Self Lubricating Thrust Bearing

Self Lubricating Thrust Bearing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Self Lubricating Thrust Bearing

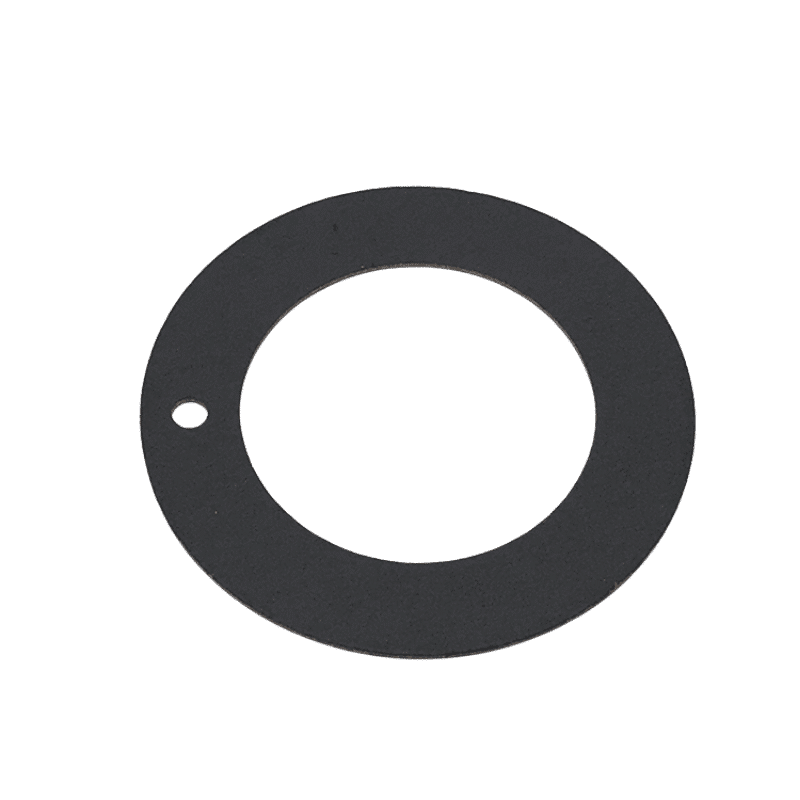

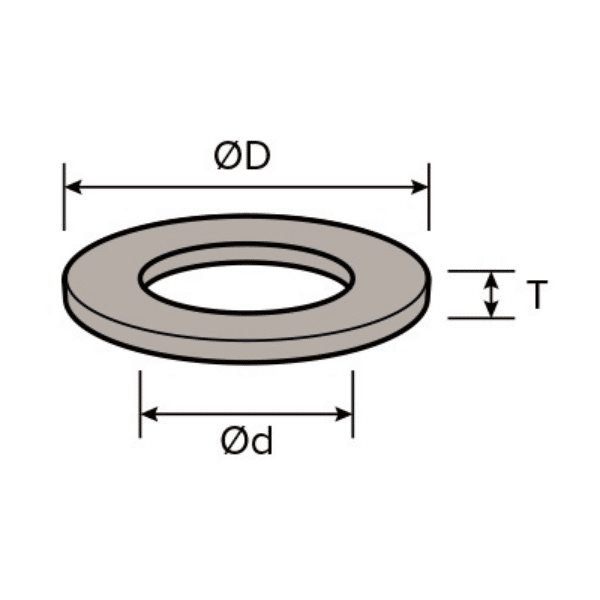

Self-lubricating thrust Washers, Carbon Steel, Metric, has a large selection of Self–Lubricating, Carbon Steel, Metric, Thrust Washers and other Sleeve Bearing Products.

Self-lubricating thrust washers are designed to provide a bearing surface that can handle axial loads while reducing friction without the need for additional lubrication. These washers are used between rotating and stationary components to prevent movement along the axis of the shaft. They are particularly useful in applications where maintenance is difficult or where contamination from lubricants must be avoided.

offers self-lubricating carbon steel metric thrust washers with a composite liner consisting of carbon steel backing, sintered bronze, and PTFE, designed for maintenance-free operation

thrust washers – maintenance-free, made of Self Lubricating, thrust washers from china are lubrication-free and need no maintenance, even in dirty or dusty environments.

Revolutionizing Industrial Applications: The Advanced Self-Lubricating Thrust Washer Bearing

In the realm of industrial applications, the Self-Lubricating Thrust Washer Bearing stands as a pinnacle of innovation. This marvel of engineering seamlessly blends the high load capacity and dimensional rigidity of traditional metallic plain bearings with the groundbreaking design freedoms offered by self-lubricating materials. Its core competency lies in its ability to operate far beyond the limits of conventional lubricants, opening new horizons in various fields.

Diverse Industrial Applications

The versatility of the Self-Lubricating Metric PTFE Thrust Washer is evident in its wide range of applications, catering to industries as diverse as:

- Agricultural Equipment: Enhancing the efficiency and durability of farm machinery.

- Off-Highway, Truck, and Automotive: Offering robust solutions for the demanding automotive sector.

- Aviation: Elevating performance standards in the high-stakes aviation industry.

