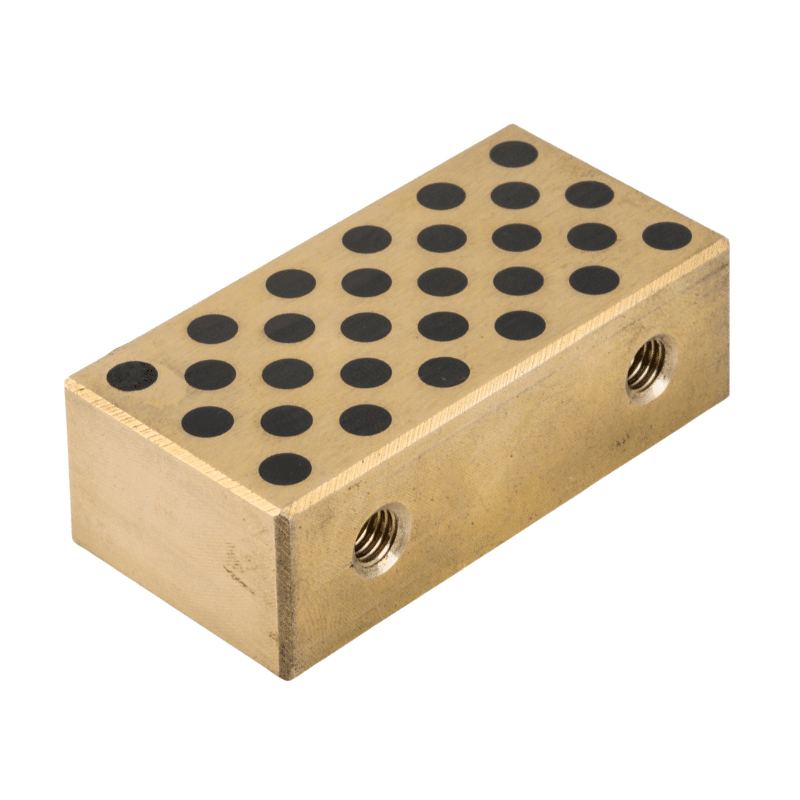

sesw wear plate

sesw wear plate

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

sesw wear plate

SESW Wear Plate: The term “SESW” isn’t standard and might be specific to certain manufacturers or applications. It could represent a specialized type of wear plate, possibly denoting specific materials or design features like “Self-lubricating,” “Embedded,” “Solid,” and “Wear” characteristics. Clarification from a manufacturer or detailed product specification would be needed to provide accurate information.

The Material: SO#50SP2 Brass Washer, Bronze Washer With Graphite Sobw size

SO#50SP2 is a specialized brass alloy known for its strength and corrosion resistance. The choice of this material for manufacturing oilless washers is crucial due to its inherent properties that ensure longevity and reliability under extreme conditions. This alloy forms the base of the washer, providing a sturdy foundation that can withstand significant mechanical stress.

Solid Graphite: The Self-Lubricating Element, U and V slides

One of the key features of these washers is the integration of solid graphite as a self-lubricating element. Graphite is renowned for its excellent lubrication properties, which remain effective across a broad temperature range. By embedding graphite into the washer, the need for additional lubrication is eliminated, making these components ideal for use in clean-room environments or in machinery where oil or grease can contaminate sensitive processes.

Graphite Brass oilless Thrust bearing Temperature Tolerance

The oilless washers crafted from SO#50SP2 with embedded graphite can operate effectively in a temperature range from -50°C to +300°C. This wide range allows them to be used in various industrial applications, from cold storage machinery to high-temperature processing equipment. The washers also feature a maximum short-term temperature tolerance of up to +300°C, accommodating temporary spikes in heat without compromising performance.

oilless Washer Applications and Suitability, material SO#50SP2, with graphite plugs

These washers are particularly suited to applications where oil-based lubrication is impractical or undesirable. Industries such as food processing, pharmaceuticals, and electronics, where contamination from lubricants can lead to product spoilage or equipment failure, find these washers especially beneficial. Moreover, their resistance to wear makes them ideal for use in heavy machinery and automotive applications, where frequent maintenance and lubrication are challenging.

oilless bearing SOBW Washer Sizes and Availability

The SOBW series of oilless washers come in various sizes to cater to different mechanical needs. Each size is designed to maintain the same high standards of durability and performance, ensuring that all applications, regardless of scale, can benefit from this advanced technology.

In conclusion, the development of SO#50SP2 brass oilless washers with solid graphite represents a leap forward in component engineering. These washers provide a dependable, maintenance-free solution in extreme conditions, making them a top choice for industries looking to enhance operational efficiency and reduce downtime. As technology progresses, the importance of components like these, which balance performance with environmental and practical considerations, will only continue to grow.

“Oilless Washer” refers to a type of gasket that does not require lubrication. Such washers are commonly used in mechanical and engineering fields to prevent liquid or gas leakage. They are often made of wear-resistant materials, such as PTFE or other synthetic materials, and are able to work without additional lubrication, thus reducing maintenance requirements and potential contamination risks.

If you need more information please contact us. Check the sobw washer size!

SOBW self-lubricating gaskets and SPW bearings are self-lubricating mechanical parts. They are usually used to reduce friction and wear, especially at low speed and heavy load. These parts can work without additional lubrication because they are embedded with solid lubricants such as graphite or PTFE (Polytetrafluorethylene) during the manufacturing process.

Bronze thrust washers and slide plates, as well as custom parts, are available as wear components made from brass graphite material, specifically SO#50SP2 with graphite plugs.

SO#50SP2 is a bronze alloy material containing graphite plugs, commonly used in the manufacture of self-lubricating bearings and sliding plates. Based on the search results, here are some detailed insights about SO#50SP2 material:

- SO#50SP2 is a copper alloy material used for making self-lubricating bronze parts, such as straight bronze oilless bearings.

- This material features high load capacity, excellent wear resistance, and moderate corrosion resistance, making it particularly suitable for use as swing mechanism bushings in injection molding machines.

- SO#50SP2 bronze material contains graphite, which releases from the material through micro-motion, forming a robust solid lubrication film that maintains contact area lubrication even under heavy loads.

- Sliding plates made from SO#50SP2 material are maintenance-free and long-lasting, ideal for high static and dynamic loads, offering low and smooth friction coefficients without stick-slip effects, and suitable for dirty, corrosive, impact-loaded, and edge-loaded environments.

- SO#50SP2 sliding plates are widely used in continuous casting mills, mining machinery, marine machinery, turbines, injection molding machines, automotive molds, and more.

- In high-temperature environments (150°C or higher), the embedded solid lubricant specifications of SO#50SP2 material may vary; contact the manufacturer for detailed information.

- The standard operating temperature range for SO#50SP2 material is -50°C to +150°C.

These details indicate that SO#50SP2 is a high-performance self-lubricating material suitable for applications requiring low friction, wear resistance, and corrosion resistance.

Sliding Bearing Material: Bronze with graphite inserts

Features: Self-lubricating bronze Notes: The sliding plates are designed for vertical movement.

The bronze elements require no maintenance and are highly durable against wear.

The inclusion of graphite ensures lifelong lubrication.

The steel sliding plates are hardened and do not contain solid lubricant.

Technical Data:

Material Properties:

Basic alloy: CuZn25Al5Mn4Fe3-C

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.