Dry Thrust Washer

Dry Thrust Washer

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Dry Thrust Washer

Self-Lubricating Thrust Washer Plain Bearing

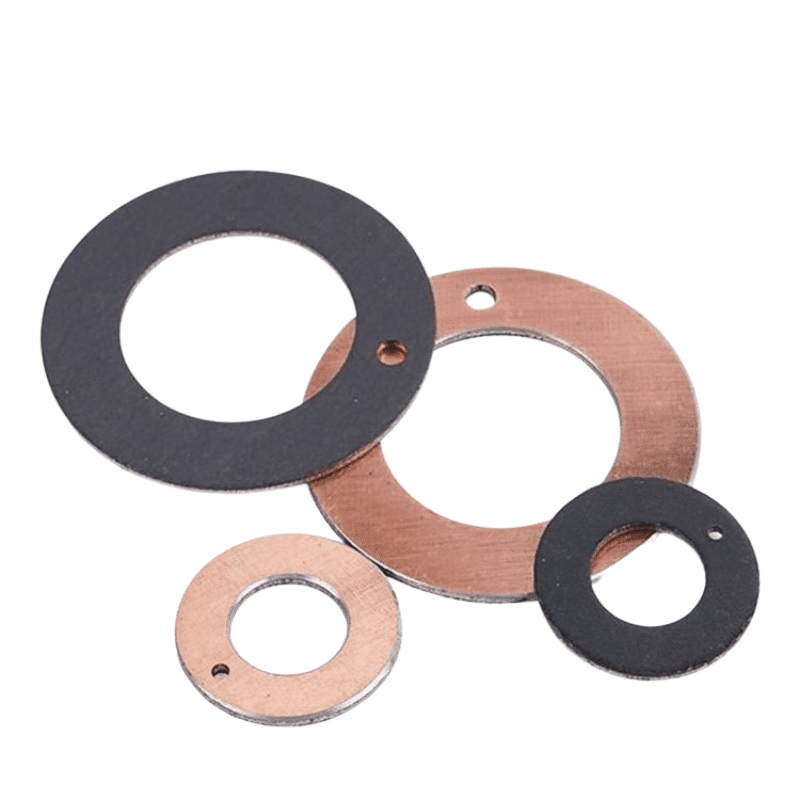

Carbon Steel self-lubricating bearings used high-quality low-carbon steel plate as base, sintered porous bronze as its interlayer, and the Compound of PTFE and Lead as its surface. It offers the property of good self-lubrication, low wear, low friction good sliding characteristics, low noise. It has been widely applied to various mechanical sliding positions, such as textile machinery, printing machinery, hydraulic pressure transit vehicle, tobacco machinery, gymnastic instrument, and agricultural machinery, etc.

Composite Polytetrafluoroethylene PTFE Dry Thrust Washer. Proven, long-lasting composite washer, thrust bearing washer, sleeve bushing washer, thrust bearing washer material

Dry Thrust Washer

Steel PTFE washers, bronze Polytetrafluoroethylene washers, and ceramic washers are all types of washers that are commonly used in mechanical applications to prevent leakage, reduce friction, or provide a seal. However, they differ in terms of their material composition, properties, and applications.

Steel PTFE washers are made of a steel core coated with a layer of PTFE (polytetrafluoroethylene), a synthetic fluoropolymer with high chemical resistance, low friction, and non-stick properties. These washers are typically used in applications where chemical resistance, temperature resistance, and low friction are important, such as in the chemical processing, food and beverage, and medical industries.

Bronze Polytetrafluoroethylene washers are made of a bronze core coated with a layer of Polytetrafluoroethylene (PTFE). The bronze core provides strength and stability, while the Polytetrafluoroethylene coating provides low friction and chemical resistance. These washers are commonly used in applications where moderate to high loads are encountered, such as in hydraulic systems, pumps, and valves.

Ceramic washers are made of ceramic materials, such as alumina or zirconia, which have high hardness, high temperature resistance, and excellent wear resistance. These washers are typically used in applications where high temperature, high pressure, and wear resistance are important, such as in automotive engines, turbines, and high-pressure pumps.

In summary, steel PTFE washers are best suited for applications where chemical resistance and low friction are important, bronze Polytetrafluoroethylene washers are best suited for applications where moderate to high loads are encountered, and ceramic washers are best suited for applications where high temperature, high pressure, and wear resistance are important.

