provides these bushings with a high load-carrying capacity, making them suitable for heavy-duty applications.

- Resistance to Wear: The combination of the bronze alloy and graphite plugs provides excellent wear resistance, prolonging the lifespan of these bushings.

- Versatility: These bushings are versatile and suitable for use in various applications, including machinery, automotive parts, hydraulic systems, and more.

While 500SP1-SL1 oilless graphite bronze bearings offer numerous benefits, they still require a certain level of care. For instance, they might not be suitable for high-speed applications. Also, while the need for lubrication is significantly reduced, occasional maintenance checks are essential to ensure the bushings continue to operate efficiently.

The 500SP1-SL1 bushings represent a significant innovation in bearing technology, marrying the benefits of high-strength bronze alloys with the self-lubricating properties of graphite. Their versatility and low-maintenance characteristics make them an appealing choice for various applications, delivering efficiency, durability, and longevity.

Machinery maintenance is a vital aspect of any industrial operation. Proper lubrication is key to ensuring that the machines run smoothly and efficiently. However, traditional lubrication methods often involve the use of oils, which can be messy, require frequent maintenance, and are not suitable for certain applications. This is where the SPB Oilless Bushing Graphite Impregnated Bronze comes in as an innovative solution.

The SPB Oilless Bushing Graphite Impregnated Bronze is a specific type of bushing used in machinery that is made of bronze material impregnated with graphite. This unique combination provides a self-lubricating solution that eliminates the need for oil, making it an ideal solution for applications where oil is not suitable, such as high-temperature environments.

The graphite impregnation allows the bushing to function effectively without any external lubrication, providing a long-lasting and reliable solution. The graphite acts as a solid lubricant that can withstand high loads and temperatures, reducing friction and wear on the bushing and other components.

The bronze material used in the SPB Oilless Bushing Graphite Impregnated Bronze is a high-strength and wear-resistant material that can handle heavy loads and provide a long service life. Additionally, the material has excellent corrosion resistance, making it suitable for use in harsh environments.

The SPB Oilless Bushing Graphite Impregnated Bronze has several advantages over traditional lubrication methods. First and foremost, it eliminates the need for messy and time-consuming oil lubrication. It also reduces maintenance requirements, as it does not require frequent re-lubrication or replacement. This results in lower maintenance costs and less downtime for machinery.

Furthermore, the SPB Oilless Bushing Graphite Impregnated Bronze is an environmentally friendly solution. The elimination of oil lubrication reduces the risk of oil leaks, spills, and contamination, which can harm the environment.

In conclusion, the SPB Oilless Bushing Graphite Impregnated Bronze is a reliable, efficient, and environmentally friendly solution for machinery lubrication. Its unique combination of bronze and graphite materials provides a self-lubricating solution that eliminates the need for messy oil lubrication, reduces maintenance requirements, and provides long-lasting and reliable service. It is a must-have for any industrial operation looking to improve efficiency and reduce maintenance costs.

Our oil-free bearing bushing series is the perfect solution for projects where lubrication is not readily available or where conventional lubricants may carbonize. Oil supply systems are designed to be both time-consuming and costly – using our oil-free bearings can significantly reduce maintenance and oil costs because it eliminates any need for such systems.

oil-free bearing bushing Oil-free bearings are developed for high load, low-speed applications and are made of rotationally cast high strength bronze, using specially formed graphite plugs as a lubricant.

Our oil-free bearings contain graphite and can withstand temperatures up to 400°C (800F) and low temperatures down to -200°C (-400°F), depending on the material selected.

Typical applications include, but are not limited to.

Kilns

Dryers

Injection molding machines

Dust collectors

Blinds

Heat Conveyors

oil-free bearing bushing Oil-free bearings have excellent chemical and corrosion resistance. The lubricant used in these bearings is formed from anti-wear materials (e.g. graphite, PTFE, etc.) and has a stable molecular structure.

These oil-free bearings are suitable for dry environments where there is a risk of contamination, wet applications with high humidity and applications where the bearing is in an inaccessible position. oil-free bearing bushing oil-free bearings are lubricated!

Please feel free to contact our technical team to determine which combination is best for your application.

SPB Oilless Bushing Graphite plugged bronze bearings- Standard dimensions, High-Quality Price, High-strength brass bearings with embedded solid lubricant, Find the perfect graphite plugged bronze bearings for your requirement at bronzelube.com, Browse through the First choice in bronze for sliding bush that matches yours.

- Self Lubricated Leaded Tin Bronze Bearings

- Self Lubricated Manganese Bronze Bushings

- Self Lubricated Aluminum Bronze Sleeve

- Self Lubricated Graphite Bushes

- Other Base Materials Parts

High-Quality SlidingBearingTechnology & lubricating bushings!

Manufacturers supply self-lubricating bearings quality assurance affordable

We have the latest measurement and quality assurance systems.

Oil-Free Bushings SPB Type

SPB Oilless Bushing Introduction:

Self-lubricating bearings are divided into composite self-lubricating bearings, solid inlaid self-lubricating bearing bearings, bimetallic material self-lubricating bearings, and special material self-lubricating bearings. According to different uses and working conditions, different self-lubricating bearings are selected.

One of the major categories of solid inlaid self-lubricating bearings (JDB for short) is a novel lubricating bearing with both the characteristics of metal bearings and oil-free bearings. The metal matrix bears the load, and the solid lubricating material with special formula plays the role of lubrication.

It has the characteristics of high bearing capacity, impact resistance, high-temperature resistance, and strong self-lubrication ability, especially suitable for heavy load, low speed, reciprocating or swing, and other difficult lubrication and oil film formation occasions, also not afraid of water and other acid erosion and scouring. Products have been widely used in metallurgical caster, steel rolling equipment, mining machinery, mold, lifting machinery, textile machinery, wind power generation, ships, steam turbines, water turbines, injection molding machines, and equipment production lines. Wear resistance is one time of ordinary sleeve.

| PV (N/mm² x m/s) | 3.3 max |

|---|---|

| Static load (N/mm²) | 100 max |

| Sliding speed (m/s) | 0.3 max |

| Operating temperature (°C) | Up to 300 (alternative specs up to 400) |

| Coefficient of thermal expansion | 19 x 10-5/°C |

| Coefficient of friction | 0.16 |

| Hardness (HB) | 210 min |

| Tensile strength (N/mm²) | 750 min |

| Elongation (%) | 12 min |

| Density (g/cm³) | 8 |

Oilless Bushing Product advantages:

The advantages of self-lubricating bearings (oil-free bearings), most of the bearings used in various machinery industries are ball bearings, needle rolls and so on, but a small part of the use of self-lubricating bearings, I believe that in the near future will come from lubricating bearings will become the dominant bearings.

The following are the application characteristics and advantages of partially self-lubricating bearings:

Oil-free lubricated bearing series:

1, no oil lubrication or less oil lubrication, suitable for refueling or difficult to refueling places, can be used without maintenance or less maintenance. Self-lubricating bearing

2, good wear resistance, small friction coefficient, long service life.

3. With the right amount of elastoplastic, the stress can be distributed on a wider contact surface and the bearing capacity can be improved.

4, static and dynamic friction coefficient is similar, can eliminate crawling at low speed, so as to ensure the working accuracy of machinery.

5, can make the machine reduce vibration, reduce noise, prevent pollution, improve working conditions.

