JSP Wear Plate

JSP Wear Plate

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

JSP Wear Plate

JSP Wear Plates: The Ultimate Solution for Heavy-Duty Operations

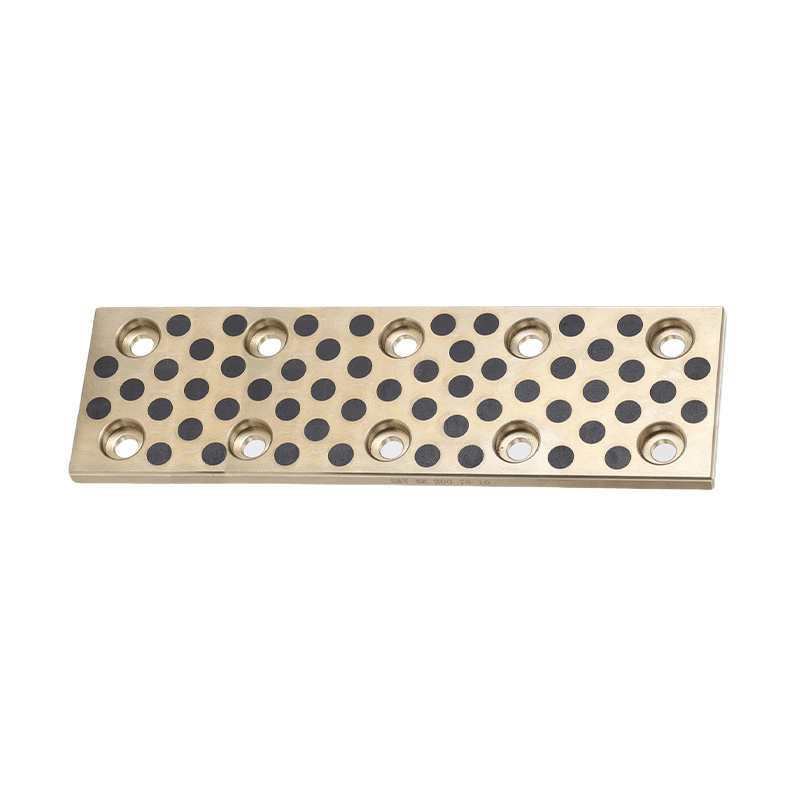

The JSP wear plate is a self-lubricating high-performance solid lubrication product embedded with graphite or MoS2 solid lubricant on the high-wear-resistant metal material as the matrix.

JSP Wear Plates are not just another component; they are a testament to excellence in engineering and design. Whether you’re in the automotive sector, metal stamping, or any other industry requiring robust support for linear motion, JSP has the solution for you.

For those who prioritize quality, durability, and performance, JSP Wear Plates are the go-to choice. Upgrade your machinery, enhance efficiency, and ensure longevity with JSP.

Self-lubricating JSP wear plate base inlaid graphite self-lubricating plate wear-resisting slide plate copper graphite slide plate with high force brass (ZCuZn25Al6) as the matrix, through the matrix inlaid solid lubricant (graphite or molybdenum disulfide) as the lubricating medium to replace the traditional tin bronze, can not be easy to oil, long-term lack of oil or no oil environment. We can also process oil grooves and positioning holes according to the customer’s actual demand.

Series Description:

Wear resistant metal material as the matrix, by adding various lubricating materials to reduce friction coefficient, and achieve self-lubrication. This material structure combines the advantages of high load of metal, good impact resistance and low friction coefficient of nonmetal, which can be used in various working conditions. According to the distribution of solid lubricant is different, divided into according to certain proportion rule configuration set and evenly distributed in the working layer of dispersion of two kinds of solid lubricating bearing, Mosaic solid lubrication bearing is suitable for low speed and high load, and the dispersive solid lubricated bearing even under the condition of high speed in the micro, can keep a very low coefficient of friction.

JSP Wear Plate Graphite: An Innovative Solution for Metric Size, Blank Plates for Slide Guides – Oil-less Plates with Graphite, Solid-Lubricant-Embedded Bearing Plate

Applications

Slide plates and oilless plates with graphite are specialized components used in various industrial and mechanical applications. We specialize in supply various bushing and wear plates with different materials.

