Self lubricating sleeve bearings

Self lubricating sleeve bearings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Self lubricating sleeve bearings

Self-lubricating shaft bushing manufacturer, Self-lubricating sleeve bearings flange size Hi-Temp Bearing Solution. Non-galling. Run dry & keep running.

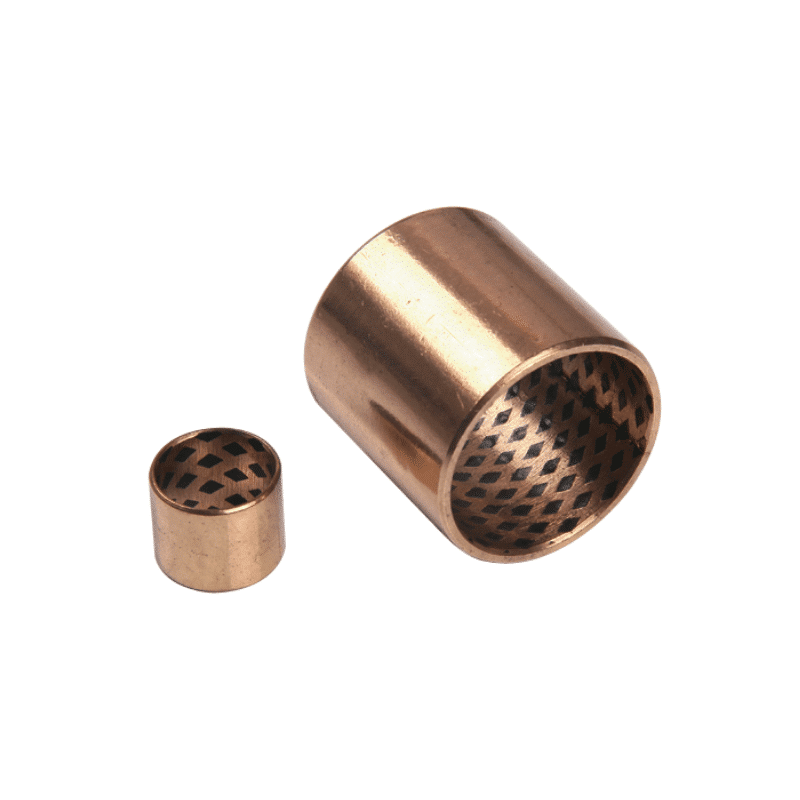

Self-lubricating sleeve bearings are designed to automatically provide their own lubrication, eliminating the need for frequent reapplication of solid lubricants. Often hailed as maintenance-free, these bearings incorporate lubricants directly into their material, enabling the formation of a lubricating layer that supports precise operation at high speeds across diverse applications. There are primarily two categories of self-lubricating sleeve bearings: metallic bearings, crafted from sintered bronze, copper, aluminum alloys, and non-metallic bearings, which are made from a range of materials tailored for specific environmental conditions.

These bearings are adept at managing significant reversing, non-reversing loads, or continuous oscillations, making them a robust option for dynamic conditions in sectors such as aerospace, defense, and advanced technology. They come in various styles, including flanged sleeve bearings and oil-embedded sleeve bearings, to meet different load requirements and application scenarios.

The advantages of self-lubricating sleeve bearings are manifold. They significantly cut down on maintenance costs and operational downtime, proving to be an invaluable choice in situations where regular lubrication is either difficult or not preferred. Offering low-friction performance and high resistance to wear, these bearings can function either dry or with additional lubrication, providing versatility in both maintenance and application needs.

Overall, self-lubricating sleeve bearings represent a highly adaptable and low-maintenance option for various industrial uses. Thanks to their inherent lubrication capabilities, they deliver exceptional performance across a multitude of operating environments, alongside offering a reduction in upkeep demands.

Supplier of bearings & bushing. Plain bearing types Available wrapped approaches include cylindrical, flange self-lubricating PTFE bushing, steel flanged bushes bushing, and steel bearing bushing. thrust washer, slide bearings, spherical thrust & strips.

Manufacturer of standard and custom PTFE-based self-lubricating metal-polymer bearings. Available in metric size and inch size. The bushing is flow erosion, contamination, shock, wear, chemical, corrosion, and cavitation resistant. Suitable for linear, oscillating, and rotating movements. Serves the agriculture, automotive, construction, energy, fluid power, oil and gas, primary metal, railway, and recreational industries. Standard flange bushing size. REACH and RoHS compliant.

