Drilling Oilless Plates

Drilling Oilless Plates

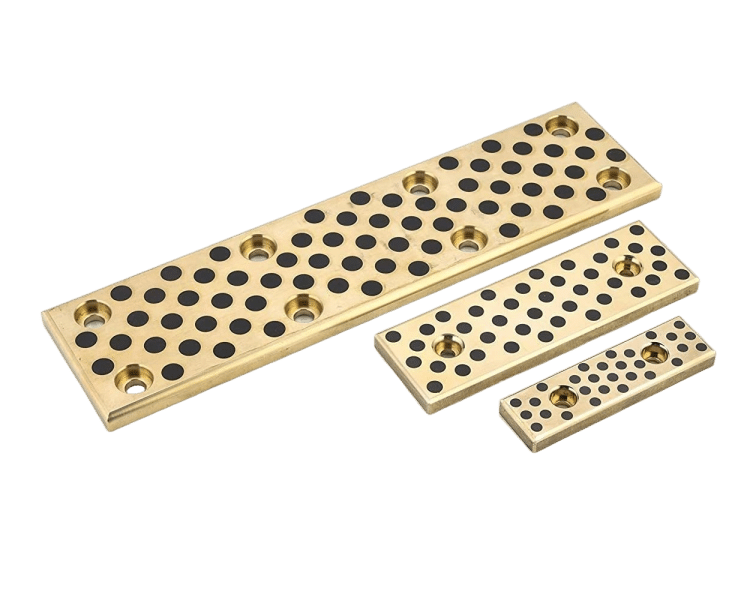

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Drilling Oilless Plates

Oilless bushes with solid-lubricant depots are designed to provide maintenance-free operation in various industrial applications. These bushes are typically made from strong base materials like bronze or cast iron and have solid lubricants such as graphite or MoS2 embedded within them. Here’s a detailed overview of their features, benefits, and applications:

Features of Oilless Bushes with Solid-Lubricant Depots

- Material Composition:

- Base Material: Commonly used materials include strong cast bronze (e.g., CuZn25Al5) and cast iron. These materials provide high load capacity and durability.

- Solid Lubricants: Graphite and MoS2 are frequently used. These lubricants are embedded in the form of plugs or dispersed within the base material.

- Design:

- Embedded Lubricant: The solid lubricant is embedded in radial holes or pockets that cover a significant portion of the working surface (up to 30% in some designs.

- Self-Lubricating: During operation, the solid lubricant is transferred to the mating surface, creating a low-friction film that reduces wear and tear.

Drilling and Countersinking Techniques for Oilless Plates, Graphite Plate Manufacturers

Composition of Oil-Free Slide Plates

Base Materials:

- Copper Alloys: Oil-free slide plates often use high-strength brass or other copper alloys as their foundational material. These alloys are chosen for their excellent strength and durability.

- Bronze: Frequently selected for its robustness, bronze is commonly enhanced with embedded solid lubricants such as graphite to facilitate sliding action.

- Special Brass: Some manufacturers opt for proprietary brass alloys, engineered specifically for oil-free applications.

- Cast Iron: Certain oil-free slide plates incorporate cast iron, like FC250, known for its durability, as the base material.

Lubrication Features: These base materials are integrated with solid lubricants, key for achieving self-lubricating properties:

- Graphite: Widely recognized as a premier solid lubricant, graphite is extensively utilized in oil-free slide plates.

- Special Solid Lubricants: In some cases, manufacturers embed proprietary solid lubricant blends at strategic locations within the base material.

Functional Advantages: This combination of materials and embedded lubricants allows the slide plates to operate without external lubrication. This feature is particularly beneficial in environments where traditional lubrication methods are either impractical or unwelcome. The metallic base supports the structural load, while the embedded solid lubricants ensure continuous lubrication, providing exceptional durability and performance under demanding conditions.

Drilling from the Underside: When working with oilless plates that incorporate solid lubricants like graphite, it is advisable to drill from the underside. This method helps prevent the dislodging or damage of solid lubricant inserts on the sliding surface. By drilling from the underside, the integrity of the solid lubricant is preserved, ensuring its continuous effective performance in reducing friction.