- Business Machines: Ensuring reliability in office equipment.

- Garden, Lawn, and Outdoor Equipment: Bringing durability to outdoor machinery.

- Hydraulics and Valves: Optimizing performance in fluid control systems.

- Home Appliances and Consumer Goods: Upgrading everyday household items.

- Materials Handling: Streamlining operations in logistics.

- Medical and Dental Equipment: Providing precision and reliability in sensitive applications.

Key Features and Benefits

- Steel Backing: Imparts exceptional load-carrying capacity.

- Compact and Efficient Design: Offers excellent heat dissipation, with superior dimensional and structural rigidity.

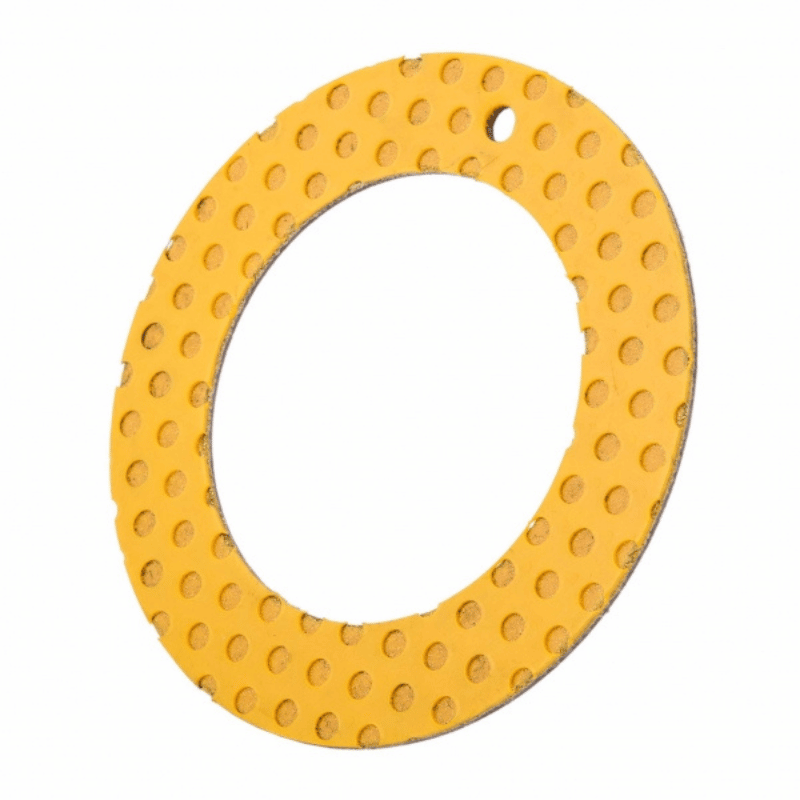

- Porous Bronze Innerstructure: A 0.25 mm thick layer of high-quality bronze powder, sintered onto the steel backing, creates a robust, porous structure.

- PTFE-Lead Overlay: This 0.025 mm thick low friction layer ensures an effective initial transfer film, reducing wear and enhancing performance.

- Dynamic Load and Speed Capacity: Can handle dynamic pressures up to 140 N/mm² and speeds up to 10 m/s, making it ideal for high-stress environments.

- Temperature Resilience: Operates effectively in temperatures ranging from -200 °C to 280 °C, surpassing most liquid lubricants.

- Versatile Application: Suitable for rotating, oscillating, sliding motions, and radial and thrust loading, with or without intermittent lubrication.

In summary, the Self-Lubricating Thrust Washer Bearing represents a leap forward in bearing technology. Its adaptability across various industries, combined with its exceptional features, makes it an indispensable component in modern machinery and equipment.

what is a thrust washer?

A thrust washer is a specific type of bearing designed primarily to support axial loads — that is, loads parallel to the axis of rotation. Unlike radial bearings, which are used to support loads perpendicular to the axis, thrust washers are specialized for the task of handling forces along the axis. Here are some key aspects of thrust washers:

- Functionality: Thrust washers are designed to allow for rotation between parts while supporting axial loads. They are often used in applications where space is limited and where a traditional rolling-element bearing is not suitable.

- Design: They are typically flat and round, resembling a washer. The simplicity of their design makes them easy to install and maintain. Some thrust washers may have grooves or other features to aid in lubrication distribution.

- Materials: These components can be made from various materials, including metals like bronze or steel, and polymers like PTFE (Polytetrafluoroethylene). The choice of material depends on the specific requirements of the application, such as load capacity, speed, and environmental conditions.

- Applications: Thrust washers are used in a wide range of applications, including automotive transmissions, gearboxes, electric motors, and in machinery where axial load support is needed. They are particularly useful in applications that involve oscillating or intermittent rotary motion.

- Self-Lubricating Variants: Some thrust washers are designed to be self-lubricating. This means they are made of, or coated with, materials that reduce friction and wear without the need for additional lubrication. This is particularly beneficial in environments where regular maintenance is challenging.

In summary, thrust washers are an essential component in many mechanical systems, providing a simple, effective solution for supporting axial loads and allowing for smooth rotation between parts. Their design, material composition, and application can vary widely based on the specific requirements of the machinery in which they are used.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.