SF-1WC series thrust washer

SF-1 self-lubricating bearing is a sliding bearing made of steel plate as the base, sintered spherical bronze powder in the middle, and rolled mixture of polytetrafluoroethylene (PTFE) and fiber on the surface.

Features: 1. PTFE and fiber mixture 0.01~0.03mm, can form a good transfer film to protect the shaft, providing the self-lubricating performance of the bearing. 2. Copper powder layer 0.20~0.30mm, has good bearing capacity and wear resistance, good thermal conductivity can transfer the heat generated during the operation of the bearing. The composite material can penetrate into the gap of copper powder ball, which improves the bonding strength.3. Low carbon steel, which provides good load-bearing performance and heat transfer. The products have been widely used in the sliding parts of various machinery, such as printing machines, elevators, textile machines, tobacco machines, fitness machines, hydraulic trucks, micro motors, solenoid valves, automobiles, motorcycles, etc.

Dry Thrust Washer Material [M] Material vinyl tetrafluoride resin layer with filler

Bronze sintered layer

Steel metal Substrate (SPCC: tin plating)

Heat resistance -195 ~ 280℃

The basic information

Multi-layer material standard/heat resistant/oil medium

SF-1 Thrust Washer WC10 12 14 16 18 20 24 26 28 32 38 42 48 52 62, self-lubricating PTFE

Thrust Washer introduction

SF-1 self-lubricating bearing is a sliding bearing made of steel plate as the base, sintered spherical bronze powder in the middle and rolled mixture of polytetrafluoroethylene (PTFE) and fiber on the surface.

Features: 1. PTFE and fiber mixture 0.01~0.03mm, can form a good transfer film to protect the shaft, providing the self-lubricating performance of the bearing. 2. Copper powder layer 0.20~0.30mm, has good bearing capacity and wear resistance, good thermal conductivity can transfer the heat generated during the operation of the bearing. The composite material can penetrate into the gap of copper powder ball, which improves the bonding strength.3. Low carbon steel, which provides good load-bearing performance and heat transfer. The products have been widely used in the sliding parts of various machinery, such as printing machines, elevators, textile machines, tobacco machines, fitness machines, hydraulic trucks, micro motors, solenoid valves, automobiles, motorcycles, etc.

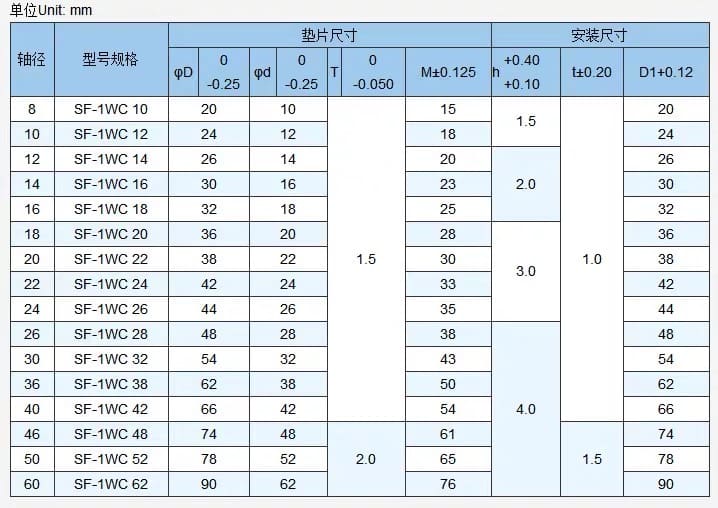

Fiber Reinforced Composite Polytetrafluoroethylene PTFE Thrust Washer Size

| unit:mm | ||||||||

| Washer size | Installation size | Hd+0.12 | ||||||

| Designation | Ds | Di+0.25 | D°-0.25 | Sr-0.05 | dp±O.125 | 0.4 | Ha±0.2 | |

| dD +0.1 | ||||||||

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC10 | 8 | 10 | 20 | 1.5 | 15 | 1.5 | 1 | 20 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC12 | 0 | 12 | 24 | “ | 18 | “ | “ | 24 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC14 | 12 | 14 | 26 | “ | 20 | 2 | “ | 26 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC16 | 4 | 16 | 30 | “ | 23 | “ | “ | 30 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC18 | 16 | 18 | 32 | “ | 25 | “ | “ | 32 |

