C93200 SAE 660 High Lead Tin Bearing

C93200 SAE 660 High Lead Tin Bearing

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

C93200 SAE 660 High Lead Tin Bearing

C93200, also known as SAE 660, is a type of leaded tin bronze-bearing material widely used for its superior wear resistance and other favorable properties.

Lead tin bronze, SAE 660 bronze, also known as C932 bronze, is a popular material for manufacturing bushings due to its excellent mechanical properties. This bronze alloy is known for its good hardness and strength, excellent wear resistance, and superior anti-friction qualities. It also has excellent machining properties, making it easy to shape into various forms.

SAE 660 bronze bushings are favored across various sectors for their robustness and efficiency, finding applications in bearings, bushings, lightweight gears and sprockets, impellers, wear strips, plates, and automotive components. Additionally, their extensive use in pumps, cylinders, machine tools, and earth-moving equipment underscores their versatility.

A notable attribute of SAE 660 bronze is its resistance to dezincification, a condition that results in the weakening and brittleness of brass or bronze alloys due to zinc depletion. This characteristic ensures the longevity and reliability of SAE 660 bronze in demanding applications.

Despite its commendable corrosion resistance, SAE 660 bronze might not be optimal for all conditions, particularly in marine environments where there have been instances of corrosion.

When compared to other bronze alloys, SAE 660 bushings exhibit superior load-bearing capabilities, outperforming sintered bronze bushings. This quality makes them exceptionally suited for high-stress applications, though they may not offer the same ease of machining as some other bronze variants.

In summary, SAE 660 bronze bushings present a durable and efficient option for a broad range of uses, thanks to their outstanding mechanical properties and high load capacity. However, their application should be carefully considered against specific environmental exposures and load demands.

C93200 SAE 660 High Lead Tin Bearing Bronze Bushing For lift arms application!

The use of SAE 660 bronze as the material for these bushings is a suitable choice given its proven performance in similar applications. By incorporating solid lubricant graphite into the SAE 660 material, you can maintain the mechanical properties and corrosion resistance of the bronze while significantly enhancing its lubrication capabilities.

