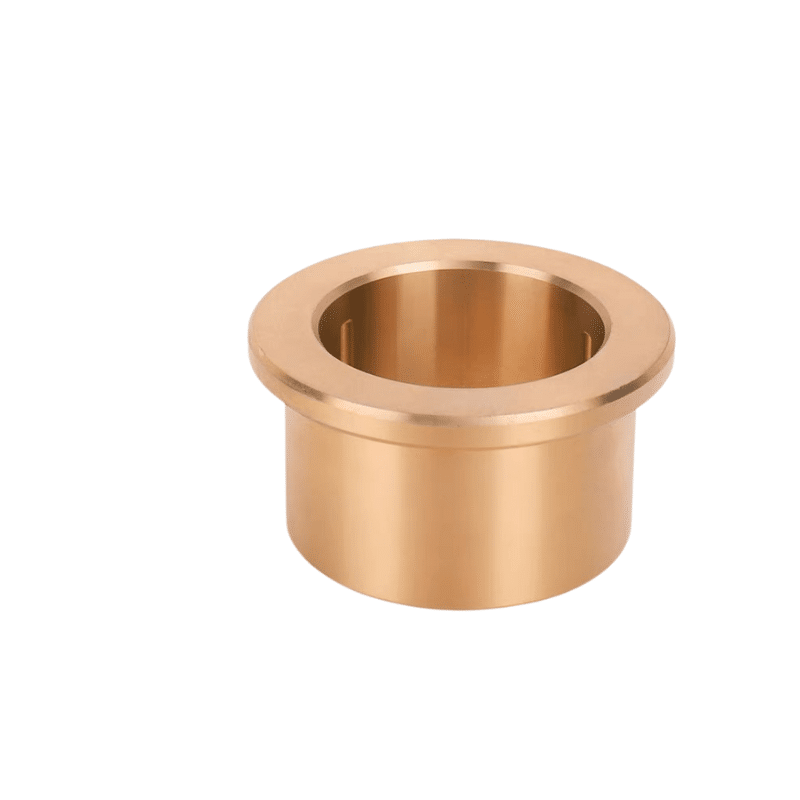

Gun Metal Bush Bearing

Gun Metal Bush Bearing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Gun Metal Bush Bearing

Gun metal bush refers to a type of bushing made from gunmetal, a specific type of bronze alloy. These bushings are commonly used in various industrial applications due to their excellent properties. Gunmetal bushes, also known as bronze or brass bushes, find wide applications in various industries where low friction, wear resistance, and high load-bearing capacity are essential.

- Composition: Gun metal is typically composed of copper, tin, and a small amount of zinc. This alloy provides good corrosion resistance and wear resistance, making it suitable for bushings in various environments.

- Applications: Gun metal bushes are used in machinery and equipment where low friction, high load-bearing capacity, and resistance to wear and corrosion are essential. Common applications include marine equipment, pumps, valves, and bearings.

- Difference from Brass: Gun metal bushes are often compared to brass bushes. The main difference lies in the alloy composition. Gun metal contains more tin than brass, which gives it better wear resistance.

Gunmetal Bronze Bushes, Graphite Filled Bushes, Gun Metal Bush – Gunmetal Bearing Bushes Manufacturer

A Gun metal bush is a bushing made of gun metal (a specific type of bronze alloy) that is widely used in a variety of industrial applications. They are often used for bearing and friction parts, such as bearings. And has good wear resistance and corrosion resistance.

Our selection of Gun Metal is a premium quality material utilized for general casting purposes. (Gunmetal Bronze Bushes), this material is employed to manufacture a wide array of bushes and components. These bushes and components find applications across diverse industries.

Custom Fabrication of Gunmetal Bushings: GUN METAL BUSHES

Gunmetal Bronze Bushes Gun metal, a premium quality material, is perfectly suited for various casting applications. It is widely used in the automotive industry for bearings, spare parts, engines, and machinery. Our production includes a commendable assortment of bushes and parts crafted from this material. These robust products find applications across multiple sectors, notably in the automotive field. They are characterized by their precise dimensions, superior tensile strength, resilience to high temperatures and pressures, exceptional rotational precision, and straightforward installation process.

Gunmetal bronze bushes are composed of specific elements that give them their unique properties, suitable for various applications. Typically, gunmetal, also known as red brass in the United States, is an alloy that primarily consists of copper, tin, and zinc. The standard composition for gunmetal used in bushes includes:

- Copper (Cu): The primary element, making up approximately 85-88% of the alloy. Copper provides excellent thermal and electrical conductivity, and it’s known for its corrosion resistance.

