Metal-Polymer Bearings Bushing

Metal-Polymer Bearings Bushing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Metal-Polymer Bearings Bushing

High-quality red PTFE Self-Lubricating Bushings are Available. Explore Our Online Catalog and Get a Quote Today! Find Metal-Polymer Bearings Bushing Bushing Alternatives in Various Sizes! Exceptional Customer Service. Alternatives Metal-Polymer Bearings Bushing Bushes.

SF-1D Hydraulic Bushing, SF-1S Stainless Steel Bushings

Material: Steel+bronze+PTFE

The PTFE bushing is made of steel plate, sintered spherical bronze powder in the middle, rolled ptfe and mixture on the surface. It has the characteristics of low friction coefficient, wear resistance, good corrosion resistance and no oil lubrication. It can reduce the cost, reduce the size of the machine, avoid the phenomenon of shaft biting and reduce the noise. PTFE Bushings have been widely used in various machinery sliding parts such as: printing press, textile machine, tobacco machinery, automobile, motorcycle and agricultural and forestry machinery.

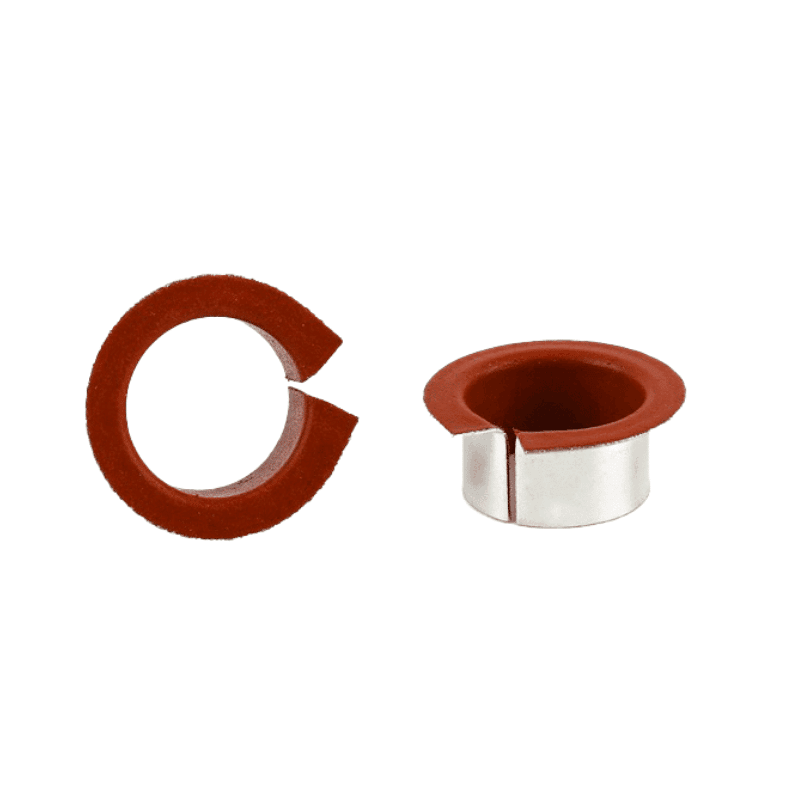

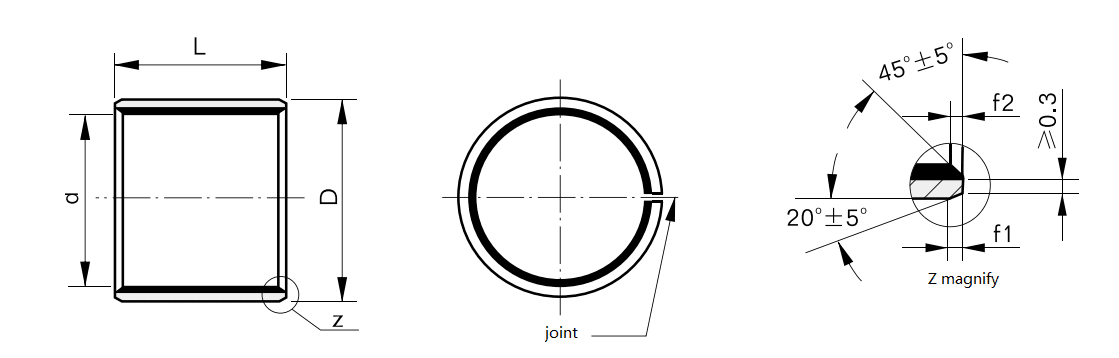

Slide Bearing Straight Bushing Cylinder Slit (Opening) Type,

Dry sleeves & Dry Plain Bushings, Stainless steel bushings, Quality Self-lubricating Red PTFE Bushings. See Our Online Catalog & Request A Quote! Equivalent or alternative Low Friction Plain Bushing In Different Sizes! Customer Service. PTFE Composite Plain Bearing Shell with Sintered Bronze and Steel Back, Split Design

Dry sleeves are bushings or sleeves that are designed to fit between the seat in the housing and the shaft. The main function of these products is to separate the rotating parts of the moving structure to prevent them from coming into contact with each other.

Plain bushings, also known as radial bearings, are designed to facilitate the rotation of elements. Crafted from stainless steel, these bushings boast an extended lifespan. Their deployment minimizes the heating of frictional components, thereby enhancing durability. Lubricants are strategically placed between the shaft and the bushing’s bore to enable smooth operation.

These bushings, with an internal diameter starting at 6 mm, feature a cylindrical design and are capable of enduring high radial loads, making them ideal for industrial machinery and tools. Customers can acquire these parts either through online shopping or by placing custom orders.