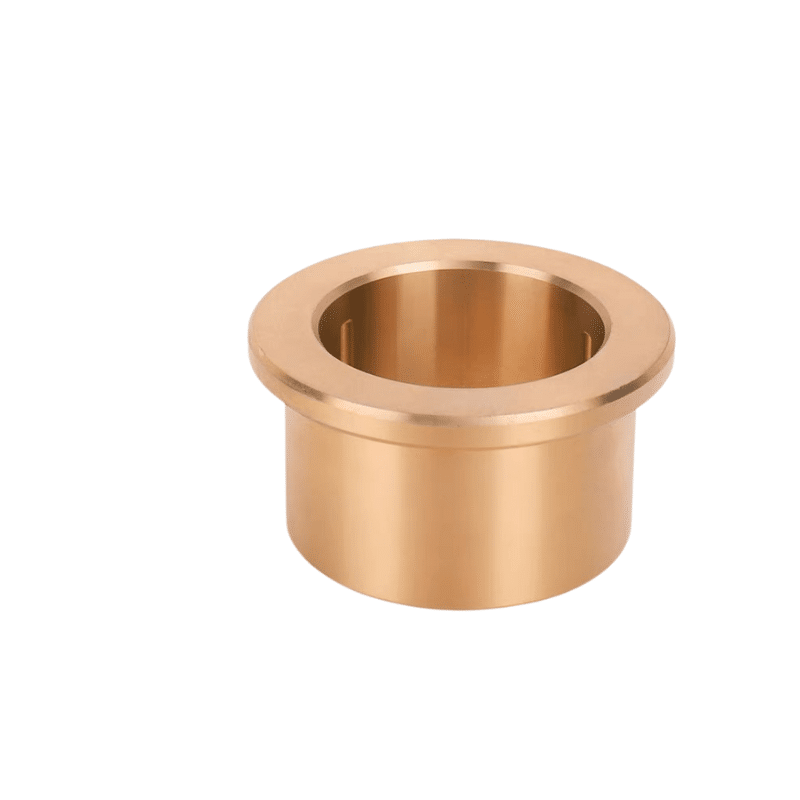

Bronze sleeve bearings featuring oil grooves, such as the 932 Bearing Bronze (SAE660), are crafted for diverse applications, offering notable hardness, strength, and wear resistance. Available in an array of styles and sizes, including Bronze Alloy 932 Bushings, these bearings cater to various needs. The C93200 Bronze Bearings, distinguished by their grease groove designs, provide dependable performance. These bearings are produced from continuous cast bronze, allowing for customized orders and quick delivery options.

For systems utilizing lift arms with various-sized bronze bushings that don’t fully rotate 180 degrees, leading to uneven grease distribution and binding, there are two primary solutions to consider:

- Grooved Figure 8 Design Bearings made of SAE 660 Bearing Bronze: This material is frequently chosen for crafting grooved Figure 8 design bearings. These bearings feature oil grooves to enhance lubrication efficiency. The unique “Figure 8” oil grooves in these bronze bushings, constructed from SAE 660 bronze, are tailored for cold-finished shafts to ensure optimal lubrication.

- Cast Bronze Sleeve Bearings with a Grease Groove Design: These bushings, crafted from continuous cast C93200 (SAE 660) bronze, are meticulously designed with grease grooves for effective lubrication. They are particularly effective in applications with oscillatory movements, both axial and radial, as they guarantee the even spread of lubrication to minimize friction and wear.

In the specific scenario of lift arms that don’t complete a full 180-degree rotation, resulting in challenges with grease spreading, the Cast Bronze Sleeve Bearings featuring a Grease Groove Design may offer a better solution. The design of the grease grooves in these bearings is intended to ensure that lubrication reaches all parts of the bushing, even with restricted rotation, thereby aiding in the prevention of binding.

SAE 660 bronze bushings are a versatile and reliable choice for many applications due to their excellent mechanical properties, good corrosion resistance, and ability to withstand high loads. However, their suitability for a specific application should be evaluated based on the specific environmental and load conditions.

C93200, also referred to as SAE 660, is a leaded tin bronze alloy celebrated for its exceptional wear resistance among other advantageous characteristics. This alloy finds widespread use across numerous industrial fields, including automotive, construction equipment, and general machinery, due to its notable qualities. It stands out for its excellent capabilities in brazing and welding, minimal shrinkage coefficient, and its non-magnetic nature. Standard sleeve bearings made from C93200 bronze are readily available, yet there’s also the option for custom fabrication to accommodate specific needs. This material is distinguished by its robust strength and wear resistance, available in a variety of forms like solid pieces, tubes, cored bars, and plates. C93200 bronze bearings are esteemed for their dependable operation, high load-bearing capacity, and superior wear resistance, rendering them ideal for an extensive array of industrial and mechanical uses.

SAE 660 material, also known as C93200, is a type of leaded tin bronze alloy. It is widely recognized for its excellent wear resistance, making it a popular choice for various industrial applications. This alloy is part of the Bronze family, specifically within the high-leaded tin bronze category. SAE 660 is known for its strength, durability, and ability to withstand high loads and speeds, which makes it suitable for bearings, bushings, and similar components.

The composition of SAE 660 includes a mix of copper, tin, lead, and zinc, which provides a good balance between strength and wear resistance, as well as the ability to form a lubricating film to reduce friction in moving parts. Its lead content helps in enhancing its machinability and antifriction properties. SAE 660 is also noted for its good performance in brazing and welding, low shrinkage coefficient during casting, and its non-magnetic properties.

Due to these characteristics, SAE 660 (C93200) is extensively used in applications such as automotive parts, earth-moving machinery, and general mechanical components where durability and reliability are essential.