Custom manufacturer of precision plain bearings made from Self-lubricating sleeve bearings, PEEK, acetal, steel flanged bushes Bushing, PTFE Self lubricating sleeve bearings, Self-lubricating bronze bushing, steel bushes, and stainless steel bearings. Types include flange, sleeve, spherical and self-lubricating bearings. Features include lightweight and chemical, temperature, wear, and washdown resistance. Prototype and low to high-volume production. Serves the analytical instrumentation, sample preparation, life sciences, marine, food processing, and material handling industries.

Custom manufacturer of self-lubricating steel bearings, PTFE bushing bearings, and components. Available in metric size and inch size. Also offered in different slide-bearing bushing materials. RoHS compliant!

Custom manufacturer of self-lubricating flange bearing bushings parts including bearing components and customized flange bushes size. Products include bearing strips from steel and bronze with glass-filled PTFE materials. Self-lubricating sleeve bearings flange size

Advanced Coatings and Composites Bearing Bushing

an advanced technology company specializing in the development, manufacture, and application of products for the prevention of friction, wear, and corrosion. Our products are utilized in an increasingly broad spectrum of industries including automotive, marine, and electronics. Almost any application that involves lubrication for friction and wears or corrosion barriers for galling and corrosion can benefit from sliding bearings technology.

What is a Shaft sleeve?

A shaft sleeve is an essential component in many mechanical systems, including pumps, compressors, and turbines. It is a cylindrical hollow sleeve made of various materials, such as bronze, stainless steel, or ceramic, that fits over a rotating shaft to protect it from wear and corrosion.

The primary purpose of a shaft sleeve is to protect the shaft from damage caused by the environment or the process fluid. In most cases, the shaft is exposed to corrosive and abrasive fluids that can damage the surface of the shaft over time. A shaft sleeve creates a barrier between the shaft and the fluid, preventing direct contact and minimizing the risk of corrosion or wear.

Shaft sleeves also play a crucial role in maintaining the integrity of the system. They help to reduce the clearance between the shaft and the housing, which, in turn, reduces the risk of leaks and improves the efficiency of the system. A tight fit between the sleeve and the shaft also reduces vibration and noise, which can have a significant impact on the lifespan of the system and the comfort of the operator.

There are several types of shaft sleeves available on the market, each with its own unique properties and applications. Bronze sleeves, for example, are commonly used in seawater applications because they offer excellent corrosion resistance. Stainless steel sleeves, on the other hand, are suitable for applications where high temperatures and pressures are present. Ceramic sleeves are used in high-wear applications, such as mining and cement manufacturing, because of their exceptional wear resistance.

When selecting a shaft sleeve, it is essential to consider the operating conditions of the system, such as temperature, pressure, and fluid properties. The size and material of the sleeve must also be carefully selected to ensure a proper fit and maximum protection.

In conclusion, shaft sleeves are a critical component in many mechanical systems, providing protection against wear, corrosion, and other forms of damage. With the right selection of materials and proper installation, a shaft sleeve can significantly improve the lifespan and efficiency of a system.

Flange self-lubricating ptfe shaft sleeve

Flange self-lubricating PTFE (Polytetrafluoroethylene) shaft sleeves are a type of self-lubricating shaft sleeve that is commonly used in high-load and high-temperature applications. They consist of a flanged sleeve made of PTFE, which incorporates lubricants into the material, providing continuous lubrication to the shaft during operation.

One of the primary advantages of flange self-lubricating PTFE shaft sleeves is their ability to operate in extreme temperatures and corrosive environments. PTFE is a thermoplastic material with excellent chemical resistance, making it ideal for use in applications where the shaft is exposed to harsh chemicals or fluids. Additionally, PTFE can withstand temperatures ranging from -200°C to +260°C, making it ideal for use in high-temperature applications.

The flange design of these sleeves provides additional benefits, including easy installation and removal. The flange allows the sleeve to be easily attached to the housing, providing a secure fit that reduces the risk of leaks and vibration. The flange also allows for easy removal and replacement of the sleeve, reducing downtime and maintenance costs.

Another advantage of flange self-lubricating PTFE shaft sleeves is their ability to reduce friction and wear between the shaft and the sleeve. The lubricants incorporated into the material provide a constant supply of lubrication, reducing friction and wear, and improving the lifespan of the system.

When selecting a flange self-lubricating PTFE shaft sleeve, it is essential to consider the specific requirements of the application. Different types of PTFE materials are available, each with its unique properties and advantages. For example, filled PTFE sleeves, which incorporate fillers, such as glass or carbon, can provide increased strength and wear resistance.

In conclusion, flange self-lubricating PTFE shaft sleeves offer several advantages over traditional shaft sleeves, including high-temperature resistance, chemical resistance, and reduced maintenance. With the right selection of materials and proper installation, these sleeves can provide long-lasting protection and reliable operation for a wide range of mechanical systems.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.