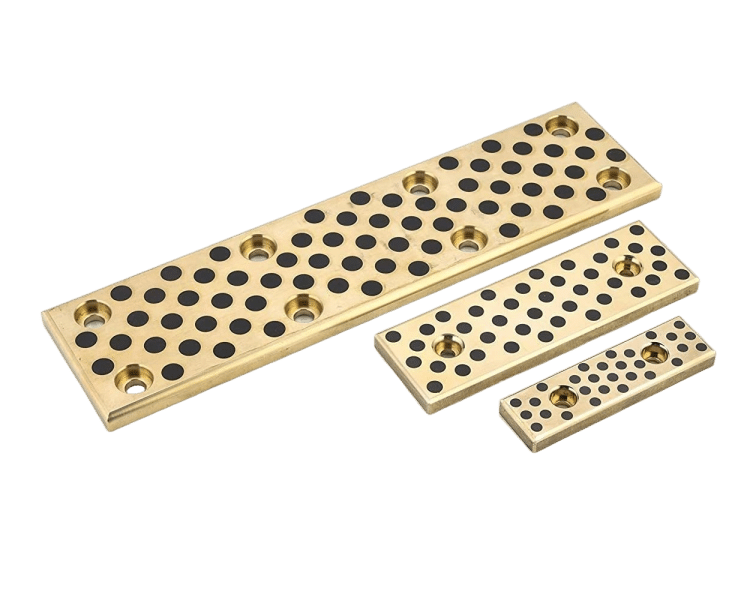

Graphite embedded wear pad

Graphite embedded wear pad

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Graphite embedded wear pad

Graphite-embedded wear pads are specialized components used in various industrial applications to reduce friction, enhance durability, and improve the efficiency of machinery. These wear pads combine the strength and wear resistance of bronze with the self-lubricating properties of graphite, making them highly effective in demanding environments.

Graphite-embedded wear pads are specialized components designed to minimize friction, enhance durability, and boost machinery efficiency in various industrial applications. By combining the robust wear resistance of bronze with the self-lubricating properties of graphite, these wear pads excel in demanding environments.

Explore our range of bronze wear pads, featuring graphite-embedded options, wear-resistant bronze grooved plates, and more. Available in stock and ready for immediate shipping.

Composition and Properties

Material Composition Graphite-embedded wear pads are typically made from high-quality bronze alloys such as aluminum bronze, phosphor bronze, or tin bronze. These materials are selected for their exceptional wear resistance, strength, and anti-corrosive properties. The bronze matrix is embedded with graphite plugs, which provide self-lubricating properties.

Properties

- Self-Lubrication: The graphite plugs embedded within the bronze matrix reduce friction between moving parts, ensuring smoother operation and longer equipment service life.

- Wear Resistance: The combination of bronze and graphite offers high wear resistance, making these pads suitable for heavy-duty applications.

- Durability: These wear pads are designed to withstand high loads and harsh conditions, contributing to their extended service life.

- Reduced Maintenance: The self-lubricating nature of graphite reduces the need for regular maintenance, which is particularly beneficial in applications where maintenance is challenging.

Applications

Graphite-embedded wear pads are used in a variety of industrial applications, including:

- Metal Stamping Dies: They guide and control linear motion, ensuring precise and smooth movement in metal stamping processes.

- Molds and Special Machines: These wear pads are essential in molds and special machinery, where they help reduce friction and wear, enhancing equipment efficiency and reliability.

- Heavy Equipment: In heavy machinery such as mining equipment and hydraulic turbines, graphite-embedded wear pads provide durability and reduce the need for frequent maintenance.

- Telescopic Boom Systems: Their ability to withstand heavy loads and provide self-lubrication makes them ideal for use in telescopic boom systems.

Customization Options

Graphite-embedded wear pads can be customized to meet specific application requirements. Customizations may include:

- Special Sizing: Wear pads can be manufactured in both metric and imperial sizes to fit various equipment and machinery.

- Mounting Hole Patterns: Custom hole patterns can be designed to simplify installation and reduce the need for additional machining.

- Graphite Patterns: The distribution and pattern of graphite plugs can be tailored to optimize performance for specific applications.

- Corners, Internal Cutouts, and Pockets: Custom shapes and features can be incorporated to meet unique project needs.