These bronze alloys contain lead concentrations ranging from 7% to 15%. The presence of high lead levels in these tin bronzes enhances their machinability and maintains advantageous thermal conductivity and lubrication qualities, thanks to the lead. Alloy C93200 stands out as the primary choice within this group, serving as the go-to alloy for numerous bearing applications due to its widespread utility and reliability.

LIFT ARM SEA660 bronze bushing with a groove and circular design

a critical element in mechanical assemblies that demand a robust and low-friction pivot. The term SEA660 is indicative of the SAE 660 bronze alloy, recognized for its superior strength, outstanding resistance to wear, and the ability to withstand high loads as well as resist corrosion and fatigue. This alloy is particularly well-suited for demanding applications found in sectors like maritime, automotive, and heavy machinery due to these properties.

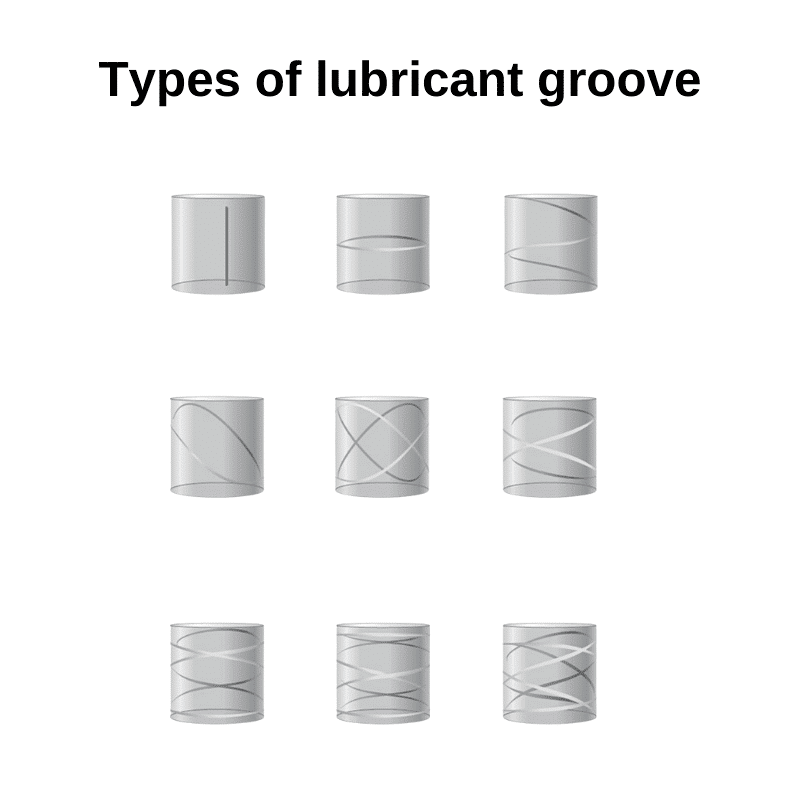

The inclusion of a groove within the bushing’s structure is purposefully engineered to ensure an even spread of lubricant, which is essential for the seamless functioning and increased lifespan of both the bushing and the lift arm it accommodates. The “Figure 8” groove pattern exemplifies one method of lubrication groove implementation aimed at enhancing lubricant spread over the bearing surface to optimize performance and reduce wear. Various groove configurations, including circumferential, spiral, and straight patterns, can be customized to meet specific operational needs.

Manufacturing of SAE 660-bearing bronze is achievable through different techniques, such as casting for intricate shapes and sizes at a lower cost, and machining for superior precision and detail. The self-lubricating feature of this alloy is especially advantageous in scenarios where consistent lubrication is crucial. bronzelube.com, A member of the VIIPLUS of companies.

