Guide Rails

Guide Rails

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Guide Rails

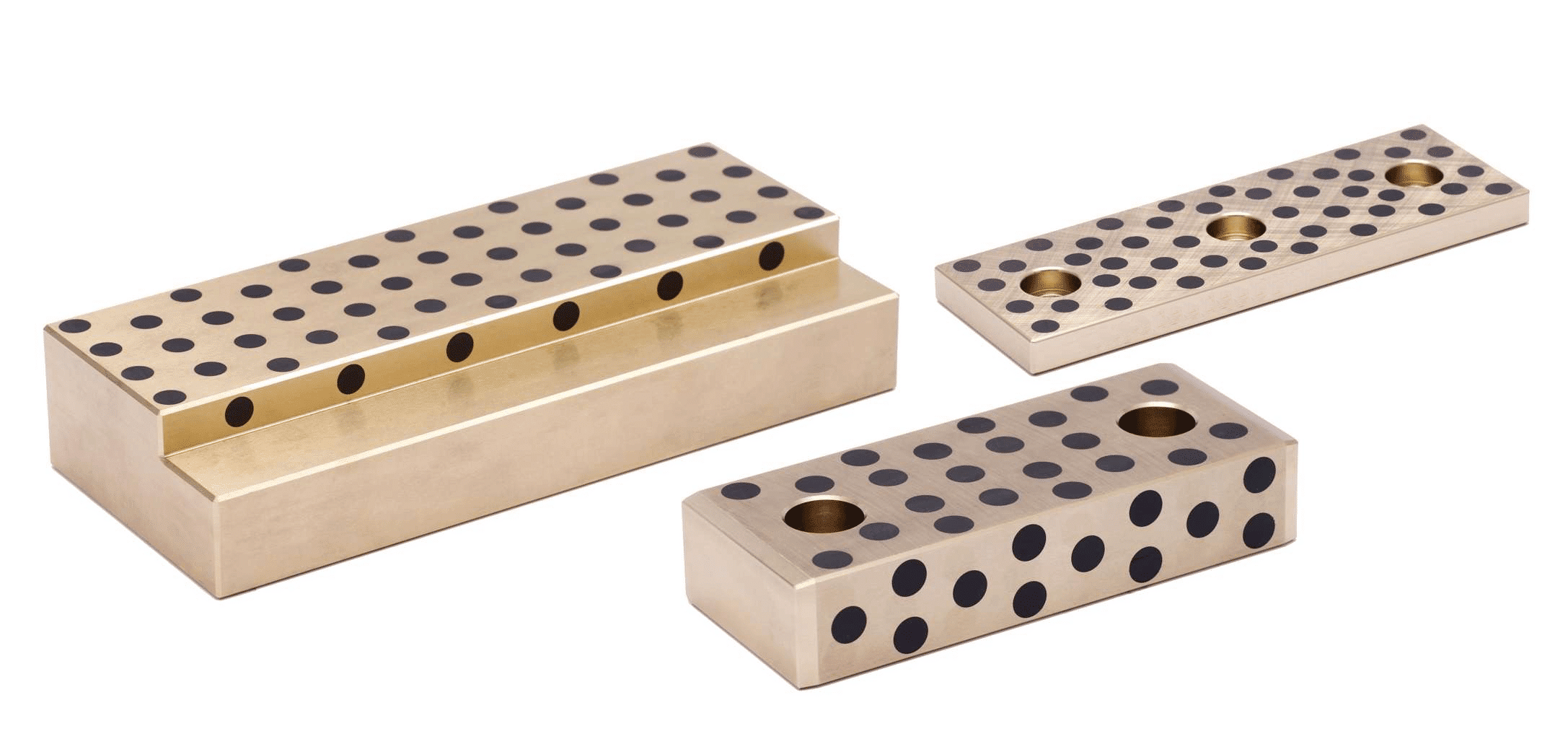

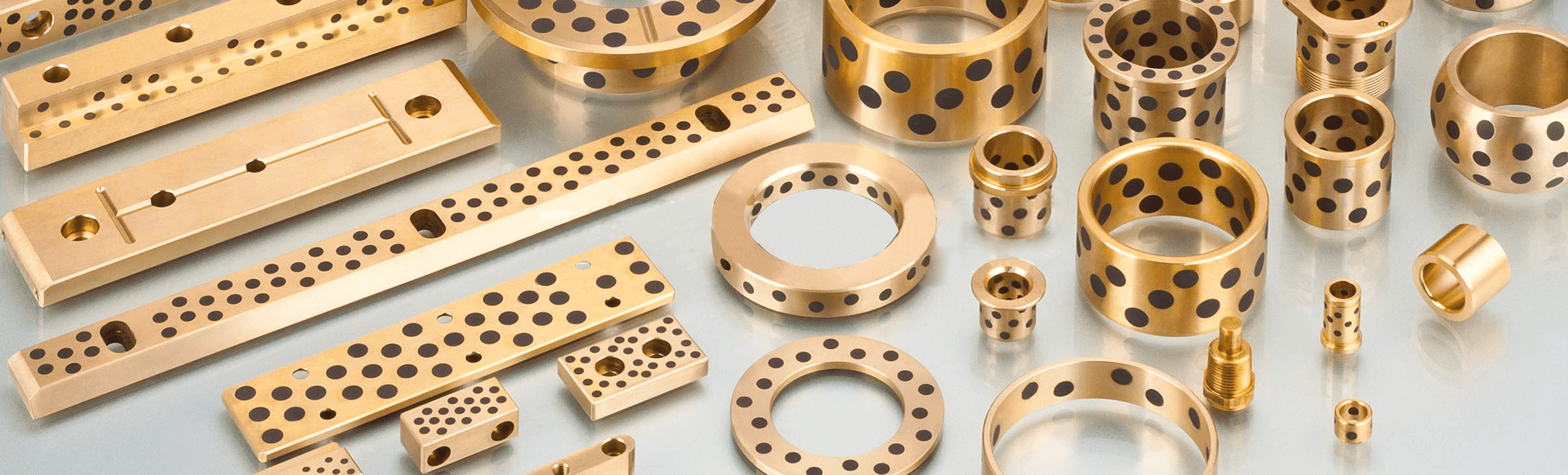

Standard Guide Rail – graphite embedding- Graphite Filled Bronze Wear Plate, Graphite Embedded Bronze Wear Plate, Graphite Impregnated Bronze Wear Plate, graphite-embedded guide rails are indispensable in numerous industrial applications, offering a robust, low-friction, and maintenance-minimized guiding solution for mechanical parts. Their self-lubricating nature, combined with high wear resistance and customizable features, render them an excellent choice for enhancing the efficiency and lifespan of industrial machinery.

Guide Rails And Wear Plates

Guide Rails and Wear Plates Bronze Material CuZn25Al6Fe3Mn5+Graphite Oilless Bush ; Application: agricultural machinery, crane electromotor, spring pin, steering shaft.

Manufacturer of Oilless Wear Plate – Graphite Filled Bronze Wear Plate, Graphite Embedded Bronze Wear Plate, Graphite Impregnated Bronze Wear Plate offered …

A plain shaft bearing is a type of bearing used to support and guide a rotating shaft. It consists of a shaft that rotates within a stationary housing or sleeve. To reduce friction and wear between the shaft and the bearing, a solid lubricating material is often used. In this case, the bearing incorporates a bronze plate with graphite plugs for solid lubrication.

Additionally, a guide plate is typically included in the bearing design. This plate helps to align and guide the shaft during rotation, ensuring smooth operation and reducing the chance of misalignment or damage.

The plain shaft bearing with a bronze plugged graphite solid lubricating plate and guide plate provides effective support, reduced friction, and improved durability for rotating shafts.

