Connecting Rod Bushing

Connecting Rod Bushing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Connecting Rod Bushing

- Low cost;

- Thin-walled construction;

- Small construction;

- Good wear resistance;

- Oil grooves and oil holes can be designed according to the application and mass production can be realized.

Steel Backed Bronze Bushings – High Load Capacity,

BIMETAL BEARING

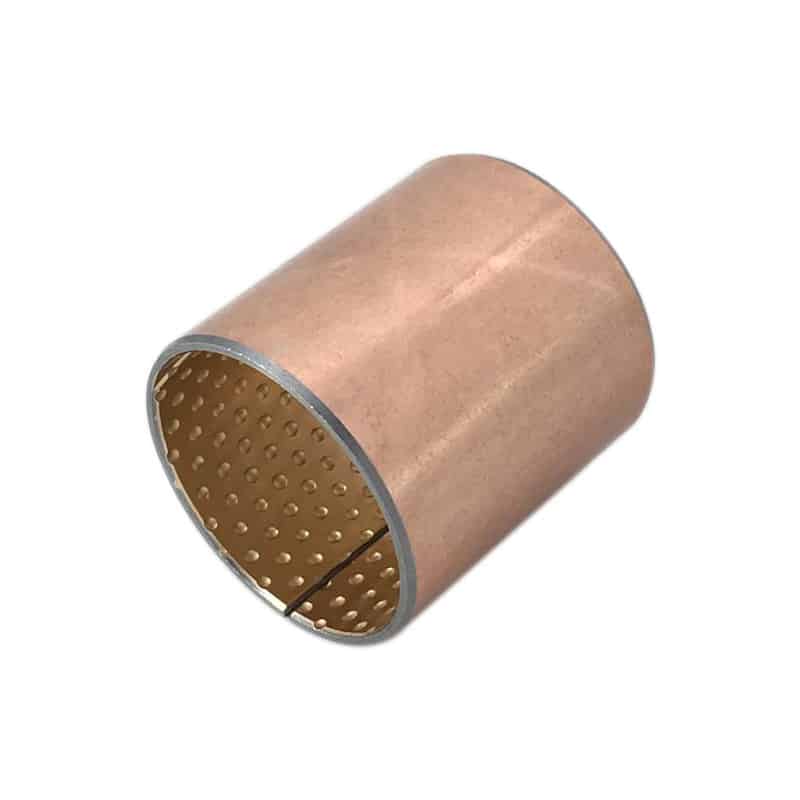

High-precision steel Sleeve Bushings from China. Ideal for heavy machinery and equipment. Hardened steel bushings for high specific loads with oscillating motion and low frequency. Self-lubricating Connecting Rod Bushing & Maintenance-free!

►JF800 Alloy CuPb10Sn10 Chemical Composition ( % ):

| Cu | Pb | Sn | Zn | P | Fe | Ni | Sb | other |

| rest | 9-11 | 9-11 | ≤ 0.5 | ≤ 0.1 | ≤ 0.7 | ≤ 0.5 | ≤ 0.2 | ≤ 0.5 |

Bimetal Bushings Manufacturers – Select High-Quality Bushings Bearing In Good Price