Bronze Self-Lubricating Bearings

In essence, the grooved LIFT ARM SEA660 bronze bushing represents a premium quality component crafted from SAE 660 bronze alloy, engineered to ensure a friction-minimizing pivot in mechanical systems. Its design not only promotes lubricant distribution for smooth operation but also contributes to the durability of the system under high-stress and load conditions.

| Technical Data of Alloys | |||||

| Material Code | |||||

| Material Grade | CuZn25Al5Mn4Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 | CuZn25Al5Mn4Fe3 |

| Density | 8 g/cm3 | 8.9 g/cm3 | 7.8 g/cm3 | 8.9 g/cm3 | 8 g/cm3 |

| Hardness | >210 HB | >70 HB | >150 HB | >95 HB | >235 HB |

| Tensile Strength | >750 N/mm2 | >200 N/mm2 | >600 N/mm2 | >260 N/mm2 | >780 N/mm2 |

| Yield Strength | >450 N/mm2 | >90 N/mm2 | >260 N/mm2 | >150 N/mm2 | >450 N/mm2 |

| Percentage Elongation % | >12 | >15 | >10 | >8 | >8 |

| Linear Expansion Coefficient | 1.9×10-5/℃ | 1.8×10-5/℃ | 1.6×10-5/℃ | 1.8×10-5/℃ | 1.9×10-5/℃ |

| Working Temperature | -40~+300 ℃ | -40~+400 ℃ | -40~+400 ℃ | -40~+400 ℃ | -40~+400 ℃ |

| Max Load | 100 N/mm2 | 60 N/mm2 | 50 N/mm2 | 70 N/mm2 | 120 N/mm2 |

| Max Speed (Dry) | 15 m/min | 10 m/min | 20 m/min | 10 m/min | 15 m/min |

| Max PV (Lubrication) N/mm2·m/min | 200 | 60 | 60 | 80 | 200 |

| Compression Deformation 300N/mm2 | <0.01mm | <0.05mm | <0.04mm | <0.05mm | <0.005mm |

Bronze Self-Lubricating Bearings, available with or without a flange, are constructed from high-quality cast bronze embedded with a proprietary solid lubricant. This combination is designed to support high-load applications without the need for additional lubrication.

Features & Advantages: The bronze composition enhances the bearing’s mechanical strength and load-bearing capabilities, while the embedded solid lubricant ensures a consistent lubrication supply, creating a reliable lubrication system. These bearings are ideal for medium to high load applications, especially where frequent stops and starts are common.

- Layer 1: Initial Lubricating Film – Provides early lubrication to minimize friction.

- Layer 2: Solid Lubricants – Arranged to align with the motion direction, these create a lubricating film.

- Layer 3: Bronze Alloy – Enhances mechanical strength, as well as impact and corrosion resistance.

Custom fabrication is available to meet specific customer requirements and specifications.

SAE 660 cast bronze sleeve bearings are crafted from continuous cast bronze, specifically C93200 bearing bronze, aligning with ASTM B505 standards. This material blend typically contains around 83% copper, 7% tin, 7% lead, and 3% zinc, offering notable hardness, strength, wear resistance, and superior anti-friction properties. The SAE 660 bronze is particularly adept at supporting heavy loads at moderate speeds or light loads at elevated speeds.

The standard tolerances for these bearings are defined as F7 for the inner diameter (ID) and m6 for the outer diameter (OD). Post press fitting, the F7 tolerance ensures the ID is nearly equivalent to the actual size, facilitating a tight fit within a housing that usually has an H7 tolerance. The m6 tolerance for the OD provides a range of fit that can either slightly interfere or transition, suitable for precise applications where minor interference is permissible.

While specific ID and OD tolerances can vary by manufacturer. Such tolerances guarantee a precise fit, preserving the functionality of the machinery’s moving components. It’s crucial to recognize that these standard tolerances apply to typical bearing sizes and may differ for bespoke sizes or unique requirements. Additionally, manufacturers might offer customization options like resizing, adding oil grooves, or drilling the bearings to accommodate specific needs.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.