6, in the process of operation can form a transfer film, play a protective role on the grinding shaft, no shaft biting phenomenon.

7, for grinding shaft hardness requirements are low, without quenching and tempering treatment of the shaft can be used, so as to reduce the processing difficulty of the relevant parts.

8, thin wall structure, light weight, can reduce the mechanical volume.

9, the back of steel can be electroplated with a variety of metals, can be used in corrosive media; It has been widely used in sliding parts of various machinery, such as printing press, textile machine, tobacco machinery, micromotor, automobile, motorcycle and agricultural and forestry machinery, etc.

Boundary lubricated bearing series:

1. Good bearing capacity, good wear resistance.

2. It is suitable for rotating motion and swinging motion under high load and low speed, and for occasions where opening and closing frequently under load is not easy to form hydrodynamic lubrication.

3. In the condition of boundary lubrication, it can be long-term without refueling and maintenance, while refueling in the layer makes the bearing longer service life.

4. The plastic layer on the surface can leave a certain allowance when processing and forming, and can be processed by itself after assembling and pressing into the seat hole, so as to achieve better assembly size.

5. The products are mainly used in automobile chassis, metallurgical machinery, mining machinery, water conservancy machinery, construction machinery, agricultural machinery, steel rolling equipment, etc.

JDB solid inlaid bearing series:

General basic products, whether high pressure, low pressure, high temperature, low temperature, oil lubrication, oil free lubrication or water lubrication, can be adapted. The base of the product is high force brass, which is twice as hard as the general copper sleeve and more than twice as wear-resistant.

Widely used in: light industry machinery, heavy industry machinery, construction machinery, metallurgical machinery, conveying machinery, such as: continuous casting machine, rolling mill, injection molding machine, paper machine, mold guide post, ships, machine tools and so on.

Oilless Bushings Metric Size

Oilless Bushing Features

Conventional models are available in stock.

It can be used without oil.

Excellent friction performance under high load and low speed.

Suitable for reciprocating, shaking, and frequent start and stop situations where oil film is difficult to form, with excellent wear resistance.

Good drug resistance and corrosion resistance.

BUCHA BRONZE GRAFITADO

Process and Principle:

Special production process:

Due to the requirements of special production technology, some key equipment of industrial and mining enterprises run under extremely bad conditions. Due to the heavy equipment, high temperature, dust or air containing acid corrosion in gas CO, SO2, etc., bring many problems of equipment lubrication, friction and wear is serious, so far, most of the domestic enterprises is still using the traditional oil, grease, and the fact that the industrial and mining condition is beyond the scope of oil, grease, It is easy to bite or kill bearings and other friction pairs, causing serious wear and damage of parts, and often recognized to equipment outage.

In order to produce continuous operation, in addition to the original design required the installation of multiple equipment wheel repair, also need to invest a large number of maintenance personnel. Seriously restrict the improvement of productivity, spare parts and energy consumption, has become an important obstacle to the development of production. Automobile manufacturing, cement production, petrochemical and other enterprises have put forward the requirements of special lubricating materials under complex working conditions.

Therefore, the research on inlaid self-lubricating composite material highlights its own characteristics in material formulation and preparation process, and the material performance has reached the international advanced level, which solves the lubrication problem under special working conditions for enterprises, and brings obvious economic and social benefits. But for a variety of reasons more domestic enterprises have not adopted, the situation still exists.

Key technical principles:

The composite material used for inlaid self-lubricating bearing is a new type of extreme pressure resistant solid lubricating material, which is composed of metal substrate and solid lubricant paste embedded in the hole or groove of the substrate. In the friction process, the metal substrate bears most of the load. After the friction, the solid lubricant in the hole or groove transfers to the friction surface or reverse transfer, forming a solid transfer film with good lubrication, firm adhesion and uniform coverage on the friction surface, greatly reducing the friction and wear. As the friction goes on, the solid lubricant embedded in the friction surface is constantly provided to ensure the good lubrication of the friction pair during long-term operation

Solid Bronze Bushings SPB Bushing Self Lubricating Bearings

|

bucha grafitada

|

Tags: bucha grafitada, bucha de bronze grafitada, bucha grafitada de bronze

Key Characteristics:

1. May work without any oil for long period.

2. Extremely high load capacity, good anti-wear, and low friction.

3. Particularly appropriate for low speed and high load.

4. Suitable single direction axial loads

5. Free design is possible on the shape and size

6. Can be used in a wide range of temperatures, from - 40℃+ 300℃

Oil-free Bushing & Bronze Bearing Design

The geometry, as well as the choice of material, is based on the specific application of the bearing. This means that each bearing is specially made to meet all load, environmental, and temperature requirements where it is to be used.

Base material produces a wide range of copper-based alloys, which are used as base material on oil-free bushing bearings. Data relating to four of those alloys are given in the table below. The capacity or carrying load is very much dependent on the choice of alloy, The selection of the base material will thus be based on the requirement of load-carrying capacity. Note that the temperature has an influence on the allowable load values and also the choice of lubricant.

- CuSn5Pb5Zn5 Gun Metal oil-free bronze bushing

- CuSn12 Tin Bronze oil-free bronze bushing

- CuSn10Pb10 Lead-Tin Bronze bushing

Oilless Bushings SPB Alloy materials

| Model | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Grade China Brands GB1776-87 |

ZCuZn25 AI6Fe3Mn3 |

ZCuSn6Zn6Pb3 | ZCuAI10Fe3 | ZCuSu10P1 | Steel+ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| International ISO1338 |

GCuZn25 AI6Fe3Mn3 |

GCuSn6Zn6Pb3 | GCuAI10Fe3 | CuSn12 | Steel+CuSn6Zn6Pb3Fe3Ni5 | – | B1 |

| Germany DIN |

G-CuZn25 AI5 |

GB-CuSn5Zn5Pb5 | GB-CuAI10Ni | GB-CuSn10 | Steel+CuSn6Zn6Pb3Ni | – | 100Cr6 |

| Japanese JIS |

HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| United States ASTM/UNS |

C86300 | C83600 | C95500 | C90800 | C83600 | Class40 | 52100 |

| British Standard | HTB2 | LG2 | AB1 | PB4 | LG2 | – | – |

Material alloy chemical composition

| Chemical Elements | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Cu ( % ) | Rest | Rest | Rest | – | – | ||

