C95500 Nickel-Aluminum Bronze

C95500 Nickel-Aluminum Bronze

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

C95500 Nickel-Aluminum Bronze

C95500 Alloy, C955 Nickel-Aluminum Bronze Bushing, Customized Shaft Bronze Sleeve, OEM ODM Copper Bushings Production, Brass Bushing Manufacturer

Composition: C95500 is primarily composed of copper, aluminum, nickel, and iron. It typically contains around 10-11% aluminum, 4-5% nickel, and smaller amounts of iron and other elements.

Applications: C95500 finds extensive use in marine environments for components like propellers, pump parts, and ship fittings due to its resistance to saltwater corrosion. It’s also utilized in valve and pump components, gears, and bushings where wear resistance and durability are crucial

Nickel aluminum bronze alloys are widely used in various industrial applications, including bearing bushings, due to their excellent strength, corrosion resistance, and wear resistance.

- C63000 Nickel Aluminum Bronze (AMS 4640 / CDA 630): This alloy is known for its high strength and resistance to wear and corrosion, making it suitable for bearing bushings in heavy-duty application.

- C63020 Nickel Aluminum Bronze (AMS 4590): C63020 is another variant of nickel aluminum bronze, specifically designed for applications requiring excellent bearing properties, anti-galling characteristics, and good corrosion resistance.

- C95510 Nickel Aluminum Bronze (AMS 4880): This alloy offers superior mechanical properties and is used in demanding applications such as high-load bearing bushings, thanks to its high strength and excellent corrosion resistance.

ASTM, JIS, AISI, EN, BS;

Manganese brass: C86300 and etc.;

Tin bronze: C83600, C93200, CuSn12, CuSn7Zn4Pb7 and etc.;

Aluminum Bronze: C62900, C95400, C95500, CuAl10Fe5Ni5 and etc..

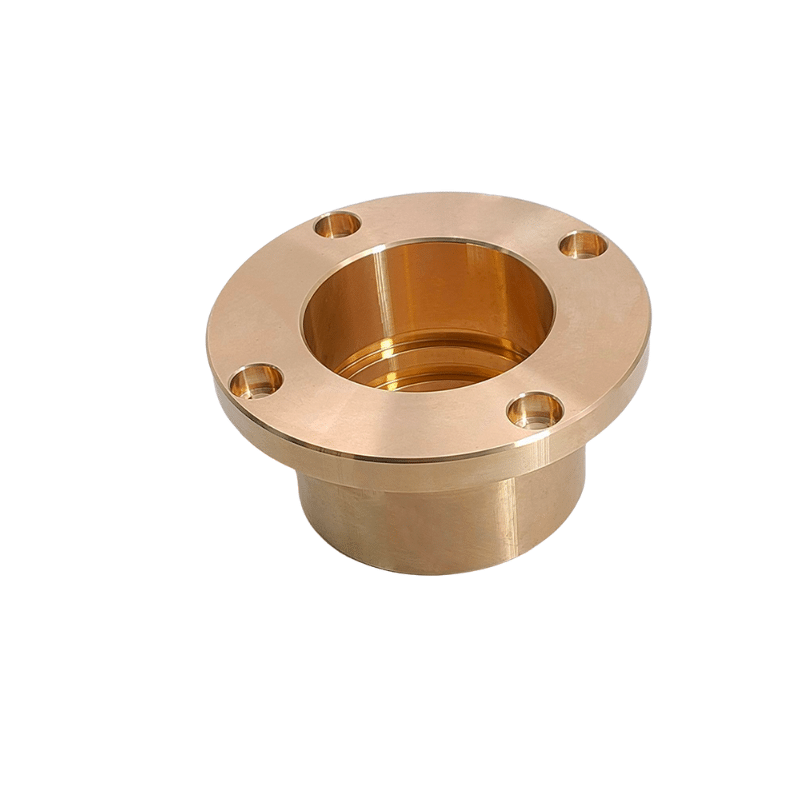

C95500 Nickel-Aluminum Bronze, High Durability Brass Oil Groove, Maintenance-Free Copper Bushing, Custom Double Oil Groove, Eight Groove, Ring Groove Sliding Bearing

C95500 Nickel-Aluminum Bronze, bronze/brass bushing, centrifugal casting, self-lubricating sleeve bushing Length Metal, aluminium bronze alloys

C95500 Nickel-Aluminum Bronze is widely used in various applications due to its exceptional strength, self-lubricating properties, and resistance to wear and fatigue, making it a valuable material for manufacturing self-lubricating bearings.

C95500 Nickel-Aluminum Bronze – Self-Lubricating Bearing, Customized Brass Bushes Oil Groove Bronze Bushing Copper Sleeves

C95500 Nickel-Aluminum Bronze is a high-strength copper-based alloy known for its self-lubricating properties, making it ideal for bearing applications.