| Polytetrafluoroethylene WC20 | 8 | 20 | S6 | “ | 28 | 3 | “ | 36 |

| Polytetrafluoroethylene WC22 | 20 | 22 | 38 | “ | 30 | “ | “ | 38 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC24 | 22 | 24 | 42 | “ | 33 | “ | “ | 42 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC26 | 24 | 26 | 44 | “ | 35 | “ | “ | 44 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC28 | 26 | 28 | 48 | “ | 38 | 4 | “ | 48 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC32 | 30 | 32 | 54 | “ | 43 | “ | “ | 54 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC38 | 36 | 38 | 62 | “ | 50 | “ | “ | 62 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC42 | 40 | 42 | 66 | “ | 54 | “ | “ | 66 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC48 | 46 | 48 | 74 | 2 | 61 | “ | 1.5 | 74 |

| PolytetrafluoroethylenePTFE Steel Thrust Bearing Washer SF-1WC52 | 50 | 52 | 78 | “ | 65 | “ | “ | 78 |

| Polytetrafluoroethylene PTFE Steel Thrust Bearing Washer SF-1WC62 | 60 | 62 | 90 | “ | 76 | “ | “ | 90 |

Dry Thrust Washer & Polytetrafluoroethylene sleeve washer

SF-1WC Standard dimensions for thrust washer bearings(SF-1、SF-1T、SF-1P、SF-1D、SF-1B、SF-1S)

| Unit:mm | ||||||||

| shaft | SIZE CODE | WASHER SIZE | Installation dimensions | |||||

| d +0.25 | D -0.25 | T -0.05 | M ±0.12 | h+0.4 | T±0.2 | D1+0.12 | ||

| 0.1 | ||||||||

| 8 | WC10 | 10 | 20 | 1.5 | 15 | 1.5 | 1 | 20 |

| SF-1 | ||||||||

| 10 | WC12 | 12 | 24 | 18 | 24 | |||

| SF-1 | ||||||||

| 12 | WC14 | 14 | 26 | 20 | 2 | 26 | ||

| SF-1 | ||||||||

| 14 | WC16 | 16 | 30 | 23 | 30 | |||

| SF-1 | ||||||||

| 16 | WC18 | 18 | 32 | 25 | 32 | |||

| SF-1 | ||||||||

| 18 | WC20 | 20 | 36 | 28 | 3 | 36 | ||

| SF-1 | ||||||||

| 20 | WC22 | 22 | 38 | 30 | 38 | |||

| R-1 | ||||||||

| 22 | WC24 | 24 | 42 | 33 | 42 | |||

| RCB-1 | ||||||||

| 24 | WC26 | 26 | 44 | 35 | 44 | |||

| SF-1 | ||||||||

| 26 | WC28 | 28 | 48 | 38 | 4 | 48 | ||

| SF-1 | ||||||||

| 30 | WC32 | 32 | 54 | 43 | 54 | |||

| RCB-1 | ||||||||

| 36 | WC38 | 38 | 62 | 50 | 62 | |||

| SF-1 | ||||||||

| 40 | WC42 | 42 | 66 | 54 | 66 | |||

| SF-1 | ||||||||

| 46 | WC48 | 48 | 74 | 2 | 61 | 1.5 | 74 | |

| SF-1 | ||||||||

| 50 | WC52 | 52 | 78 | 65 | 78 | |||

| SF-1 | ||||||||

| 60 | WC62 | 62 | 90 | 76 | 90 | |||

| SF-1 | ||||||||

See Our Online Dry Sliding Composite Bearings Catalog & Request A Quote! Bearings & Materials Made To The Higher Standards.

Plain Bearings & Thrust Washers | www.bronzelube.com

Shop bronzelube.com for all your Thrust Washers and Plain Bearings & Thrust Washers needs. We offer free CAD download, short lead times, competitive pricing, ..

Materials

| Support material | Steel backing 0.4-2.2mm |

| Intermediate layer | Porous bronze 0.2-0.3mm |

| Sliding layer | POM with fiber 0.3-0.5mm |

| Plating | Tin plating 0.005mm or Copper plating 0.008mm |

Sf-1 Self-lubricating Thrust Washer, metal flat washer, large size washer

SF1 self-lubricating thrust washer, low friction PTFE DU washers

This thrust washer is steel based, an intermediate layer of porous bronze particles sintered and calendered with PTFE and filler mixture as a surface layer.

It is low-friction, anti-wear, and anti-corrosion, and can be used without lubrication. Furthermore, it is low cost, low vibration, and low noise.

