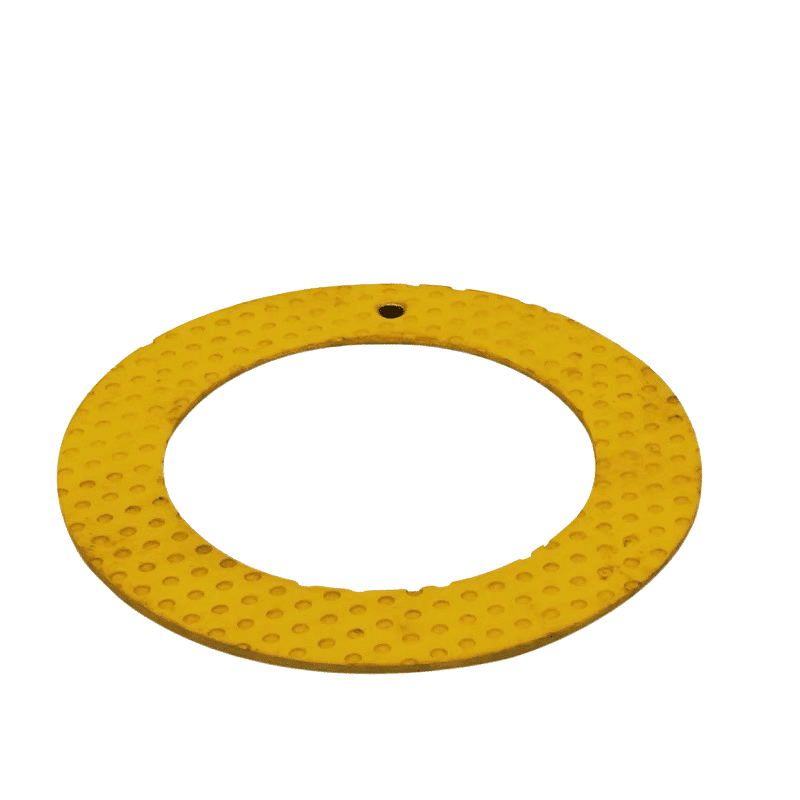

SF-2 Washer

SF-2 Washer

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

SF-2 Washer

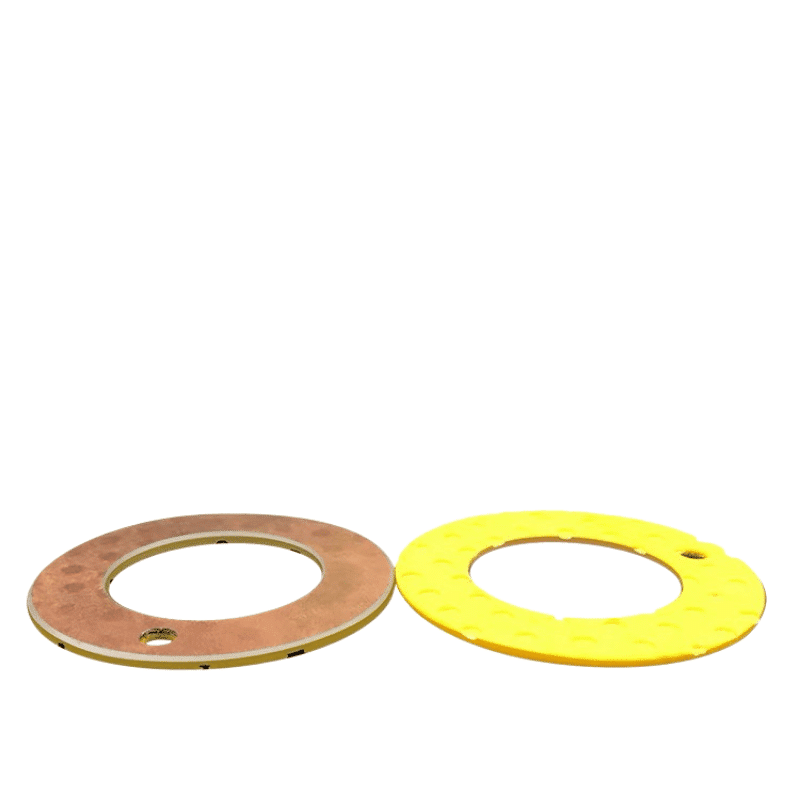

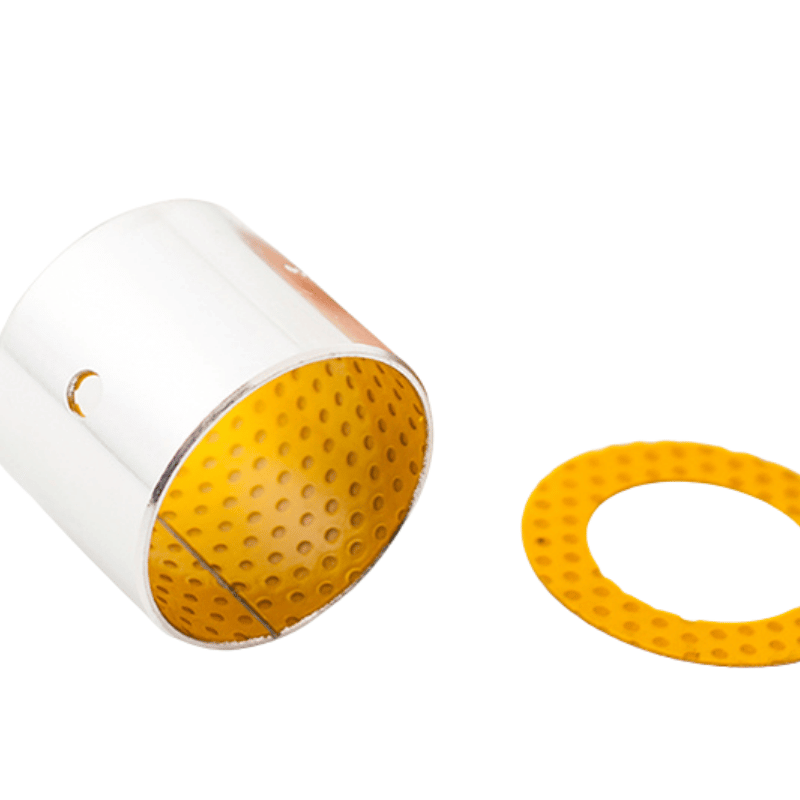

POM (polyoxymethylene) lined washers, also known as self-lubricated washers, are a type of thrust washer that provides a low-friction, wear-resistant surface and is designed to operate without the need for additional lubrication. These washers are used in various applications to accommodate axial loads and reduce friction between moving parts.

