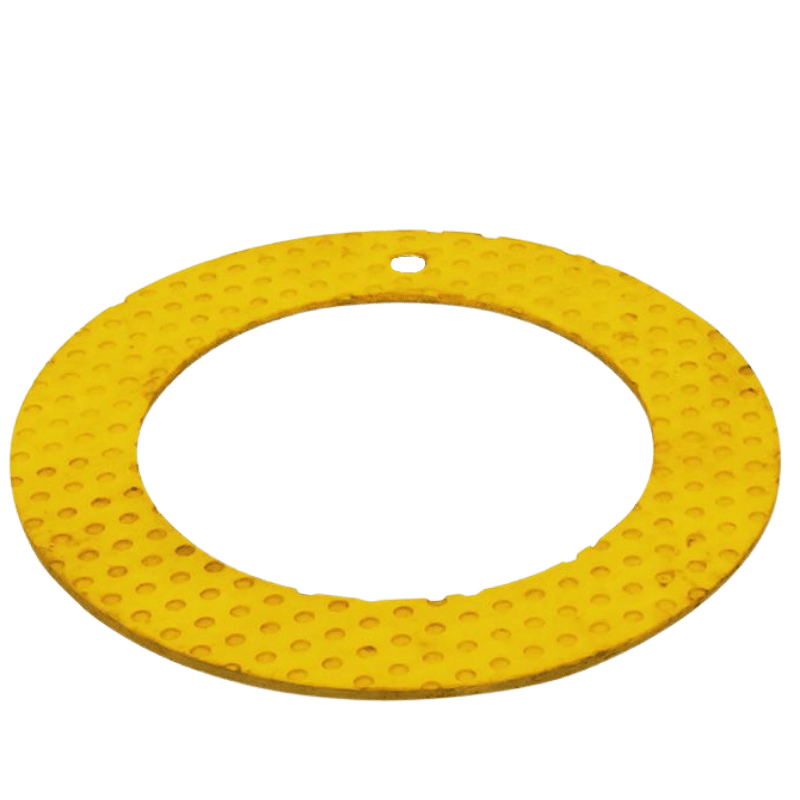

PTFE lined thrust washer

PTFE lined thrust washer

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

PTFE lined thrust washer

Self-lubricating thrust Washer Plain Bearing, PTFE lined thrust washer. PTFE And POM Composite Materials

Discover High-Quality Plain Bearings at Competitive Prices. Explore a Wide Range of PTFE-Lined Thrust Washers Sizes from China. Request Your Quotes Now!

PTFE (polytetrafluoroethylene) lined thrust washers are designed to provide low friction and self-lubrication in high-load and low-speed applications. The PTFE lining, combined with a steel or bronze backing, offers excellent wear resistance and low friction properties, making them suitable for dry running and reducing the need for external lubrication. These thrust washers can withstand heavy loads parallel to the shaft and are used in various industries, including metallurgical casting, steel rolling equipment, mining machinery, ships, and gas turbines.

PTFE lined thrust washer

The PTFE lined thrust washers you are interested in are designed to withstand heavy loads parallel to the shaft while offering exceptional low friction characteristics. These thrust washers are PTFE-lined with a steel backing, providing durability and resistance to chemicals and high temperatures.

The primary attributes of these PTFE lined thrust washers encompass:

- Capability for self-lubrication, ideal for applications requiring dry operation.

- Minimal friction coefficient and low wear rate.

- Favorable sliding traits, including a transfer film that safeguards mating components.

- Excellent resistance to corrosion and extended lifespan.

- Applicability across a range of machinery, particularly in scenarios where regular lubrication poses a challenge.

The design of these thrust washers generally consists of:

- A PTFE/Fibre blend that creates an initial lubricating transfer film.

- Sintered bronze powder, enhances thermal conductivity and serves as a lubrication reservoir.

- A low-carbon steel base that ensures robust load-bearing capacity and efficient heat dissipation.

- Copper/Tin coating to boost corrosion resistance.

These thrust washers, with their PTFE lining, are extensively utilized in the sliding mechanisms of machines, owing to their inherent self-lubricating features, resistance to wear, low friction, and overall operational advantages. They are particularly valuable in various settings where conventional lubrication approaches are either impractical or ineffective.

Straight Linear Plain Thrust Bearing, which features a multi-layered construction and is steel-backed with a PTFE (Polytetrafluoroethylene) coating. These bearings are eco-friendly and devoid of lead, boasting superior low-friction qualities without the necessity for added lubrication. The incorporation of PTFE resin enhances the bearing’s strength and ensures its dimensional stability.