Countersinking the Sliding Surface: Occasionally, it may be necessary to drill through areas where solid lubricants are embedded. In such scenarios, countersinking at the sliding surface is crucial. Countersinking creates a tapered hole that allows fasteners to lie flush with the plate surface, essential for maintaining a smooth sliding area and avoiding operational disruptions due to protruding fastener heads.

Advantages of Proper Drilling and Countersinking:

- Preservation of Lubrication: Careful drilling practices help protect the self-lubricating features of the plate, critical for minimizing friction and wear.

- Smooth Functionality: Ensuring fasteners are flush with the surface eliminates obstructions, facilitating seamless movement and efficient plate operation.

- Enhanced Durability: Using appropriate drilling and countersinking methods can significantly extend the oilless plate’s lifespan by maintaining its structural and functional integrity.

Key Considerations:

- Material Specifications: Oilless plates are usually crafted from robust materials like bronze or copper alloys, embedded with solid lubricants such as graphite. These materials are selected for their durability and their capacity to handle high loads and temperatures.

- Use Cases: These plates find applications across various sectors such as die/mold machinery, automation, construction, and the automotive industry. They are especially valuable in settings where conventional lubrication methods are unfeasible.

Illustrative Examples:

- Bronze Wear Plates: Typically utilized in heavy-load situations, these can be customized with pre-drilled holes and integrated self-lubricating graphite inserts.

- Graphite Plugged Bronze Plates: Designed to continually release a lubricating graphite film on the wear surface, these plates help reduce friction and boost performance.

Adhering to these guidelines ensures that oilless plates retain their self-lubricating properties and perform reliably under strenuous conditions.

Selecting Graphite Oilless Flat Plates with Embedded MoS2: A Comprehensive Guide

Material Considerations:

Graphite Plates: Known for their self-lubricating properties, high temperature resistance, and low friction coefficient, graphite plates are ideal for scenarios where traditional lubrication methods are unfeasible. These plates are extensively used in various industrial contexts.

Bronze Graphite Plates: These plates blend the durability and wear resistance of bronze with the lubricating qualities of graphite, making them suitable for high-load and low-speed applications like injection molding machines, construction equipment, and automotive parts.

Design Essentials:

Drilling Technique: Drilling from the backside to embed solid lubricants such as graphite or MoS2 is a strategic choice. This method ensures an even distribution of lubricant across the contact surface, enhancing lubrication continuity and reducing wear.

Lubricant Integration: Graphite and MoS2 are favored for their lubricating efficiency—graphite excels in high-temperature conditions, whereas MoS2 performs exceptionally well under high pressure and in vacuum settings.

Application Benefits:

Self-Lubrication: The self-lubricating feature of these plates minimizes the need for regular maintenance, cutting operational costs and improving equipment uptime.

Resilience Under Load and Heat: Bronze graphite plates are engineered to endure strenuous loads and high temperatures, offering a robust solution for demanding industrial uses.

Customization Opportunities: Manufacturers often provide tailored solutions to meet specific operational requirements, including custom dimensions, configurations, and material compositions, ensuring peak performance for unique applications.

Implementation Steps:

- Assess Requirements: Evaluate the necessary load capacity, operating temperatures, and environmental conditions of your application.

- Material Selection: Based on these requirements, select the most suitable material, such as bronze graphite plates for environments with high loads and temperatures.

- Define Design Specifications: Decide on the dimensions, shape, and drilling layout of the plates, ensuring that the lubricant embedding sites are optimally positioned for uniform lubrication.

- Lubricant Embedding: Insert graphite or MoS2 into the pre-drilled holes using a pressing technique or a specialized embedding process.

- Installation: Fit the plates into your machinery or equipment, making sure they are properly aligned and securely attached.

- Ongoing Maintenance: Conduct regular inspections and replace the plates as necessary to sustain top performance.

By adhering to these guidelines, you can effectively select and deploy graphite oilless flat plates with MoS2 embedding, thereby enhancing both the performance and longevity of your equipment.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.