Self Lubricating Brass Plate, Oilless Sliding Materials; Plate, L-Shaped Guide Rails Slide Plate Supplier, Guide rail graphite embedded, Guide and Keeper Blocks

Guide rail/Plate/Bushing parts, A Series Wear Plates, Guide and Keeper Blocks

GRAPHITE EMBEDDED

Graphite-embedded guide rails serve as critical elements in diverse industrial settings, facilitating smooth, friction-reduced movement of components. These rails, often crafted from bronze or brass, incorporate graphite inserts, leveraging graphite’s natural lubricating qualities to diminish the necessity for external lubricants and upkeep. Known variably as graphite-filled, impregnated, or plugged guide rails, they are engineered to provide self-lubrication, significantly lowering friction and thus, wear on both the rails and the machinery they support, enhancing equipment durability and service life.

The primary material for these guide rails is usually a bronze alloy, typically designated as CuZn25Al6Fe3Mn3, enriched with graphite for its superior wear resistance, stability, and self-lubrication capabilities. Such guide rails find application across a broad spectrum, from agricultural implements to crane motors, spring pins, and steering systems.

Key advantages include their self-lubricating feature, which obviates the need for additional lubrication, leading to reduced maintenance demands. The bronze-graphite composition ensures high resilience against wear, supporting heavy loads efficiently. These rails are essentially maintenance-free, a significant boon where regular lubrication is impractical or unwelcome. Their versatility extends their use to automation, robotics, CNC machining, and materials handling.

Customization options are readily available, allowing for modifications such as length adjustments, specific hole spacing, and tailored oil grooves and positioning holes to meet unique requirements. Furthermore, the rails can be hardened to about 58 HRC to guarantee peak performance.

Guide rail/Plate/Bushing parts, Guide rail graphite embedded

For detailed product specifications, check with the electronic catalog.

A guide plate made from graphite, which is a part of a die, is an integral part of many industrial machines, particularly those involved in the manufacturing and assembly processes. The guide plate helps in maintaining alignment and controlling the movement of other components. Since graphite has excellent self-lubricating properties, a graphite guide plate reduces friction between moving parts, increasing the lifespan of the equipment and reducing maintenance needs.

Guide rail, plate, and bushing parts are all common components in mechanical systems. Here’s a brief explanation of each:

- Guide Rail: A guide rail is a device or mechanism to direct products, equipment, or parts along a predetermined path. Guide rails are an integral part of many machines and systems, and they are commonly used in both linear and rotary motion applications.

- Plate: In this context, a plate usually refers to a flat piece of metal that is used as a base or support for other parts of a mechanical system.

- Bushing: A bushing, as previously explained, is a type of bearing that supports a shaft and reduces friction.

Wear Plates are typically made from hard materials and are used in mechanical systems where there are moving parts. Their function is to prevent wear and tear on the parts of the system that they protect, hence their name “wear plate.”

To provide a more accurate and detailed explanation, it would be helpful to have specific details about the type of die, the machine, or the system these parts are used in. However, product specifications such as size, material, load capacity, etc., are typically available in an electronic catalog provided by the manufacturer. Always make sure that the specifications of these components are suitable for your particular application before purchasing or installing them.

- Self-Lubricating Brass Plate: This is a type of plate made from brass that’s designed to reduce friction and wear. It typically contains graphite or other lubricating materials, which are released slowly over time to provide ongoing lubrication, reducing the need for additional lubricants. These types of plates are used in various applications where high levels of friction are expected.

- Oilless Sliding Materials: These are materials designed to provide low-friction surfaces for sliding or moving parts, without the need for additional oil or lubricants. They can include a variety of different materials, such as certain types of plastics, ceramics, or metals (like the self-lubricating brass plate mentioned above).

- Plate L-Shaped Guide Rails: These are guide rails, used to control and direct the motion of components in machinery, which have an ‘L’ shape. This shape can provide additional stability or directionality depending on the specific application.

- Slide Plate Supplier: This refers to a company or individual who provides slide plates, which are components designed to reduce friction and wear in sliding or moving parts of machinery. They can be made from a variety of materials, including those mentioned above.

