Oilless Washers

Oilless Washers

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Oilless Washers

Oil-free Thrust Washer

Copper base Mosaic solid lubrication thrust bearing washers Material: CuZn25Al5, also with different alloys available upon request

– Cast bronze bearing washer, bronze thrust washer, bronze washer, graphite lubricant bronze bearing

– Solid bronze washer with graphite points, solid bronze spring washer cast, bronze washer with graphite lubricant

Maintenance-free Oilless Washers, Oil Free Washer

Oilless washers, also known as self-lubricating washers, are used in applications where traditional lubrication is challenging. They are made of cast bronze with solid lubricant inserts, such as graphite, to provide continuous lubrication without the need for external lubrication. These washers are suitable for high-load and medium-speed applications and can be developed to specific customer requirements. They offer advantages such as reduced maintenance, low friction, and excellent emergency sliding properties. The solid lubricant, typically covering about 25-30% of the bearing surface, reduces wear and extends the life of the bearing or thrust washer.

Thrust washer bearings with solid lubricant plugs, such as graphite, are essential components in various industrial applications. They provide continuous lubrication, eliminating the need for external lubrication and reducing maintenance costs. These bearings offer low friction, excellent emergency sliding properties, and can function even in case of unexpected failures. They are designed for high-load applications and can be grooved to provide additional lubrication distribution. The use of graphite plugs in these bearings provides several benefits, including self-lubrication and the ability to withstand high temperatures and pressures.

Oilless Solid Lubricant Thrust Washers, Cast bronze washer with solid graphite lubrication, CuZn25Al6Mn4 Bronze with solid graphite lubricant inserts (alternative specifications are available on request)

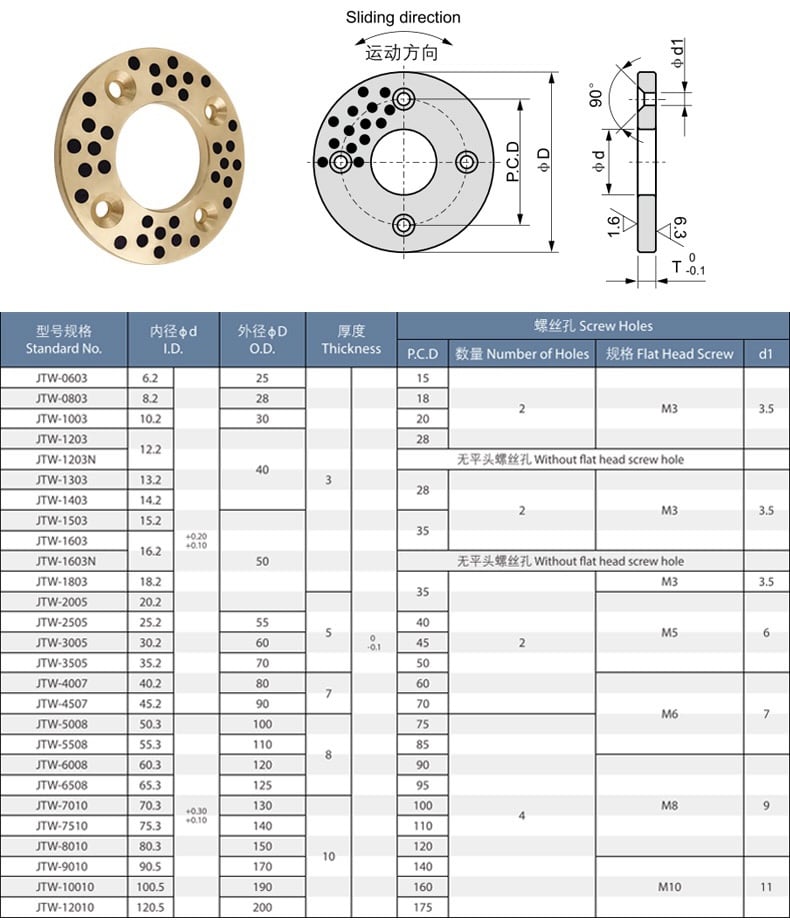

Metric Solid lubricated Thrust Washer Part number:

Oil-Free Washers – Configure and purchase

Oil-Free Washer

Oil-Free Washer for universal use in many dry applications such as die/mold, machinery,

automation, construction, and automobile. The Oil Free bush is self-lubrication and works without grease.

Material : #500SP

(High Strength Brass / Copper Alloy + Solid Lubricant)

Solid lubricated Thrust Washers have been developed for high load, low-speed applications and are made of rotational cast high-strength bronze using a specially formed graphite plug as a lubricant.

Our range of JTW Solid lubricated Thrust Washers is available in metric and imperial sizes. Our in-house machining service can produce non-standard sizes to suit specific customer requirements.