The structure of these thrust bearings is segmented into three distinct layers:

Surface Layer: Composed of PTFE, this layer facilitates smooth movement by providing low friction and high lubricity.

Middle Layer: Made of sintered bronze, this layer contributes to the bearing’s strength and serves as a reservoir for lubricants, bolstering its self-lubricating features.

Back Metal Layer: This foundational layer offers essential structural support.

Employing a PTFE composite, these bearings are engineered to be compact and suitable for a broad spectrum of uses. They are self-lubricating, maintenance-free, and can endure temperature ranges from -200°C to 250°C. Such bearings are versatile, finding utility in sectors like agriculture, construction, material handling, office machinery, medical devices, and beyond.

In essence, these multi-layered, steel-backed bearings with a PTFE coating are a cost-efficient, maintenance-free option for various applications that demand self-lubrication and consistent high performance under diverse operational conditions.

PTFE lined thrust washer, long-lasting composite bearings. PTFE-lined thrust washers are ideal for applications where low friction, low wear rate, and self-lubricating properties are required. Has a Thin wall and is compact.

- Volume Discount is available

- Spec Expansion

- New Pricing

- Rapid Design

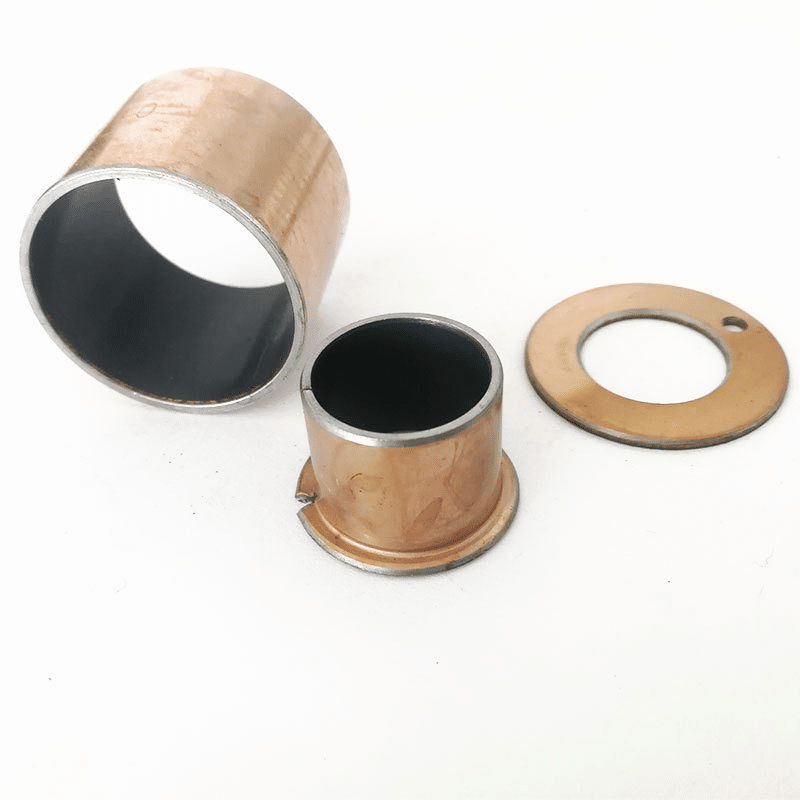

sleeve bushing washer, DU thrust washer, PTFE lined, steel backing, self-lubricating dry washers