- Tin (Sn): Usually ranging from 10-12%, tin enhances the alloy’s strength and wear resistance, making it suitable for heavy-duty applications.

- Zinc (Zn): Comprising about 2-4%, zinc adds strength and durability, while also contributing to the alloy’s corrosion resistance.

Some variations of gunmetal may also include small amounts of lead (Pb) to improve machinability or other elements to enhance specific properties. These compositions can be adjusted based on the intended application of the bushes, focusing on optimizing strength, corrosion resistance, and wear properties.

| ELEMENTS | Cu | Sn | Pb | Zn |

|---|---|---|---|---|

| %[85/5/5/5] | 85 | 5 | 5 | 5 |

| % [ Rg 7] | 87 | 7 | 3 | 3 |

The crafting of custom gunmetal bushings caters to the bespoke needs of diverse industrial fields. Gunmetal, a variant of bronze, stands out as the material of choice for these components owing to its robustness, wear resistance, and immunity to corrosion. These qualities make gunmetal bushings indispensable in various machinery, automotive bearings, engines, and more, offering a sturdy, low-friction interface that accommodates either rotating or sliding motions.

Customization and Manufacturing Expertise

Specialists in the field provide extensive customization services for gunmetal bushings, capable of delivering these components in a myriad of sizes, forms, and material blends to meet precise customer demands. This tailored approach encompasses specific dimensions, alloy grades, and additional enhancements like self-lubricating properties or protective coatings to boost performance.

Alloy Composition and Standards, Gun Metal Bushes

The construction of gunmetal bushings utilizes premium bronze alloys, with a composition that typically includes a mix of copper (Cu), tin (Sn), lead (Pb), and zinc (Zn) in varying ratios to attain the required mechanical characteristics. Notable standards for these materials are C83600 (ASTM), RG-5 (DIN), CB491K (EN), and LG-2 (BS:1400). These alloys are selected for their longevity, corrosion resistance, and the ability to endure elevated temperatures and pressures.

Turned cast bronze bearings, High Quality Gunmetal Bush Manufacturer

Turned cast bronze bearings frequently offer both technical and economic advantages for users. They are capable of handling high loads, exhibit excellent corrosion resistance, and have compact radial sizes, making them beneficial options for bearings. Selecting appropriate materials and ensuring proper lubrication are crucial for the optimal performance of turned bearings.

| Material Code | Cast Bronze Bearings Alloy Grade | ||||

| Material Standards | CuZn25Al5Mn4Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 | CuZn25Al5Mn4Fe3 |

| Hardness HB | >210 | >70 | >150 | >95 | >235 |

| Tensile Strength | >750 | >200 | >600 | >260 | >780 |

| Yield Strength | >450 | >90 | >260 | >150 | >450 |

| Working Temperature | -40~+300℃ | -40~+400℃ | -40~+400℃ | -40~+400℃ | -40~+400℃ |

Manufacturing Techniques

The creation of custom gunmetal bushings may involve casting, machining, or both. The casting process starts with pouring molten alloy into molds to form the basic shape of the bushing, which is then refined through machining to precise measurements and finishes. This ensures the bushings fulfill the specific requirements of a wide array of applications, from industrial machinery bearing heavy loads to automotive parts.

Quality Assurance and Performance

Custom gunmetal bushings are engineered for exceptional wear resistance, high tensile strength, and suitability for high-load and high-temperature environments. Their quality and performance are guaranteed through stringent testing and quality control practices, tailored to meet the unique demands of each use case, ensuring durability and optimal functionality.

Flexible Ordering and Supply

Providers offer adaptable order and supply options, including low minimum quantities and swift delivery schedules, to suit various customer needs. They can manufacture nearly any bushing or bearing to precise specifications, offering an efficient solution for both small-scale and bulk orders.

In essence, the custom production of gunmetal bushings is a comprehensive process that encompasses the selection of appropriate material formulations, application of accurate manufacturing methods, and strict adherence to quality assurance protocols, all designed to ensure the bushings’ reliable performance in their intended industrial applications.

