Copper Alloy Bushings

Copper Alloy Bushings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Copper Alloy Bushings

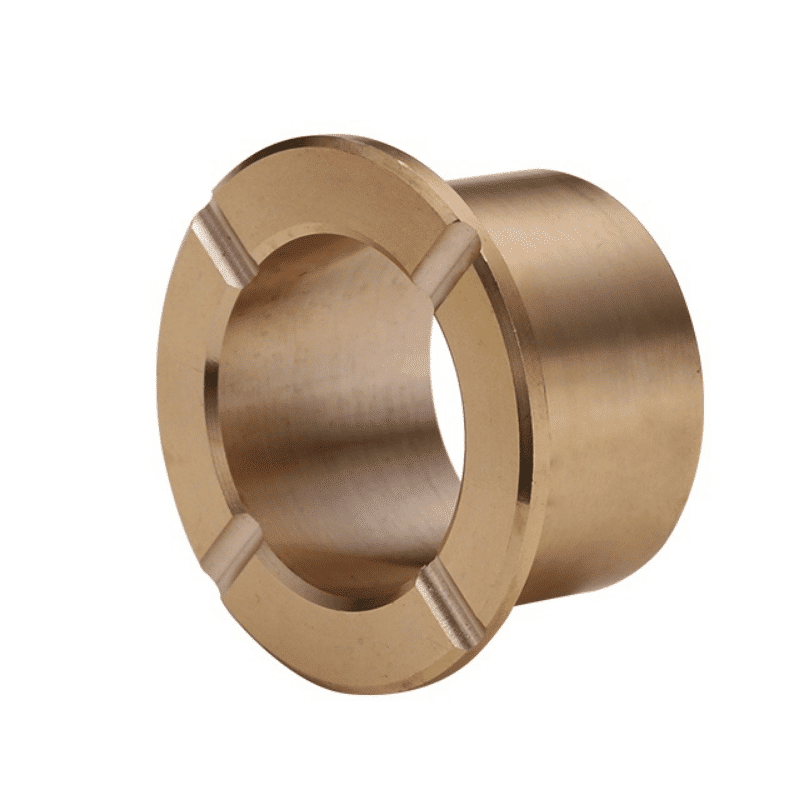

Solid Bronze Bearings Are Made From Tin Bronze Cusn7zn4pb7 Continuously Cast Bronze. Offers Standard Size Plain & Flanged Cylindrical Bushing. Solid bronze graphite Self-Lubricating Bushing, Brass graphite bushing, bronze bearings · Graphite Embedded Brass Bearing.

Copper Bushings for All Uses, Precision Engineering

Explore our wide selection of copper bushings, precision-engineered for various applications. Easy online ordering and quick shipping. Start improving your equipment now!

The copper alloy bushings available, including their features and potential uses, have been detailed. Among the offerings are standard-size plain and flanged copper groove bushings crafted from solid bronze to improve the longevity of machinery. These bushings are constructed from tin bronze Cusn7zn4pb7, making them ideal for a variety of uses thanks to their high load-bearing capabilities, excellent resistance to corrosion, and other advantageous properties. Furthermore, there’s a mention of incorporating self-lubricating substances like POM and composite materials to lessen friction and wear in plain bushings.

According to the information retrieved, the copper alloy bushings provided by Switch from Bearing are designed to offer a straightforward and cost-effective solution for utilizing bearings that boast a high load-bearing capacity, excellent corrosion resistance, among other positive attributes. The lineup includes standard-size plain and flanged copper groove bushings made from solid bronze, specifically using tin bronze Cusn7zn4pb7. These components are versatile, catering to diverse applications and contributing to the extended durability of machinery.

Additionally, the search underscores the employment of self-lubricating materials, such as POM and composites, aimed at decreasing friction and wear in plain bushings. This suggests that the company provides a selection of bushing solutions engineered to minimize the necessity for external lubrication while boosting equipment performance and longevity.

In essence, the gathered information offers an in-depth look at the copper alloy bushings by Switch from Bearing, detailing their composition and the advantages they bring to various industrial settings.

Copper Alloy Bushing Overview: finishing copper alloy bushings provide a simple, economical way to use bearings with high bearing, good corrosion resistance, size, and other characteristics of any process.

Safe Copper Bushing From China. Sourcing Copper Bushing from China Now. Quality China Bronze Alloy Products. Providing High-Quality Products, New Size Development Available.