The JSP wear plate stands out as a cutting-edge, self-lubricating solution engineered to diminish friction and facilitate self-lubrication under diverse operational conditions. This product integrates either graphite or MoS2 as a solid lubricant into a durable, wear-resistant metal base. It is crafted from materials like high-hardness brass or aluminum bronze, which are complemented with graphite plugs impregnated with oil. This combination delivers numerous benefits, including superior wear resistance, a low friction coefficient, self-lubricating capabilities, resistance to chemicals, high-temperature endurance, and consistent dimensional stability. The construction of the wear plate encompasses a solid lubricant film, solid lubricant plugs, and a bronze backing, providing a durable wear surface and ongoing lubrication throughout its use. Employed in sectors that demand robust, maintenance-free solutions for intensive use—like the automotive industry, metal stamping, mold making, specialized machinery, and heavy equipment—the JSP wear plate is a preferred choice for enhancing operational efficiency and longevity.

Self-Lubricating Bearings: Overview and Features

Self-lubricating bearings are used in applications where the bearing operates without lubricant or with minimal lubricant during operation. Our focus is on ensuring optimal performance and extended lifespan under various conditions. The working principle of self-lubricating bearings involves the formation of a solid lubricating film during the initial run-in period. This film is created by the transference of a small amount of material from the bearing layer in direct contact with the moving parts, which protects and lubricates the mating components, thereby extending the service life of both the bearing and the shaft.

Features

Modern designs place enormous demands on today’s self-lubricating bearing materials, requiring maintenance-free operation even under severe environments and extreme load conditions. Additionally, the constant pressure on costs necessitates increased machine and plant availability without compromising reliability. Metallic self-lubricating bearing materials are designed to meet these requirements, offering long-term maintenance-free and self-lubricated performance. This makes it possible to design reliable, long-term self-lubricating systems.

Metallic self-lubricating bearing materials can be applied to a wide range of low-speed, high-load conditions, including rotating, swinging, and straight-line reciprocating motions. These bearing materials are also suitable for situations where traditional lubrication is either not possible or prohibited, as well as in special conditions such as dust, radiation, and impact loads, where long-term stability is required.

Wear Plates at VIIPLUS.COM: A Perfect Blend of Durability and Performance for Your Press Die Needs

Material Grade for Solid-Lubricant-Embedded Bearing Plate

| Grade | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | CuZn25Al5Mn4Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn10Pb1 | CuSn7ZnPb | CuSn12Pb | CuZn25Al5Mn4Fe3 | |

| Density | 8 | 8.9 | 7.8 | 8.9 | 8.8 | 8.9 | 8 | |

| Hardness | > 210 | > 70 | > 140 | > 80 | > 75 | > 95 | > 250 | |

| Tensile strength | N/mm | > 750 | > 200 | > 600 | > 330 | > 270 | > 260 | > 800 |

| Yield strenght | N/mm2 | > 450 | > 90 | > 260 | > 170 | > 130 | > 150 | > 450% |

| Elongation | % | > 12 | > 15 | > 10 | > 6 | > 16 | > 10 | > 8 |

| Coefficient of linear expansion | 1.9X10-5/℃ | 1.8X10-5/℃ | 1.6X10-5/℃ | 1.8X10-5/℃ | 1.8X10-5/℃ | 1.8X10-5/℃ | 1.9X10-5/℃ | |

| Max.temp. | ℃ | -40~+300 | -40~+400 | -40~+400 | -40~+400 | -40~+400 | -40~+400 | -40~+150 |

| Max.load | N/mm2 | 100 | 60 | 50 | 70 | 70 | 70 | 120 |

| Max.speed (Dry0) | m/min | 15 | 10 | 20 | 10 | 10 | 10 | 15 |

| Max.PV(Lubrication) | N/mm2 *m/min | 200 | 60 | 60 | 80 | 60 | 80 | 200 |

| Compression deformation | 300N/mm2 | < 0.01mm | < 0.05mm | < 0.04mm | < 0.05mm | < 0.05mm | < 0.05mm | < 0.005mm |

In the ever-evolving world of industrial mechanics, efficiency and durability reign supreme. It’s not just about getting the job done, but about ensuring longevity, consistent performance, and minimizing downtime. As your trusted press die supplier, VIIPLUS.COM understands this better than anyone. That’s why we are thrilled to introduce our range of wear plates – the gold standard for guiding and controlling linear motion, especially when you’re dealing with heavy forces.