| Sn ( % ) | – | 6 | – | 10 | 6 | – | – |

| Zn ( % ) | 25 | 6 | – | – | 6 | – | – |

| Ni ( % ) | – | – | – | – | – | – | – |

| AI ( % ) | 6 | – | 10 | – | – | – | – |

| Fe ( % ) | 3 | – | 3 | – | – | Rest | Rest |

| Mn ( % ) | 3 | – | – | – | – | 0.905 – 1.3 | 0.20 – 0.40 |

| Cr ( % ) | – | – | – | – | – | – | 1.30 – 1.65 |

| C ( % ) | – | – | – | – | – | 2.5 – 4 | 0.95 – 1.05 |

| Si ( % ) | – | – | – | – | – | 1.0 – 1.3 | 0.15 -0.35 |

| Pb ( % ) | – | 3 | – | – | 3 | – | – |

Technical Parameters

| Performance | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-5 | ||

|---|---|---|---|---|---|---|---|

| Max.load P ( N/mm² ) | 100 | 60 | 70 | 60 | 250 | ||

| Max.speed V ( m/s ) | Dry0.4 oil5 | 2 | 2 | 0.5 | 0.1 | ||

| Max.PV ( N/mm²·m/s ) | 3.8 | 0.5 | 0.6 | 0.8 | 2.5 | ||

| Density ρ( g/cmsup3 ) | 8.0 | 8.0 | 7.6 | 7.3 | 7.8 | ||

| Tensile strength ( N/mm² ) | > 600 | > 250 | > 500 | > 250 | > 1500 | ||

| Elongation ( % ) | > 10 | > 4 | > 10 | – | – | ||

| Hardness ( HB ) | > 210 | > 80 | > 80 | > 160 | HRC> 55 | ||

| Max.temp ( ℃ ) | 300 | 350 | 300 | 400 | 350 | ||

| Friction coef. ( μ ) | Oil lubrication: 0.03 | Friction(dry): 0.16 | |||||

OIL-FREE BEARING SIZE

Oilless Lubricating Bushings: The Self-Lubricating Effect – bronzelube.com

Serviceable without the need for lubrication. Demonstrates high performance under high-load and low-speed operations. Demonstrates superior wear resistance in applications where oil film is seldom produced such as reciprocating motions, oscillation, frequent starts, and stops, etc. Superior chemical resistance and corrosion resistance. Standard products are available in various sizes. Applicable to rotation, oscillation, and reciprocating motion. Not for use underwater.

Contact Us

For inquiries or to request an oilless bearing size and catalog, click here!

Manufacturer of castings OILES 500 bushing and machined components made of bronze. Manufacturing units are located in China;

Installation selflubricating bearings require minimum or no maintenance provided they are correctly dimensioned and installed. Their high strength will then give a long bearing life. The following points are important when installing the bearing:

oil-free bushing is specially packed for transporation. Please do not remove the protective cover until installation.

The sliding surface of the bearing is treated with a solid lubricant coating.

This is applied to improve the running-in process.

Please make sure that this film is not damaged at the installation.

Make sure the mating material is cleaned carefully. This is very important for the life of the oil-free bearing.

The bronze lubricating bushings release tiny amounts of solid lubricant during movement.

| id | od | L tolerance(-0.3~-0.1) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| φd | tolerance | φD | tolerance | 8 | 10 | 12 | 15 | 16 | 19 | 20 | 25 |

| 6 | +0.022 +0.010 |

10 | +0.015 +0.006 |

061008 | 061010 | 061012 | – | – | – | – | – |

| 8 | +0.028 +0.013 |

12 | +0.018 +0.007 |

081208 | 081210 | 081212 | 081215 | – | – | – | – |

| 10 | +0.028 +0.013 |

14 | +0.018 +0.007 |

101408 | 101410 | 101412 | 101415 | – | – | 101420 | – |

| 12 | +0.034 +0.016 |

18 | +0.018 +0.007 |

121808 | 121810 | 121812 | 121815 | 121816 | 121819 | 121820 | 121825 |

| 13 | +0.034 +0.016 |

19 | +0.021 +0.008 |

– | 131910 | 131912 | 131915 | – | – | 131920 | 131925 |

| 14 | +0.034 +0.016 |

20 | +0.021 +0.008 |

– | 142010 | 142012 | 142015 | – | – | 142020 | 142025 |

| 15 | +0.034 +0.016 |

21 | +0.021 +0.008 |

– | 152110 | 152112 | 152115 | 152116 | – | 152120 | 152125 |

| 16 | +0.034 +0.016 |

22 | +0.021 +0.008 |

– | 162210 | 162212 | 162215 | 162216 | 162219 | 162220 | 162225 |

| 17 | +0.034 +0.016 |

23 | +0.021 +0.008 |

– | – | – | 172315 | – | – | – | – |

| 18 | +0.034 +0.016 |

24 | +0.021 +0.008 |

– | 182410 | 182412 | 182415 | 182416 | – | 182420 | 182425 |

| 19 | +0.041 +0.020 |

26 | +0.021 +0.008 |

– | – | – | 192615 | – | – | 192620 | – |

| 20 | +0.041 +0.020 |

28 | +0.021 +0.008 |

– | 202810 | 202812 | 202815 | 202816 | 202819 | 202820 | 202825 |

| 20 | +0.041 +0.020 |

30 | +0.021 +0.008 |

– | 203010 | 203012 | 203015 | 203016 | – | 203020 | 203025 |

| 22 | +0.041 +0.020 |

32 | +0.025 +0.009 |

– | – | 223212 | 223215 | – | – | 223220 | 223225 |

| 25 | +0.041 +0.020 |

33 | +0.025 +0.009 |

– | – | 253312 | 253315 | 253316 | – | 253320 | 253325 |

| 25 | +0.041 +0.020 |

35 | +0.025 +0.009 |

– | – | 253512 | 253515 | 253516 | – | 253520 | 253525 |

| 28 | +0.041 +0.020 |

38 | +0.025 +0.009 |

– | – | – | – | – | – | 283820 | 283825 |

| 30 | +0.041 +0.020 |

38 | +0.025 +0.009 |

– | – | 303812 | 303815 | – | – | 303820 | 303825 |

| 30 | +0.041 +0.020 |

40 | +0.025 +0.009 |

– | – | 304012 | 304015 | – | – | 304020 | 304025 |

| 31.5 | +0.050 +0.025 |

40 | +0.025 +0.009 |

– | – | – | – | – | – | – | – |

| 32 | +0.050 +0.025 |

42 | +0.025 +0.009 |

– | – | – | – | – | – | 324220 | – |

| 35 | +0.050 +0.025 |

44 | +0.025 +0.009 |

– | – | – | – | – | – | 354420 | 354425 |

| 35 | +0.050 +0.025 |

45 | +0.025 +0.009 |

– | – | – | – | – | – | 354520 | 354525 |

| 38 | +0.050 +0.025 |

48 | +0.025 +0.009 |

– | – | – | – | – | – | – | – |

| 40 | +0.050 +0.025 |

50 | +0.025 +0.009 |

– | – | – | 405015 | – | – | 405020 | 405025 |

| 40 | +0.050 +0.025 |

55 | +0.030 +0.011 |

– | – | – | 405515 | – | – | – | – |

| 45 | +0.050 +0.025 |

55 | +0.030 +0.011 |

– | – | – | – | – | – | – | – |

| 45 | +0.050 +0.025 |

56 | +0.030 +0.011 |

– | – | – | – | – | – | – | – |

| 45 | +0.050 +0.025 |

60 | +0.030 +0.011 |

– | – | – | – | – | – | – | – |

| ID | OD | L tolerance(-0.3~-0.1) |

Internal diameter tolerance after holdout (Reference Value) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| φd | tolerance | φD | tolerance | 30 | 35 | 40 | 50 | 60 | 70 | 80 | SPW | |