Thrust bearings for sale, Self-Lubricating Thrust Washers, Brass, Metric – Bronze Washer…

Material: CuZn25Al6Mn4 Bronze with solid graphite lubricant inserts

(alternative specifications are available on request)

Click here to find your oilless washer bearing

| Oilless Washer | JTW10 | 10.2 | 30 | 3 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW12 | 12.2 | 40 | 3 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW13 | 13.2 | 40 | 3 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW14 | 14.2 | 40 | 3 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW15 | 15.2 | 50 | 3 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW16 | 16.2 | 50 | 3 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW18 | 18.2 | 50 | 3 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW20 | 20.2 | 50 | 5 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW25 | 25.2 | 55 | 5 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW30 | 30.2 | 60 | 5 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW35 | 35.2 | 70 | 5 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW40 | 40.2 | 80 | 7 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW45 | 45.3 | 90 | 7 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW50 | 50.3 | 100 | 8 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW55 | 55.3 | 110 | 8 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW60 | 60.3 | 120 | 8 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW65 | 65.3 | 125 | 8 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW70 | 70.3 | 130 | 10 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW75 | 75.3 | 130 | 10 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW80 | 80.3 | 150 | 10 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW90 | 90.5 | 170 | 10 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW100 | 100.5 | 190 | 10 | Cast bronze bearings with solid graphite lubrication |

| Oilless Washer | JTW120 | 120.5 | 200 | 10 | Cast bronze bearings with solid graphite lubrication |

Features Self Lubricating Thrust Washer Lubricant

| Solid Lubricant | ||

|---|---|---|

| Lubricant | Features | Typical application |

| SL1 Graphite+add | Excellent resistance against chemical attacks and low friction.Temp limit 400 ℃ | Suite for general machines and under an atmosphere |

| SL4 PTFE+Additives | Lowest in friction and the good of water lubrication, Temp. limit 300℃ | The ship, hydraulic turbine, gas turbine, etc |

Caution

1. Where possible, try to use standard design;

2. Please note that the surface of any foreign body assembly;

3. Sliding surface after use, because the solid lubricant film formation results in a surface with black or gray-black phenomenon, please do not scrub, as usual;

4. Before assembly, if the lubricating oil is applied to the wear parts, can shorten the running-in period, in favor of mechanical operation, operation;

5. The assembly should be slowly pushed forbidden beat, so as not to damage bearings and cause deformation;

6. Design should be used in different parts of the appropriate material, in order to improve the mechanical properties, extending bearing life;

7. In the high load, the reciprocating motion, it is recommended to use screws;

8. In freshwater, seawater, and at sea, the shaft, or recommend the use of stainless steel, chrome plated.

Self-Lubricating Thrust Washers & Graphite Bearings Advantage

1. The design is flexible, simple, and convenient, and has a wide range of use;

The fuel supply system is a heavy-duty, time-consuming, and labor-intensive device in mechanical design. There is no need to consider the use of solid self-lubricating bearings when designing fuel, which saves fuel device equipment and can be applied to various special occasions. The solid self-lubricating bearings are designed in a variety of shapes to meet the needs of various special occasions. The use of solid self-lubricating bearings can significantly reduce the cost of mechanical maintenance and fuel.

2. No oil can be used;

Since the coefficient of linear expansion is greater than that of the solid lubricant of the metal matrix when the solid self-lubricating bearing starts to run, the piece will be transferred to the mill members to realize self-lubrication, so it is difficult to use solid self-lubricating bearings in oil and can not be oil or fat. Locally, even in the case of low speed and high load, it can also play a good lubrication effect.

3. Low cost of use;

With the traditional mechanical design, the fuel gauge should be checked at all times during refueling and maintenance within a certain operating time. The installation of the oil is smooth. Regular refueling will cause pollution to the surrounding environment and increase maintenance costs. After lubrication, not only can the environment be cleaned, but also the use cost of the lubricant can be greatly reduced.

4. Under high load and low-speed conditions, it can exert superior performance;

The solid self-lubricating bearing uses centrifugal casting high-strength brass alloy as a matrix, which plays a role in the load. The special formula of graphite with good self-lubricating performance is used as a lubricant, playing a role in self-lubricating, which combines their respective advantages, Even under high load and low-speed conditions, it can exert superior performance.

5. Reciprocating motion, rocking motion, and frequent start-stop film formation difficulties, exert excellent wear resistance;

The principle of the self-lubricating bearing arrangement of solid lubricants is to ensure that all parts of the grinding member have the role of lubricant during the operation. Therefore, the arranged lubricant must be arranged based on the direction of movement of the grinding to determine the location of the lubricant.

6. Excellent chemical resistance and corrosion resistance;

The solid self-lubricating bearing lubricant is specially formulated from graphite, polytetrafluoroethylene, molybdenum disulfide, and other wear-resistant materials. It has a stable molecular structure. The metal matrix can have different chemical resistance and corrosion resistance according to the metal selected. Therefore, solid self-lubricating bearings have excellent chemical resistance and corrosion resistance.

7. The product is more competitive in cost performance, compared with similar products, it has a long service life, less maintenance, a long replacement cycle, and good performance.

Contact Us

To make an inquiry about or request a catalog of self-Lubricating Thrust Washers , click here!

Thrust Washer Description

|

Size

|

Customized brass graphite washer

|

|

Material

|

Brass / Bronze(CuZn25Al5Mn4Fe3)

|

|

Color

|

Brass color

|

|

Size

|

Metric Size

|

|

Max line speed V

|

Dry Lubrication 0.3m/s,Oil Lubrication1.0m/s

|

|

PV value limit

|

Dry Lubrication 1.65N/mm²· m/s,Oil Lubrication 3.25N/mm²· m/s

|

|

Friction coef u

|

Dry Lubrication 0.12~0.16, Oil Lubrication 0.03~0.08

|

|

Max Working temperature

|

-40~200℃

|

|

Mating Axis

|

Hardness >220 HB, Roughness Ra=0.4~1.25

|

|

Thermal conductivity

|

38-55W/(m·k)

|

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.