graphite bush bearing

graphite bush bearing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

graphite bush bearing

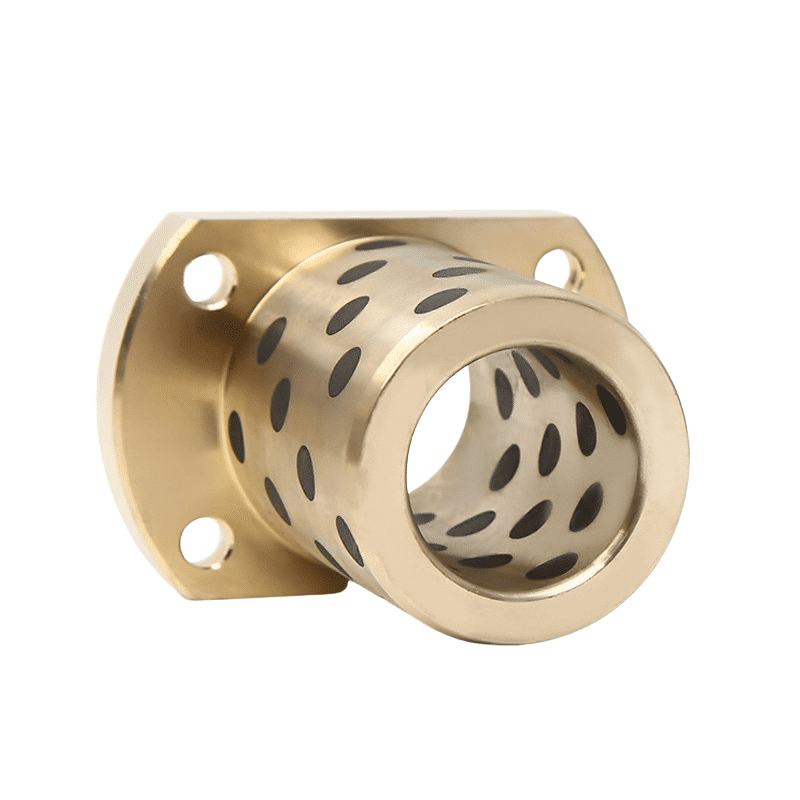

Self-Lubricating Graphite Plugged Bronze Sleeve Bushing

Shop a large range of flanged bearing bushings – maintenance-free self-lubricating slide bearings with dry lubricating pins at bronzelube.com. Support all your metal copper bushing and maintenance repair needs … with excellent quality, to win customers of all ages.

Brief Description

Custom Parts Services and Prototyping!

Leaded, Phosphor And Aluminium Bronze Bearing, Search Our Material Alloy

Graphite Bronze Bearings & Bushings, Self-lubricating.

Self-lubricating slide bearings with dry lubricating. On the bronze alloy with lubricating, solid lubricant Graphite, PTFE, or MoS2.

Solid bronze with plugs: bronze bushings with solid lubricant plugs made of graphite, Maintenance-free.

Individual Customer Solutions: We Provide Special Sizes Tailored to Your Specifications!

Do you require specialized custom products or are you in search of bearings for unique requirements? No problem: We fabricate and deliver custom plain bearing variants beyond standard dimensions, including special parts—all according to your specifications or technical drawings!

Oilless Graphite Lubricating Brass Bearing Bushing

Graphite oilless bushing/bearing

Oilless Bearing Oilless Brass Flange Bushing Graphite Plugged Bearing. Graphite Bushings And Bearings – Reduced Costs & Downtime

Material: graphite bush bearing metric size available upon request, graphite oilless bushing/bearing inch size.

The model of self-lubricating graphite copper sleeve is digital group, that is, inner diameter + outer diameter + length, such as inner hole 30, outer diameter 38, the model of self-lubricating graphite copper sleeve of length 30 is 303830.

The following is a list of models, specifications, and sizes of self-lubricating graphite copper bushing commonly used without a stop (tick “√” indicates the size and model of this specification) :

Graphite Bush Bearings: A Self-Lubricating Solution for Challenging Applications

Graphite bush bearings are self-lubricating bearings crafted from carbon graphite materials, combining the lubricity of graphite with the durability of metal. This makes them exceptionally well-suited for scenarios where traditional lubricants are impractical. Here are some essential insights into graphite bush bearings:

Self-Lubrication: Graphite bush bearings naturally lubricate themselves, eliminating the need for external lubrication. This feature is particularly beneficial in environments where applying lubricants is challenging.

High Load Capacity: These bearings are capable of supporting high loads, making them a robust choice for high-temperature applications.

Material Strength: Made from carbon graphite, these bearings offer superior strength, hardness, and wear resistance, enhancing their longevity and performance.

Customization: We provide custom manufacturing services for graphite bush bearings, accommodating a variety of sizes, shapes, and quantities to meet specific requirements.

Versatile Designs: Our offerings include both standard and custom-designed graphite and tin bronze bushings and bearings, tailored to diverse industrial needs.

Broad Applications: Graphite bush bearings are versatile and used in a range of applications, including those in submerged and high-temperature environments.

Material Variants: Beyond pure graphite bushings, we also offer graphite-impregnated brass bushings, which leverage the combined benefits of graphite’s lubricity and brass’s mechanical strength.

Diverse Options: Available in multiple sizes and configurations, including radial, thrust, and sleeve bearings, our graphite bush bearings are designed to meet various application demand

Graphite Bronze Bushings, graphite bush bearing. Wouldn’t you like to work with a professional team?