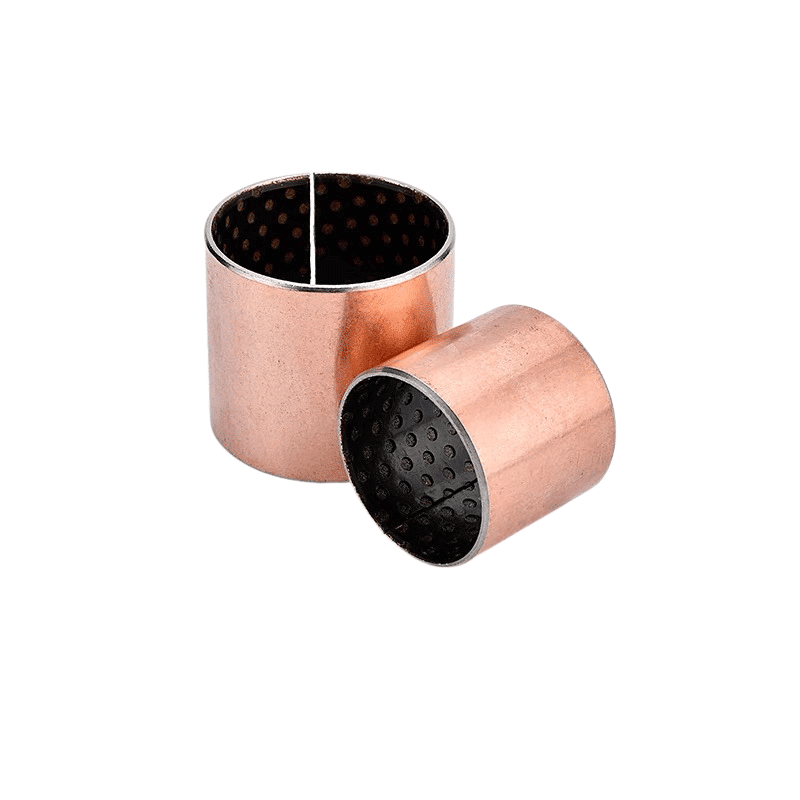

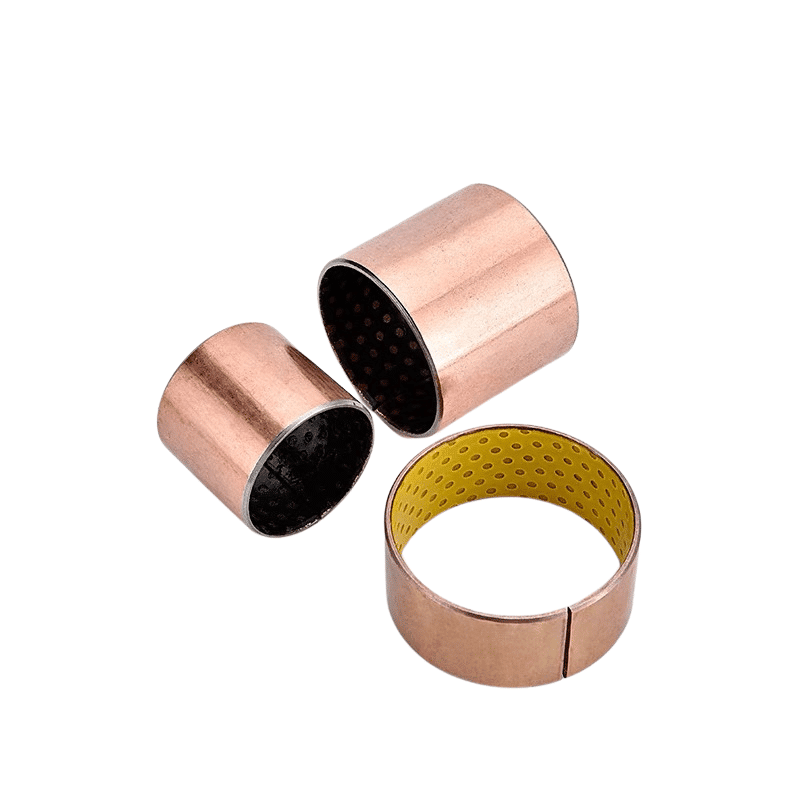

Self-Lubricating SF-1WC

Carbon Steel self-lubricating bearings used high-quality low-carbon steel plate as base, sintered porous bronze as its interlayer, and the Compound of PTFE and Lead as its surface. It offers the property of good self-lubrication, low wear, low friction good sliding characteristics, low noise. It has been widely applied to various mechanical sliding positions, such as textile machinery, printing machinery, hydraulic pressure transit vehicle, tobacco machinery, gymnastic instrument, and agricultural machinery, etc.

POM lined washer, Self-Lubricated Washer, Proven, long-lasting composite washer, SF-2 WC Thrust Washer WC10 12 14 16 18 20 24 26 28 32 38 42 48 52 62

Composition and Features of POM Lined Washers

POM lined washers are constructed from several distinct layers, each serving a specific function:

- Steel Backing: This foundational layer ensures the washer’s structural stability and its capacity to bear loads.

- Porous Bronze Layer: Attached to the steel through sintering, this layer secures the self-lubricating surface firmly in place and aids in heat distribution.

- POM Sliding Layer: Positioned at the top, this polyoxymethylene layer includes lubrication pockets and may be enhanced with MoS2 (molybdenum disulfide) to improve resistance to wear and decrease friction.

During use, a portion of the POM layer is transferred to the contact surface, forming a lubricating film that diminishes friction and safeguards the counterpart shaft.

Advantages and Characteristics

- Self-Lubricating: Designed to generate a continuous lubrication film, eliminating the need for additional lubricants.

- Maintenance-Free: Ideal for scenarios where upkeep is challenging or not viable.

- Cost Efficiency: Offers a compact solution that can reduce expenses owing to decreased maintenance demands.

- High Resistance to Wear: The inclusion of MoS2 in the POM layer significantly enhances its durability and performance under low lubrication conditions.

- Adaptable: Well-suited for various mechanical movements and capable of supporting substantial axial forces.

Use Cases

These washers find utility in diverse settings, such as:

- Machinery for printing, textile manufacturing, and tobacco processing.

- Equipment used in gymnastics.

- Locations that are inaccessible for regular maintenance.

- Environments prone to contamination where constant lubrication is impractical.

Choosing the Right Washer

To select an appropriate POM lined washer, consider the following:

- Size and Load Handling: The washer should fit the specific application and be capable of supporting the anticipated loads.

- Operating Conditions: Choose a washer that can withstand the particular environmental challenges, including temperature ranges and levels of contamination.

Maintenance Recommendations

Even though these washers are designed to be low-maintenance, regular inspections are advisable to monitor wear and ensure ongoing reliability and performance.