| 6 | +0.022 +0.010 |

10 | +0.015 +0.006 |

– | – | – | – | – | – | – | +0.019 +0.007 |

0603 |

| 8 | +0.028 +0.013 |

12 | +0.018 +0.007 |

– | – | – | – | – | – | – | +0.025 +0.010 |

0803 |

| 10 | +0.028 +0.013 |

14 | +0.018 +0.007 |

– | – | – | – | – | – | – | +0.025 +0.010 |

1003 |

| 12 | +0.034 +0.016 |

18 | +0.018 +0.007 |

121830 | – | – | – | – | – | – | +0.031 +0.013 |

1203 |

| 13 | +0.034 +0.016 |

19 | +0.021 +0.008 |

131930 | – | – | – | – | – | – | +0.030 +0.012 |

1303 |

| 14 | +0.034 +0.016 |

20 | +0.021 +0.008 |

142030 | – | – | – | – | – | – | +0.030 +0.012 |

1403 |

| 15 | +0.034 +0.016 |

21 | +0.021 +0.008 |

152130 | 152135 | 152140 | – | – | – | – | +0.030 +0.012 |

1503 |

| 16 | +0.034 +0.016 |

22 | +0.021 +0.008 |

162230 | 162235 | 162240 | – | – | – | – | +0.030 +0.012 |

1603 |

| 17 | +0.034 +0.016 |

23 | +0.021 +0.008 |

– | – | – | – | – | – | – | +0.030 +0.012 |

1803★ |

| 18 | +0.034 +0.016 |

24 | +0.021 +0.008 |

182430 | 182435 | 182440 | – | – | – | – | +0.030 +0.012 |

1803 |

| 19 | +0.041 +0.020 |

26 | +0.021 +0.008 |

– | – | – | – | – | – | – | +0.037 +0.016 |

2005★ |

| 20 | +0.041 +0.020 |

28 | +0.021 +0.008 |

202830 | 202835 | 202840 | 202850 | – | – | – | +0.037 +0.016 |

2005 |

| 20 | +0.041 +0.020 |

30 | +0.021 +0.008 |

203030 | 203035 | 203040 | 203050 | – | – | – | +0.037 +0.016 |

2505★ |

| 22 | +0.041 +0.020 |

32 | +0.025 +0.009 |

– | – | – | – | – | – | – | +0.037 +0.016 |

2505 |

| 25 | +0.041 +0.020 |

33 | +0.025 +0.009 |

253330 | 253335 | 253340 | 253350 | 253360 | – | – | +0.037 +0.016 |

2505 |

| 25 | +0.041 +0.020 |

35 | +0.025 +0.009 |

253530 | 253535 | 253540 | 253550 | 253560 | – | – | +0.037 +0.016 |

3005★ |

| 28 | +0.041 +0.020 |

38 | +0.025 +0.009 |

283830 | – | 283840 | – | – | – | – | +0.037 +0.016 |

3005 |

| 30 | +0.041 +0.020 |

38 | +0.025 +0.009 |

303830 | 303835 | 303840 | 303850 | 303860 | – | – | +0.037 +0.016 |

3005 |

| 30 | +0.041 +0.020 |

40 | +0.025 +0.009 |

304030 | 304035 | 304040 | 304050 | 304060 | – | – | +0.037 +0.016 |

3505★ |

| 31.5 | +0.050 +0.025 |

40 | +0.025 +0.009 |

314030 | – | 314040 | – | – | – | – | +0.046 +0.021 |

3505 |

| 32 | +0.050 +0.025 |

42 | +0.025 +0.009 |

324230 | – | 324240 | – | – | – | – | +0.046 +0.021 |

3505 |

| 35 | +0.050 +0.025 |

44 | +0.025 +0.009 |

354430 | 354435 | 354440 | 354450 | 354460 | – | – | +0.046 +0.021 |

3505 |

| 35 | +0.050 +0.025 |

45 | +0.025 +0.009 |

354530 | 354535 | 354540 | 354550 | 354560 | – | – | +0.046 +0.021 |

4007★ |

| 38 | +0.050 +0.025 |

48 | +0.025 +0.009 |

– | – | 384840 | – | – | – | – | +0.046 +0.021 |

4007 |

| 40 | +0.050 +0.025 |

50 | +0.025 +0.009 |

405030 | 405035 | 405040 | 405050 | 405060 | 405070 | 405080 | +0.046 +0.021 |

4007 |

| 40 | +0.050 +0.025 |

55 | +0.030 +0.011 |

405530 | 405535 | 405540 | 405550 | 405560 | – | – | +0.045 +0.020 |

4507★ |

| 45 | +0.050 +0.025 |

55 | +0.030 +0.011 |

455530 | 455535 | 455540 | 455550 | 455560 | – | – | +0.045 +0.020 |

4507 |

| 45 | +0.050 +0.025 |

56 | +0.030 +0.011 |

455630 | 455635 | 455640 | 455650 | 455660 | – | – | +0.045 +0.020 |

4507 |

| 45 | +0.050 +0.025 |

60 | +0.030 +0.011 |

456030 | 456035 | 456040 | 456050 | 456060 | 456070 | 456080 | +0.045 +0.020 |

4507 |

- ※ 圧入後内径公差は参考値です。

内径φ50~200(内径50~200mm)

| 内径 | 外径 | 長さL 公差(-0.3~-0.1) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| φd | 公差 | φD | 公差 | 20 | 30 | 35 | 40 | 50 | 60 | 70 | 80 |