We are at your service with our expert staff and high technology devices.

Graphite copper bushings, also known as graphite copper bearings, are self-lubricating components that combine the lubricity of graphite with the durability of metal, typically copper or bronze alloys. These bushings are designed to provide maintenance-free operation, high load capacity, and excellent wear resistance, making them suitable for various industrial applications.

Key Features and Benefits

Self-Lubrication

Graphite copper bushings are embedded with graphite or other solid lubricants, allowing them to self-lubricate. This eliminates the need for external lubrication, which is particularly beneficial in environments where applying lubricants is challenging or impractical.

High Load Capacity and Durability

These bushings can support high loads and are highly durable. They are made from robust materials such as carbon graphite and copper alloys, which provide superior strength, hardness, and wear resistance. This makes them ideal for high-temperature and high-load applications.

Maintenance-Free Operation

The self-lubricating nature of graphite copper bushings means they require no maintenance, reducing downtime and operational costs. This feature is especially advantageous in applications where regular maintenance is difficult or impossible.

Versatility

Graphite copper bushings are available in various sizes and configurations, including flanged, cylindrical, and thrust bearings. They can be customized to meet specific requirements, making them suitable for a wide range of applications, from heavy machinery to high-temperature environments.

High Temperature and Corrosion Resistance

Graphite copper bushings can withstand high temperatures and are resistant to corrosion, making them suitable for use in harsh environments such as marine applications and industrial machinery.

Graphite copper bushings Applications

Graphite copper bushings are used in a variety of applications, including:

- Heavy Machinery: Suitable for high load and low-speed operations, such as in construction and mining equipment.

- Marine Environments: Ideal for use in saltwater conditions due to their corrosion resistance and self-lubricating properties.

- Industrial Equipment: Used in turbines, hoisting equipment, and press tools where high temperature and load capacities are required.

- Automotive: Employed in components like propeller shafts and rudder bearings due to their durability and maintenance-free operation.

Graphite copper bushing

Graphite copper bushings offer a reliable, maintenance-free solution for a wide range of industrial applications. Their combination of self-lubrication, high load capacity, and durability makes them an excellent choice for environments where traditional lubricants are impractical or where maintenance is challenging. Whether in heavy machinery, marine applications, or high-temperature industrial equipment, these bushings provide enhanced performance and longevity.

| IDF7 | ODm6 | L | |||||||||||||||

| d | D | 8 | 10 | 12 | 15 | 16 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | ||

| 8 | +0.028 +0.013 |

12 | +0.018 +0.007 |

√ | √ | √ | √ | ||||||||||

| 10 | 14 | √ | √ | √ | √ | √ | |||||||||||

| 12 | +0.034 +0.016 |

18 | √ | √ | √ | √ | √ | √ | √ | ||||||||

| 13 | 19 | +0.021 +0.008 |

√ | √ | √ | ||||||||||||

| 14 | 20 | √ | √ | √ | √ | √ | √ | ||||||||||

| 15 | 21 | √ | √ | √ | √ | √ | √ | √ | |||||||||

| 16 | 22 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||

| 18 | 24 | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||

| 20 | +0.041 +0.020 |

28 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||

| 22 | 32 | +0.025 +0.009 |

√ | √ | √ | √ | |||||||||||

| 25 | 33 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 30 | 38 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||

| 35 | +0.050 +0.025 |

45 | √ | √ | √ | √ | √ | √ | √ | ||||||||

| 40 | 50 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||

| 45 | 55 | +0.030 +0.011 |

√ | √ | √ | √ | √ | ||||||||||

| 50 | 60 | √ | √ | √ | √ | √ | √ | √ | |||||||||

| F7 | ODm6 | L | |||||||||||||

| d | D | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 100 | 120 | 130 | 140 | 150 | ||

| 50 | +0.050 +0.025 |

62 | +0.030 +0.011 |

√ | √ | √ | √ | √ | √ | ||||||

| 50 | 65 | √ | √ | √ | √ | √ | √ | √ | |||||||

| 55 | +0.060 +0.030 |

70 | √ | √ | √ | √ | |||||||||

| 60 | 74 | √ | √ | √ | √ | √ | √ | √ | |||||||

| 60 | 75 | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 63 | 75 | √ | √ | √ | |||||||||||

| 65 | 80 | √ | √ | √ | √ | ||||||||||

| 70 | 85 | +0.035 +0.013 |

√ | √ | √ | √ | √ | √ | √ | ||||||

| 70 | 90 | √ | √ | √ | √ | ||||||||||

| 75 | 90 | √ | √ | √ | √ | ||||||||||

| 75 | 95 | √ | √ | √ | √ | ||||||||||

| 80 | 96 | √ | √ | √ | √ | √ | √ | √ | |||||||

| 80 | 100 | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 90 | +0.071 +0.036 |

11 | √ | √ | √ | √ | √ | √ | √ | ||||||

| 100 | 120 | √ | √ | √ | √ | √ | √ | ||||||||

| 110 | 130 | +0.040 +0.015 |

√ | √ | √ | ||||||||||

| 120 | 140 | √ | √ | √ | √ | ||||||||||

| 125 | +0.083 +0.043 |

145 | √ | √ | |||||||||||

| 130 | 150 | √ | √ | ||||||||||||

| 140 | 160 | √ | |||||||||||||

| 150 | 170 | √ | √ | ||||||||||||

| 160 | 180 | √ | √ | ||||||||||||

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.