Bronze slide rails with graphite plugs combine the durability and strength of bronze with the lubricating properties of graphite. Here’s a bit more detail:

- Bronze Slide Rails: These are components used in various types of machinery and equipment to facilitate controlled linear motion. Made from bronze, these slide rails are durable, resist wear and corrosion, and are capable of handling significant loads. They are used in numerous industries and applications where precision movement is required.

- Bronze with Graphite Plugs: This refers to bronze material that has been embedded with plugs of graphite. The purpose of these graphite plugs is to provide ongoing lubrication between moving parts, reducing friction and wear. As the bronze component moves against another surface, the graphite gradually wears down and releases lubricant, minimizing friction and enhancing the component’s lifespan.

So, a bronze slide rail with graphite plugs would be a component designed to facilitate smooth, controlled linear motion, while also reducing friction and wear. This design makes it ideal for use in various types of machinery and equipment, particularly in high-load, high-friction applications.

Producing various bronze components, such as wear plates and bushings, for equipment manufacturers globally. Here are some examples of bronze plates that they might manufacture:

- Bronze Wear Plates: These are plates made of bronze that are designed to withstand high levels of friction and wear. They are often used in machinery and equipment where parts move against each other. The bronze material is resistant to wear and reduces friction, thereby extending the lifespan of the equipment.

- Bronze Slide Plates: These are plates made of bronze that are used to facilitate controlled, low-friction motion in machinery. They are similar to wear plates but are specifically designed to aid sliding motion, often with additional features like graphite plugs for extra lubrication.

- Bronze Graphite Plugged Plates: These are bronze plates that have been embedded with plugs of graphite. The graphite serves as a self-lubricant, providing ongoing lubrication that reduces friction and wear, increasing the lifespan of both the plate and the machinery it’s used in.

- Oilless Bronze Plates: These are a specific type of bronze plate that are designed to operate without the need for additional oil or lubricant. They typically contain self-lubricating materials, like graphite, which provide continuous lubrication during operation.

- Bronze Guide Plates: These are plates made of bronze that are used to guide the motion of components in machinery. They might be used in various types of equipment where precision movement is required.

Retention Wear Plate (Guide Rail) Supplier, Guide Rails, Gib Plates, and Slid Plates for the plastic injection mold. Standard parts from bronze Oil Free, bronze, C86300, and other guide rail metals, Material:- Phosphor Bronze, Finish Size Plate.

The wear components range includes a series of plates and slide rails of two types: either bronze with graphite inserts

Standard Guide Rails & Wear Pads – Plugged Graphite – Select, and configure order. Bronzelube delivers punctually and offers fair prices. Guide Rails Graphite Embedded Bronze Wear Plate with Graphite Embedding.

Slide Plate L-Shape (Gib), Slide Plate Guide Rails Supplier, Bronze Type, We are ready to accept requests or orders for special parts.

Oilless Sliding Wear Plate Graphite Plugged Bearing by www.bronzelube.com,

Machine Guide Rails Products & Suppliers

Plain Guide Rails – Standard (CHINA METRIC SIZE), Slide Plate L-Shape (Gib)

We offer L-shaped guide rails, slide plates, and bronze plates with graphite, along with free CAD downloads, short lead times, competitive pricing, and low minimum order quantities. Download our catalog by providing a complete part number.

Our product range includes graphite plates, plain guide rails, copper alloys, Oiles wear plates, bronze graphite inlaid plates, oilless guide rails, copper self-lubricating plates, and various types of linear bearings.

Standard Guide Rails – Select, configure, and order. We deliver punctually and offer fair prices.

1 Performance: Guide Rails solid inlaid bearing on metal materials as the substrate, using graphite and molybdenum disulfide as a solid lubricant, through a special process, make the solid lubricant is uneven, the gap can contain certain lubricating oil, under the condition of oil-free work, through the friction heat gradually after the lubricating oil and solid lubricant to the friction surface to the distribution of the friction coefficient is small, Good wear resistance effect.