Professional Bimetal Bearings Supplier – www.bronzelube.com

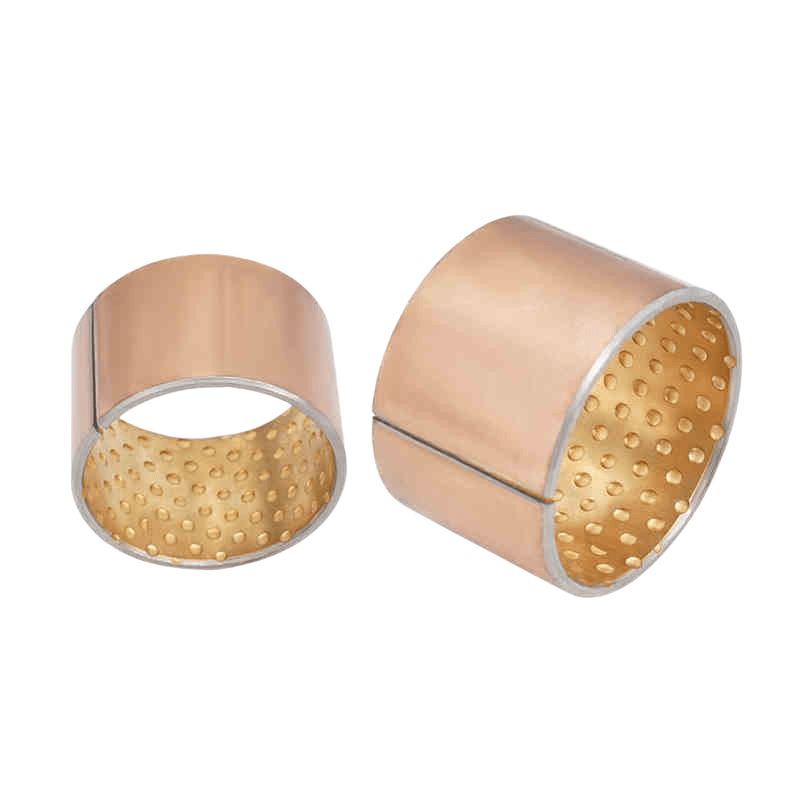

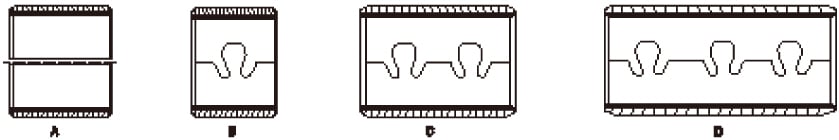

Bushing Design

Material introduction: Bimetal rolling products are made of low carbon steel with sintered tin bronze powder or rolled aluminum tin alloy on the surface. After many times of rolling and sintering, the product structure forms are bushing, bushing, thrust gasket, and so on, among which the most common bushing form is used. HS130 bimetal alloy materials are commonly used: CuPb10Sn10, CuPb24Sn4, CuPb30, CuSn6Zn6Pb3, AlSn20Cu, and so on. Due to more and more attention to environmental protection in the world, our company also developed a kind of cusN6.5-0.1 alloy material to meet the requirements of the environment has been widely used in the market.

– Lubrication characteristics: Due to the characteristics of bimetal materials, bimetal bearings must work in an oil lubrication environment. According to the different application occasions, they can generally be designed for three lubrication conditions. Such as low-speed movement occasions, such as automobile balance bridge, leaf spring, brake shoe, steering knuckle, punch guide plate, bulldozer driving wheel, from the driving wheel and other parts. It can be designed for grease lubrication, that is, the bearing surface is coated with grease during assembly, and then grease is regularly added during use; In the case of medium speed movements, such as connecting rod, punching and shearing machine shaft, conveying wheel and other parts, can be designed to configure oil cup lubrication; In high-speed motion occasions such as gearbox, oil pump, oil cylinder, engine, clutch, and other parts, can be designed for oil immersion lubrication.

– Product packaging: industrial packaging, carton packaging.

Connecting rod

Connect the piston and the crankshaft, and transfer the force of the piston to the crankshaft, the reciprocating movement of the piston into the rotation of the crankshaft.

Bimetal Sleeve Bushing Specification, Bimetal Bearing Size Chart- High-Quality Price Ratio

Bimetallic composite bearings to the high-quality low-carbon steel substrate, the surface of the sintered copper alloy having a low friction characteristic (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as bearing wear layer, copper alloy surface may need to use conditions processing various types of sump hole, oil hole, so as to not be suitable for continuous refueling or difficult situations.

Bimetal bushing

To high-quality low-carbon steel substrate, the sintered surface having a low coefficient of friction…

Bimetal Bush Typical application

Application: con-rod of automobile engines, engineering, and agriculture machinery, heavy-duty construction machinery, etc.

| Performance | Data | |

| Max dynamic Load P | 140N/mm² | |

| Max line speed V | Grease lubrication | 2.5m/s |

| Max PV value | Grease lubrication | 2.8N/mm²·m/s |

| Friction coef μ | Grease lubrication | 0.05~0.15 |

| Max line speed V | Oil lubrication | 5m/s |

| Max PV value | Oil lubrication | 10N/mm²· m/s |

| Friction coef μ | Oil lubrication | 0.04~0.12 |

| Max Working temperature | Grease lubrication | 150℃ |

| Performance | Data | |||

| Max Working temperature | Oil lubrication | 250℃ | ||

| Mating Axis | Hardness | ≥53HB | ||

| Mating Axis | Roughness | Ra=0.32~0.63 | ||

| Alloy Hardness | 80~120 | |||

| Heat-conducting Coefficient | 47W/(m·k) | |||

| Coefficient of linear expansion | 18×10-6K-1 | |||

according to customers’ special requests while out of this table.

|

||||

bimetal bushing size

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.