| 50 | +0.050 +0.025 |

60 | +0.030 +0.011 |

506020 | 506030 | 506035 | 506040 | 506050 | 506060 | 506070 | 506080 |

| 50 | +0.050 +0.025 |

62 | +0.030 +0.011 |

– | 506230 | 506235 | 506240 | 506250 | 506260 | 506270 | 506280 |

| 50 | +0.050 +0.025 |

65 | +0.030 +0.011 |

– | 506530 | – | 506540 | 506550 | 506560 | 506570 | 506580 |

| 55 | +0.060 +0.030 |

70 | +0.030 +0.011 |

– | 557030 | 557035 | 557040 | 557050 | 557060 | 557070 | – |

| 60 | +0.060 +0.030 |

74 | +0.030 +0.011 |

– | 607430 | 607435 | 607440 | 607450 | 607460 | 607470 | 607480 |

| 60 | +0.060 +0.030 |

75 | +0.030 +0.011 |

– | 607530 | 607535 | 607540 | 607550 | 607560 | 607570 | 607580 |

| 63 | +0.060 +0.030 |

75 | +0.030 +0.011 |

– | – | – | – | – | 637560 | 637570 | 637580 |

| 65 | +0.060 +0.030 |

80 | +0.030 +0.011 |

– | – | – | 658040 | 658050 | 658060 | 658070 | 658080 |

| 70 | +0.060 +0.030 |

85 | +0.035 +0.013 |

– | 708530 | 708535 | 708540 | 708550 | 708560 | 708570 | 708580 |

| 70 | +0.060 +0.030 |

90 | +0.035 +0.013 |

– | – | – | – | 709050 | 709060 | 709070 | 709080 |

| 75 | +0.060 +0.030 |

90 | +0.035 +0.013 |

– | – | – | – | 759050 | 759060 | 759070 | 759080 |

| 75 | +0.060 +0.030 |

95 | +0.035 +0.013 |

– | – | – | – | – | 759560 | 759570 | 759580 |

| 80 | +0.060 +0.030 |

96 | +0.035 +0.013 |

– | – | – | 809640 | 809650 | 809660 | 809670 | 809680 |

| 80 | +0.060 +0.030 |

100 | +0.035 +0.013 |

– | – | – | 8010040 | 8010050 | 8010060 | 8010070 | 8010080 |

| 85 | +0.071 +0.036 |

100 | +0.035 +0.013 |

– | – | – | – | – | 8510060 | – | 8510080 |

| 90 | +0.071 +0.036 |

110 | +0.035 +0.013 |

– | – | – | – | 9011050 | 9011060 | – | 9011080 |

| 100 | +0.071 +0.036 |

120 | +0.035 +0.013 |

– | – | – | – | 10012050 | 10012060 | 10012070 | 10012080 |

| 110 | +0.071 +0.036 |

130 | +0.040 +0.015 |

– | – | – | – | 11013050 | – | 11013070 | 11013080 |

| 120 | +0.071 +0.036 |

140 | +0.040 +0.015 |

– | – | – | – | – | – | 12014070 | 12014080 |

| 125 | +0.083 +0.043 |

145 | +0.040 +0.015 |

– | – | – | – | – | – | – | – |

| 130 | +0.083 +0.043 |

150 | +0.040 +0.015 |

– | – | – | – | – | – | – | 13015080 |

| 140 | +0.083 +0.043 |

160 | +0.040 +0.015 |

– | – | – | – | – | – | – | – |

| 150 | +0.083 +0.043 |

170 | +0.040 +0.015 |

– | – | – | – | – | – | – | 15017080 |

| 160 | +0.083 +0.043 |

180 | +0.040 +0.015 |

– | – | – | – | – | – | – | 16018080 |

| 170 | +0.083 +0.043 |

190 | +0.046 +0.017 |

– | – | – | – | – | – | – | – |

| 180 | +0.083 +0.043 |

200 | +0.046 +0.017 |

– | – | – | – | – | – | – | – |

| 190 | +0.096 +0.050 |

210 | +0.046 +0.017 |

– | – | – | – | – | – | – | – |

| 200 | +0.096 +0.050 |

230 | +0.046 +0.017 |

– | – | – | – | – | – | – | – |

| ID | OD | L tolerance(-0.3~-0.1) |

Internal diameter tolerance after holdout (Reference Value) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| φd | tolerance | φD | tolerance | 90 | 100 | 120 | 130 | 140 | 150 | 200 | SPW | |

| 50 | +0.050 +0.025 |

60 | +0.030 +0.011 |

– | – | – | – | – | – | – | +0.045 +0.020 |

5008 |

| 50 | +0.050 +0.025 |

62 | +0.030 +0.011 |

– | – | – | – | – | – | – | +0.045 +0.020 |

5008 |

| 50 | +0.050 +0.025 |

65 | +0.030 +0.011 |

– | 5065100 | – | – | – | – | – | +0.045 +0.020 |

5008 |

| 55 | +0.060 +0.030 |

70 | +0.030 +0.011 |

– | – | – | – | – | – | – | +0.055 +0.025 |

5508 |

| 60 | +0.060 +0.030 |

74 | +0.030 +0.011 |

– | – | – | – | – | – | – | +0.055 +0.025 |

6008 |

| 60 | +0.060 +0.030 |

75 | +0.030 +0.011 |

– | 6075100 | – | – | – | – | – | +0.055 +0.025 |

6008 |

| 63 | +0.060 +0.030 |

75 | +0.030 +0.011 |

– | – | – | – | – | – | – | +0.055 +0.025 |

6508★ |

| 65 | +0.060 +0.030 |

80 | +0.030 +0.011 |

– | – | – | – | – | – | – | +0.055 +0.025 |

6508 |

| 70 | +0.060 +0.030 |

85 | +0.035 +0.013 |

– | 7085100 | – | – | – | – | – | +0.055 +0.025 |

7010 |

| 70 | +0.060 +0.030 |

90 | +0.035 +0.013 |

– | – | – | – | – | – | – | +0.055 +0.025 |

7010 |

| 75 | +0.060 +0.030 |

90 | +0.035 +0.013 |

– | 7590100 | – | – | – | – | – | +0.055 +0.025 |

7510 |

| 75 | +0.060 +0.030 |

95 | +0.035 +0.013 |

– | 7595100 | – | – | – | – | – | +0.055 +0.025 |

7510 |

| 80 | +0.060 +0.030 |

96 | +0.035 +0.013 |

– | 8096100 | 8096120 | – | – | – | – | +0.055 +0.025 |

8010 |

| 80 | +0.060 +0.030 |

100 | +0.035 +0.013 |

– | 80100100 | 80100120 | – | 80100140 | – | – | +0.055 +0.025 |

8010 |

| 85 | +0.071 +0.036 |

100 | +0.035 +0.013 |

– | – | – | – | – | – | – | +0.065 +0.030 |

9010★ |

| 90 | +0.071 +0.036 |

110 | +0.035 +0.013 |

9011090 | 90110100 | 90110120 | – | – | – | – | +0.065 +0.030 |

9010 |

| 100 | +0.071 +0.036 |

120 | +0.035 +0.013 |

10012090 | 100120100 | 100120120 | – | 100120140 | – | – | +0.065 +0.030 |

10010 |

| 110 | +0.071 +0.036 |

130 | +0.040 +0.015 |

– | 110130100 | 110130120 | – | – | – | – | +0.064 +0.029 |

12010★ |

| 120 | +0.071 +0.036 |

140 | +0.040 +0.015 |

12014090 | 120140100 | 120140120 | – | 120140140 | – | – | +0.064 +0.029 |

12010 |

| 125 | +0.083 +0.043 |

145 | +0.040 +0.015 |

– | 125145100 | 125145120 | – | – | – | – | +0.076 +0.036 |

– |

| 130 | +0.083 +0.043 |

150 | +0.040 +0.015 |

– | 130150100 | – | 130150130 | – | – | – | +0.076 +0.036 |

– |

| 140 | +0.083 +0.043 |

160 | +0.040 +0.015 |

– | 140160100 | – | – | 140160140 | – | – | +0.076 +0.036 |

– |

| 150 | +0.083 +0.043 |

170 | +0.040 +0.015 |

– | 150170100 | – | – | – | 150170150 | – | +0.076 +0.036 |

– |

| 160 | +0.083 +0.043 |

180 | +0.040 +0.015 |

– | 160180100 | – | – | – | 160180150 | – | +0.076 +0.036 |

– |

| 170 | +0.083 +0.043 |

190 | +0.046 +0.017 |

– | *170190100 | – | – | – | *170190150 | – | +0.076 +0.036 |

– |

| 180 | +0.083 +0.043 |

200 | +0.046 +0.017 |

– | *180200100 | – | – | – | *180200150 | – | +0.076 +0.036 |

– |

| 190 | +0.096 +0.050 |

210 | +0.046 +0.017 |

– | *190210100 | – | – | – | *190210150 | – | +0.088 +0.042 |

– |

| 200 | +0.096 +0.050 |

230 | +0.046 +0.017 |

– | – | – | – | – | *200230150 | *200230200 | +0.088 +0.042 |

– |

Oilless Bushings Metric Size

| SIZE | CODE | Φd | ΦD | L | CODE | Φd | ΦD | L | CODE | Φd | ΦD | L | CODE | Φd | ΦD | L |

| 1 | SPB-061008 | 6 | 10 | 8 | SPB-253515 | 25 | 35 | 15 | SPB-506540 | 50 | 65 | 40 | SPB-13015080 | 130 | 150 | 80 |

| 2 | SPB-061010 | 6 | 10 | 10 | SPB-253516 | 25 | 35 | 16 | SPB-506550 | 50 | 65 | 50 | SPB-130150100 | 130 | 150 | 100 |