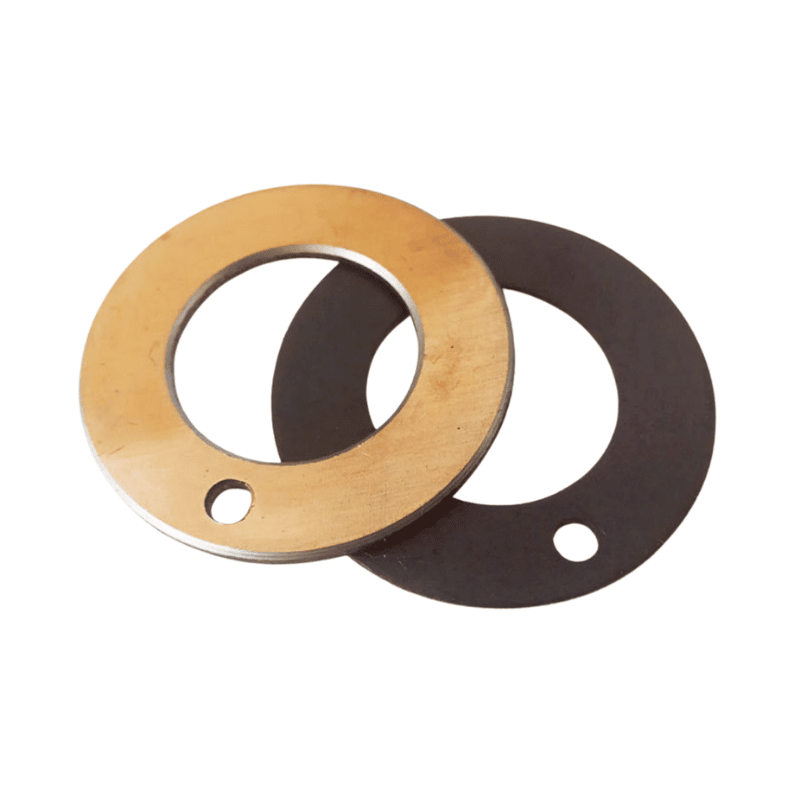

PTFE / Fibre + Bronze + Steel Backing + Copper Plating / Tin-Plating washer

Sintered PTFE and Bronze on Steel Backing, surface with copper-plating or tin-plating

Features

Suitable for dry running with a low coefficient of friction, low wear rate, good sliding characteristics, the transfer film created will protect the mating metal surface. Suitable for rotary and oscillating movement, high chemical resistance, lower absorption of water, and reduced swelling. Also performs well with lubrication.

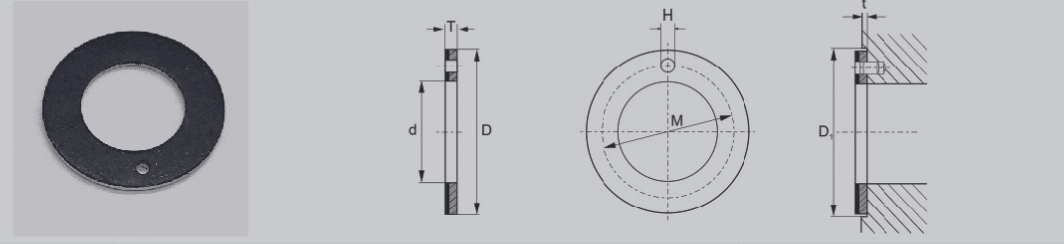

PTFE lined thrust washer size

| Washer size | ||||||||

| Size | d | D | T | M | Shaft Dia. | H | t±0.2 | D1 |

| WC10SF-1 | 10 | 20 | 15 | 8 | 1.5 | 20 | ||

| WC12SF-1 | 12 | 24 | 18 | 10 | 24 | |||

| WC14SF-1 | 14 | 26 | 20 | 12 | 26 | |||

| WC16SF-1 | 16 | 30 | 23 | 14 | 2 | 30 | ||

| WC18SF-1 | 18 | 32 | 25 | 16 | 32 | |||

| WC20SF-1 | 20 | 36 | 28 | 18 | 36 | |||

| WC22SF-1 | 22 | 38 | 1.5 | 30 | 20 | 3 | 1 | 38 |

| WC24SF-1 | 24 | 42 | 33 | 22 | 42 | |||

| WC26SF-1 | 26 | 44 | 35 | 24 | 44 | |||

| WC28SF-1 | 28 | 48 | 38 | 25 | 48 | |||

| WC32SF-1 | 32 | 54 | 43 | 30 | 54 | |||

| WC38SF-1 | 38 | 62 | 50 | 35 | 62 | |||

| WC42SF-1 | 42 | 66 | 54 | 40 | 4 | 66 | ||

| WC48SF-1 | 48 | 74 | 61 | 45 | 74 | |||

| WC52SF-1 | 52 | 78 | 2 | 65 | 50 | 1.5 | 78 | |

| WC62SF-1 | 62 | 90 | 76 | 60 | 90 | |||

High temperature resistant

Low noise

High precision

High speed

Wear resistance dimensions

Product parameters

– Product Parameters

Product name Thrust gasket

Product composition

The steel base copper plating

Bearing mechanism solid friction

The product features a small friction coefficient, wear resistance, good corrosion resistance, no oil lubrication

Product use

Used in sliding parts of various machinery, such as automatic machinery equipment. Applicable when unable to refuel or

More difficult refueling occasions

The SF-1 gasket (steel + spherical bronze powder + PTFE) is made of the steel substrate, sintered spherical bronze powder in the middle, and rolled PTFE and mixture on the surface. It has the characteristics of low coefficient of friction, wear resistance, good corrosion resistance, and oil-free lubrication. It can reduce the cost, reduce the size of the machine, avoid the phenomenon of shaft biting and reduce the noise.