Aluminum Bronze – Copper Casting Alloy UNS C95500

C95500 is a high-strength copper-based alloy that falls under the category of aluminum bronzes. It is known for its exceptional strength, making it suitable for various applications. Here are some key details about C95500 Nickel-Aluminum Bronze:

- Chemical Composition:

- Copper (Cu): 78.00% minimum

- Aluminum (Al): 10.00-11.50%

- Iron (Fe): 3.00-5.50%

- Nickel (Ni): 3.50%

- Manganese (Mn): 3.00-5.00%

- Mechanical Properties:

- Tensile Strength: 95 ksi (655 MPa) minimum

- Yield Strength: 42 ksi (290 MPa) minimum

- Elongation: 10% minimum

- Brinell Hardness: 208 BHN (3000 kg load)

- Physical Properties:

- Melting Point – Liquidus: 1930 °F (1054 °C)

- Melting Point – Solidus: 1900 °F (1038 °C)

- Density: 0.272 lb/in3 at 68 °F (7.53 gm/cm3 at 20 °C)

- Fabrication Properties:

- Soldering: Good

- Brazing: Fair

- Oxyacetylene Welding: Not Recommended

- Gas Shielded Arc Welding: Good

- Coated Metal Arc Welding: Good

- Machinability Rating: 50

Brass Bushes and Shaft Sleeves Material

CuZn25Al5Mn4Fe3 Material, Flange Bronze Bushing, Comprising CuZn25Al5Mn4Fe3/CuSn8P Alloys, Ideal for Use in Machine Tools, Agricultural Equipment, Crane Motors, Spring Pins, Steering Shafts, and Transmissions.

Aluminum Bronze: A Robust and Durable Alloy

Aluminum bronze, particularly the C954 alloy, is renowned for its robustness and is extensively utilized in various sectors for applications like bearings, bushings, gears, valves, and wear-resistant strips or plates. This alloy predominantly consists of copper (approximately 85.5%), aluminum (10.5%), and iron (4%). It’s celebrated for its high tensile and yield strengths, excellent ductility, and outstanding resistance to corrosion, making it an ideal choice for heavy-duty applications in industries such as aerospace, marine, machine tools, and more.

Characteristics and Uses

Aluminum bronze stands out for its exceptional strength and corrosion resistance when compared to other bronze alloys. It demonstrates minimal corrosion in atmospheric conditions, maintains stability at elevated temperatures, and has a low reaction rate with sulfurous compounds. Introducing tin can enhance its resistance to corrosion. The copper content provides a biostatic quality, deterring the growth of marine organisms like algae and barnacles.

Applications in Various Fields

Due to its corrosion resistance, aluminum bronze is preferred in many industrial applications. It’s utilized in components like plain bearings, aircraft landing gear, guitar strings, valve parts, marine engine components, underwater fastenings in naval construction, and ship propellers. Its appealing golden hue also makes it a popular choice in jewelry making. Moreover, aluminum bronze complies with the ATEX directive for certain zones, making it suitable for specific anti-corrosion tasks.

Welding Techniques and Coinage

Aluminum bronze is weldable using MIG welding with an aluminum bronze filler and pure argon gas. Historically, its use in coinage is notable in several countries, offering an economical alternative to gold due to its similar appearance.

Overall, aluminum bronze is a highly valued material for its strength, corrosion resistance, and versatility across numerous industries.

Nickel aluminum bronze alloys are widely used across numerous industrial domains for making components such as bearing bushings, thanks to their impressive qualities like enhanced strength, excellent corrosion resistance, and superior wear resistance.

- C63000 Nickel-Aluminum Bronze (AMS 4640 / CDA 630): Celebrated for its substantial strength and exceptional resistance to both wear and corrosion, this alloy stands out as a prime selection for robust bearing bushings, providing dependability and longevity in strenuous environments.

- C63020 Nickel Aluminum Bronze (AMS 4590): Tailored for specialized requirements, C63020 serves applications requiring superior bearing characteristics, galling resistance, and strong corrosion resistance, positioning it as a flexible choice for a range of industrial uses.

- C95510 Nickel Aluminum Bronze (AMS 4880): Distinguished by its outstanding mechanical properties, C95510 is perfectly suited for high-load bearing bushings, delivering high strength and excellent corrosion resistance, vital for operations in demanding conditions.

These alloys play a crucial role in the production of components that must withstand severe environments while preserving their structural integrity, thereby ensuring durability and efficiency in their various applications.

Nickel-Aluminum Bronze Bearing With Groove

| TYPE | SINGLE LOOP GROOVE | FIGURE EIGHT GROOVE | STRAIGHT & CIRCULAR GROOVE | DOUBLE LOOP GROOVE | DOUBLE FIG.EIGHT GROOVE | HALF FUG.EIGHT GROOVE | STRAIGHT GROOVE | CIRCULAR GROOVE |

| MARK | It is commonly used when the equipment capacity is small and safety concerns or cost considerations are more significant. Single bearings are suitable for applications with moderate radial loads and thrust loads in both directions | This design allows the bearing to support both axial and radial loads with minimal friction and wear. They are commonly used in applications where space is limited and both axial and radial loads need to be supported, such as in automotive transmissions and industrial machinery. | It supports a load in a linear and rotational direction.It is designed to minimize friction and allow for smooth movement along a straight path. | Double loop can withstand greater loads, accuracy requirements are usually higher, suitable for high-speed and high-load mechanical equipment, can provide more stable support and balance, thereby improving the reliability and life of the equipment. | Its design facilitates the sharing of loads and enhances resistance against deformation, thereby granting it greater load capacity and stiffness. Consequently, the double 8-groove bearing excels in environments characterized by high loads and speeds. | This type of groove could be used in applications where lubrication needs to be directed or limited to specific areas of the bushing to avoid over-lubrication or to ensure lubricant reaches areas under higher load or wear conditions. | It is designed to support and guide the movement of a rotating component, such as a shaft, in a straight line. Straight bearings are commonly used in various applications, including mechanical systems, machinery, and robotics. They are available in different materials, such as steel, aluminum, and plastic. | These bearings are designed for linear motion applications, where the bearing supports a load in a straight line. They feature a round flange on one end, which helps to produce straight motion and are used in combination with a cylindrical shaft. |

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.