| 3 | SPB-061012 | 6 | 10 | 12 | SPB-253520 | 25 | 35 | 20 | SPB-506560 | 50 | 65 | 60 | SPB-130150130 | 130 | 150 | 130 |

| 4 | SPB-081208 | 8 | 12 | 8 | SPB-253525 | 25 | 35 | 25 | SPB-506570 | 50 | 65 | 70 | SPB-140160100 | 140 | 160 | 100 |

| 5 | SPB-081210 | 8 | 12 | 10 | SPB-253530 | 25 | 35 | 30 | SPB-506580 | 50 | 65 | 80 | SPB-140160140 | 140 | 160 | 140 |

| 6 | SPB-081212 | 8 | 12 | 12 | SPB-253535 | 25 | 35 | 35 | SPB-5065100 | 50 | 65 | 100 | SPB-15017080 | 150 | 170 | 80 |

| 7 | SPB-081215 | 8 | 12 | 15 | SPB-253540 | 25 | 35 | 40 | SPB-557030 | 55 | 70 | 30 | SPB-150170100 | 150 | 170 | 100 |

| 8 | SPB-101408 | 10 | 14 | 8 | SPB-253550 | 25 | 35 | 50 | SPB-557035 | 55 | 70 | 35 | SPB-150170150 | 150 | 170 | 150 |

| 9 | SPB-101410 | 10 | 14 | 10 | SPB-253560 | 25 | 35 | 60 | SPB-557040 | 55 | 70 | 40 | SPB-16018080 | 160 | 180 | 80 |

| 10 | SPB-101412 | 10 | 14 | 12 | SPB-283820 | 28 | 38 | 20 | SPB-557050 | 55 | 70 | 50 | SPB-160180100 | 160 | 180 | 100 |

| 11 | SPB-101415 | 10 | 14 | 15 | SPB-283825 | 28 | 38 | 25 | SPB-557060 | 55 | 70 | 60 | SPB-160180150 | 160 | 180 | 150 |

| 12 | SPB-101420 | 10 | 14 | 20 | SPB-283830 | 28 | 38 | 30 | SPB-557070 | 55 | 70 | 70 | SPB-170190100 | 170 | 190 | 100 |

| 13 | SPB-121808 | 12 | 18 | 8 | SPB-283840 | 28 | 38 | 40 | SPB-607430 | 60 | 74 | 30 | SPB-170190150 | 170 | 190 | 150 |

| 14 | SPB-121810 | 12 | 18 | 10 | SPB-303812 | 30 | 38 | 12 | SPB-607435 | 60 | 74 | 35 | SPB-180200100 | 180 | 200 | 100 |

| 15 | SPB-121812 | 12 | 18 | 12 | SPB-303815 | 30 | 38 | 15 | SPB-607440 | 60 | 74 | 40 | SPB-180200150 | 180 | 200 | 150 |

| 16 | SPB-121815 | 12 | 18 | 15 | SPB-303820 | 30 | 38 | 20 | SPB-607450 | 60 | 74 | 50 | SPB-190210100 | 190 | 210 | 100 |

| 17 | SPB-121816 | 12 | 18 | 16 | SPB-303825 | 30 | 38 | 25 | SPB-607460 | 60 | 74 | 60 | SPB-190210150 | 190 | 210 | 150 |

| 18 | SPB-121819 | 12 | 18 | 19 | SPB-303830 | 30 | 38 | 30 | SPB-607470 | 60 | 74 | 70 | SPB-200230150 | 200 | 230 | 150 |

| 19 | SPB-121820 | 12 | 18 | 20 | SPB-303835 | 30 | 38 | 35 | SPB-607480 | 60 | 74 | 80 | SPB-200230200 | 200 | 230 | 200 |