As a leading supplier in hydraulic components, we offer top-notch quality bushings. Our extensive collection includes various hydraulic bushings and related equipment. Reach out to us for more information!

Our inventory encompasses a diverse range of hydraulic bushings, including valves, pumps, and motors, catering to multiple industries.

Explore our services and request a free quote for PTFE bushings. Our offerings include bushings, flanged bushes!

Discover our coated bushings, designed for transmission systems. These bushings retain engine oil on their surface, providing additional lubrication during extreme conditions or temporary oil shortages.

Red PTFE Coated Low Friction Plain bushing Bushings Oilless Dry Bearing Customized Bushing, SF-1D/ SF1S

Choose from our selection of Red PTFE bushings in a wide range of styles and sizes. In stock and ready to ship.

Low Friction Plain bushing composite bushings offer good wear and low friction performance over a wide range of loads, speeds, and temperatures in dry running conditions. We offer high-performance, maintenance-free solutions for many applications.

The SF-1D hydraulic sleeve was developed on the basis of the SF-1P taking into account the principle of operation of the oil pump and shock absorber.

SF-1D hydraulic bushing is developed on the basis of SF-1P while taking into account the working principle of the oil pump and shock absorber. It shows better performance in working conditions without oil lubrication. produced abroad. In addition to covering the same usage of SF-1P, SF-1D in particular frequently adapts to reciprocating motion with high lateral force. It is a trend to gradually replace SF-1P with SF-1D, the latter will cover wide applications in automobiles, engine shock absorbers,s and oil pumps, etc.

CHARACTERISTICS

- Good wear and low friction performance over a wide range of loads, speeds, and temperatures in dry running conditions

- Very good performance in lubricated applications particularly in marginally lubricated applications

- Suitable for linear, oscillating, and rotating movements

- Lead-free material match RoHS specifications.

COMPOSITION

Metal-Polymer Composite Bushing Material

Steel Backed Bushing + Porous Bronze Sinter + PTFE + Fillers

1. PTFE/Fibre mixture thickness 0.01~0.03mm, provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide-type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides Max. thermal conductivity away from the bearing surface also serves as a reservoir for the PTFE-Fibre mixture.

3. Low-carbon steel, gives exceptionally high load carrying capacity, and excellent heat dissipation.

4. Copper/Tin plating thickness of 0.002mm, provides good corrosion resistance

CYLINDER RED PTFE BUSHINGS

TECHNICAL DATA

| Load capacity N/mm² | 140 | Temperature ℃ | -195~280 | |

| Friction coef μ | 0.04~0.20 | PV limit

N/mm²·m/s |

dry | 3.8 |

| Speed limit m/s | 3 | oil | 50 | |

TECHNICAL SPECIFICATIONS

| BEARING PROPERTIES | Value | Unit |

|---|---|---|

| Maximum load, p | ||

| – Static | 250 | N/mm2 |

| – Dynamic | 140 | N/mm2 |

| Operating Temperature | ||

| – Min | -200 | °C |

| – Max | 280 | °C |

| Coefficient of Thermal Expansion | ||

| – Parallel to the surface | 6 | 10-⁶/F |

| – Normal to the surface | 17 | 10-⁶/F |

| Dry | ||

| Maximum sliding speed, U | 2.5 | fpm |

| Maximum pU factor | 1.0 | psi x fpm |

| Coefficient of friction, f | 0.04 – 0.25* | |

| Oil Lubricated | ||

| Maximum sliding speed, U | 5.0 | fpm |

| Maximum pU factor | 10.0 | psi x fpm |

| Coefficient of friction, f | 0.02 – 0.08 | |

| Recommendations | ||

| Shaft surface roughness, Ra | ||

| – Dry | 0.3 – 0.5 | μin |

| – Lubricated | ≤ 0.05 – 0.40* | μm |

| Shaft surface hardness | ||

| – Unhardened acceptable, improved bearing life | > 200 | HB |

| For Superior Performance | Value | |

| Water Lubricated | Low Friction Plain bushing | |

| * Depending on operating conditions |

APPLICATION ADVANTAGES

-

No oil lubrication or little oil lubrication. It is suitable for situations where refueling is impossible or difficult and can be used without or with little maintenance.

-

Good wear resistance, small friction coefficient, long service life.

-

can be used in the range of -195℃~+280℃.

-

Good running performance, low noise, no pollution.

-

A thin wall structure, lightweight, can reduce the volume of machinery.

-

In operation can form transfer film, play a protective role on the grinding shaft, no shaft biting phenomenon.

-

The hardness of the grinding shaft is low, and the shaft without quenching and tempering treatment can be used, thus reducing the processing difficulty of the relevant parts.

-

No water absorption, oil absorption thermal expansion coefficient is small, good heat dissipation, size stability.

- The back of the steel can be plated with a variety of metals, so it can be used in corrosive media and will not rust.

APPLICATIONS

Due to the performance characteristics under dry and lubricated operating conditions, Low Friction Plain bushing bearing materials are widely used in a wide range of automotive and industrial applications, such as:

Automotive

Brakes, clutches, gearbox and transmissions, hinges – hood and trunk of doors, roofs of folding roofs, pedal systems, pumps – axial, radial, toothed-blade, seat mechanisms, steering systems, struts and shock absorbers, wiper systems.

Industrial

Aerospace, agricultural, construction, food, marine, transshipment, office equipment, packaging equipment, pneumatic and hydraulic actuators, railway and tramway, textile machinery, and valves.

AVAILABILITY

Low Friction Plain bushings bearing forms made to order: standard forms in special dimensions, half-bearings, special shapes obtained by stamping or deep drawing, bearings with locating notches, lubricant holes, and machined/stamped grooves, customized bearing designs.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.