Bronze Bushing Sleeve

Bronze Bushing Sleeve

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

Bronze Bushing Sleeve

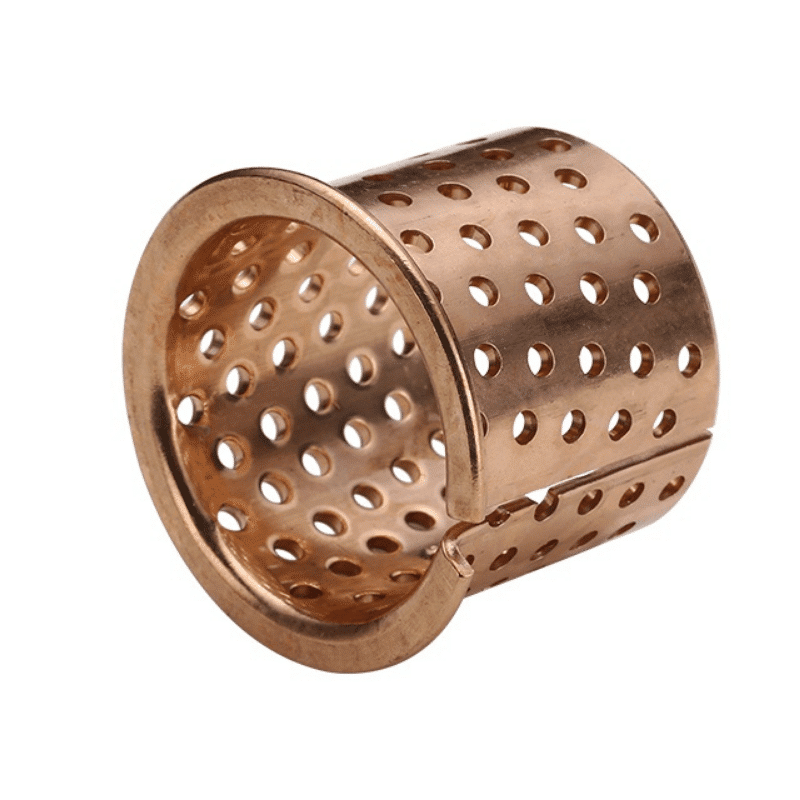

Self-lubricating Wrapped Bronze Bushing Bearing, Bronze Bushing Sleeve, Wrapped Bronze Bearings

Bronze bushings are indispensable in the mining industry, particularly for drill rigs and other heavy machinery. Their durability, wear resistance, self-lubricating properties, and high load capacity make them ideal for the demanding conditions of mining operations. By choosing high-quality bronze bushings, mining operations can enhance productivity, minimize downtime, and ensure the safe and efficient performance of their equipment.

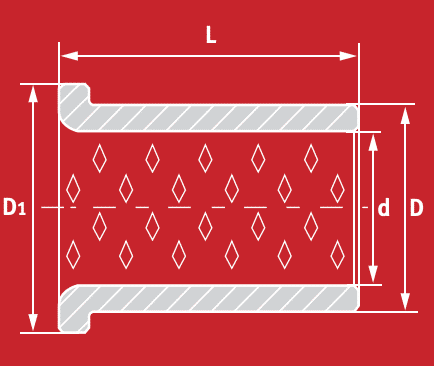

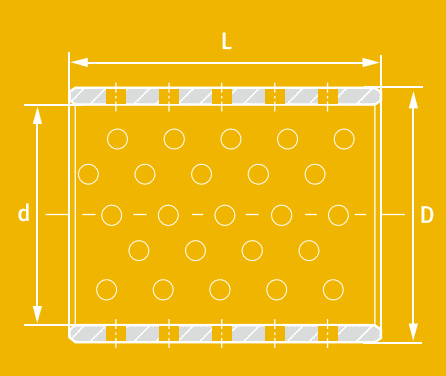

Cylindrical Bushing & Flanged Bushing, Wrapped Bronze Sliding Bearing, Lubrication Pockets, Low-Maintenance. We produce all special designs in a short time! Flanged bronze bushing sizes are produced on the customer’s requirements.