| 20 | SPB-121825 | 12 | 18 | 25 | SPB-303840 | 30 | 38 | 40 | SPB-607530 | 60 | 75 | 30 | ||||

| 21 | SPB-121830 | 12 | 18 | 30 | SPB-303850 | 30 | 38 | 50 | SPB-607535 | 60 | 75 | 35 | ||||

| 22 | SPB-131910 | 13 | 19 | 10 | SPB-303860 | 30 | 38 | 60 | SPB-607540 | 60 | 75 | 40 | ||||

| 23 | SPB-131912 | 13 | 19 | 12 | SPB-304012 | 30 | 40 | 12 | SPB-607550 | 60 | 75 | 50 | ||||

| 24 | SPB-131915 | 13 | 19 | 15 | SPB-304015 | 30 | 40 | 15 | SPB-607560 | 60 | 75 | 60 | ||||

| 25 | SPB-131920 | 13 | 19 | 20 | SPB-304020 | 30 | 40 | 20 | SPB-607570 | 60 | 75 | 70 | ||||

| 26 | SPB-131925 | 13 | 19 | 25 | SPB-304025 | 30 | 40 | 25 | SPB-607580 | 60 | 75 | 80 | ||||

| 27 | SPB-131930 | 13 | 19 | 30 | SPB-304030 | 30 | 40 | 30 | SPB-6075100 | 60 | 75 | 100 | ||||

| 28 | SPB-142010 | 14 | 20 | 10 | SPB-304035 | 30 | 40 | 35 | SPB-637560 | 63 | 75 | 60 | ||||

| 29 | SPB-142012 | 14 | 20 | 12 | SPB-304040 | 30 | 40 | 40 | SPB-637570 | 63 | 75 | 70 | ||||

| 30 | SPB-142015 | 14 | 20 | 15 | SPB-304050 | 30 | 40 | 50 | SPB-637580 | 63 | 75 | 80 | ||||

| 31 | SPB-142020 | 14 | 20 | 20 | SPB-304060 | 30 | 40 | 60 | SPB-658040 | 65 | 80 | 40 | ||||

| 32 | SPB-142025 | 14 | 20 | 25 | SPB-314030 | 31.5 | 40 | 30 | SPB-658050 | 65 | 80 | 50 | ||||

| 33 | SPB-142030 | 14 | 20 | 30 | SPB-314040 | 31.5 | 40 | 40 | SPB-658060 | 65 | 80 | 60 | ||||

| 34 | SPB-152110 | 15 | 21 | 10 | SPB-324220 | 32 | 42 | 20 | SPB-658070 | 65 | 80 | 70 | ||||

| 35 | SPB-152112 | 15 | 21 | 12 | SPB-324230 | 32 | 42 | 30 | SPB-658080 | 65 | 80 | 80 | ||||

| 36 | SPB-152115 | 15 | 21 | 15 | SPB-324240 | 32 | 42 | 40 | SPB-708530 | 70 | 85 | 30 | ||||

| 37 | SPB-152116 | 15 | 21 | 16 | SPB-354420 | 35 | 44 | 20 | SPB-708535 | 70 | 85 | 35 | ||||

| 38 | SPB-152120 | 15 | 21 | 20 | SPB-354425 | 35 | 44 | 25 | SPB-708540 | 70 | 85 | 40 | ||||

| 39 | SPB-152125 | 15 | 21 | 25 | SPB-354430 | 35 | 44 | 30 | SPB-708550 | 70 | 85 | 50 | ||||

| 40 | SPB-152130 | 15 | 21 | 30 | SPB-354435 | 35 | 44 | 35 | SPB-708560 | 70 | 85 | 60 | ||||

| 41 | SPB-152135 | 15 | 21 | 35 | SPB-354440 | 35 | 44 | 40 | SPB-708570 | 70 | 85 | 70 | ||||

| 42 | SPB-152140 | 15 | 21 | 40 | SPB-354450 | 35 | 44 | 50 | SPB-708580 | 70 | 85 | 80 | ||||

| 43 | SPB-162210 | 16 | 22 | 10 | SPB-354460 | 35 | 44 | 60 | SPB-7085100 | 70 | 85 | 100 | ||||

| 44 | SPB-162212 | 16 | 22 | 12 | SPB-354520 | 35 | 45 | 20 | SPB-709050 | 70 | 90 | 50 | ||||

| 45 | SPB-162215 | 16 | 22 | 15 | SPB-354525 | 35 | 45 | 25 | SPB-709060 | 70 | 90 | 60 | ||||

| 46 | SPB-162216 | 16 | 22 | 16 | SPB-354530 | 35 | 45 | 30 | SPB-709070 | 70 | 90 | 70 | ||||

| 47 | SPB-162219 | 16 | 22 | 19 | SPB-354535 | 35 | 45 | 35 | SPB-709080 | 70 | 90 | 80 | ||||

| 48 | SPB-162220 | 16 | 22 | 20 | SPB-354540 | 35 | 45 | 40 | SPB-759050 | 75 | 90 | 50 | ||||

| 49 | SPB-162225 | 16 | 22 | 25 | SPB-354550 | 35 | 45 | 50 | SPB-759060 | 75 | 90 | 60 | ||||

| 50 | SPB-162230 | 16 | 22 | 30 | SPB-354560 | 35 | 45 | 60 | SPB-759070 | 75 | 90 | 70 | ||||

| 51 | SPB-162235 | 16 | 22 | 35 | SPB-384840 | 38 | 48 | 40 | SPB-759080 | 75 | 90 | 80 | ||||

| 52 | SPB-162240 | 16 | 22 | 40 | SPB-405015 | 40 | 50 | 15 | SPB-7590100 | 75 | 90 | 100 | ||||

| 53 | SPB-172315 | 17 | 23 | 15 | SPB-405020 | 40 | 50 | 20 | SPB-759560 | 75 | 95 | 60 | ||||

| 54 | SPB-182410 | 18 | 24 | 10 | SPB-405025 | 40 | 50 | 25 | SPB-759570 | 75 | 95 | 70 | ||||

| 55 | SPB-182412 | 18 | 24 | 12 | SPB-405030 | 40 | 50 | 30 | SPB-759580 | 75 | 95 | 80 | ||||

| 56 | SPB-182415 | 18 | 24 | 15 | SPB-405035 | 40 | 50 | 35 | SPB-7595100 | 75 | 95 | 100 | ||||

| 57 | SPB-182416 | 18 | 24 | 16 | SPB-405040 | 40 | 50 | 40 | SPB-809640 | 80 | 96 | 40 | ||||

| 58 | SPB-182420 | 18 | 24 | 20 | SPB-405050 | 40 | 50 | 50 | SPB-809650 | 80 | 96 | 50 | ||||

| 59 | SPB-182425 | 18 | 24 | 25 | SPB-405060 | 40 | 50 | 60 | SPB-809660 | 80 | 96 | 60 | ||||

| 60 | SPB-182430 | 18 | 24 | 30 | SPB-405070 | 40 | 50 | 70 | SPB-809670 | 80 | 96 | 70 | ||||

| 61 | SPB-182435 | 18 | 24 | 35 | SPB-405080 | 40 | 50 | 80 | SPB-809680 | 80 | 96 | 80 | ||||

| 62 | SPB-182440 | 18 | 24 | 40 | SPB-405515 | 40 | 55 | 15 | SPB-8096100 | 80 | 96 | 100 | ||||

| 63 | SPB-192615 | 19 | 26 | 15 | SPB-405530 | 40 | 55 | 30 | SPB-8096120 | 80 | 96 | 120 | ||||

| 64 | SPB-192620 | 19 | 26 | 20 | SPB-405535 | 40 | 55 | 35 | SPB-8010040 | 80 | 100 | 40 | ||||

| 65 | SPB-202810 | 20 | 28 | 10 | SPB-405540 | 40 | 55 | 40 | SPB-8010050 | 80 | 100 | 50 | ||||

| 66 | SPB-202812 | 20 | 28 | 12 | SPB-405550 | 40 | 55 | 50 | SPB-8010060 | 80 | 100 | 60 | ||||

| 67 | SPB-202815 | 20 | 28 | 15 | SPB-405560 | 40 | 55 | 60 | SPB-8010070 | 80 | 100 | 70 | ||||

| 68 | SPB-202816 | 20 | 28 | 16 | SPB-455530 | 45 | 55 | 30 | SPB-8010080 | 80 | 100 | 80 | ||||

| 69 | SPB-202819 | 20 | 28 | 19 | SPB-455535 | 45 | 55 | 35 | SPB-80100100 | 80 | 100 | 100 | ||||

| 70 | SPB-202820 | 20 | 28 | 20 | SPB-455540 | 45 | 55 | 40 | SPB-80100120 | 80 | 100 | 120 | ||||

| 71 | SPB-202825 | 20 | 28 | 25 | SPB-455550 | 45 | 55 | 50 | SPB-80100140 | 80 | 100 | 140 | ||||

| 72 | SPB-202830 | 20 | 28 | 30 | SPB-455560 | 45 | 55 | 60 | SPB-8510060 | 85 | 100 | 60 | ||||

| 73 | SPB-202835 | 20 | 28 | 35 | SPB-455630 | 45 | 56 | 30 | SPB-8510080 | 85 | 100 | 80 | ||||

| 74 | SPB-202840 | 20 | 28 | 40 | SPB-455635 | 45 | 56 | 35 | SPB-9011050 | 90 | 110 | 50 | ||||