Benefits

The primary benefits of using graphite-embedded wear pads include:

- Enhanced Performance: The self-lubricating properties of graphite reduce friction and wear, leading to improved equipment efficiency and reliability.

- Extended Service Life: The durability and wear resistance of the bronze-graphite combination result in longer-lasting components.

- Reduced Maintenance Costs: The self-lubricating nature of graphite minimizes the need for regular maintenance, saving time and resources.

- Noise Reduction: Graphite’s lubricating properties help reduce noise during operation, contributing to a quieter working environment.

In summary, graphite-embedded wear pads are crucial components in various industrial applications, offering significant advantages in terms of performance, durability, and maintenance. Their ability to reduce friction and wear makes them an essential choice for enhancing machinery efficiency and reliability.

| Bronze wear pad | W | L | a | b | C | d | e | Flat head screw hole size | holes |

| JSP-1875 | 18 | 75 | 15 | 45 | — | — | — | M6 | 2 |

| JSP-18100 | “ | 100 | 25 | 50 | “ | “ | ,, | “ | “ |

| JSP-18125 | “ | 125 | “ | 75 | “ | “ | n | “ | “ |

| JSP-18150 | “ | 150 | “ | 100 | “ | “ | “ | “ | |

| JSP-2875 | 28 | 75 | 15 | 45 | “ | “ | “ | “ | |

| JSP-28100 | “ | 100 | 25 | 50 | “ | “ | “ | “ | |

| JSP-28125 | “ | 125 | “ | 75 | “ | “ | “ | “ | |

| JSP-28150 | “ | 150 | “ | 100 | “ | “ | n | “ | “ |

| JSP-351OO | 35 | 100 | 20 | 60 | “ | “ | M8 | “ | |

| JSP-35150 | “ | 150 | “ | 55 | 55 | “ | “ | 3 | |

| JSP-35200 | “ | 200 | “ | 55 | 50 | 55 | “ | 4 | |

| JSP-35250 | “ | 250 | “ | 70 | 70 | 70 | n | “ | “ |

| JSP-353OO | “ | 300 | “ | 65 | 65 | 65 | 65 | “ | 5 |

| JSP-35350 | “ | 350 | “ | 80 | 75 | 75 | 80 | “ | “ |

| JSP-3875 | 38 | 75 | 15 | 45 | — | — | — | M6 | 2 |

| JSP-38100 | “ | 100 | 25 | 50 | “ | “ | “ | “ | “ |

| JSP-38125 | “ | 125 | “ | 75 | “ | “ | “ | “ | “ |

| JSP-38150 | “ | 150 | “ | 100 | “ | “ | “ | “ | “ |

| JSP-4875 | 48 | 75 | 15 | 4S | “ | “ | “ | “ | “ |

| 2SP-48100 | “ | 100 | 25 | 50 | “ | “ | “ | “ | “ |

| JSP-48125 | “ | 125 | “ | 75 | “ | “ | “ | “ | “ |

| JSP-48150 | “ | 150 | “ | 100 | “ | “ | “ | “ | “ |

| JSP-50100 | 50 | 100 | 20 | 60 | — | — | — | M8 | “ |

| JSP-50150 | “ | 150 | “ | 55 | 55 | “ | “ | “ | 3 |

| JSP-50200 | “ | 200 | “ | n | 50 | 55 | “ | “ | 4 |

| JSP-50250 | “ | 250 | “ | 70 | 70 | 70 | “ | “ | “ |

| JSP-50300 | “ | 300 | “ | 65 | 65 | 65 | 65 | “ | 5 |

| JSP-50400 | “ | 400 | “ | 90 | 90 | 90 | 90 | “ | “ |

| JSP-75150 | 75 | 150 | “ | 110 | — | — | — | “ | 4 |

| JSP-75200 | “ | 200 | “ | 80 | 80 | “ | “ | “ | 6 |

| JSP-75250 | “ | 250 | “ | 105 | 105 | “ | “ | “ | “ |

| JSP-75300 | “ | 300 | “ | 85 | 90 | 85 | “ | “ | 8 |

| JSP-75400 | “ | 400 | “ | 120 | 120 | 120 | “ | “ | “ |

| JSP-755OO | “ | 500 | “ | 115 | 115 | 115 | 115 | “ | 10 |

| How to order: Part No.W L |

| JSP 18 75 |

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.