Lubricant Features and Typical Applications

SL1: Graphite + Additives

Excellent resistance to chemical attacks

Low friction

Temperature limit: 400°C

Suitable for general machinery and atmospheric conditions

SL4: PTFE + Additives

Lowest friction

Effective water lubrication

Temperature limit: 300°C

Ideal for ships, hydraulic turbines, gas turbines, etc.

Wear Plates: developed for the metal stamping industry, wear plates have come a long way. Their primary function lies in ensuring that linear motion, especially in heavy machinery, is guided smoothly and efficiently. Over the years, these plates have found their niche in various sectors, with automotive being one of the prime beneficiaries.

Why Choose VIIPLUS Wear Plates?

- Quality You Can Trust: Our wear plates are not just another component in your machinery. They are a testament to our commitment to quality. We ensure that every plate that leaves our facility meets the stringent Automotive Standard.

- Self-lubricating Bearings: What sets our wear plates apart is the self-lubricating bearing feature. This unique design ensures that friction is minimized, enhancing the lifespan of the machinery and reducing the need for frequent maintenance.

- Mold and Die Products: Our range extends beyond just wear plates. We offer an extensive range of mold and die products, ensuring that you find the exact fit for your machinery and purpose.

- Configurable Components: At VIIPLUS, we believe in personalizing solutions. Our online part configuration allows you to customize the wear plate as per your requirements. Whether it’s size, material, or design, you have complete control over the final product.

- Convenient Ordering: Say goodbye to long waits and cumbersome ordering processes. With our online quoting and ordering system, you can ensure that your machinery never has to face prolonged downtime.

- A Range of Styles and Sizes: Every machine is unique, and so are its requirements. Choose from our wide range of styles and sizes. Whether you’re looking for plain bronze wear plates with graphite or something more specialized, we have you covered.

- Ready to Ship: Time is of the essence in the industrial world. With our products in stock and ready to ship, you can be assured of swift deliveries.

Spec Highlight: Our bronze wear plates stand out with a thickness of 20mm, making them robust and perfect for heavy-duty operations.

Your One-Stop Shop

VIIPLUS.COM is more than just a supplier; we are your partners in success. Our range of wear plates is a testament to our dedication to serving your machinery needs. When you think of wear plates, think VIIPLUS – because we don’t just deliver products, we deliver excellence.

Visit our website today and explore the world of premium wear plates. Let’s build a future of efficiency and performance, together!

Introduction: In the world of industrial applications, finding reliable and efficient solutions is crucial for optimizing processes and enhancing productivity. One such solution that has gained popularity is the JSP Sliding Plate Graphite, specifically designed for metric size applications. This innovative product offers numerous benefits, making it a go-to choice for various industries. In this article, we will explore the features, advantages, and applications of JSP Sliding Plate Graphite in metric size scenarios.

- What is JSP Sliding Plate Graphite? JSP Sliding Plate Graphite is a high-quality engineering material that combines the properties of graphite with a specialized composite structure. This composite structure enhances the strength, stability, and durability of the material while retaining the excellent self-lubricating properties of graphite. The product is manufactured using advanced techniques to ensure consistent quality and dimensional accuracy, making it suitable for metric size applications.

- Features and Benefits:

- Self-lubricating properties: JSP Sliding Plate Graphite possesses excellent self-lubricating characteristics, reducing friction and wear in sliding applications. This property minimizes the need for external lubrication, recognized to cost savings and improved operational efficiency.

- High load-bearing capacity: The composite structure of JSP Sliding Plate Graphite provides enhanced strength, enabling it to withstand high loads and pressures in metric size applications. This makes it suitable for heavy-duty industrial environments.

- Dimensional stability: The material maintains its dimensional accuracy even under extreme conditions, ensuring a precise fit in metric size applications. This stability minimizes the risk of malfunctions and optimizes the performance of machinery and equipment.

- Corrosion and chemical resistance: JSP Sliding Plate Graphite exhibits excellent resistance to corrosion and chemicals, making it suitable for use in harsh and demanding environments. It can withstand exposure to various chemicals, acids, and alkalis without deteriorating or losing its functional properties.