SF-1 is widely used in various sliding motions of different types of machines, such as printing machines, textile machines, tobacco machines, gym machines, hydraulic vehicles, automobiles, motorcycles, agricultural and forestry machines and so on.

It is lead-free Thrust Washer Plain Bearing, Composite Polytetrafluoroethylene PTFE Thrust Washer.

High-quality low carbon steel as the matrix

The Thrust Washer Plain Bearing is a mixture of polytetrafluoroethylene (PTFE) rolled on the surface of sintered spherical bronze layer in the middle of high quality low carbon steel. It has good self-lubrication, wear resistance, low friction coefficient, good coupling performance, low noise and other properties and is widely used in sliding parts of various machinery.

- PTFE and lead mixture 0.01-0.03mm

- Spherical bronze powder 0.2-0.3mm

- Steel back 0.7-2.3mm

- Electroplating layer: tin layer thickness of 0.005mm, or copper layer thickness of 0.008mm

APPLICATION CHARACTERISTICS

- No oil lubrication or little oil lubrication, suitable for the occasions where refueling is impossible or difficult, can be used without or with little maintenance.

- Good wear resistance, small friction coefficient and long service life.

- Can be used in the range of -195°C to +280°C.

- close performance is good, low ring bitter, no pollution.

- Thin wall structure, light weight, can reduce the mechanical volume.

- Transfer film can be formed during operation to protect the grinding shaft. No axial biting phenomenon.

- The hardness of the grinding shaft is low, and the shaft without quenching and tempering can be used. Thus long low processing difficulty of the relevant parts.

- No rice water, oil absorption; The hot melt is small, so the macro is good and the size is fixed.

- The back of the steel can be plated with a variety of metals, so it can be used in corrosive media, will not rust.

The product name

Self lubricating thrust washer

Bearing mechanism

Solid friction

Product composition

The steel base copper plating

Product features

Good abrasion resistance

Small coefficient of friction

Long service life

Strong corrosion resistance

Oil free self lubrication

Product use

Used in all kinds of machinery Lubrication part

Such as automatic machinery and equipment

Sf-2 Thrust Washer Plian Bearings

The SF-2 thrust washer material is a PTFE-modified surface layer filled with POM plastic of the three-level self-lubricating composite material, which is a benign boundary lubricating material, and therefore particularly suitable for low-speed and loaded rotational movement. high, rocking motion and frequently open and close under load and difficult to form hydrodynamic lubrication of bearings, thrust washer only, slider, tees and other friction parts. The SF-2 can fully utilize the grease trace lubrication under boundary lubrication conditions without refueling for long term maintenance.

High quality low carbon steel as the matrix

The Thrust Washer Plain Bearing is made of high quality low carbon steel and sintered spherical porous bronze powder in the middle, which is firmly integrated with surface modified POM. Surface rolling oil storage pit to achieve good lubrication between friction surfaces. It has good wear resistance and bearing capacity, steel back surface coating corrosion resistance, widely used in automobile chassis, forging machine tools, mining machinery metallurgy machinery, water conservancy and steel rolling industry.

1 pom0.30-0.50mm modified polyformaldehyde, high wear resistance, low friction coefficient, assembly must be coated with lubricating grease.

2. Copper powder layer 0.2-0.3mm, with good bearing capacity and wear resistance.

3. Low carbon steel, improve bearing capacity and heat transfer effect.

4 Electroplating: tin plating thickness of 0.005mm, or copper plating thickness of 0.008mm

APPLICATION CHARACTERISTICS

Especially suitable for low speed and heavy load of rotating motion, swing motion and often open and close under the load and not easy to form fluid lubrication parts; The plastic layer on the surface of the shaft sleeve can have a certain amount of allowance when forming, pressing into the seat hole can be self-processing, in order to achieve better assembly size is mainly used in metallurgical machinery, mining machinery, water conservancy machinery, car chassis, construction machinery, agricultural machinery, steel rolling machinery, etc.

Product name

Composite thrust thrust washer

Bearing mechanism

Solid friction

Product composition

Steel base copper plating

Product features

Good wear resistance, small friction coefficient, long service life and strong corrosion resistance

Product use

Used in all kinds of machinery Lubrication part

Such as automatic machinery and equipment

Fiber-Reinforced-Composite-Polytetrafluoroethylene-PTFE-Thrust-Washers

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.