| 75 | SPB-202850 | 20 | 28 | 50 | SPB-455640 | 45 | 56 | 40 | SPB-9011060 | 90 | 110 | 60 | ||||

| 76 | SPB-203010 | 20 | 30 | 10 | SPB-455650 | 45 | 56 | 50 | SPB-9011080 | 90 | 110 | 80 | ||||

| 77 | SPB-203012 | 20 | 30 | 12 | SPB-455660 | 45 | 56 | 60 | SPB-9011090 | 90 | 110 | 90 | ||||

| 78 | SPB-203015 | 20 | 30 | 15 | SPB-456030 | 45 | 60 | 30 | SPB-90110100 | 90 | 110 | 100 | ||||

| 79 | SPB-203016 | 20 | 30 | 16 | SPB-456035 | 45 | 60 | 35 | SPB-90110120 | 90 | 110 | 120 | ||||

| 80 | SPB-203020 | 20 | 30 | 20 | SPB-456040 | 45 | 60 | 40 | SPB-10012050 | 100 | 120 | 50 | ||||

| 81 | SPB-203025 | 20 | 30 | 25 | SPB-456050 | 45 | 60 | 50 | SPB-10012060 | 100 | 120 | 60 | ||||

| 82 | SPB-203030 | 20 | 30 | 30 | SPB-456060 | 45 | 60 | 60 | SPB-10012070 | 100 | 120 | 70 | ||||

| 83 | SPB-203035 | 20 | 30 | 35 | SPB-456070 | 45 | 60 | 70 | SPB-10012080 | 100 | 120 | 80 | ||||

| 84 | SPB-203040 | 20 | 30 | 40 | SPB-456080 | 45 | 60 | 80 | SPB-10012090 | 100 | 120 | 90 | ||||

| 85 | SPB-203050 | 20 | 30 | 50 | SPB-506020 | 50 | 60 | 20 | SPB-100120100 | 100 | 120 | 100 | ||||

| 86 | SPB-223212 | 22 | 32 | 12 | SPB-506030 | 50 | 60 | 30 | SPB-100120120 | 100 | 120 | 120 | ||||

| 87 | SPB-223215 | 22 | 32 | 15 | SPB-506035 | 50 | 60 | 35 | SPB-100120140 | 100 | 120 | 140 | ||||

| 88 | SPB-223220 | 22 | 32 | 20 | SPB-506040 | 50 | 60 | 40 | SPB-11013050 | 110 | 130 | 50 | ||||

| 89 | SPB-223225 | 22 | 32 | 25 | SPB-506050 | 50 | 60 | 50 | SPB-11013070 | 110 | 130 | 70 | ||||

| 90 | SPB-253312 | 25 | 33 | 12 | SPB-506060 | 50 | 60 | 60 | SPB-11013080 | 110 | 130 | 80 | ||||

| 91 | SPB-253315 | 25 | 33 | 15 | SPB-506070 | 50 | 60 | 70 | SPB-110130100 | 110 | 130 | 100 | ||||

| 92 | SPB-253316 | 25 | 33 | 16 | SPB-506080 | 50 | 60 | 80 | SPB-110130120 | 110 | 130 | 120 | ||||

| 93 | SPB-253320 | 25 | 33 | 20 | SPB-506230 | 50 | 62 | 30 | SPB-12014070 | 120 | 140 | 70 | ||||

| 94 | SPB-253325 | 25 | 33 | 25 | SPB-506235 | 50 | 62 | 35 | SPB-12014080 | 120 | 140 | 80 | ||||

| 95 | SPB-253330 | 25 | 33 | 30 | SPB-506240 | 50 | 62 | 40 | SPB-12014090 | 120 | 140 | 90 | ||||

| 96 | SPB-253335 | 25 | 33 | 35 | SPB-506250 | 50 | 62 | 50 | SPB-120140100 | 120 | 140 | 100 | ||||

| 97 | SPB-253340 | 25 | 33 | 40 | SPB-506260 | 50 | 62 | 60 | SPB-120140120 | 120 | 140 | 120 | ||||

| 98 | SPB-253350 | 25 | 33 | 50 | SPB-506270 | 50 | 62 | 70 | SPB-120140140 | 120 | 140 | 140 | ||||

| 99 | SPB-253360 | 25 | 33 | 60 | SPB-506280 | 50 | 62 | 80 | SPB-125145100 | 125 | 145 | 100 | ||||

| 100 | SPB-253512 | 25 | 35 | 12 | SPB-506530 | 50 | 65 | 30 | SPB-125145120 | 125 | 145 | 120 |

(unit:mm)

| ID | OD | L tolerance(-0.3~-0.1) | |||||||||

| φd | tolerance | φD | tolerance | 8 | 10 | 12 | 15 | 16 | 19 | 20 | 25 |

| 6 | 0.022 0.01 |

10 | 0.015 0.006 |

61008 | 61010 | 61012 | – | – | – | – | – |

| 8 | 0.028 0.013 |

12 | 0.018 0.007 |

81208 | 81210 | 81212 | 81215 | – | – | – | – |

| 10 | 0.028 0.013 |

14 | 0.018 0.007 |

101408 | 101410 | 101412 | 101415 | – | – | 101420 | – |

| 12 | 0.034 0.016 |

18 | 0.018 0.007 |

121808 | 121810 | 121812 | 121815 | 121816 | 121819 | 121820 | 121825 |

| 13 | 0.034 0.016 |

19 | 0.021 0.008 |

– | 131910 | 131912 | 131915 | – | – | 131920 | 131925 |

| 14 | 0.034 0.016 |

20 | 0.021 0.008 |

– | 142010 | 142012 | 142015 | – | – | 142020 | 142025 |

| 15 | 0.034 0.016 |

21 | 0.021 0.008 |

– | 152110 | 152112 | 152115 | 152116 | – | 152120 | 152125 |

| 16 | 0.034 0.016 |

22 | 0.021 0.008 |

– | 162210 | 162212 | 162215 | 162216 | 162219 | 162220 | 162225 |

| 17 | 0.034 0.016 |

23 | 0.021 0.008 |

– | – | – | 172315 | – | – | – | – |

| 18 | 0.034 0.016 |

24 | 0.021 0.008 |

– | 182410 | 182412 | 182415 | 182416 | – | 182420 | 182425 |

| 19 | 0.041 0.02 |

26 | 0.021 0.008 |

– | – | – | 192615 | – | – | 192620 | – |

| 20 | 0.041 0.02 |

28 | 0.021 0.008 |

– | 202810 | 202812 | 202815 | 202816 | 202819 | 202820 | 202825 |

| 20 | 0.041 0.02 |

30 | 0.021 0.008 |

– | 203010 | 203012 | 203015 | 203016 | – | 203020 | 203025 |

| 22 | 0.041 0.02 |

32 | 0.025 0.009 |

– | – | 223212 | 223215 | – | – | 223220 | 223225 |

| 25 | 0.041 0.02 |

33 | 0.025 0.009 |

– | – | 253312 | 253315 | 253316 | – | 253320 | 253325 |

| 25 | 0.041 0.02 |

35 | 0.025 0.009 |

– | – | 253512 | 253515 | 253516 | – | 253520 | 253525 |

| 28 | 0.041 0.02 |

38 | 0.025 0.009 |

– | – | – | – | – | – | 283820 | 283825 |

| 30 | 0.041 0.02 |

38 | 0.025 0.009 |

– | – | 303812 | 303815 | – | – | 303820 | 303825 |

| 30 | 0.041 0.02 |

40 | 0.025 0.009 |

– | – | 304012 | 304015 | – | – | 304020 | 304025 |

| 31.5 | 0.05 0.025 |

40 | 0.025 0.009 |

– | – | – | – | – | – | – | – |

| 32 | 0.05 0.025 |

42 | 0.025 0.009 |

– | – | – | – | – | – | 324220 | – |

| 35 | 0.05 0.025 |

44 | 0.025 0.009 |

– | – | – | – | – | – | 354420 | 354425 |

| 35 | 0.05 0.025 |

45 | 0.025 0.009 |

– | – | – | – | – | – | 354520 | 354525 |

| 38 | 0.05 0.025 |

48 | 0.025 0.009 |

– | – | – | – | – | – | – | – |

| 40 | 0.05 0.025 |

50 | 0.025 0.009 |

– | – | – | 405015 | – | – | 405020 | 405025 |

| 40 | 0.05 0.025 |

55 | 0.03 0.011 |

– | – | – | 405515 | – | – | – | – |

| 45 | 0.05 0.025 |

55 | 0.03 0.011 |

– | – | – | – | – | – | – | – |

| 45 | 0.05 0.025 |

56 | 0.03 0.011 |

– | – | – | – | – | – | – | – |

| 45 | 0.05 0.025 |

60 | 0.03 0.011 |

– | – | – | – | – | – | – | – |

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.