In conclusion, POM lined self-lubricating washers present a dependable and efficient means for minimizing friction and wear across various mechanical applications, with the added advantage of requiring minimal upkeep.

Dry Thrust Washer- SF-2WC

self-lubricating pom washer & bearing bush, sleeve bushing

| ※Standard Washer Label Mode SF-2WC 10 | ||||||||

| unit: mm | ||||||||

| SIZE | ||||||||

| SF-2WC 10 | 8 | 10 | 20 | 1.5 | 15 | 1.5 | 1 | 20 |

| SF-2WC 12 | 10 | 12 | 24 | 18 | 24 | |||

| SF-2WC 14 | 12 | 14 | 26 | 20 | 26 | |||

| SF-2WC 16 | 14 | 16 | 30 | 23 | 30 | |||

| SF-2WC 18 | 16 | 18 | 32 | 25 | 32 | |||

| SF-2WC 20 | 18 | 20 | 36 | 28 | 3 | 36 | ||

| SF-2WC 22 | 20 | 22 | 38 | 30 | 38 | |||

| SF-2WC 24 | 22 | 24 | 42 | 33 | 42 | |||

| SF-2WC 26 | 24 | 26 | 44 | 35 | 44 | |||

| SF-2WC 28 | 26 | 28 | 48 | 38 | 4 | 48 | ||

| SF-2WC 32 | 30 | 32 | 54 | 43 | 54 | |||

| SF-2WC 38 | 36 | 38 | 62 | 50 | 62 | |||

| SF-2WC 42 | 40 | 42 | 66 | 54 | 66 | |||

| SF-2WC 48 | 46 | 48 | 74 | 61 | 1.5 | 74 | ||

| SF-2WC 52 | 50 | 52 | 78 | 65 | 78 | |||

| SF-2WC 62 | 60 | 62 | 90 | 76 | 90 | |||

See Our Online Dry Sliding Composite Bearings Catalog & Request A Quote! Bearings & Materials Made To The Higher Standards.

Plain Bearings & Thrust Washers | www.bronzelube.com

Shop bronzelube.com for all your Thrust Washers and Plain Bearings & Thrust Washers needs. We offer free CAD download, short lead times, competitive pricing, ..

Materials

1. Modified polytetrafluoroethylene (PTFE) lead (Pb) mixture 0.01~0.03mm, a wear-resistant material, the operation process can form a transfer film to protect the grinding shaft.

2. Copper powder layer 0.2~0.3mm to improve the binding strength of PTFE/Pb and steel plate, with good bearing capacity and wear resistance. At the same time, copper is a good thermal conductivity material, which can quickly transfer the heat generated during the operation of bearings.

3. Low carbon steel 0.7~2.3mm, improve bearing capacity and heat transfer effect.

4. Copper/tin electroplating, copper plating 0.008mm, tin plating 0.005mm, so that the bearing has a good corrosion resistance.

High-quality Thrust Washer

Sf-2 Thrust Washer Plain Bearings

The SF-2 thrust washer material is a PTFE-modified surface layer filled with POM plastic of the three-level self-lubricating composite material, which is a benign boundary lubricating material, and therefore particularly suitable for low-speed and loaded rotational movement. high, rocking motion and frequently open and close under load and difficult to form hydrodynamic lubrication of bearings, thrust washer only, slider, tees, and other friction parts. The SF-2 can fully utilize the grease trace lubrication under boundary lubrication conditions without refueling for long-term maintenance.

High-quality low carbon steel as the matrix

The Thrust Washer Plain Bearing is made of high-quality low carbon steel and sintered spherical porous bronze powder in the middle, which is firmly integrated with surface modified POM. Surface rolling oil storage pit to achieve good lubrication between friction surfaces. It has good wear resistance and bearing capacity, steel back surface coating corrosion resistance, widely used in automobile chassis, forging machine tools, mining machinery metallurgy machinery, water conservancy and steel rolling industry.

1 pom0.30-0.50mm modified polyformaldehyde, high wear resistance, low friction coefficient, assembly must be coated with lubricating grease.

2. Copper powder layer 0.2-0.3mm, with good bearing capacity and wear resistance.

3. Low carbon steel, improve bearing capacity and heat transfer effect.

4 Electroplating: tin plating thickness of 0.005mm, or copper plating thickness of 0.008mm

Composite thrust thrust washer

Bearing mechanism

Solid friction

Product composition

Steel base copper plating

Product features

Good wear resistance, small friction coefficient, long service life and strong corrosion resistance

Product use

Used in all kinds of machinery Lubrication part

Such as automatic machinery and equipment

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.