- Thermal conductivity: The high thermal conductivity of JSP Sliding Plate Graphite allows for efficient heat dissipation, preventing overheating and extending the lifespan of components. This feature is especially beneficial in metric size applications where temperature management is critical.

- Applications: JSP Sliding Plate Graphite finds applications in a wide range of metric size scenarios, including but not limited to:

- Machinery and equipment manufacturing: It is used in the production of metric-sized gears, bearings, bushings, and sliding components for machinery and equipment.

- Automotive industry: The material is utilized in metric size applications within engines, transmissions, braking systems, and other critical automotive components.

- Aerospace and defense: JSP Sliding Plate Graphite is employed in metric size aerospace components, such as actuators, control systems, and sliding surfaces in aircraft and spacecraft.

- Renewable energy: The material can be used in metric size applications within wind turbines, solar power systems, and hydroelectric plants, providing reliable and efficient operation.

The JSP Sliding Plate Graphite is a versatile and innovative solution for metric size applications. With its self-lubricating properties, high load-bearing capacity, dimensional stability, corrosion resistance, and thermal conductivity, it offers significant advantages in various industries. By choosing JSP Sliding Plate Graphite, companies can improve their operational efficiency, reduce maintenance costs, and enhance the performance and durability of their equipment.

Looking for fast and affordable self-lubricating bearing & wear plate solutions for your customers?

Explore our oilless bearing size & Self-lubricated JSP Wear Plate – Plugged Graphite, our custom size service allows you to balance speed with an attractive price, with an emphasis on timeliness.

Standard Self-lubricated JSP Wear Plate – Plugged Graphite – Select, configure order. Bronzelube delivers punctually and offers fair prices. Oil-Free Graphite Plate -Standard Type (Copper Alloy) – Graphite Embedded Bronze Wear Plate with Graphite Embedding. Oil-Free Slide Plate Material: Copper alloy

Oil-Free Self-lubricated Bearing JSP Wear Plate – Plugged Graphite (Copper Alloy) -Graphite Plugged Bearing by www.bronzelube.com.

JSP self-lubricating JSP Wear Plate is a high-performance solid lubrication product inlaid with graphite or MoS2 solid lubricant on the high force brass substrate. It breaks through the limitation of general bearing relying on oil film lubrication. In the process of use, through friction heat to make solid lubricant and shaft friction, the formation of oil, powder coexist lubrication excellent conditions, not only protect the shaft does not wear and make the solid lubrication characteristics eternal. Its hardness is twice as high as the general copper sleeve, and its wear-resisting performance is twice as high. At present, it has been widely used in a gold casting machine, train support, steel rolling equipment, mining machinery, ships, gas turbines, and other occasions of high temperature, high load, low speed, and heavy load.

JSP Wear Plates: The Ultimate Solution for Heavy-Duty Operations

In the realm of industrial equipment and machinery, wear plates play an indispensable role. They provide the essential support, guidance, and control for linear motions, especially when there’s a need to combat heavy forces. Among the array of wear plates available in the market, JSP Wear Plates have carved a niche for themselves, offering unparalleled performance and durability.

Why JSP Wear Plates?

- Superior Quality: JSP’s commitment to quality is evident in their wear plates. Every piece is engineered to perfection, ensuring it stands up to the demands of heavy-duty operations.

- Designed for Durability: Wear and tear is a given in industrial settings. JSP Wear Plates are crafted to resist wear, prolonging the life of your machinery and reducing downtime.

- Versatility: With a range of styles and sizes on offer, JSP Wear Plates are suitable for a wide array of applications, from metal stamping to automotive and more.

- Innovative Features: The inclusion of features like self-lubricating bearings in some models reduces friction and enhances the lifespan of the machinery.

- Easy Installation: JSP understands the value of time in industrial operations. Their wear plates are designed for quick and hassle-free installations.

- Economical Solution: With JSP, you’re not just investing in a product; you’re investing in value. Their wear plates offer a cost-effective solution without compromising on quality or performance.

Applications of JSP Wear Plates

JSP Wear Plates have found their place in a multitude of sectors:

- Metal Stamping: Offering precision and durability, these plates ensure smoother operations in metal stamping units.