Copper Alloy Bushings & Solid bronze bushings

Bushing, Copper Bushings Alloy + Graphite, Graphite Copper Bushing Copper-based alloys bushings

Copper Bushings: CNC Machined Bushings

Copper bushings are precision-engineered components widely used in various mechanical applications due to their excellent properties, including low friction, high load capacity, and corrosion resistance. CNC (Computer Numerical Control) machining enhances the manufacturing process, allowing for high precision and customization in size and shape.

Key Features of Copper Bushings

Material Composition: Copper bushings are primarily made from copper or copper alloys, such as bronze, which may include tin and other elements to enhance their mechanical properties. These materials offer excellent wear resistance and durability.

Self-Lubricating Properties: Many copper bushings incorporate solid graphite or other lubricants within their structure, reducing friction and wear during operation. This self-lubricating feature minimizes maintenance needs and prolongs service life.

High Load Capacity: Copper bushings can handle substantial radial and axial loads, making them suitable for heavy-duty applications in industries like automotive, aerospace, and manufacturing.

CNC Machining Process

The CNC machining process for copper bushings involves several steps:

Material Selection: Choosing the appropriate copper alloy based on the specific application requirements.

Turning and Milling: Using CNC lathes and mills to shape the bushing to precise dimensions. This process ensures high accuracy in the final product.

Finishing Operations: Additional processes such as grinding or polishing may be employed to achieve the desired surface finish and tolerances.

Quality Control: Rigorous testing and inspection ensure that the machined bushings meet the required specifications for performance and durability.

“Copper alloy oil groove bushing” might refer to a specific type of bushing made from a copper alloy that is used within an oil groove. Bushings are cylindrical components that are used to reduce friction between parts, and they can be found in various mechanical systems, including those that involve the lubrication of moving parts with oil.

- Copper Alloy: This refers to a material that is made by combining copper with one or more other elements, such as zinc, tin, or nickel. Copper alloys are known for their good thermal and electrical conductivity, corrosion resistance, and strength.

- Oil Groove: This might refer to a channel or groove in a mechanical component that is designed to hold and direct oil for lubrication purposes.

- Bushing: A bushing is a type of bearing that is used to provide a smooth surface for other parts to move against. They can be plain (without any rolling elements) or flanged (with a flange to help secure the bushing in place).

The bushes can be manufactured as one piece up to a maximum of 800 kg, Your source for high-grade copper bushings in all sizes. Catering to all industrial needs with a vast inventory. Enjoy fast delivery and excellent service. Order today! Premium Copper Bushing Supplier!

Machine parts, Gears bronze parts. High-Quality Copper Bushings, Discover top-tier copper bushings known for their durability and reliability. Perfect for various industrial applications. Get premium quality at competitive prices. Shop now!

Self Lubricating Copper Bushing

Solid bronze bushings are available in metric sizes as straight or flanged bushings. This robust bushing material is suitable for a wide range of applications. These bushings are applicable for oscillating movements in both radial and axial directions or for applications where rotating speeds are low.

Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties but also reduces wear and prevents corrosion. Those bushings with a bore diameter d > 14 mm have an axial lubrication groove in their sliding surface and are indicated by the designation suffix G1.

All surfaces of a solid bronze bushing are machined.

Switch from Bearing, Offers Standard Size Plain & Flanged Copper Groove Bushing. Extend the life of your equipment with solid bronze. Copper Alloy Bushings or bronze bearings are hard and strong, almost often an alloy of bronze with tin, aluminum, or manganese, … C86300 Bronze Bushing, C93200 Bronze Bushing, C95400 Copper Alloy Bushing with groove.

Cast bronze grooves are available in metric sizes as a straight or flanged bronze bushing. This solid bronze bushing material is suitable for a wide range of applications. The copper alloy bearing bushings are applicable for oscillating movements for applications where rotating speeds are low. … All surfaces of a solid bronze bushing are machined.

Copper bushings alloyed with graphite are an increasingly popular choice in various industrial applications due to their unique combination of properties. In this article, we will explore the characteristics, applications, advantages, and considerations for using copper-graphite bushings.

CNC machined copper bushings are integral components in various industries due to their durability, low maintenance requirements, and excellent performance characteristics. Their ability to withstand high loads while minimizing friction makes them a preferred choice for many mechanical systems.

Copper bushings are a type of bearing used in machinery and equipment to reduce friction and wear between moving parts. By alloying copper with graphite, these bushings gain enhanced properties that make them suitable for more demanding applications.