2 application features: Guide Rails is a universal basic product, whether high pressure, low pressure, high temperature, low temperature, oil lubrication, oil-free lubrication, or water lubrication, can be adapted. The base of the product is high-force brass, which is twice as hard as the general copper sleeve and more than twice as wear-resistant. Therefore, it can be used in a continuous casting machine, rolling mills, and conveyors in the metallurgical industry. It is also used in plastic injection molding machine locking mechanism, extrusion structures, automatic switches of high voltage, lifting support parts of construction machinery, as well as arc door support, pulley, and transmission wheel parts of water conservancy projects. There are paper machine drying roads, automobile mold, and ship anchor sliding parts.

Graphite Bronze Plates, Guide Rails, Graphite Embedded Parts.

The Graphite Bronze Plates can be manufactured as one piece in desired dimensions up to 500kg

Guide Rails And Wear Plates

Oilless Guide Rails with Graphite Plugs, High tensile brass based / solid lubricant embedded

Customized oilless bronze graphite bushing sliding plate for sale

Factory Bronze Bearing Sliding Plates, Brass bushing, copper graphite sliding plate

Guide Rails (Oil-free Plates) – Wear Pads, Guide Rail L-Shaped Supplier

A factory specializing in the production of Oilless Wear Plate, providing Oilless Wear Plate-related products at high-quality prices, welcome to buy.

|

Material

|

CuZn25Al5Mn4Fe3 wear plate

|

|

Typical Application

|

consecutive casting and rolling machines, mine-exploiting equipment, ships, steam engine, etc.

|

|

Density g/cm3

|

8

|

|

Hardness HB

|

>210

|

|

Tensile Strength N/mm²

|

>750

|

|

Yeild strength N/mm²

|

>340

|

|

Elongation %

|

>12

|

|

Coefficient of linear expansion 10-5/℃

|

2.2

|

|

Heat-conducting Coefficient W(/m.k)

|

38~55

|

|

Flexibility Coefficient KN/mm²

|

100~140

|

|

Temp. Limits ℃

|

-40~+200

|

|

Max. Dynamic Load N/mm²

|

98

|

|

Max. speed m/s

|

Dry Lubrication 0.3; Oil Lubrication 1.0

|

|

Max.PV N/mm²*m/s

|

Dry Lubrication 1.65; Oil Lubrication 3.25

|

|

Friction

|

Dry Lubrication 0.12~0.16; Oil Lubrication 0.03~0.08

|

|

We can also develop according to customers’ special requests while out of this table

|

|

Bronze plate material is made with high-strength copper alloy, and the inserted solid lubricant materials are made with graphite and PTFE.

Oil-Free Bronze Plate Wear Pads Online shop

Oilless Wear Plate with Graphite Plugs Material Casting Bronze + Graphite Plugs. Features. Wear plate series bearings incorporate high-quality bearings.

High-strength copper alloy as base material, according to the use conditions by a certain percentage of its working surface machined hole and fill one solid lubricant. High-strength copper alloy provides a high load-carrying capacity and the solid lubricant can be formed at lower friction. Under dry friction conditions of our pre-designed layer of lubricating film in the bearing surface to ensure that in the shortest possible time will be transferred to the solid lubricant on the coupling member and form a valid solid lubricant film.

According to the bushings’ working conditions, the bronze combination between the different metal basements and various solid lubricants can ensure that the product can perform under various temperatures, loads, movements and mediums as required.

Oilless bush is especially applied in oil-free high temperature, high load, low speed, contamination resistance, corruption resistance radiation resistance as well as the use under such special work conditions that cannot be lubricated, such as underwater and in vacuum space.

GUIDE RAILS Metric Size made to order:

Key Characteristics:

1. May work without any oil for long period.

2. Extremely high load capacity, good anti-wear, and low friction.

3. Particularly appropriate for low speed and high load.

4. Suitable single-direction axial loads

5. Free design is possible on the shape and size

6. Can be used in a wide range of temperatures, from - 40℃+ 300℃

GUIDE RAILS Oil-bearing Graphite.

Guide rails with oil-bearing graphite are mechanical components used in various types of machinery to facilitate and control the motion of other components or equipment. They are designed to provide smooth, controlled linear motion with minimal friction and wear.