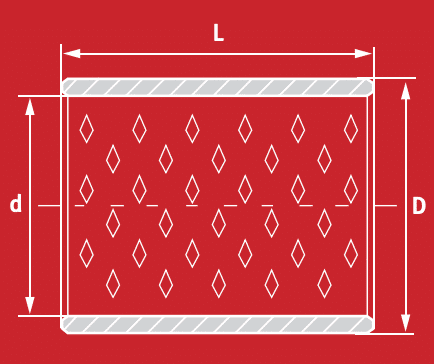

Custom sizes are produced in a short term, Cylindical bushing by the size of our standard dimensions in mm.

Metric Bronze Bushing Sleeve – Wrapped Bearings, Wrapped Flanged bronze Bushings

We have bushing sleeve parts, discount spare parts, bronze bushing for sale and more to meet your needs. diamond-shaped Wrapped Flanged Bronze Bushings!

Bronze Flanged Bushing customize parts for the mining & construction industries for dill rigs!

Bronze bushings are essential components in the mining industry, particularly for drill rigs and other heavy machinery. These bushings are valued for their durability, wear resistance, and ability to operate under extreme conditions.

Applications of Bronze Bushings in Mining Drill Rigs

1. Drill Rigs

Bronze bushings are used extensively in mining drill rigs to support rotating and moving parts. They help reduce friction and wear, ensuring smooth operation and extending the lifespan of the equipment. Specific applications include:

Rotary Tables: Bronze bushings in rotary tables help manage the high loads and rotational forces during drilling operations.

Drawworks: These bushings support the drawworks’ components, which are critical for hoisting and lowering the drill string.

2. Excavators

Bronze bushings are crucial in various parts of excavators, such as:

Boom, Arm, and Bucket: They provide support and reduce friction in pivotal joints, enhancing the efficiency and precision of movements.

Track Adjusters and Pads: These bushings facilitate proper tension adjustment and smooth movement of the tracks.

Idlers: Used in the undercarriage to support tracks and ensure proper alignment, reducing wear and increasing efficiency

3. Wheel Loaders

In wheel loaders, bronze bushings are used in the articulation joints between the front and rear frames, ensuring smooth steering and maneuverability.

4. Hydraulic Cylinders

Bronze bushings are commonly employed in hydraulic cylinder components such as pistons, glands, and clevises, providing reliable support and reducing friction.

5. Other Heavy Equipment

Bronze bushings are also used in dump trucks, rock breakers, outrigger crane supports, and crane boom hinges, contributing to the overall performance and durability of these machines.

Wrapped Bronze Bearings are crafted from a homogenous bronze sheet that is cold-formable, designed for durability and efficiency. These bearings come standard with diamond-shaped indents on their surfaces, which act as lubricant reserves. These reserves swiftly establish a lubrication film at startup, significantly reducing initial friction.

Features & Advantages: The CuSn8 bronze bushing material, combined with the wrapping and calibration process, renders these bearings particularly well-suited for applications involving medium to high loads and slow movements.

Applications & Features: Wrapped bronze bearings present a cost-effective solution when tolerance levels are not excessively stringent. The diamond-shaped lubrication indents are engineered to retain grease, facilitating the formation of a lubrication film at the start of operation. The bronze alloy offers excellent corrosion resistance and thermal conductivity, making these bearings ideal for applications with medium to low loads and slow speeds. Periodic greasing is advised to maintain optimal performance.

Structure: The CuSn8 alloy is the standard for these bushings, known for its ability to withstand high loads and exhibit good wear resistance. The inclusion of a flange allows the bearings to also support axial loads, providing a versatile and economical design choice. The diamond-shaped oil deposits are strategically designed to capture and retain oil, ensuring effective lubrication from the onset of operation.

