Metal-Polymer Bearings

Metal-Polymer Bearings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Metal-Polymer Bearings

In addition to metric POM bushing products of non-standard bearings. We can also develop according to customers’ special requests while out of this table.

POM bushes are used in a wide range of industries, including agriculture, civil, mechanical, and construction. They are particularly beneficial in situations that demand high stiffness, low friction, excellent wear properties, and significant dimensional stability. Common applications include gearbox assemblies, pivot points, linkage mechanisms, steering systems, and suspension systems

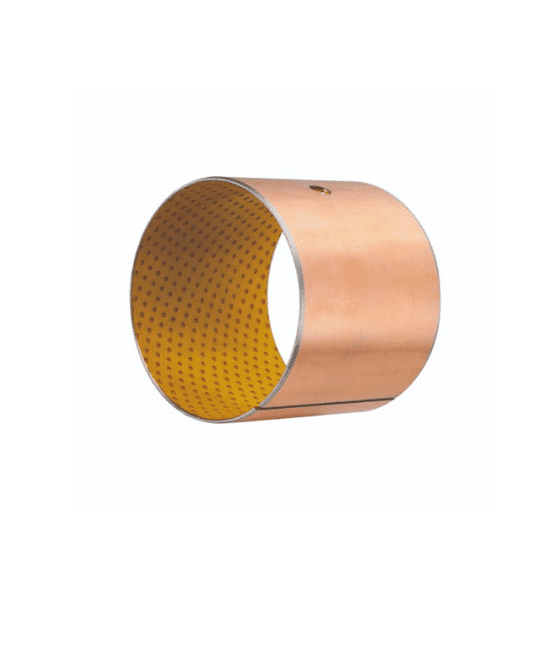

Boundary lubrication bushing

POM (Polyoxymethylene), also known as Acetal, is a high-performance engineering plastic used in the manufacture of precision parts that require low friction and excellent dimensional stability. POM cylindrical bushes are widely used in various industries due to their versatile properties, including automotive applications, industrial machinery, home appliances, electronic parts, and more.

Properties and Applications

- Low Friction and Durability: POM bushes are notable for their low friction characteristics, enhancing the efficiency and longevity of their performance.

- Robust Mechanical Strength: With the ability to retain their properties across a broad temperature spectrum, POM bushes are versatile for various conditions and uses.

- Self-Lubricating: Often supplied pre-lubricated, POM bushes minimize the necessity for further lubrication and upkeep.

- Noise and Vibration Mitigation: These bushes are adept at reducing machinery noise and vibration, facilitating smoother operations.

- High Load Capacity: Despite their streamlined design, POM bushes are capable of supporting substantial loads.

Manufacturing and Customization

POM bushes are commonly produced via precision machining processes such as CNC and automatic lathe work, tailored to the bushing’s specific application requirements. This process includes material selection, design specification, and precise machining to achieve the desired internal diameter, tolerances, and surface quality. Customization options are available, allowing for adjustments in dimensions and the addition of features like grooves or chamfers for specific applications.

Availability and Forms

Available in a wide range of standard sizes, both metric and imperial, POM bushes come in various forms including cylindrical bushes, half-bushings, and specially shaped versions created through stamping or deep drawing. These bushes are well-suited for oscillating, rotating, and linear movements under radial loads.

Industry Use

POM bushes are integral to numerous sectors such as agriculture, civil engineering, mechanical fields, and construction, offering solutions where high stiffness, low friction, superior wear resistance, and excellent dimensional stability are required. They are commonly found in gearbox assemblies, pivot points, linkage systems, steering mechanisms, and suspension systems, showcasing their wide applicability and effectiveness in demanding applications.

This is a steel-based, sintered bronze spherical powder as interlayer and overlaid by a layer of POM, the surface of which is provided with oil indentations.

The thickness of the plastics layer is about 0.5mm.

A trace of oil or grease may be utilized and may work successfully under heavy load with oscillating motion and those which start and stop frequently under load.

Moreover, it is of low cost and long life. This kind of material is now widely used as bushes in chassis of automobiles, forging presses, metallurgical and mining machines, civil engineering machines, hydroelectric industrial machines and steel strip cold rolling machines.

It is a lead-free product.

Marginally lubricated bushings for grease or oil lubricated applications · Standard parts contain grease indents in the sliding layer.

Carbon Steel + Copper Powder + POM

It’s used in vehicle chassis, forming machine tools, steel metallurgical machinery, mineral mountain machinery, hydraulic industry and rolling steel industry, etc.

| Performance | Data | |

| Max load capacity P | Static load | 140N/mm² |

| Max load capacity P | Dynamic load | 70N/mm² |

| Max line speed V | Grease lubrication | 2.5m/s |

| PV value limit | Grease lubrication | 2.8N/mm²· m/s |

| Friction coef μ | Grease lubrication | 0.06~0.12 |

| Mating Axis | Hardness | >270 HB |

| Performance | Data | |

| Mating Axis | Roughness | Ra=0.4~1.25 |

| Working temperature | -40~+120℃ | |

| Thermal conductivity | 52W/(m·k) | |

| Coefficient of linear expansion | 11×10-6K-1 | |

| Outside surface Plating | copper/tin | |

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.