Characteristics of Copper-Graphite Bushings

- Self-Lubricating: Graphite acts as a natural lubricant, reducing the need for external lubrication.

- High Thermal Conductivity: Copper’s excellent thermal conductivity is maintained, helping to dissipate heat from friction.

- Corrosion Resistance: Copper-graphite bushings resist corrosion in various industrial environments.

- Strength and Durability: While maintaining a degree of malleability, these bushings are strong and durable.

- Low Coefficient of Friction: The combination of copper and graphite provides a low friction surface, reducing wear and tear.

Applications

- Electrical Motors and Generators: Due to their conductive properties and low friction.

- Heavy Machinery: In environments where regular lubrication is difficult or impractical.

- Aerospace: Used in components where reliability and performance are critical.

- Automotive: In steering systems, transmission components, and other areas.

Advantages

- Reduced Maintenance: The self-lubricating nature of graphite minimizes the need for maintenance.

- Improved Performance: High thermal conductivity and low friction enhance the performance of machinery.

- Environmental Resistance: Ability to withstand harsh environmental conditions.

- Longevity: Increased durability leads to longer service life of components.

Considerations for Use

- Compatibility: Ensure compatibility with other materials and the specific environmental conditions of the application.

- Installation and Fit: Proper installation is crucial for optimal performance.

- Cost vs. Performance: Evaluate the cost-effectiveness based on the specific requirements of the application.

Conclusion

Copper bushings alloyed with graphite offer a unique blend of properties that make them suitable for a wide range of industrial applications. Their self-lubricating nature, combined with the strength and thermal properties of copper, make them an excellent choice for reducing friction and wear in machinery. As industries continue to evolve, the demand for such high-performance materials is likely to increase, making copper-graphite bushings a significant player in the market.

Technical Parameters

| Material Composition and Properties | ||||

| Grade | JDB-1U | JDB-1US1 | JDB-1US2 | JDB-1US3 |

| Material | CuZn25Al5Mn3Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 |

| Density | 8 | 8.9 | 7.8 | 8.9 |

| Hardness HB | >210 | >70 | >150 | >95 |

| Tensile strength N/mm² | >750 | >200 | >600 | >260 |

| Yield strength N/mm² | >450 | >90 | >260 | >150 |

| Elongation % | >12 | >25 | >10 | >8 |

| Coeffcient of linear expansion | 1.9×10-5/℃ | 1.8×10-5/℃ | 1.6×10-5/℃ | 1.8×10-5/℃ |

| Max.temp ℃ | -40~+300 | -40~+400 | -40~+400 | -40~+400 |

| Max.load N/mm² | 100 | 60 | 50 | 70 |

| Max.speed (Dry) m/min | 15 | 10 | 20 | 10 |

| Max.PV(Lubrication) N/mm² *m/min | 200 | 60 | 60 | 80 |

| Compression deformation 300N/mm² | <0.01mm | <0.05mm | <0.04mm | <0.05mm |

Oil Groove Copper Bushing Design, Custom Copper Bushings

Tailor-Made Solutions Expert Advice, Get custom-made copper bushings to meet your specific requirements. Our experts are here to provide tailored solutions and advice. Contact us for a bespoke quote! Industrial Copper Bushings, Exceptional Quality, Offering a comprehensive range of copper bushings for industrial applications. Exceptional quality, available in bulk and retail. Enhance your machinery’s performance today!

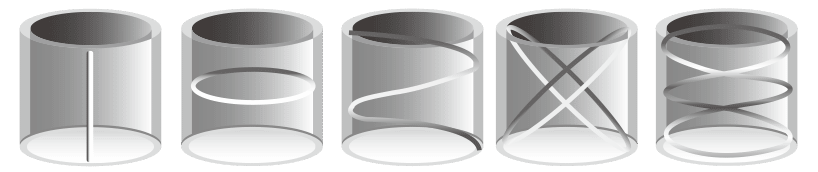

The various bushing types, its designs and variants are described in the following:

OEM parts Custom size Available. bronzelube.com can provide different grades of copper alloy according to different conditions, and in accordance with the requirements of processing different forms, it has higher accuracy than the size class copper rolling bearings.

Copper Bushing Bearing Manufacturer. Bronze Bearings Type. Order Online Today! OEM PART. Types: Cast Bronze Standards, Bronze Material, Standard Metric Bushings, Oil-less Type Bushing, Metal Bronze Bushings.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.