Wrapped bronze bushing sleeve 090 bushing material is provided with a uniform pattern of indents which act as grease reservoirs. The 090 bushings supplies lubricant through holes instead of indents which provide larger amounts of lubricant to be incorporated during operation.

The bronze wrapped plain bearings are wrapped from a cold formed homogenous bronze (CuSn8) with exceptional material properties. The standard sizes are fitted with diamond shaped lubrication indents in the bearing surface. These indents serve as lubricant reservoirs to rapidly build up a lubrication film at the start of movement and thereafter reduce the running friction.

Advantages of bronze wrapped plain bearings:

The bronze wrapped plain bearing is easy installation, and has a oil pockets store lubricating oil; High load capacity.It is operating well in harsh working conditions.

Applications:

The bronze wrapped plain bearings applications for forestry, construction and agricultural machinery , cranes, forklifts and lifting equipment, etc…

Bearing forms available in standard dimensions

- Cylindrical Bushes

- Flanged Bushes

- Thrust Washers

- Flanged Washers

Bronze bushing sleeve, sliding bearing. A new wrapped bronze bearings for the most extreme requirements.

Wrapped Bronze Bearings Outstanding professionals in the field of sliding bearing technology …bronze bushing for sale, Flanged bronze bushing sizes.

Self-lubricating sliding bearing. High-compressed with evenly applied solid lubricant. Manufactured employing sintering technique.

High-load capacity and stability, for all slow movements, unsusceptible to dirt, no moisture absorption, good chemical resistance, good respectively

very good temperature resistance, can be reworked mechanically.

Wrapped bronze sliding bearing CuSn8P (DIN 17662) DIN 1494 / ISO 3547 Low-maintenance With lubrication pockets High load

CuSn8P, HB > 120 Bronze Bushings, Sliding bearings. has been engaged in sliding bearing technology for many years. Our experience and our know-how contribute to the development of new sliding bearings.

The present catalog serves to describe our products.

Discover the sliding bearings and contact us directly for a free quote.

Sleeve Bearings – Bushings & Bronze Bearings

WRAPPED BRONZE SLIDING BEARING, LUBRICATION POCKETS, LOW-MAINTENANCE

We manufacture Bronze bushing sleeves and plain bearings for your application, years of experience in sliding bearings …

Self-lubricating bearings solutions, highest standards: A wide range of bronze sleeves for Mining.

In the past, simple bronze bearings were often used in various applications. These always required more frequent maintenance and a greater amount of lubricant, and this caused longer downtimes due to repairs if the maintenance interval was not kept by the actual operators. In addition, the entire economic working environment has also changed, with the higher expected performance of man, and mechanical demands on materials and machines., higher yield requirements, or shorter throughput times, which additionally forces all these regularly required maintenance intervals into even shorter intervals.

Wrapped bronze bushings are available in metric sizes as straight or flanged bushings. They are wrapped from strips and calibrated. These bushings are an excellent solution for dirty environments where high levels of contamination make relubrication necessary. They are resistant to shock loads and vibrations at slow speeds.

The diamond-shaped lubrication pockets in the sliding surface need to be filled initially with grease. A good quality lubricant reduces friction and wears by separating a bronze bushing from its shaft. To protect the bushing and lubricant in highly contaminated environments, we recommend using seals.

Bronze sliding bearings in accordance with DIN17662 CuSn8.

The bearing is intended for oil or grease lubrication.

Available with or without flange.

The Bronze bushing sleeve sliding surface has rhomboid lubrication pockets.

The Bronze bushing sleeve sliding surface has holes going right through.

Bushings & Bearings – Sleeve, Flange, Thrust Washer

Bronze Bushing Sleeve Properties

High load ability level

Compact dimensions

High chemical resistance in aggressive environments

High thermal conductivity

Wide working temperature range

Easy to fit and maintain

Sleeve Bearings & Wrapped Bronze Bushing, Split-Type …with diamond or through lubricating holes.

Wrapped bronze sliding bearing, low-maintenance

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.