The products have been widely used in sliding parts of various machinery.

- Composite Bearing Materials

- High Temperature / Low Wear

- Self-Lubricating

Thrust Washers Plain Bearings

See Our Online Dry Sliding Composite Bearings Catalog & Request A Quote! Bearings & Materials Made To The Higher Standards.

Common Applications

- Automotive Suspensions

- Shock Absorbers

- Hydraulic Cylinders

- Gear Pumps

- Gear Motors

- Axial Piston Pumps

- Axial Piston Motors

- Radial Piston Pumps

- Radial Piston Motors

Please Note: Metric DU washers are measured inside diameter x outside diameter in millimetres!!!

PTFE Lined Thrust Washers | www.bronzelube.com

Structures

1. PTFE/Fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides Max. thermal conductivity away from the bearing surface also serves as a reservoir for the PTFE-Fibre mixture.

3. Low-carbon steel, gives exceptionally high load carrying capacity, excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

PTFE Lined Washer Self-lubricating Thrust Washer

PTFE Lined Self Lubricating Dry DU Flanged Washer

PTFE coated dry oilless DU washer, PTFE lined self-lubricating flanged washer, Equal to GGB oilless washer

High-quality low carbon steel as the matrix

The Thrust Washer Plain Bearing is a mixture of polytetrafluoroethylene (PTFE) rolled on the surface of sintered spherical bronze layer in the middle of high-quality low carbon steel. It has good self-lubrication, wear resistance, low friction coefficient, good coupling performance, low noise and other properties and is widely used in sliding parts of various machinery.

- PTFE and lead mixture 0.01-0.03mm

- Spherical bronze powder 0.2-0.3mm

- Steel back 0.7-2.3mm

- Electroplating layer: tin layer thickness of 0.005mm, or copper layer thickness of 0.008mm

APPLICATION CHARACTERISTICS

- No oil lubrication or little oil lubrication, suitable for occasions where refueling is impossible or difficult, can be used without or with little maintenance.

- Good wear resistance, small friction coefficient, and long service life.

- Can be used in the range of -195°C to +280°C.

- close performance is good, low ring bitter, no pollution.

- A thin wall structure, light weight, can reduce the mechanical volume.

- Transfer film can be formed during operation to protect the grinding shaft. No axial biting phenomenon.

- The hardness of the grinding shaft is low, and the shaft without quenching and tempering can be used. Thus long low processing difficulty of the relevant parts.

- No rice water, oil absorption; The hot melt is small, so the macro is good and the size is fixed.

- The back of the steel can be plated with a variety of metals, so it can be used in corrosive media, will not rust.

The product name

Self-lubricating thrust washer, PTFE lined thrust washer

PTFE lined thrust washer mechanism

Solid friction

Product composition

The steel base copper plating

Product features

Good abrasion resistance

Small coefficient of friction

Long service life

Strong corrosion resistance

Oil-free self-lubrication

Product use

Used in all kinds of machinery Lubrication part

Such as automatic machinery and equipment

Installation Attention

The installation of bearings will affect the accuracy, life, and performance of bearings. To install and make

Pay attention to the following points:

Keep bearings and their working environment clean

Use clean tools or auxiliary tools to clean the working area, and the bearings can not be unsealed until they are in use. Bearings should be kept clean. Use proper operating tools and auxiliary tools that have good plasticity and are not easy to fall off.

Attention should be paid before installing bearings

Fully check the shaft and bearing body to determine whether the mating surface of the shaft and bearing body is damaged or protruded and whether there is dust or mold sand attached to the surface of the bearing housing. In order to avoid collision during installation, the shaft And the working surface of the bearing body should be coated with a small amount of lubricating oil.

Installation of bearings.

We suggest that pressing fit mode should be used, and tools such as a hammer should not be used to directly hit the bearing end face to avoid bearing damage. When installing in small batches, you can press the end face of the bearing with a sleeve and beat the sleeve with a hammer to make the bearing evenly installed in place.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.