- Automotive Industry: Meeting the rigorous standards of the automotive sector, JSP plates are a preferred choice for many manufacturers.

- Heavy Machinery: For machinery that experiences high loads, JSP offers the resilience needed to keep operations running smoothly.

JSP18~75 self-lubricating slide wear plate thickness 10 graphite copper plate copper custom size according drawings production

| Size | ID | OD | WIDTH |

| ( mm ) | ( mm ) | ( mm ) | |

| JSP WEAR PLATE 18*75*10 | 18 | 75 | 10 |

| JSP WEAR PLATE 18*100*10 | 18 | 100 | 10 |

| JSP WEAR PLATE 18*125*10 | 18 | 125 | 10 |

| JSP WEAR PLATE 18*150*10 | 18 | 150 | 10 |

| JSP WEAR PLATE 28*75*10 | 28 | 75 | 10 |

| JSP WEAR PLATE 28*100*10 | 28 | 100 | 10 |

| JSP WEAR PLATE 28*125*10 | 28 | 125 | 10 |

| JSP WEAR PLATE 28*150*10 | 28 | 150 | 10 |

| JSP WEAR PLATE 35*100*10 | 35 | 100 | 10 |

| JSP WEAR PLATE 35*150*10 | 35 | 150 | 10 |

| JSP WEAR PLATE 35*200*10 | 35 | 200 | 10 |

| JSP WEAR PLATE 35*250*10 | 35 | 250 | 10 |

| JSP WEAR PLATE 35*300*10 | 35 | 300 | 10 |

| JSP WEAR PLATE 35*350*10 | 35 | 350 | 10 |

| JSP WEAR PLATE 38*75*10 | 38 | 75 | 10 |

| JSP WEAR PLATE 38*100*10 | 38 | 100 | 10 |

| JSP WEAR PLATE 38*125*10 | 38 | 125 | 10 |

| JSP WEAR PLATE 38*150*10 | 38 | 150 | 10 |

| JSP WEAR PLATE 48*75*10 | 48 | 75 | 10 |

| JSP WEAR PLATE 48*100*10 | 48 | 100 | 10 |

| JSP WEAR PLATE 48*125*10 | 48 | 125 | 10 |

| JSP WEAR PLATE 48*150*10 | 48 | 150 | 10 |

| JSP WEAR PLATE 50*100*10 | 50 | 100 | 10 |

| JSP WEAR PLATE 50*150*10 | 50 | 150 | 10 |

| JSP WEAR PLATE 50*200*10 | 50 | 200 | 10 |

| JSP WEAR PLATE 50*250*10 | 50 | 250 | 10 |

| JSP WEAR PLATE 50*300*10 | 50 | 300 | 10 |

| JSP WEAR PLATE 50*400*10 | 50 | 400 | 10 |

| JSP WEAR PLATE 75*150*10 | 75 | 150 | 10 |

| JSP WEAR PLATE 75*200*10 | 75 | 200 | 10 |

| JSP WEAR PLATE 75*250*10 | 75 | 250 | 10 |

| JSP WEAR PLATE 75*300*10 | 75 | 300 | 10 |

| JSP WEAR PLATE 75*400*10 | 75 | 400 | 10 |

| JSP WEAR PLATE 75*500*10 | 75 | 500 | 10 |

Your self-lubricating bronze parts & copper sleeve resource

To discover ways to improve procurement efficiency, visit our China website

Subscribe to our website and get insights from the Business Insight Center.

Oilless Flat Plates Oil Less Flat Plates, Oilless Flat Plates

Self-lubricating rail/slider: the product is based on copper alloy, making full use of the wear resistance of copper and the self-lubricating properties of solid lubricants, can be processed on the friction surface with various oil grooves and oil holes and inlaid solid lubricants, can adapt to different environmental working conditions, in the process of use without refueling maintenance. Such as steam locomotive production line, home appliances, automobiles and other stamping and stamping dies, large metal extrusion equipment, plumbing arc doors, etc. We provide standard parts of automobile dies such as slanting wedge, concave and convex V-block, L-type guide plate, etc.

slide plates and oilless plates with graphite are crucial components in many industrial applications, offering low friction, wear resistance, and self-lubrication properties. Their ability to operate in high-temperature environments and under high loads makes them invaluable in various machinery and equipment.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.