POM Thrust washers

POM Thrust washers

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

POM Thrust washers

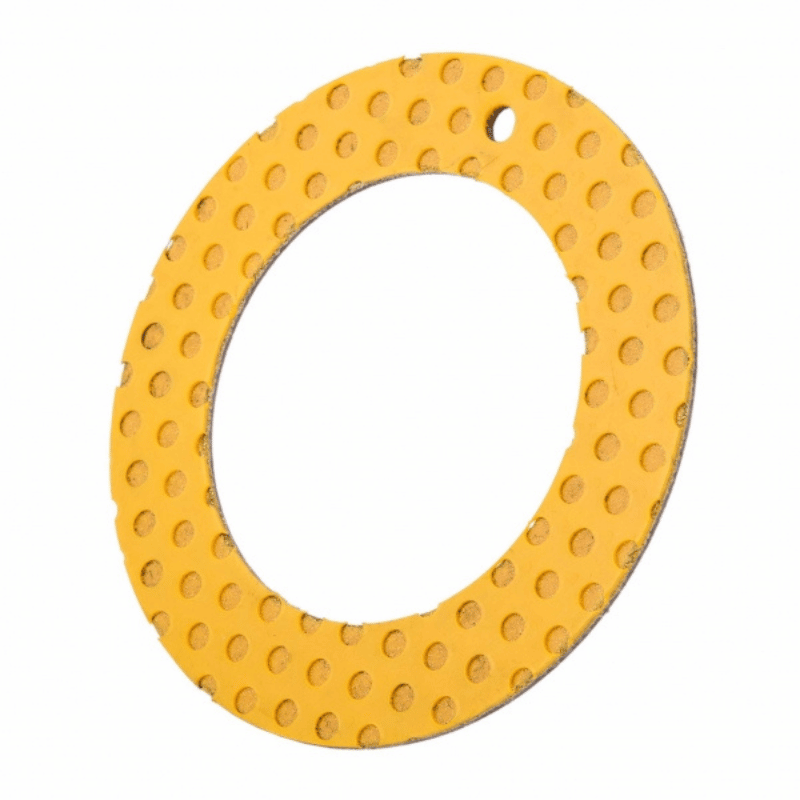

Metal-Polymer Bronze Backed POM Self-lubricating Bearing Washer, thrust washer design

Composite dry sliding thrust washers provide a cost-effective and space-saving solution for axial location. Both PTFE and POM composite thrust washers are suitable where oscillating and rotational movement can occur. These washers are punched from the composite material and have as standard a hole to take a pin or screw to prevent the washers from rotating on their seat. Explore the POM Thrust washer to become more efficient, visit the POM Thrust Washer Structure

After the rolling process is completed, POM mixtures are filled in the interstice of the bronze layer. Under normal operation, Part of the POM mixture on the top layer will be removed and transferred to the mating surface, forming a physically lubricating film, which will reduce the friction cone. and protect the mating shaft.

1.POM sliding layer with lubricant indents

2.Porous Bronze layer;

The layer provides bonded strength of Self-Lub. Layer.

3.Steel Backing

The layer provides load & thermal conductivity

4.Copper / Tin layer

Inch & Metric Thrust Washers – Sel-lubricating Bearings – www.bronzelube.com, POM thrust washer

Thrust washers, also referred to as thrust bearings or thrust plates, are made of metal-polymer material. Learn more!

POM Thrust washers, Metal polymer Bronze backed POM plain bearings available in Cylindrical bushes, flanged bushes, and sliding plates as standard.

Metal-polymer bronze backed POM plain bearing,

Thrust Washer, Metal Polymer Bearing, Self-lubricating bearings.

Polymer plain bearing – dry running/self-lubricating bearing washer

As well as for composite bushings and strips, we manufacture composite thrust washers as standard from PTFE and POM composite materials.

Cylindrical Bushes – Metric Size

POM composite thrust washers

Component: flanged bushes – metric thrust washer

POM composite thrust washers have pockets in the sliding surface, which serve as grease reservoirs and should be filled with grease prior to installation. This makes these washers suitable for applications that require minimal maintenance under difficult operating conditions, for example in contaminated environments where lubricant cannot be supplied continuously or frequently. Despite of their compact design, POM composite washers can accommodate heavy axial loads and are less sensitive to misalignment. They are suitable for slow rotational or oscillating movements.

The thickness of the covering layer makes these washers less sensitive to misalignment and the edge loading associated with that misalignment.

POM THRUST WASHER

Metal-Polymer Anti-Friction Plain Bearings

- Base material: Steel

- Intermediate layer: Sintered bronze.

- Top layer: POM

PLAIN SLEEVE THRUST WASHERS

Fiber Reinforced Composite Thrust Washer Bearings with POM Liner,

Coating Thrust Washer, Switch From Steel Bearings Are Self-Lubricating, Which Means You Never Need Grease. For Hydro Plant Application.

Metal-polymer precision bearings …

thrust washer Diameter, thrust washer, depending on the inside diameter.

POM coating thrust washer self-lubricating Washer

Metallic Rolled composite bushing:

steel backing with PTFE sliding layer coating thrust washers refer to plain bearings with self-lubricating functions.

They are high-performance, high quality, lubrication-free, and maintenance-free bearings for various industries.

AVAILABILITY

Bearing forms available in standard dimensions

- Plain cylindrical bushes

- Sliding plates

Lubrication of Sliding Bearings for Hydropower Applications

Bearing forms made to order: cylindrical bushes with non-standard dimensions, customized bearing designs

The Steel backed series are a self-lubricating PTFE coating thrust washer composed of three layers: Polytetrafluoroethylene plastic layers with fillers, sintered bronze layers, and back metals steel backing.