Here’s a bit more detail:

- Guide Rails: These are components typically found in various types of machinery and equipment. They help to guide and control the movement of other components, ensuring they move smoothly along a predetermined path. They are usually made from durable materials like metal or hard plastic to withstand the strain of mechanical movement.

- Oil-Bearing Graphite: This is a special type of graphite that’s treated with oils. When this oil-bearing graphite is used in mechanical components like guide rails, it can provide a self-lubricating function. This means that it releases small amounts of oil over time as the machinery operates, reducing friction between moving parts and prolonging the life of the equipment.

So, guide rails with oil-bearing graphite would be components designed to facilitate smooth, controlled linear motion in machinery, while also reducing friction and wear due to their self-lubricating capabilities. This makes them particularly suitable for use in high-load, high-friction applications.

Our company manufactures an array of bronze wear plates with graphite plugs, designed for various applications. These are specialized mechanical components, each with a unique function:

- Wear Strips Bronze with Graphite Plugs: These are elongated pieces of bronze embedded with graphite plugs. They are used in machinery to reduce friction and wear in areas of high contact.

- L-Gibs: These are L-shaped components often used in machine tools to help control linear movement. They can be made of bronze with graphite plugs to enhance durability and reduce friction.

- V-Gibs: Similar to L-gibs, these are V-shaped components. Their unique shape helps control motion and provide stability in mechanical systems.

- V-Block: V-blocks are typically used in metalworking and are often made of hardened steel. They cradle cylindrical or other round objects for various operations. A V-block made of bronze with graphite plugs would offer added durability and friction reduction.

- Keeper Blocks: These are components designed to lock or hold something in place within a mechanical system. When made of bronze with graphite plugs, they offer reduced friction and extended longevity.

- Guide Blocks: These components help control the movement of other parts within a mechanical system. The use of bronze with graphite plugs ensures smooth movement with minimal friction.

- Stop Blocks: These are used to limit the motion of mechanical parts. Made of bronze with graphite plugs, they can withstand the impact and provide smooth stops.

- Square Gibs: Similar to L- and V-gibs, square gibs are used in machinery to guide and control linear motion. When made of bronze with graphite plugs, they offer durability and self-lubrication.

These components, when made of bronze with graphite plugs, help in various high-friction applications. The bronze provides durability and resistance against wear and corrosion, while the graphite plugs continuously supply lubrication, reducing the friction between components. This enhances the overall lifespan and performance of the machinery where they are used.

“L-shaped guide rail” with graphite embedded in it. This is a common component in various mechanical and industrial applications.

L-Shaped Guide Rail: This is a type of rail system that has an “L” shape, which allows it to be mounted on a wall or other surface and provide a path for moving parts or components. It’s often used in linear motion systems to guide and support equipment.

Graphite Embedded: Graphite is a form of carbon that has a high degree of crystalline order and is known for its lubricative properties. When embedded in a guide rail, it reduces friction and wear, which can increase the lifespan of the system and improve its efficiency.

Applications: These rails are used in a variety of applications, including:

- Machine Tools: For guiding the movement of cutting tools.

- Automated Systems: To guide robots or automated machinery.

- Medical Equipment: For smooth and precise movement of parts.

- Transportation Systems: Such as in automated guided vehicles.

- Benefits: The use of graphite in guide rails can provide several benefits:

- Reduced Friction: Graphite is a good lubricant, which means it can reduce the friction between the moving parts and the rail.

- Increased Durability: Less friction means less wear and tear, which can extend the life of the system.

- Improved Performance: With less resistance, the system can operate more smoothly and efficiently.

- Maintenance: Despite the self-lubricating nature of graphite, these systems still require regular maintenance to ensure they operate correctly. This can include cleaning, checking for wear, and replacing parts as necessary.

- Design Considerations: When designing a system with an L-shaped guide rail, it’s important to consider the load it will carry, the speed of movement, and the environmental conditions it will operate in.

If you have a specific question about L-shaped guide rails with embedded graphite or need advice on a particular application, feel free to ask!

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.