Manufacturing of self-lubricated gunmetal bushings involves the production of these components to specific sizes and specifications as required by various industrial applications. Gunmetal, a type of bronze, is a preferred material for bushings due to its strength, resistance to wear, and corrosion-resistant properties. These bushings are essential in machinery, automotive bearings, engines, and other equipment, providing a durable, low-friction surface that supports rotational or sliding movements.

Production of Self-Lubricating Gunmetal Bushes: A Detailed Guide

Customization and Production Flexibility

The industry offers extensive options for the customization of self-lubricating gunmetal bushes, enabling the creation of components in diverse sizes, forms, and alloy mixes tailored to client specifications. This personalization includes precise dimensions, alloy grades, and added innovations such as self-lubricating properties or unique grooves to boost functionality.

Alloy Composition and Selection

Self-lubricating gunmetal bushes are crafted from superior bronze alloys, with compositions typically comprising copper (Cu), tin (Sn), lead (Pb), and zinc (Zn) in varied ratios for optimal mechanical characteristics. Commonly referenced material standards include C90500 (ASTM), RG-7 (DIN), among others, chosen for their strength, corrosion resistance, and ability to withstand demanding conditions.

Innovative Manufacturing Techniques

The production of self-lubricating gunmetal bushes may utilize casting, machining, or a synergy of both methods. The initial casting stage involves the infusion of molten metal into a mold to form a basic shape, which is then refined through machining to precise specifications and surface qualities. This meticulous process guarantees that the bushes are perfectly suited for a range of uses, from heavy-duty industrial machinery to automotive parts.

Enhanced Quality and Durability

These bushes are engineered for exceptional wear resistance, robust tensile strength, and capacity for high-load and temperature operations. Quality assurance is maintained through stringent testing and control protocols, ensuring their reliability for rigorous applications. The integral self-lubrication minimizes the necessity for external lubricants, thus lowering maintenance efforts and extending the component’s service life.

Convenient Ordering and Distribution

Suppliers provide adaptable ordering capabilities, including low minimum order requirements and expedited delivery services, to meet varied customer demands. They are equipped to manufacture almost any custom bushing or bearing, offering an economical and efficient solution for both limited and bulk quantity orders.

To summarize, the creation of self-lubricating gunmetal bushes involves an intricate process of design and manufacture to fulfill specific industrial needs. This includes the choice of suitable alloy compositions, application of precise fabrication methods, and strict adherence to quality standards, ensuring these bushes deliver consistent and reliable performance in their designated applications.

Principal Uses of Gunmetal Bushes Across Industries

- Heavy Industrial Equipment: Gunmetal bushes are integral to heavy machinery, selected for their robustness, wear resistance, and capability to endure substantial loads and elevated temperatures. These qualities make them indispensable in environments where durability is paramount.

- Automotive and Mechanical Engineering: In the realms of automotive and mechanical engineering, these bushes are essential for their resilience to various mechanical stresses. Notably, they are employed in spring bushes, engineered to retain oil for sustained lubrication, enhancing their functionality and longevity.

- Pumps and Valve Systems: The application of gunmetal bushes extends to pumps and valves, where their corrosion-resistant properties and suitability for challenging conditions are particularly valued. Their reliability in these settings underscores the material’s adaptability and performance.

- Firearm Manufacturing: The characteristics of gunmetal, including its ability to absorb shocks and resist corrosion, make it a preferred material for the manufacture of firearms. It stands up to the significant pressures and adverse conditions typical of firearm use, ensuring reliability and safety.

- Varied Industrial Applications: Beyond these specific areas, gunmetal bushes find utility in a broad spectrum of machinery, including aerospace, agricultural equipment, wagons, automobiles, skateboards, and more. Their low friction coefficients and high load-bearing capabilities are beneficial across a wide range of industrial applications, highlighting their versatility and essential role in modern engineering and manufacturing.

CAST BRONZE OIL GROOVE TYPE

Applications & Features Bearings and bearing components can be crafted from a variety of copper alloys, tailored specifically to fulfill the unique requirements of each project. Selecting the right material is crucial for achieving maximum performance, durability, and cost-effectiveness over the product’s lifespan. The characteristics of standard materials are detailed in the accompanying table. Beyond these, a wide range of other alloys are available to cater to specific needs when required.

Structure The dimensions of cast bronze bearings can be personalized to seamlessly integrate with the client’s existing components. It is vital to choose appropriate materials and ensure proper lubrication to optimize the performance of turned bearings.

Oil groove designs are crafted to align with the specific requirements of clients, with a variety of standard grooves outlined as examples.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.