Self-Lubricating POM coating thrust washer, switch from metal bearings are self-lubricating, which means you never need grease. Extend the life of your equipment by switching to composite bearings and bushings.

Similar Glacier Washer Garlock Bearings then thrust washer Bearing Technology manufactures self-lubricating, prelubricated plain bearings and tribological polymer.

Self-lubricating POM coating thrust washer

Carbon Steel + Copper Powder + (POM + Pb + Filler)

Steel backed with copper-plated steel with porous bronze sintered on the steel and polymers (pom) embedded into the bores of the bronze. By combining the metals and the polymers together, its products are endowed with a lower friction coefficient and good capacity of anti-abrasion and self-lubrication. Moreover, the steel back is plated with an erosion-prevention layer. Products of the Pom composite series are widely applied in printing, weaving, and tobacco-producing machines, gymnastic equipment, etc.

steel bronze POM strips

Dry Operation Very Good

Lubricated Operation Very Good

Machinable Applicable

RoHS Compliant Compliant

Standard Sizes Not Available

| Performance Index | Data | |

| Max Load P | Static Load | 250N/mm² |

| Max Load P | Dynamic Load | 140N/mm² |

| Max Load P | Oscillation Load | 60N/mm² |

| Linear Velocity V | Dry Lubrication | 2.5m/s |

| Linear Velocity V | Oil Lubrication | >5m/s |

| Max PV value | Grease Lubrication | 1.8N/mm²· m/s |

| Max PV value | Oil Lubrication | 3.6N/mm²· m/s |

| Performance Index | Data | |

| Friction Coefficient μ | Dry Lubrication | 0.08~0.20 |

| Friction Coefficient μ | Oil Lubrication | 0.02~0.07 |

| Mating Axis | Hardness | >200 HB |

| Mating Axis | Roughness | Ra=0.4~1.25 |

| Working Temperature | -200~+280℃ | |

| Heat-conducting Coefficient | 40W/(m·k) | |

| Heat-expansion Coefficient(Axial) | 11×10-6K-1 | |

THRUST WASHER BENEFITS

One-Piece Compact design

One-Piece Compact Design

Material is suitable for continuous sliding, rotating, and oscillating movement

Suitable for Continuous Sliding, Rotating, and Oscillating Movement

The material allows for simple assembly

Simple assembly

Material eliminates/reduces maintenance

Maintenance-Free Operation

The material performs well under lubricated operation

Lubricated operation

Material withstands high loads

High Load Capacity

The material helps extend the application’s service life

Extended service life

Material operates well in a dry environment

Dry operation

THRUST WASHER PLAIN BEARINGS STANDARD SIZE

| ITEM | Code | Material | d[mm] | D[mm] | T[mm] |

| PCMW THRUST WASHER PLAIN BEARINGS | 122401.5 | PTFE | 12 | 24 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 122401.5 | POM | 12 | 24 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 142601.5 | PTFE | 14 | 26 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 142601.5 | POM | 14 | 26 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 183201.5 | PTFE | 18 | 32 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 183201.5 | POM | 18 | 32 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 203601.5 | PTFE | 20 | 36 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 203601.5 | POM | 20 | 36 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 223801.5 | PTFE | 22 | 38 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 223801.5 | POM | 22 | 38 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 264401.5 | PTFE | 26 | 44 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 264401.5 | POM | 26 | 44 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 284801.5 | PTFE | 28 | 48 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 284801.5 | POM | 28 | 48 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 325401.5 | PTFE | 32 | 54 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 325401.5 | POM | 32 | 54 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 386201.5 | PTFE | 38 | 62 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 386201.5 | POM | 38 | 62 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 426601.5 | PTFE | 42 | 66 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 426601.5 | POM | 42 | 66 | 1.5 |

| PCMW THRUST WASHER PLAIN BEARINGS | 487402 | PTFE | 48 | 74 | 2 |

| PCMW THRUST WASHER PLAIN BEARINGS | 487402 | POM | 48 | 74 | 2 |

| PCMW THRUST WASHER PLAIN BEARINGS | 527802 | PTFE | 52 | 78 | 2 |

| PCMW THRUST WASHER PLAIN BEARINGS | 527802 | POM | 52 | 78 | 2 |

| PCMW THRUST WASHER PLAIN BEARINGS | 629002 | PTFE | 62 | 90 | 2 |

Wear-resistant

Self-Lubricating Multilayer Composite Bushing is of excellent anti-abrasion performance, mainly due to the particular molecule structure of POM. The abrasion process can be generally divided into three phases, so there are kinds of friction coefficients. See the right graph:

1. “Running-in” phrase: POM compound on the bushing is transferred to its mating surface and forms a lubricating film. At this phase, the friction coefficient is bigger, thus the abrasion pace is very quick. See the curve shown in area I of the graph.

2. “Stabilization” abrasion phrase: After the “Running-in phase”, the friction happens between POM and POM, thus the friction coefficient is smaller and keeps steady. As a result, the wear rate is low and steady. See the curve shown in areaⅡof the graph.

3. “Sharp” abrasion phrase: As POM in the porous layer is slowly consumed up, not enough lubricant can be supplied to the gliding media. The friction coefficient and wear rate will rapidly rise. When 70% of the bronze surface is exposed, the service life of Self-Lubricating Multilayer Composite Bushing closes to its end. See the curve shown in area Ⅲof the graph.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.